Professional Documents

Culture Documents

Bs 8666 2005 Shapes Guidepdf Compress

Uploaded by

Ryan SooknarineCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bs 8666 2005 Shapes Guidepdf Compress

Uploaded by

Ryan SooknarineCopyright:

Available Formats

CADS Support Team

01202 603733

support@cads.co.uk

www.cads.co.uk

BS 8666:2005 Scheduling, dimensioning, bending and

cutting of steel reinforcement for concrete

The information contained in the BS 8666:2005 Shapes Guide has been reproduced from BSI

material, and has been supplied to aid the implementation of the new code. For further

information please visit www.bsi-global.com.

Table 1 - Notation of steel reinforcement

Type of Steel reinforcement Notation

Grade B500A, Grade B500B or Grade B500C conforming to BS 4449:2005 H

Grade B500A conforming to BS 4449:2005 A

Grade B500B or Grade B500C conforming to BS 4449:2005 B

Grade B500C conforming to BS 4449:2005 C

A specified grade and type of ribbed stainless steel conforming to BS 6744:2001 S

Reinforcement of a type not included in the above list having material properties that are defined in

the design or contract specification. X

NOTE In the Grade description B500A, etc., "B" indicates reinforcing steel.

Extract 8.7 When dimensioning an acute angle the tangential lines shown in Figure 4 shall be used.

Extract 8.9 The overall offset dimensions of a crank shall be not less than twice the size of the bar. The angled length (see Figure

5) shall be not less than:

a) 10d for bars not exceeding a nominal size of 16 mm;

b) 13d for nominal sizes greater than 16 mm.

" #

$

!

Extract 8.10 For all shapes with two or more bends in the same or opposite directions (whetherin the same plane or not), the

overall dimension given on the schedule shall always include a minimum straight of 4d between the curved portion of the bends,

as shown in Figure 6. The value of x in Figure 6 shall be not less than the following:

a) 10d for bars not exceeding a nominal size of 16 mm;

b) 13d for nominal sizes greater than 16 mm.

% &' ( ! ) $ $ !

CADS Information Guides

11/01/2006 from the CADS Support Team Page 1 of 8

CADS Support Team

01202 603733

support@cads.co.uk

www.cads.co.uk

Table 2 - Minimum scheduling radii, former diameters and bend allowances

Nominal size of bar, Minimum radius for Minimum diameter of Minimum end projection, P

d. scheduling, r. bending former, M. General (min 5d Links where bend ‹150º

straight), including links (min 10d straight)

where bend 150º

mm mm mm mm mm

6 12 24 110a 110a

8 16 32 115a 115a

10 20 40 120a 130

12 24 48 125a 160

16 32 64 130 210

20 70 140 190 290

25 87 175 240 365

32 112 224 305 465

40 140 280 380 580

50 175 350 475 725

a

The minimum end projections for smaller bars is governed by the practicalities of bending bars.

NOTE 1 Due to "spring back" the actual radius of bend will be slightly greater than half the diameter of the former.

NOTE 2 BS 4449:2005 grade B500A in sizes below 8mm does not conform to BS EN 1992-1.1:2004.

CADS Information Guides

11/01/2006 from the CADS Support Team Page 2 of 8

CADS Support Team

01202 603733

support@cads.co.uk

www.cads.co.uk

Table 3 - Standard shapes, their method of measurement and calculation of length

Shape Code Shape Diagram Total Length of Bar,

L measured along centre line

00 A

01 A

Stock Lengths

New See Note 4.

11 A+(B)-0.5r-d

Neither A nor B shall be less than P

in Table 2.

12 A+(B)-0.43R-1.2d

Neither A nor B shall be less than P

in Table 2 nor less than (R+6d) .

13 A+0.57B+(C)-1.6d

B shall not be less than 2(r+d) .

Neither A nor C shall be less than P

in Table 2 nor less than (B/2+5d)

See Note 3.

14 A+(C)-4d

New Neither A nor (C) shall be less than P

in Table 2. See Note 1.

15 A+(C)

Neither A nor (C) shall be less than P

in Table 2. See Note 1.

21 A+B+(C)-r-2d

Neither A nor (C) shall be less than P

in Table 2.

CADS Information Guides

11/01/2006 from the CADS Support Team Page 3 of 8

CADS Support Team

01202 603733

support@cads.co.uk

www.cads.co.uk

Table 3 - Standard shapes, their method of measurement and calculation of length

Shape Code Shape Diagram Total Length of Bar,

L measured along centre line

22 A+B+C+(D)-1.5r-3d

C shall not be less than 2(r+d) .

New Neither A nor (D) shall be less than P

in Table 2. D shall not be less than C/2+5d .

23 A+B+(C)-r-2d

New Neither A nor B shall be less than P

in Table 2.

24 A+B+(C)

New

A and (C) are at 90° to one another.

25 A+B+(E)

Neither A nor B shall be less than P

in Table 2. If E is the critical dimension,

schedule a 99 and specify A or B as the free

& dimension. See Note 1.

26 A+B+(C)

Neither A nor (C) shall be less than P

in Table 2. See Note 1.

27 A+B+(C)-0.5r-d

New Neither A nor (C) shall be less than P

in Table 2. See Note 1.

28 A+B+(C)-0.5r-d

New Neither A nor (C) shall be less than P

in Table 2. See Note 1.

29 A+B+(C)-r-2d

New Neither A nor (C) shall be less than P

in Table 2. See Note 1.

CADS Information Guides

11/01/2006 from the CADS Support Team Page 4 of 8

CADS Support Team

01202 603733

support@cads.co.uk

www.cads.co.uk

Table 3 - Standard shapes, their method of measurement and calculation of length

Shape Code Shape Diagram Total Length of Bar,

L measured along centre line

31 A+B+C+(D)-1.5r-3d

Neither A nor (D) shall be less than P

in Table 2.

32 A+B+C+(D)-1.5r-3d

New Neither A nor (D) shall be less than P

in Table 2.

33 2A+1.7B+2(C)-4d

A shall not be less than 12d+30 mm.

B shall not be less than 2(r+d).

(C) shall not be less than P in Table 2,

nor less than B/2+5d. See Note 3.

34 A+B+C+(E)-0.5r-d

&

New Neither A nor (E) shall be less than P

in Table 2. See Note 1.

35 A+B+C+(E)-0.5r-d

&

New Neither A nor (E) shall be less than P

in Table 2. See Note 1.

36 A+B+C+(D)-r-2d

&

New Neither A nor (D) shall be less than P

in Table 2. See Note 1.

41 A+B+C+D+(E)-r-2d

Neither A nor (E) shall be less than P

in Table 2.

&

May also be used for flag link:

&

CADS Information Guides

11/01/2006 from the CADS Support Team Page 5 of 8

CADS Support Team

01202 603733

support@cads.co.uk

www.cads.co.uk

Table 3 - Standard shapes, their method of measurement and calculation of length

Shape Code Shape Diagram Total Length of Bar,

L measured along centre line

44 A+B+C+D+(E)-2r-4d

&

Neither A nor (E) shall be less than P

in Table 2.

46 & A+2B+C+(E)

Neither A nor (E) shall be less than P

in Table 2. See Note 1.

47 2A+B+2C+1.5r-3d

(C) and (D) shall be equal and not more than A

nor less than P in Table 2. Where (C) and (D)

are to be minimised the following formula may be

used:

New L=2A+B+max(21d, 240)

51 2(A+B+(C))-2.5r-5d

(C) and (D) shall be equal and not more than A

or B nor less than P in Table 2. Where (C) and

(D) are to be minimised the following formula

may be used:

L=2A+2B+max(16d, 160)

56 A+B+C+(D)+2(E)-2.5r-5d

New & (E) and (F) shall be equal and not more than B

or C, nor less than P in Table 2.

63 2A+3B+2(C)-3r-6d

(C) and (D) shall be equal and not more than A

or B nor less than P in Table 2. Where (C) and

(D) are to be minimised the following formula

may be used:

New L=2A+3B+max(14d, 150)

64 A+B+C+2D+E+(F)-3r-6d

New Neither A nor (F) shall be less than P

in Table 2. See Note 2.

67 A

See Clause 10.

CADS Information Guides

11/01/2006 from the CADS Support Team Page 6 of 8

CADS Support Team

01202 603733

support@cads.co.uk

www.cads.co.uk

Table 3 - Standard shapes, their method of measurement and calculation of length

Shape Code Shape Diagram Total Length of Bar,

L measured along centre line

75 (A-d)+B

New Where B is the lap

77 C (A-d)

Where B is greater than A/5 this equation no

longer applies, in which case the following

formula may be used:

! L=C(( (A-d))2+B2)0.5

98 A+2B+C+(D)-2r-4d

Isometric Sketch.

New Neither C nor (D) shall be less than P in

Table 2.

99 All other shapes where standard shapes cannot be To be calculated.

used.

No other shape code number, form of designation or

abbreviation shall be used in scheduling.

A dimensioned sketch shall be drawn over the

dimension columns A to E. Every dimension shall be

specified and the dimension that is to allow for

permissible deviations shall be indicated in

parentheses, otherwise the fabricator is free to choose

which dimension shall allow for tolerance. See Note 2.

The values for minimum radius and end projection, r and P respectively, as specified in Table 2, shall apply to all shape codes (see 7.6).

The dimensions in parentheses are the free dimensions. If the shape given in the table is required but a different dimension is to allow for

possible deviations, the shape shall be drawn out and given the shape code 99 and the free dimension shall be indicated in parentheses.

The straight length between two bends shall be at least 4d, see figure 6.

NOTE 1 The length equations for shape codes 14, 15, 25, 26, 27, 28, 29, 34, 35, 36 and 46 are approximate and where the bend angle is

greater than 45º, the length should be calculated more accurately allowing for the difference between the specified overall dimensions and

the true length measured along the central axis of the bar. When the bending angles approach 90º, it is preferable to specify shape code 99

with a fully dimensioned sketch.

NOTE 2 Five bends or more might be impractical within permitted tolerances.

NOTE 3 For shapes with straight and curved lengths (e.g. shape codes 12, 13, 22, 33 and 47) the largest practical mandrel size for the

production of a continuous curve is 400 mm. See also Clause 10.

NOTE 4 Stock lengths are available in a limited number of lengths (e.g. 6 m, 12 m).

Dimension A for shape code 01 should be regarded as indicative and used for the purpose of calculating total length.

Actual delivery lengths should be by agreement with the supplier. See also the footnote to Table 5.

CADS Information Guides

11/01/2006 from the CADS Support Team Page 7 of 8

CADS Support Team

01202 603733

support@cads.co.uk

www.cads.co.uk

Tolerances on cutting and bending dimensions

The tolerances for cutting and / or bending dimensions shall be in accordance with Table 5 and shall be

taken into account when completing the schedule. The end anchorage or the dimension in parentheses

in the shape codes specified in Table 3 shall be used to allow for any permissible deviations resulting

from cuttin and bending.

Table 5 Tolerances

Cutting and bending processes Tolerances

mm

Cutting of straight lengths (including +25, -25

reinforcement for subsequent bending)a

Bending:

1000 mm +5, -5

>1000 mm to 2000 mm +5, -10

>2000 mm +5, -25

Length of bars in fabric ±25 or 0.5% of the length (whichever is greater)

a

Tolerances for shape code 01, stock lengths, shall be subject to the relevant product standard,

e.g. BS 4449:2005

Radius of Bending

Reinforcement to be formed to a radius exceeding that specified in Table 6 shall be supplied straight.

Table 6 - Maximum limit for which a preformed radius is required

Bar Size Radius

mm m

6 2.5

8 2.75

10 3.5

12 4.25

16 7.5

20 14

25 30

32 43

40 58

50 ?

NOTE 1 The required curvature maybe obtained during placing.

NOTE 2 For shapes with straight and curved lengths (e.g. shape codes 12, 13, 22 and 33) the largest practical

radius for the production of continuous curves is 200mm, and for larger radii the curve may be produced by a

series of straight sections.

CADS Information Guides

11/01/2006 from the CADS Support Team Page 8 of 8

You might also like

- Charles Zastrow, Karen K. Kirst-Ashman-Understanding Human Behavior and The Social Environment-Thomson Brooks - Cole (2007)Document441 pagesCharles Zastrow, Karen K. Kirst-Ashman-Understanding Human Behavior and The Social Environment-Thomson Brooks - Cole (2007)joan82% (17)

- Ionic Bonding Worksheet - Type 1 PracticeDocument2 pagesIonic Bonding Worksheet - Type 1 Practicerichwenekylejc o Evaristo100% (6)

- Taylorism vs. FordismDocument2 pagesTaylorism vs. FordismLiv Maloney67% (3)

- C955 09Document4 pagesC955 09jacr27No ratings yet

- Prometric Questions-1 AnswersDocument45 pagesPrometric Questions-1 AnswersNina Grace Joy Marayag-Alvarez100% (1)

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- Saso Astm A615mDocument12 pagesSaso Astm A615mMohammed Imadullah Khan100% (1)

- Masonry Structures Changes To As 3700 2018 Fact Sheet For Builders PDFDocument2 pagesMasonry Structures Changes To As 3700 2018 Fact Sheet For Builders PDFalexNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Additional Mathematics SbaDocument9 pagesAdditional Mathematics SbaRyan SooknarineNo ratings yet

- Rebar Hook, Bend & Lap Allowance - Quantity Surveyor OnlineDocument2 pagesRebar Hook, Bend & Lap Allowance - Quantity Surveyor OnlineVeraNo ratings yet

- Bs 8666 2005 Shape Codes GuideDocument6 pagesBs 8666 2005 Shape Codes GuideDurgam Pruthvi100% (1)

- Fabrication of Reinforcement: CaresDocument6 pagesFabrication of Reinforcement: CaresRamraj RamachandranNo ratings yet

- BS8666 Shape Codes - KB Rebar LimitedDocument10 pagesBS8666 Shape Codes - KB Rebar LimitedRyan SooknarineNo ratings yet

- Structure Calculation Connection Design For Alar HotelDocument63 pagesStructure Calculation Connection Design For Alar Hotelmilenaglisic1121No ratings yet

- Chapter 6: Welding: Drafting and Design Presentation Standards Volume 3: Structural Drafting StandardsDocument12 pagesChapter 6: Welding: Drafting and Design Presentation Standards Volume 3: Structural Drafting StandardsaaronNo ratings yet

- Bridge Manual: 9.0 General 2 9.1 Concrete 3 9.2 Reinforcement Bars 4Document20 pagesBridge Manual: 9.0 General 2 9.1 Concrete 3 9.2 Reinforcement Bars 4Maan GalangNo ratings yet

- BS4466 Bends and ShapesDocument5 pagesBS4466 Bends and Shapesprasad perka0% (1)

- American Steel Bars - s440Document6 pagesAmerican Steel Bars - s440Emeka OdinyeNo ratings yet

- Chapter 6 - ColumnDocument4 pagesChapter 6 - Columnlau lauNo ratings yet

- Saso Astm A706mDocument12 pagesSaso Astm A706mEduard AbastillasNo ratings yet

- Block Shear Connection Design Checks PDFDocument7 pagesBlock Shear Connection Design Checks PDF112160rbc100% (1)

- Bearings For Industrial Machinery: Nskhps - High Performance StandardDocument24 pagesBearings For Industrial Machinery: Nskhps - High Performance Standardram.ag.cesarNo ratings yet

- Steel Stud Solutions Product CatalogDocument15 pagesSteel Stud Solutions Product CatalogDGWNo ratings yet

- Baskar-Barsched 8666Document33 pagesBaskar-Barsched 8666Ganesh Kumar GuptaNo ratings yet

- R/F - 600Lb Rating Medium Duty 'Y'-Type Strainer: Sizes: " To 12" Nominal Bore Pressure: FeaturesDocument1 pageR/F - 600Lb Rating Medium Duty 'Y'-Type Strainer: Sizes: " To 12" Nominal Bore Pressure: FeaturesNagLakshmananNo ratings yet

- Shear Stud CapacityDocument12 pagesShear Stud CapacityMurali2130No ratings yet

- AsdDocument25 pagesAsdIswell Bert ApongolNo ratings yet

- A615A615M Vbyv3593Document8 pagesA615A615M Vbyv3593Aris ComilangNo ratings yet

- Bearing Tolerances and Precision LevelsDocument15 pagesBearing Tolerances and Precision LevelsAbdul Junaedi100% (1)

- Daniel 4IN-600LB DataDocument2 pagesDaniel 4IN-600LB DataEndra BudimansyahNo ratings yet

- Recent Developments With Respect To High-Strength Reinforcing Bars - FanellaDocument35 pagesRecent Developments With Respect To High-Strength Reinforcing Bars - FanellaerosNo ratings yet

- FT AC enDocument6 pagesFT AC enMOHAMEDNo ratings yet

- Weldox SteelDocument2 pagesWeldox SteelHugo RodriguezNo ratings yet

- BS 8666-2005 Scheduling, Dimensioning, Bending and Cutting of Steel Reinforcing For ConcreteDocument8 pagesBS 8666-2005 Scheduling, Dimensioning, Bending and Cutting of Steel Reinforcing For ConcreteapirakqNo ratings yet

- Guia de Diseño Anclajes Basf CCDocument49 pagesGuia de Diseño Anclajes Basf CCBECKET ULLOANo ratings yet

- Drafting and Design Presentation Standards CH 6 WeldingDocument13 pagesDrafting and Design Presentation Standards CH 6 Weldingpaul.butlerNo ratings yet

- FERRULE Clamp BS 4825 Dimensions Rev3Document1 pageFERRULE Clamp BS 4825 Dimensions Rev3sergioNo ratings yet

- Rebar Us To Metric ConversionDocument10 pagesRebar Us To Metric ConversionmdeenkNo ratings yet

- Rapid Manufacturing Sheet Metal DesignDocument18 pagesRapid Manufacturing Sheet Metal Designniloy_67No ratings yet

- Bollards THRDocument1 pageBollards THRPlingu RazvanNo ratings yet

- Rebar Shear AreaDocument1 pageRebar Shear AreadakotaaaNo ratings yet

- Thermoplastic Support Catalog 1st Edition PDFDocument38 pagesThermoplastic Support Catalog 1st Edition PDFlaguna028No ratings yet

- Brecoflex Polyurethane Timing Belts With Weld On Profiles Us PDFDocument16 pagesBrecoflex Polyurethane Timing Belts With Weld On Profiles Us PDFMikel1020No ratings yet

- ANSI B16.9 ElbowDocument3 pagesANSI B16.9 ElbowMahmoud Reda ElSherifNo ratings yet

- ANSI B16.9 ElbowDocument3 pagesANSI B16.9 ElbowLuna LukaNo ratings yet

- BBS Preparation of Bar Bending Schedule and Its AdvantagesDocument14 pagesBBS Preparation of Bar Bending Schedule and Its AdvantagesNatarajan Krishnan100% (4)

- ANSI B16.9 ElbowDocument3 pagesANSI B16.9 Elbowzguy360No ratings yet

- H4091-Mm24-Lathe FinalDocument73 pagesH4091-Mm24-Lathe FinalАндрей РознатовскийNo ratings yet

- FERRULE Clamp BS 4825 Dimensions Rev.2Document1 pageFERRULE Clamp BS 4825 Dimensions Rev.2Gigin PlusNo ratings yet

- Anchor Guide-2-04 BASFDocument49 pagesAnchor Guide-2-04 BASFjuancaesjuancho_9762No ratings yet

- Opss-Prov 906 - 2020 - Construction Specification For Structural Steel For BridgesDocument16 pagesOpss-Prov 906 - 2020 - Construction Specification For Structural Steel For BridgesPubcrawlNo ratings yet

- Weldlok GratingDocument16 pagesWeldlok Gratingnovadistributors100% (3)

- Better Bevels With Plasma Arc CuttingDocument8 pagesBetter Bevels With Plasma Arc CuttingSonnexNo ratings yet

- SabicDocument46 pagesSabicdhdfh0% (1)

- 30+ Bar Bending Schedule Formulas - BBS Steel CalculationDocument18 pages30+ Bar Bending Schedule Formulas - BBS Steel Calculationsatyendra pratap gautamNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Advances in Ceramic Armor, Bioceramics, and Porous MaterialsFrom EverandAdvances in Ceramic Armor, Bioceramics, and Porous MaterialsJerry C. LaSalviaNo ratings yet

- AutoCAD Electrical 2020 for Electrical Control Designers, 11th EditionFrom EverandAutoCAD Electrical 2020 for Electrical Control Designers, 11th EditionNo ratings yet

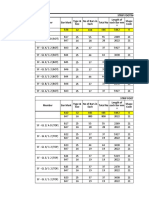

- Foundation BBS Schedule DWG V3-C1GL3&4-D.6Document1 pageFoundation BBS Schedule DWG V3-C1GL3&4-D.6Ryan SooknarineNo ratings yet

- Foundation BBS Schedule DWG V3-C1GL3&4-C.6Document1 pageFoundation BBS Schedule DWG V3-C1GL3&4-C.6Ryan SooknarineNo ratings yet

- Foundation BBS Schedule DWG V3-C1GL2B-DDocument1 pageFoundation BBS Schedule DWG V3-C1GL2B-DRyan SooknarineNo ratings yet

- Foundation BBS Schedule DWG V3-C1GL3&4-D-E-F-GDocument1 pageFoundation BBS Schedule DWG V3-C1GL3&4-D-E-F-GRyan SooknarineNo ratings yet

- Labour & Equipment Record - Beam Repair 2Document3 pagesLabour & Equipment Record - Beam Repair 2Ryan SooknarineNo ratings yet

- Section 7a - Prelim DesignDocument15 pagesSection 7a - Prelim DesignRyan SooknarineNo ratings yet

- Execution - Planning SFNDO CARPARKDocument2 pagesExecution - Planning SFNDO CARPARKRyan SooknarineNo ratings yet

- Request For Information And/or Query Sheet: Kee-Chanona LTDDocument1 pageRequest For Information And/or Query Sheet: Kee-Chanona LTDRyan SooknarineNo ratings yet

- Post-Concrete Inspection SheetDocument1 pagePost-Concrete Inspection SheetRyan SooknarineNo ratings yet

- Internal Meeting/Conversation Record: Record Of: San Fernando Multi Storey Car Park SFMSCPDocument2 pagesInternal Meeting/Conversation Record: Record Of: San Fernando Multi Storey Car Park SFMSCPRyan SooknarineNo ratings yet

- Preconcreting Notice & Inspection Sheet: Project Qa/Qc Plan R0Document1 pagePreconcreting Notice & Inspection Sheet: Project Qa/Qc Plan R0Ryan SooknarineNo ratings yet

- Sections For Setting Out-ModelDocument1 pageSections For Setting Out-ModelRyan SooknarineNo ratings yet

- Strip Footing Bottom Steel Location Member Bar Mark Total No Type & Size No of Bars in Each Length of Each Bar MM + Shape CodeDocument4 pagesStrip Footing Bottom Steel Location Member Bar Mark Total No Type & Size No of Bars in Each Length of Each Bar MM + Shape CodeRyan SooknarineNo ratings yet

- This Is A Text File For ScribidDocument1 pageThis Is A Text File For ScribidRyan SooknarineNo ratings yet

- Truck TrackingDocument4 pagesTruck TrackingRyan SooknarineNo ratings yet

- Inertia FormulasDocument1 pageInertia FormulasrohitkapyarNo ratings yet

- Conc Mix DesignDocument2 pagesConc Mix DesignRyan SooknarineNo ratings yet

- Concrete Grout Washout AreasDocument1 pageConcrete Grout Washout AreasRyan SooknarineNo ratings yet

- MatLab Dev For Civil EngDocument182 pagesMatLab Dev For Civil EngRyan SooknarineNo ratings yet

- Downey (2011) - Physical Modelling With MatlabDocument157 pagesDowney (2011) - Physical Modelling With MatlabGeorges Kouroussis100% (5)

- Downey (2011) - Physical Modelling With MatlabDocument157 pagesDowney (2011) - Physical Modelling With MatlabGeorges Kouroussis100% (5)

- Sistemas de Mando CST Cat (Ing)Document12 pagesSistemas de Mando CST Cat (Ing)Carlos Alfredo LauraNo ratings yet

- PV Power To Methane: Draft Assignment 2Document13 pagesPV Power To Methane: Draft Assignment 2Ardiansyah ARNo ratings yet

- The Other Twelve Part 1Document5 pagesThe Other Twelve Part 1vv380100% (2)

- Ims DB DCDocument90 pagesIms DB DCpvnkraju100% (1)

- 全新全真题库一 PDFDocument36 pages全新全真题库一 PDFTzarlene100% (1)

- Unit-5 Harmonics & FiltersDocument25 pagesUnit-5 Harmonics & FiltersBhanu100% (1)

- A Structural Modelo of Limital Experienci Un TourismDocument15 pagesA Structural Modelo of Limital Experienci Un TourismcecorredorNo ratings yet

- Panera Bread Case StudyDocument28 pagesPanera Bread Case Studyapi-459978037No ratings yet

- The Ethics of Peacebuilding PDFDocument201 pagesThe Ethics of Peacebuilding PDFTomas Kvedaras100% (2)

- 2021 Individual 20546 (Lawrence, Stephen R. and Bette F.) ClientDocument18 pages2021 Individual 20546 (Lawrence, Stephen R. and Bette F.) ClientVANDA MOORENo ratings yet

- Swot Analysis of Indian EconomyDocument2 pagesSwot Analysis of Indian EconomymyeyesrbeautNo ratings yet

- Chapter 9Document28 pagesChapter 9Aniket BatraNo ratings yet

- Matutum View Academy: (The School of Faith)Document14 pagesMatutum View Academy: (The School of Faith)Neil Trezley Sunico BalajadiaNo ratings yet

- Some Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsDocument5 pagesSome Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsVedant MahajanNo ratings yet

- Iso 22301 2019 en PDFDocument11 pagesIso 22301 2019 en PDFImam Saleh100% (3)

- BLG311 Cell Biology: Course Outline (Fall 2020)Document11 pagesBLG311 Cell Biology: Course Outline (Fall 2020)Emilija BjelajacNo ratings yet

- 3E Hand Over NotesDocument3 pages3E Hand Over NotesAshutosh MaiidNo ratings yet

- An Introduction To Routine and Special StainingDocument13 pagesAn Introduction To Routine and Special StainingBadiu ElenaNo ratings yet

- Circuit Construction: Assignment 3Document45 pagesCircuit Construction: Assignment 3ali morisyNo ratings yet

- Chudamani Women Expecting ChangeDocument55 pagesChudamani Women Expecting ChangeMr AnantNo ratings yet

- 2396510-14-8EN - r1 - Service Information and Procedures Class MDocument2,072 pages2396510-14-8EN - r1 - Service Information and Procedures Class MJuan Bautista PradoNo ratings yet

- Royal British College Dancesport TeamDocument10 pagesRoyal British College Dancesport TeamAnna rose CabatinganNo ratings yet

- Bullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceDocument174 pagesBullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceAlexandre AndréNo ratings yet

- VERGARA - RPH Reflection PaperDocument2 pagesVERGARA - RPH Reflection PaperNezer Byl P. VergaraNo ratings yet

- WCDMA Radio Access OverviewDocument8 pagesWCDMA Radio Access OverviewDocMasterNo ratings yet

- Class 1 KeyDocument3 pagesClass 1 Keyshivamsingh.fscNo ratings yet