Professional Documents

Culture Documents

Material Safety Data Sheet (M.S.D.S.) : Updated March 24, 2014

Uploaded by

UtamiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Safety Data Sheet (M.S.D.S.) : Updated March 24, 2014

Uploaded by

UtamiCopyright:

Available Formats

SCHMOLZ+BICKENBACH USA, INC.

365 Village Drive

Carol Stream, IL 60188

Tel: 800-323-1233 Fax: 630-682-3428

www.schmolz-bickenbach.us

Updated March 24, 2014

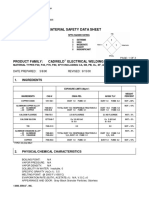

MATERIAL SAFETY DATA SHEET (M.S.D.S.)

Description of Product

Product Name: UGITECH SA Stainless Steel long products

Grades: 200 Series/300 Series/400 Series/Duplex

Hazardous Ingredients: N.B.- Products under normal conditions do not represent an

inhalation, ingestion or contact health hazard.

BASE METAL CAS % ACGIH TLV-TWA OSHA PEL

ALLOYING ELEMENTS NUMBER (1) RANGE (mg/m3) (2) (mg/m3) (3)

Iron (FE) 7439-89-5 >40

5 Oxide Fume 10 Oxide Fume

Chrome (Cr) 7440-47-3 >10-30

0.5 (metal) 1 (metal)

Nickel (Ni) 7440-02-0 <35

1 (metal) 1 (metal)

Manganese (Mn) 7439-96-5 <25

5 (dust); 1 (fume) 5 (as Manganese)

Silicon (Si) 7440-21-3 <2.5

10 (dust 15 (dust

Molybdenum (Mo) 7439-98-7 <7

10 ( insoluble compound) 15 ( insoluble compound)

Copper (Cu) 7440-50-3 <5

1 (dust and mist); 0.2 1 (dust and mist); 0.1

(fume) (fume)

Cobalt (Co) 7440-48-4 <1 0.1 (dust and fume) 0.1 (dust and fume)

Titanium (Ti) 7440-32-6 <2 10 dust 15 dust

Niobium (Nb) 7440-03-1 <2 none established none established

Carbon (C) 7440-44-0 <.7 none established none established

Nitrogen (N) 10102-44-0 <.5 6 (as NOx) 6 (as NOx)

Phosphorus (P) 7723-14-0 <.1 0.1(yellow P) 0.1(yellow P)

Sulfur (S) 7704-34-9 <.4 5 (as SOx) 13 (as SOx)

* COATINGS: Certain materials such as lime, alkaline salts, borax or mineral oil in the

processing, and certain residuals (<1% total weight of product) may remain on the product’s

surface.

(1) Chemical Abstract Service Number (2) 1985-1986 ACGIH Threshold Limit Value – Time Weighted Average (3) OSHA Permissible Exposure Limit

Listed below are certain critical effects (TLV Basis) which apply to hazardous

ingredients found in alloys supplied. Please refer to table above of potential

hazardous ingredients found in the subject alloy(s).

Chromium : Irritation; dermatitis.

Cobalt : Asthma; lung; CVS

Copper : Irritation; GI; metal fume fever

Iron : Pneumoconiosis

Manganese : CNS (manganism); lung; reproductive

Molybdenum : Irritation

Nickel : Dermatitis; pneumoconiosis; kidney; Cancer (lung); irritation

Silicon : Lung

Titanium : (Dioxide) Lung.

Vanadium : (Pentoxide Dust & Fume) Irritation; lung.

MSDS UGITECH SA 200/300/400/DUPLEX Page 1 of 3 Date: 03/24/2014

SCHMOLZ+BICKENBACH USA, INC.

365 Village Drive

Carol Stream, IL 60188

Tel: 800-323-1233 Fax: 630-682-3428

www.schmolz-bickenbach.us

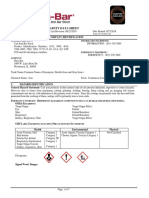

PHYSICAL DATA

Material is (under normal conditions): SOLID Evaporation Rate: N/A

Melting Point (Base Metal): >2400°F Boiling Point: N/A

Specific Gravity: approx. 8 g/cm³ Solubility in water: N/A

Vapor Pressure: N/A Appearance and order: Gray, Silvery

Vapor Pressure: N/A or Black, Odorless

Vapor Density: N/A

PRIMARY ROUTES OF ENTRY

Exposure occurs generally through inhalation of fumes and dust created during certain

manufacturing operations. Certain elements, however, may be hazardous through direct skin

and/or eye contact. Ingestion, while highly unlikely, could also be harmful in the case of certain

elements.

FIRE and EXPLOSION

Steel products in the solid state present no fire or explosion hazard.

SPECIAL PROTECTION INFORMATION

VENTILATION: Local Exhaust ventilation should be utilized when welding, burning, brazing or grinding

when exposure exceeds TLV’s or PEL’s.

RESPIRATORY: When engineering or administrative controls are not feasible to control overexposure,

or while they are being instituted, appropriate NIOSH-approved respirators should be used, selected

according to 29 CFR 1910.134.

EYE PROTECTION AND PROTECTIVE CLOTHING: Safety glasses or goggles should be utilized as

required by exposure. Other protective equipment should be utilized as required by the welding

standards.

WELDING AND BRAZING: On welding and brazing, hazardous constituents of basic electrode

coatings, coated brazing rods or flux materials can contaminate the air. These material should only be

used according to the manufacturer or supplier. Particular care must be taken when carrying out the

above-mentioned work in restricted rooms or containers.

PHYSIOLOGICAL EFFECTS: The inhalation of high concentrations of various metals fumes or

extremely fine metal dusts at or near to their source can cause an acute reaction known as “metal fume

fever.”

Although metals such as copper and zinc have been ,most associated with metal fume fever, this

condition can also by the inhalation of iron, manganese and nickel fumes or dust.

The symptoms consist of temporary chills and fever which may last from few hours to a full day:

characteristic are outbreaks of perspiration, coughing, chest pains (if the case history is uncertain, a

head cold at the same time indicates infection). Long-term effects of metal fume fever on healthy

individuals have not been noted.

Chronis inhalation of high concentrations of iron oxide fumes or dust mat lead to siderosis, a benign

pneumoconiosis. The siderosis can subside on removal from the hazardous environment.

MSDS UGITECH SA 200/300/400/DUPLEX Page 2 of 3 Date: 03/24/2014

SCHMOLZ+BICKENBACH USA, INC.

365 Village Drive

Carol Stream, IL 60188

Tel: 800-323-1233 Fax: 630-682-3428

www.schmolz-bickenbach.us

It is generally believed that the hexavalent forms of chrome (chromic acid and chromates) are

responsible for its toxic effects, whereas the metal itself and its trivalent compounds are largely

regarded as harmless. Chromic acid and chromates cause irritation and ulceration. Chromates

are potential skin sensitizers with regard to allergies. Long-term inhalation of hexavalent chrome

compounds can cause cancer.

Inhalation of nickel dusts or aerosols containing metallic nickel, nickel sulfide, nickel oxide, or of

cobalt dust / aerosols can also cause cancer.

Acute toxic effects of these two metals are not known. However, frequent contact with nickel and

cobalt can cause allergic skin reactions.

EMERGENCY and FIRST AID PROCEDURES

If acute overexposure to fumes occurs, remove victim from the adverse environment immediately and

seek medical attention.

ADDITIONAL COMMENTS

The percentage composition reflects the range that is possible within this group of products.

These are not the technical specifications for a particular product. Actual composition will fall

within this range, but will depend on specifications for the particular product. Thus, when welding

or cutting products containing chromium or nickel (for example), the potential for exposure to

chromium or nickel obviously increases as their percentage composition increases. Therefore,

we strongly urge that all operations with potentially hazardous exposures be evaluated by a

competent industrial hygienist.

The steel itself presents no health hazard unless it is welded, burned, ground or cut. During

these procedures, hazardous amounts of fume or dusts may be generated. It is advised that your

particular operation be evaluated by a competent health professional to determine whether a

hazard exists.

NOTE

The information in the M.S.D.S. was obtained from sources, which we believe are reliable. The

information, however, is provided without any representation or warranty, expressed or implied,

regarding its accuracy or correctness.

MSDS UGITECH SA 200/300/400/DUPLEX Page 3 of 3 Date: 03/24/2014

You might also like

- SDS-metal DustDocument10 pagesSDS-metal DustAzuan MABKNo ratings yet

- SDS Underwater Cutting Rods 2018 PDFDocument8 pagesSDS Underwater Cutting Rods 2018 PDFVictor AcostaNo ratings yet

- Msds Cobalt PDFDocument3 pagesMsds Cobalt PDFwangchao821No ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- SDS PC Strand Sumiden Wire Products 2017 06 23 PDFDocument8 pagesSDS PC Strand Sumiden Wire Products 2017 06 23 PDFfehmi boudabousNo ratings yet

- Safely weld alloys with MSDSDocument2 pagesSafely weld alloys with MSDSElMacheteDelHuesoNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Msds Silica FumeDocument5 pagesMsds Silica Fume11sajidNo ratings yet

- GAF Corporation Safety Data Sheet SDS #1095 SDS Date: March 2018Document8 pagesGAF Corporation Safety Data Sheet SDS #1095 SDS Date: March 2018srcNo ratings yet

- Safety Data Sheet for RB-26 Welding ElectrodeDocument7 pagesSafety Data Sheet for RB-26 Welding Electrodehorry andresNo ratings yet

- Msds Carbon SteelDocument2 pagesMsds Carbon SteelRober Moises Chumbe SoveroNo ratings yet

- J79 195 Rev H AMPCO SDS Rod WireDocument10 pagesJ79 195 Rev H AMPCO SDS Rod WireNair R RakeshNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Adc12 MSDSDocument3 pagesAdc12 MSDSClaudia Mata100% (1)

- MSDS METAL CORED WIREDocument2 pagesMSDS METAL CORED WIREElMacheteDelHuesoNo ratings yet

- Brass Alloys Material Safety Data SheetDocument3 pagesBrass Alloys Material Safety Data SheetALEJANDRA FONTALVO STUDENTNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationadityadhNo ratings yet

- Silica FumeDocument5 pagesSilica FumeMohamed HassanNo ratings yet

- Material Safety Data Sheet (MSDS) : Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet (MSDS) : Section I - IdentificationSalem GarrabNo ratings yet

- MSDS SoldaduraDocument4 pagesMSDS SoldaduraJosé YáñezNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product Identificationmohamed AdelNo ratings yet

- Sds For Gray CastDocument7 pagesSds For Gray CastPravin PatilNo ratings yet

- Safety Data Sheet: 1. Product and Company InformationDocument6 pagesSafety Data Sheet: 1. Product and Company Informationfehmi boudabousNo ratings yet

- Aluminum A380 MSDS SheetDocument3 pagesAluminum A380 MSDS SheetAndy KrolNo ratings yet

- 32 EX Msds 9-07Document3 pages32 EX Msds 9-07Mohamed AdelNo ratings yet

- Esab Sds Can332-C Ercuni 70-30Document5 pagesEsab Sds Can332-C Ercuni 70-30jromero_rpgNo ratings yet

- Material Safety Data Sheet: Section 1 - IdentificationDocument4 pagesMaterial Safety Data Sheet: Section 1 - IdentificationAmjad MehmoodNo ratings yet

- 1 TufTrak EC SMAW Msds 2-10Document3 pages1 TufTrak EC SMAW Msds 2-10mohamed AdelNo ratings yet

- Safety Data Sheet for Welding Consumable NC-38Document7 pagesSafety Data Sheet for Welding Consumable NC-38Indra WibawaNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product Identificationmohamed AdelNo ratings yet

- Material Safety Data Sheet: Metglas 2714A Cobalt Based AlloyDocument8 pagesMaterial Safety Data Sheet: Metglas 2714A Cobalt Based AlloyHwalam LeeNo ratings yet

- Material Safety Data Sheet: Welding Alloys USA IncDocument4 pagesMaterial Safety Data Sheet: Welding Alloys USA IncShenny AldanaNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company IdentificationMohamed AdelNo ratings yet

- Safety Data Sheet for DW-308 Welding WireDocument7 pagesSafety Data Sheet for DW-308 Welding WireKang Kawe Waone SetiaoneNo ratings yet

- SDS 316 Stainless SteelDocument5 pagesSDS 316 Stainless SteelAshish BhanderiNo ratings yet

- Copper BasedDocument4 pagesCopper Basedcpmc66No ratings yet

- Harm) and Cancer. (California Health & Safety Code 25249.5 Et Seq.)Document3 pagesHarm) and Cancer. (California Health & Safety Code 25249.5 Et Seq.)mohamed AdelNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Member of the BÖHLER -UDDEHOLM Group MATERIAL SAFETY DATA SHEETDocument6 pagesMember of the BÖHLER -UDDEHOLM Group MATERIAL SAFETY DATA SHEETantoncanuckNo ratings yet

- SDS Safety Data Sheet for Welding MaterialsDocument12 pagesSDS Safety Data Sheet for Welding MaterialsJose Antonio AlarconNo ratings yet

- MSDS-Hebei Botou-BeCuDocument8 pagesMSDS-Hebei Botou-BeCuTaherNo ratings yet

- MSDS Blades 6-12-01Document3 pagesMSDS Blades 6-12-01Wisnu Akhmad SNo ratings yet

- Msds Diamond WheelsDocument4 pagesMsds Diamond WheelsThuý VyNo ratings yet

- I. Product Identification: Material Safety Data SheetDocument5 pagesI. Product Identification: Material Safety Data SheetSteel BridgeNo ratings yet

- MSDS BatreiDocument9 pagesMSDS BatreiMuhamad HasbiNo ratings yet

- Material Safety Data Sheet For BOSS WELD ELECTRODES - 84651098. 1106, 1117, 1128Document4 pagesMaterial Safety Data Sheet For BOSS WELD ELECTRODES - 84651098. 1106, 1117, 1128mohamed AdelNo ratings yet

- MIG Welding Electrode MSDSDocument6 pagesMIG Welding Electrode MSDSDheeraj E MohananNo ratings yet

- MSDS - Yuasa Battery WetDocument9 pagesMSDS - Yuasa Battery WetBatanNo ratings yet

- Acero HSDocument2 pagesAcero HSEdgar MOrenoNo ratings yet

- Mild Steel Solid Mig Wire MSDSDocument2 pagesMild Steel Solid Mig Wire MSDSsalcabesNo ratings yet

- Msds Plus Weld Metal Lt1 298Document7 pagesMsds Plus Weld Metal Lt1 298Juan franNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Nickel Base Welding Wire MSDS Provides Health and Safety InformationDocument7 pagesNickel Base Welding Wire MSDS Provides Health and Safety InformationLawrence Lancy LoboNo ratings yet

- 4 EC SMAW Msds 5-08Document4 pages4 EC SMAW Msds 5-08Mohamed AdelNo ratings yet

- MSDS - Slag PDFDocument2 pagesMSDS - Slag PDFAyu Wanda SaraswatiNo ratings yet

- 51 EX Msds 9-07Document3 pages51 EX Msds 9-07Mohamed AdelNo ratings yet

- MSDS for MG Welding ElectrodesDocument3 pagesMSDS for MG Welding Electrodesmohamed AdelNo ratings yet

- Steel-Shot-Grit-MSDS-sheet_wabbrasiveDocument2 pagesSteel-Shot-Grit-MSDS-sheet_wabbrasivelukmanNo ratings yet

- Material Safety Data Sheet Thoriated TungstensDocument5 pagesMaterial Safety Data Sheet Thoriated TungstensveraNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Sulphur VapoursDocument12 pagesSulphur VapoursAnvay Choudhary100% (1)

- Egg, Boiled: Nutrition FactsDocument5 pagesEgg, Boiled: Nutrition FactsbolajiNo ratings yet

- M.E. Applied Electronics Curriculum RegulationsDocument21 pagesM.E. Applied Electronics Curriculum RegulationsRamya VNo ratings yet

- Book E-Ticket for SETC Bus TravelDocument1 pageBook E-Ticket for SETC Bus TravelMohamed MNo ratings yet

- 2006 Conference On IEEE 1588 - TutorialDocument57 pages2006 Conference On IEEE 1588 - TutorialliolioskNo ratings yet

- Engineering Economy 15th Edition Sullivan Test BankDocument25 pagesEngineering Economy 15th Edition Sullivan Test BankDannyStaffordctbi100% (53)

- Thermal Physics SLDocument4 pagesThermal Physics SLIBstudent10No ratings yet

- Amc Offer 500 Kva & 380 Kva DGDocument8 pagesAmc Offer 500 Kva & 380 Kva DGabhibawa100% (3)

- Seminar Report On Hydrogen As The Future FuelDocument63 pagesSeminar Report On Hydrogen As The Future FuelMOHIT MGMNo ratings yet

- OCDM2223 Tutorial7solvedDocument5 pagesOCDM2223 Tutorial7solvedqq727783No ratings yet

- DR Tian Sing NG, BOSFA Fibres For Crack Control PDFDocument68 pagesDR Tian Sing NG, BOSFA Fibres For Crack Control PDFsaiNo ratings yet

- Introduction to NFFHTDocument44 pagesIntroduction to NFFHTTAPASVI BHATTNo ratings yet

- LCOH - Science 10Document4 pagesLCOH - Science 10AlAr-JohnTienzoTimeniaNo ratings yet

- Vo 1263 AaDocument8 pagesVo 1263 Aa801400No ratings yet

- Differential Release of Mast Cell Mediators and The Pathogenesis of InflammationDocument14 pagesDifferential Release of Mast Cell Mediators and The Pathogenesis of InflammationklaumrdNo ratings yet

- Clippers and ClampersDocument8 pagesClippers and Clamperspuneeth kumarNo ratings yet

- Health & Performance Monitoring Using Active Magnetic BearingsDocument104 pagesHealth & Performance Monitoring Using Active Magnetic BearingsAbhinav RajNo ratings yet

- BS en 480-6-2005Document5 pagesBS en 480-6-2005Abey Vettoor0% (1)

- Spek Dental Panoramic Rotograph EVODocument2 pagesSpek Dental Panoramic Rotograph EVOtekmed koesnadiNo ratings yet

- 2004 Timbre To DissonanceDocument4 pages2004 Timbre To DissonancetgraubaenaNo ratings yet

- Solving Poisson's Equation Using The FFTDocument9 pagesSolving Poisson's Equation Using The FFTJhon CerónNo ratings yet

- Aviation Fuel Quality Control Manual - Rev.2015Document56 pagesAviation Fuel Quality Control Manual - Rev.2015Aswin Lorenzo Gultom100% (1)

- Hydro PDFDocument139 pagesHydro PDFVan Quynh100% (2)

- Reverse Circulation DrillingDocument6 pagesReverse Circulation DrillingHabib Ur Rahman100% (1)

- Mua prc007 en - 12042009Document73 pagesMua prc007 en - 12042009sachinsaklani23No ratings yet

- EAU2 - I - 04 - Ruins of The Lost RealmDocument127 pagesEAU2 - I - 04 - Ruins of The Lost RealmHache73% (15)

- Pharmacology SamplexDocument12 pagesPharmacology SamplexLiezel Dejumo BartolataNo ratings yet

- Just Walk Across The RoomDocument8 pagesJust Walk Across The Roomstuutterrs100% (1)

- Dry-Heat Destruction of Destruction KineticsDocument5 pagesDry-Heat Destruction of Destruction KineticsFabioEspinolaNo ratings yet

- Unit 14 Workbook BussinessDocument45 pagesUnit 14 Workbook BussinessAna Victoria DíazNo ratings yet