Professional Documents

Culture Documents

1.1.6 Some Miscellaneous Incidents Involving Isolation For Maintenance

1.1.6 Some Miscellaneous Incidents Involving Isolation For Maintenance

Uploaded by

kara_250 ratings0% found this document useful (0 votes)

11 views1 pageOriginal Title

1_25

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 page1.1.6 Some Miscellaneous Incidents Involving Isolation For Maintenance

1.1.6 Some Miscellaneous Incidents Involving Isolation For Maintenance

Uploaded by

kara_25Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

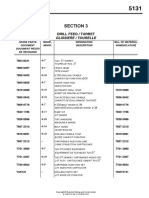

10 1.

PREPARATION FOR MAINTENANCE

1.1.6 Some Miscellaneous Incidents Involving Isolation for

Maintenance

(a) A slip-plate that had been in position for many months, perhaps

years, was relied on to isolate equipment. It had corroded right

through (Figure 1-5). Slip-plates in position for a long time should

be removed and inspected before being used as maintenance isola-

tions. (Such slip-plates should be registered for inspection every few

years.)

(b) A slip-plate with a short tag was overlooked and left in position

when maintenance was complete. Tags should be at least 130 mm

long on lines up to and including 6 in. diameter and at least 150 mm

long on larger lines. Figure-8 plates are better than slip-plates, as

their position can be seen at a glance; figure-8 plates should be used

on lines that have to be slip-plated regularly. Although the initial cost

is higher, they are always available on the job, while slip-plates tend

to disappear and have to be replaced.

(c) On several occasions, small bore branches have been covered by

insulation, overlooked, and not isolated.

(d) On several occasions, thin slip-plates have been used and have

become bowed; they are then difficult to remove. Figure 1-6 shows a

thin slip-plate that has been subjected to a gauge pressure of 470 psi

(32 bar).

Slip-plates should normally be designed to withstand the same

pressure as the piping. However, in some older plants that have not

been designed to take full-thickness slip-plates, it may be impossible

to insert them. A compromise will be necessary.

(e) A butane pump was isolated for repair by valves only. When it was

opened up, the pump and adjoining lines were found to be full of

hydrate, a compound of water and butane that stays solid at a higher

temperature than ice. A steam hose was used to clear the choke. Soon

afterward there was a leak of butane, which was ignited by a furnace

40 m away, and exploded. The suction valve was also blocked by ice

and was one turn open [22].

If you are not convinced that all isolation valves should be backed up

by slip-plates before maintenance takes place, at least back up valves on

lines containing materials that might turn solid and then melt.

1.1.7 Electrical Isolation

When an electrical supply has been isolated, it is normal practice to

check that the right switches have been locked or fuses removed by try-

ing to start the equipment that has been isolated. However, this system is

not foolproof, as the following incidents illustrate.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- G.weike CatalogDocument33 pagesG.weike CatalogManuelNo ratings yet

- GTS 2Document730 pagesGTS 2Aveek Sengupta100% (1)

- Test 804: Ursus C-325 (Diesel)Document2 pagesTest 804: Ursus C-325 (Diesel)tzababagita936No ratings yet

- V90 Turbine SpecificationsDocument38 pagesV90 Turbine SpecificationsTrevor ClineNo ratings yet

- Crowe 1983Document8 pagesCrowe 1983kara_25No ratings yet

- 10.1016@0009 25096780187 8Document11 pages10.1016@0009 25096780187 8kara_25No ratings yet

- Vaclavek 1979Document11 pagesVaclavek 1979kara_25No ratings yet

- Crowe 1986Document8 pagesCrowe 1986kara_25No ratings yet

- 10.1016@0009 25097685029 4Document7 pages10.1016@0009 25097685029 4kara_25No ratings yet

- 1.6 A Personal NoteDocument1 page1.6 A Personal Notekara_25No ratings yet

- Crowe 1975Document6 pagesCrowe 1975kara_25No ratings yet

- 1.4.7 A Permit To Work Dangerously?: 1.5 Quality of MaintenanceDocument1 page1.4.7 A Permit To Work Dangerously?: 1.5 Quality of Maintenancekara_25No ratings yet

- 10.1016@0009 25097280081 2Document8 pages10.1016@0009 25097280081 2kara_25No ratings yet

- 1.2.1 The Need For Tagging: 1.2 IdentificationDocument1 page1.2.1 The Need For Tagging: 1.2 Identificationkara_25No ratings yet

- 1985 FSM General Engine ServiceDocument25 pages1985 FSM General Engine ServiceDiego Armando Martinez UrquijoNo ratings yet

- ADS HFC-227ea DIOM 06-236068-001 - BA With AddendaDocument364 pagesADS HFC-227ea DIOM 06-236068-001 - BA With AddendaHector Ernesto Cordero AmaroNo ratings yet

- Ficha Técnica Motor TechtopDocument1 pageFicha Técnica Motor TechtopLUISA FERNANDA SALDARRIAGA VASCONo ratings yet

- 63-82 Steering Box RebuildDocument10 pages63-82 Steering Box Rebuildvince cNo ratings yet

- 330 D y 336 D Plano Sistema HidralicoDocument2 pages330 D y 336 D Plano Sistema HidralicometanirvanaNo ratings yet

- MODULE I Injection Molding ProcessDocument40 pagesMODULE I Injection Molding ProcessAntonius PrakosaNo ratings yet

- SFD N004 2013 PDFDocument21 pagesSFD N004 2013 PDFMohamed Abo-ZaidNo ratings yet

- Sunu 1Document16 pagesSunu 1Ayca Betul BingolNo ratings yet

- Deconstructing The Propulsion ConundrumDocument13 pagesDeconstructing The Propulsion ConundrumNajmul Puda PappadamNo ratings yet

- Tutorial Problems NS EquationDocument2 pagesTutorial Problems NS EquationSubhajit BagNo ratings yet

- Crib InstructionsDocument7 pagesCrib InstructionsLynne GomesNo ratings yet

- D60P-6 S - N 20006-Up - Fuel Control LeverDocument3 pagesD60P-6 S - N 20006-Up - Fuel Control LeverKHORN MANYNo ratings yet

- Astm B517-09Document3 pagesAstm B517-09Srinivasan KrishnamoorthyNo ratings yet

- s03 Drill Feed TurretDocument130 pagess03 Drill Feed TurretJorge Luis Pinedo Sulca100% (2)

- Form 5 Phy MR Theva 25.05.2023Document29 pagesForm 5 Phy MR Theva 25.05.2023LittleDavieGNo ratings yet

- 4TH ED Pagess From Vol. Text B 31 Chapters 37 38 PROPIETARY ASME 3-26-13Document72 pages4TH ED Pagess From Vol. Text B 31 Chapters 37 38 PROPIETARY ASME 3-26-13namasralNo ratings yet

- Map 30 FxxaeDocument100 pagesMap 30 FxxaeJesus CasillasNo ratings yet

- ANP Strand Anchor PDFDocument36 pagesANP Strand Anchor PDFGuoqiang LiuNo ratings yet

- 2006 Volvo XC90Document204 pages2006 Volvo XC90St Julian Lloyd33% (3)

- Barrenas Triconicas PDFDocument4 pagesBarrenas Triconicas PDF4s0m0z4No ratings yet

- 2.2 SpecificationDocument13 pages2.2 SpecificationĐình NamNo ratings yet

- 5 - Ce6101-Cam Clay Model-03102020Document30 pages5 - Ce6101-Cam Clay Model-03102020rihongkeeNo ratings yet

- 008 - Column Load AnalysisDocument17 pages008 - Column Load AnalysisVAIBHAVNo ratings yet

- WG Me-485Document64 pagesWG Me-485Jonathan BareñoNo ratings yet

- EGR Valve Emulator EML810/24 Installation Guide: BrownDocument1 pageEGR Valve Emulator EML810/24 Installation Guide: BrownРадослав БошковNo ratings yet

- Hydac MpfiltriDocument1 pageHydac MpfiltriVijay BhureNo ratings yet