Professional Documents

Culture Documents

MSDS - Slag PDF

Uploaded by

Ayu Wanda Saraswati0 ratings0% found this document useful (0 votes)

90 views2 pages1) The document provides information on the composition and safety hazards of steel slag. It lists various chemical constituents like aluminum, barium, cadmium, calcium hydroxide, and chromium that may be present in steel slag.

2) Exposure to dust from steel slag can cause irritation of the eyes, skin, and respiratory tract. Long term exposure increases risk of lung diseases and some components are potential carcinogens.

3) Proper protective equipment like respirators and gloves should be used when handling steel slag to prevent inhalation or skin contact with dust.

Original Description:

Original Title

MSDS - SLAG.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document provides information on the composition and safety hazards of steel slag. It lists various chemical constituents like aluminum, barium, cadmium, calcium hydroxide, and chromium that may be present in steel slag.

2) Exposure to dust from steel slag can cause irritation of the eyes, skin, and respiratory tract. Long term exposure increases risk of lung diseases and some components are potential carcinogens.

3) Proper protective equipment like respirators and gloves should be used when handling steel slag to prevent inhalation or skin contact with dust.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

90 views2 pagesMSDS - Slag PDF

Uploaded by

Ayu Wanda Saraswati1) The document provides information on the composition and safety hazards of steel slag. It lists various chemical constituents like aluminum, barium, cadmium, calcium hydroxide, and chromium that may be present in steel slag.

2) Exposure to dust from steel slag can cause irritation of the eyes, skin, and respiratory tract. Long term exposure increases risk of lung diseases and some components are potential carcinogens.

3) Proper protective equipment like respirators and gloves should be used when handling steel slag to prevent inhalation or skin contact with dust.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Material Safety Data Sheet

MANUFACTURER: Structural Metals, Inc. dba (CMC Steel Texas)

ADDRESS: P.O. Box 911

Seguin, TX 78156-0911

PHONE: (830) 372-8200

DATE: February 2007

I. Material Identification

CHEMICAL NAME: Steel Slag

SYNONYMS: NA

CHEMICAL FAMILY: Inorganic Compounds

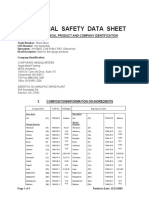

II. Ingredients and Hazards

a b 3 c 3

Constituent CAS # % OSHA PEL (mg/m ) ACGIH TLV-TWA (mg/mg )

Aluminum 7429-90-5 1-7 5 (resp frac) 10 (dust)

15 (total dust) 5 (welding fumes)

Barium (soluble compounds) 7440-39-3 0.02-<0.2 0.5 0.5

Cadmium 7440-43-9 <0.005 5 0.01 (elemental)

0.002 (as compounds)

Calcium hydroxide 1305-62-0 17-32 5 (resp frac) / 15 (total dust) 5

Carbon (carbonate foam) 7440-44-0 0.01-<1.5 3.5 3.5

Chromium (total) 7440-47-3 0.03-<1 0.5 (Chromium II and III) 0.5 (metal and Cr III)

1 (metal)

Chromium VI 7440-47-3 <0.001 1 (metal) 0.05 (water-soluble)

0.1 (oxide) 0.01 (insoluble)

Copper 7440-50-8 0.006-<0.1 0.1 (dust and mist) 0.2 (fume)

1 (dusts and mists)

Iron 1309-37-1 3-31 10 (oxide dust and fume) 5 (dust and fume)

Lead 7439-92-1 <0.05 0.050 0.05

Magnesium 1309-48-4 2-9 15 (oxide fume) 10 (oxide fume)

Manganese 7439-96-5 1-6 5 0.2

Nickel 7440-02-0 <0.05 1 1.5 (metal)

0.1 (soluble compounds)

0.2 (insoluble compounds)

Phosphorous (yellow) 7723-14-0 0.06-<0.5 0.1 0.05

Selenium 7782-49-2 <0.005 0.2 0.2

Silicon 7440-21-3 4-15 15 10

Silver 7440-22-4 <0.05 0.01 0.1 (metal)

0.01 (soluble compounds)

Sulfur 7446-04-95 0.06-<0.5 13 (dioxide) 5.24 (dioxide)

Vanadium 1314-62-1 0.02-<0.5 0.1 (pentoxide fume) 0.05 (pentoxide dust or fume)

0.5 (pentoxide dust)

Zinc 1314-13-2 <0.1 5 (fume) 5 (fume)

15 (dust) 10 (dust)

Notes:

(a) This listing is a summary of elements used in producing slag as a byproduct of steel alloying. Since various grades of steel contain different

combinations of these elements, slag will also contain different combinations. Trace elements may be present in minute amounts. No permissible

exposure limits (PELs) or threshold limit values (TLVs) exist for steel mill scale. Values shown are applicable to component elements.

(b) Chemical Abstract Number

(c) Occupational Safety and Health Administration, Permissible Exposure Limit

(d) American Conference of Governmental Industrial Hygienists, Threshold Limit Value, Time-Weighted Average - the time-weighted average

concentration for a conventional 8-hour workday and a 40-hour workweek, to which it is believed that nearly all workers may be repeatedly exposed,

day after day, without adverse effect.

III. Physical Data APPEARANCE AND ODOR: Odorless hard, gray solid.

BOILING PT. At 1 atm., deg. F: 5000

MELTING PT.: 3000

VAPOR PRESSURE at (mm Hg): NA

VAPOR DENSITY (Air=1): NA

W ATER SOLUBILITY: Insoluble

SPECIFIC GRAVITY (H2O=1): 2.0-2.5

EVAP. RATE (NA=1): NA

VOLATILES, % Volume: NA

MOLECULAR W T.: NA

IV. Fire and Explosion Data

EXTINGUISHING MEDIA: NA

SPECIAL FIRE FIGHTING PROCEDURES: NA

UNUSUAL FIRE OR EXPLOSION HAZARDS: NA

Note: Slag in the solid state presents no fire or explosion hazard.

V. Health Hazard Information

ROUTE OF ENTRY - SKIN: Yes

ROUTE OF ENTRY - INHALATION: Yes (as dust)

ROUTE OF ENTRY - INGESTION: Yes

HEALTH HAZARDS ACUTE AND CHRONIC/ EFFECTS OF OVEREXPOSURE: Short term exposure to steel slag dust may result in irritation to eyes,

mucous membranes and respiratory tract. Inhalation of fumes or dust may result in metal fume fever with symptoms such as metallic taste,

throat irritation, coughing, pains in muscles and joints, fever and chills. Inhalation of dust and fumes may cause respiratory system irritation

or effects such as pneumoconiosis (siderosis). Prolonged contact with slag may cause irritation or dermatitis. Exposure to nickel,

manganese and lead may lead to metabolic, reproductive, gastrointestinal, blood, kidney and central nervous system disorders. Exposure

to manganese fumes may adversely affect the reproductive or central nervous system (Amanganism@) with symptoms such as weakness in

lower extremities, sleepiness, salivation, nervousness and apathy. Exposure to silver may cause argyria of the skin, eyes or mucous

membranes. Chronic conditions may include respiratory conditions or allergic conditions. Chronic respiratory effects such as asthma,

silicosis, or other pneumoconioses and chronic bronchitis may occur.

MEDICAL CONDITIONS AGGRAVATED: Chronic diseases or disorders of the respiratory system may be aggravated by slag dust or fumes.

CARCINOGENICITY - NTP: Yes (constituents)

EXPLANATION OF CARCINOGENICITY:

IARC 1987: Iron and steel founding entails exposures that are carcinogenic to humans. Elevated risk of cancers of the lung, stomach

and genito-urinary system have been observed among iron and steel industry workers.

th

NTP 8 Annual Report on Carcinogens, 1998: Crystalline silica, nickel, lead acetate and cadmium reasonably anticipated to be human

carcinogens. Hexavalent chromium known to be a human carcinogen. Inadequate data available to evaluate the carcinogenicity of

chromium and trivalent chromium compounds.

FIRST AID:

Eye Contact: Flush well with running water to remove particles; obtain medical attention.

Skin Contact: Brush off excess dust; wash area well with soap and water.

Inhalation: Remove to fresh air; obtain medical attention.

Ingestion: Seek medical attention if large quantities of material have been ingested.

VI. Reactivity Data

STABILITY: Stable

INCOMPATIBILITY (Materials to Avoid): NA

HAZARDOUS DECOMPOSITION PRODUCTS: NA

HAZARDOUS POLYMERIZATION: Will not occur.

CONDITIONS TO AVOID: NA

VII. Spill, Leak and Disposal Procedures

SPILLS, LEAKS (Steps to be taken): Use dust suppression techniques as needed to control dust during processing and construction

operations.

W ASTE DISPOSAL METHOD: Material should be reclaimed for re-use as construction material; follow local, state and federal waste

disposal requirements.

VIII. Special Protection Information

RESPIRATORY PROTECTION: Use general service or nuisance dust respirator of type approved by NIOSH/MSHA as needed.

VENTILATION:

Local Exhaust: To control dust, fumes, etc. when grinding, cutting/burning.

Mechanical (General): NA

PROTECTIVE GLOVES: Recommended to protect against skin abrasion.

EYE PROTECTION: Safety glasses with sideshields of type approved by OSHA/MSHA.

IX. Special Precautions and Comments

STORAGE AND HANDLING INFORMATION: Exercise caution when working with hot slag. To avoid superheated steam explosions, do not place

hot slag in standing water.

OTHER PRECAUTIONS: None

DOT CLASS: Nonhazardous

You might also like

- The Uniqueness of Biological Materials: International Series of Monographs in Pure and Applied Biology: ZoologyFrom EverandThe Uniqueness of Biological Materials: International Series of Monographs in Pure and Applied Biology: ZoologyNo ratings yet

- Metal StudsDocument9 pagesMetal StudsMeita RizkyNo ratings yet

- SDS PC Strand Sumiden Wire Products 2017 06 23 PDFDocument8 pagesSDS PC Strand Sumiden Wire Products 2017 06 23 PDFfehmi boudabousNo ratings yet

- SDS-metal DustDocument10 pagesSDS-metal DustAzuan MABKNo ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company Identificationrmsa17No ratings yet

- Msds Carbon SteelDocument2 pagesMsds Carbon SteelRober Moises Chumbe SoveroNo ratings yet

- MSDS Leadframe (16 Items)Document8 pagesMSDS Leadframe (16 Items)bennisg8No ratings yet

- Material Safety Data Sheet: For Welding Consumables and Related ProductsDocument2 pagesMaterial Safety Data Sheet: For Welding Consumables and Related ProductsVinodhkanna GandhiNo ratings yet

- PEC16 EncoderDocument2 pagesPEC16 EncoderBaCresNo ratings yet

- Pmeg2010er Chemical ContentDocument2 pagesPmeg2010er Chemical ContentKarthik ManiNo ratings yet

- Steel-Shot-Grit-MSDS-sheet_wabbrasiveDocument2 pagesSteel-Shot-Grit-MSDS-sheet_wabbrasivelukmanNo ratings yet

- Adc12 MSDSDocument3 pagesAdc12 MSDSClaudia Mata100% (1)

- Safety Data Sheet for Steel RulesDocument1 pageSafety Data Sheet for Steel RulesHendra SeptaNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Sa-S - Mds (EHS)Document2 pagesSa-S - Mds (EHS)chamelibanerjee0083No ratings yet

- Integris Metals - Metal and Metal Alloys of Aluminum, Copper, Lead, Nickel and SteelDocument4 pagesIntegris Metals - Metal and Metal Alloys of Aluminum, Copper, Lead, Nickel and Steeljaredf@jfelectric.com100% (1)

- Kino Flo Lamp Safety Data SheetDocument2 pagesKino Flo Lamp Safety Data SheetAnderson PimentelNo ratings yet

- Bronze Alloys MsdsDocument11 pagesBronze Alloys MsdssalcabesNo ratings yet

- Material Safety Data Sheet (M.S.D.S.) : Updated March 24, 2014Document3 pagesMaterial Safety Data Sheet (M.S.D.S.) : Updated March 24, 2014UtamiNo ratings yet

- MSDS - BeCu AlloyDocument6 pagesMSDS - BeCu AlloyTaherNo ratings yet

- Introduction to Slag Fundamentals Under 40 CharactersDocument38 pagesIntroduction to Slag Fundamentals Under 40 CharactersNicole Altamirano Catalán100% (1)

- McKay Hard Facing Electrodes MsdsDocument2 pagesMcKay Hard Facing Electrodes MsdssalcabesNo ratings yet

- AFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Document1 pageAFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Safrin SangiaNo ratings yet

- Tungsten Carbide Manufacturing Material Safety Data Sheet: MSDS # 908Document5 pagesTungsten Carbide Manufacturing Material Safety Data Sheet: MSDS # 908ALDONo ratings yet

- Gas Metal Arc Welding WiresDocument3 pagesGas Metal Arc Welding Wiresmuhamad bukhari abu hassanNo ratings yet

- Material Content Data Sheet: Semipack 3DDocument2 pagesMaterial Content Data Sheet: Semipack 3DArun MuruganNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product Identificationmohamed AdelNo ratings yet

- SEMIKRON Material Content Data Sheet SEMITRANS® 2 EN 2019-07-13 Rev-05Document2 pagesSEMIKRON Material Content Data Sheet SEMITRANS® 2 EN 2019-07-13 Rev-05erode els erodeNo ratings yet

- Stainless Steel Mig & Tig Wire MSDSDocument3 pagesStainless Steel Mig & Tig Wire MSDSsalcabesNo ratings yet

- J79 195 Rev H AMPCO SDS Rod WireDocument10 pagesJ79 195 Rev H AMPCO SDS Rod WireNair R RakeshNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Infineon-MA005560621-MaterialContentSheet-v01_00-ENDocument1 pageInfineon-MA005560621-MaterialContentSheet-v01_00-ENJulio Cesar Tapia ReyesNo ratings yet

- Dutch Pollutant Standards PDFDocument5 pagesDutch Pollutant Standards PDFERNESTONo ratings yet

- Aluminum A380 MSDS SheetDocument3 pagesAluminum A380 MSDS SheetAndy KrolNo ratings yet

- Sds Msds 000033 Telco (Telllurium Copper) 1991 Na MwiDocument5 pagesSds Msds 000033 Telco (Telllurium Copper) 1991 Na MwieadriesNo ratings yet

- Infineon MA005408980 MaterialContentSheet v01 - 00 ENDocument1 pageInfineon MA005408980 MaterialContentSheet v01 - 00 ENJulio Cesar Tapia ReyesNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product Identificationmohamed AdelNo ratings yet

- Infineon-MA005735498-MaterialContentSheet-v01_00-ENDocument1 pageInfineon-MA005735498-MaterialContentSheet-v01_00-ENJulio Cesar Tapia ReyesNo ratings yet

- Trade Effluent Discharge LimitsDocument2 pagesTrade Effluent Discharge Limitsjiaolei9848No ratings yet

- Usp EstrategiasDocument62 pagesUsp EstrategiasAlana PachecoNo ratings yet

- HINGED 42MM SERIES PROFILESDocument120 pagesHINGED 42MM SERIES PROFILESViswanathan Kannoor67% (3)

- MIG Welding Electrode MSDSDocument6 pagesMIG Welding Electrode MSDSDheeraj E MohananNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationadityadhNo ratings yet

- IWE4-5 Health and SafetyDocument10 pagesIWE4-5 Health and SafetyIrmantas ŠakysNo ratings yet

- Dutch Standards for Environmental Pollutant Reference ValuesDocument5 pagesDutch Standards for Environmental Pollutant Reference Valuesumair2kplus492No ratings yet

- Polish Rod SpecificationsDocument1 pagePolish Rod SpecificationsRisky PradikaNo ratings yet

- Member of the BÖHLER -UDDEHOLM Group MATERIAL SAFETY DATA SHEETDocument6 pagesMember of the BÖHLER -UDDEHOLM Group MATERIAL SAFETY DATA SHEETantoncanuckNo ratings yet

- (Carbon) C: - 0-2746-5148, 08-1565-5678 1 5Document5 pages(Carbon) C: - 0-2746-5148, 08-1565-5678 1 5Suriyachai NiamsornNo ratings yet

- Sheet - PDF 3Document4 pagesSheet - PDF 3Nazar JabbarNo ratings yet

- Hinged 45 MMDocument134 pagesHinged 45 MMMuraleedharanNo ratings yet

- MSDS for LC-318HR Welding ElectrodeDocument5 pagesMSDS for LC-318HR Welding ElectrodeMohamed AdelNo ratings yet

- Wilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Document3 pagesWilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Ray Mark De TorresNo ratings yet

- Min Ign EnergyDocument9 pagesMin Ign Energywerdna67No ratings yet

- Material Content Data Sheet for TLE4290DDocument1 pageMaterial Content Data Sheet for TLE4290DTakemasa KosekiNo ratings yet

- QW-440 Weld Metal Chemical CompositionDocument1 pageQW-440 Weld Metal Chemical Compositionmetal treat ind.No ratings yet

- M S D S: Aterial Afety ATA HeetDocument7 pagesM S D S: Aterial Afety ATA HeetJhony MedranoNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Sra0020 Lone WorkingDocument6 pagesSra0020 Lone WorkingRajesh gpNo ratings yet

- Sra0008 Brickwork and Concrete RepairsDocument9 pagesSra0008 Brickwork and Concrete RepairsAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument3 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Safety Risk Assessment Carpentry Safety Risk Assessment CarpentryDocument9 pagesSafety Risk Assessment Carpentry Safety Risk Assessment CarpentryAyu Wanda SaraswatiNo ratings yet

- Sra0005 PlumbingDocument10 pagesSra0005 PlumbingRajesh gpNo ratings yet

- Sra0023 Commercial GasDocument12 pagesSra0023 Commercial GasAyu Wanda SaraswatiNo ratings yet

- Sra0028 Stress ManagementDocument5 pagesSra0028 Stress ManagementRajesh gpNo ratings yet

- Sra0010 Demolition WorksDocument9 pagesSra0010 Demolition WorksRajesh gpNo ratings yet

- Procedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresDocument10 pagesProcedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresradhouaneNo ratings yet

- Manual Handling Safety Risk AssessmentDocument6 pagesManual Handling Safety Risk Assessmentgueettaf faresNo ratings yet

- Sra0029 Roof Works - Surveying - InspectionsDocument12 pagesSra0029 Roof Works - Surveying - InspectionsAyu Wanda SaraswatiNo ratings yet

- Consolidated Construction Consortium LTD: Procedure For Competence Training and AwarenessDocument4 pagesConsolidated Construction Consortium LTD: Procedure For Competence Training and AwarenessAyu Wanda SaraswatiNo ratings yet

- Risk Assessment Vulnerable AdultsDocument4 pagesRisk Assessment Vulnerable AdultsAyu Wanda SaraswatiNo ratings yet

- Procedure For Internal Audits: Consolidated Construction Consortium LTDDocument5 pagesProcedure For Internal Audits: Consolidated Construction Consortium LTDradhouaneNo ratings yet

- Procedure For Control of Records: Consolidated Construction Consortium LTDDocument3 pagesProcedure For Control of Records: Consolidated Construction Consortium LTDAyu Wanda SaraswatiNo ratings yet

- Procedure For Emergency Preparedness and Response: Consolidated Construction Consortium LTDDocument6 pagesProcedure For Emergency Preparedness and Response: Consolidated Construction Consortium LTDAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Procedure For Health & Safety Management Programs and Environmental Management ProgramsDocument3 pagesProcedure For Health & Safety Management Programs and Environmental Management ProgramsAyu Wanda SaraswatiNo ratings yet

- Risk Assessment Vulnerable AdultsDocument4 pagesRisk Assessment Vulnerable AdultsAyu Wanda SaraswatiNo ratings yet

- Legal Requirements Identification ProcedureDocument5 pagesLegal Requirements Identification ProcedureAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Work EquipmentDocument4 pagesOne Direct Method Statement: Main Hazards Work EquipmentFaisal RazaNo ratings yet

- Procedure For Setting Objectives and TargetsDocument3 pagesProcedure For Setting Objectives and TargetsradhouaneNo ratings yet

- Electrical - Consumer Unit Method StatmentDocument4 pagesElectrical - Consumer Unit Method StatmentFaisal RazaNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Safety Systems MinesDocument28 pagesSafety Systems MinesAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main HazardsDocument4 pagesOne Direct Method Statement: Main HazardsAyu Wanda SaraswatiNo ratings yet

- HIRARC GuideLine From DOSHDocument34 pagesHIRARC GuideLine From DOSHMohd Hadri50% (2)

- Class - 10th Chemistry Chapter 1 Chemical Equations PDFDocument248 pagesClass - 10th Chemistry Chapter 1 Chemical Equations PDFHarsh Sheokand0% (1)

- PEKA Experiment Chemistry Form 4 Chapter 2 To 5Document9 pagesPEKA Experiment Chemistry Form 4 Chapter 2 To 5James Chua Hong Kheng67% (6)

- Extraction of Metals and S - Block ElementsDocument5 pagesExtraction of Metals and S - Block ElementsAshwin BalajiNo ratings yet

- Atmospheric ChemistryDocument4 pagesAtmospheric ChemistryBrian MachariaNo ratings yet

- Classification of Chemical Reactions and Substances PDFDocument43 pagesClassification of Chemical Reactions and Substances PDFDaniel YordanovNo ratings yet

- Problem Solving Teaching AcidsDocument9 pagesProblem Solving Teaching AcidsNatalia WhyteNo ratings yet

- 1 Determination of The Empirical Formula of Silver Oxide (Flinn AP Lab 1) - Short VersionDocument5 pages1 Determination of The Empirical Formula of Silver Oxide (Flinn AP Lab 1) - Short Versionsohaila ibrahimNo ratings yet

- Preparation and Purification of Soluble SaltsDocument12 pagesPreparation and Purification of Soluble SaltsJuni FarhanaNo ratings yet

- TMP 39 F4Document5 pagesTMP 39 F4FrontiersNo ratings yet

- Chapter 3 Exam Review and Practice ProblemsDocument3 pagesChapter 3 Exam Review and Practice ProblemsNURUL HUSNA ABDUL MUTALIBNo ratings yet

- Metals and Non-Metals: Multiple Choice QuestionsDocument6 pagesMetals and Non-Metals: Multiple Choice QuestionsAkash SahaNo ratings yet

- Advanced Gas Tanker TrainingDocument136 pagesAdvanced Gas Tanker TrainingPrassanna Venkatesh100% (2)

- CopperDocument26 pagesCopperShirjak ThokarNo ratings yet

- Class 7 ScienceDocument40 pagesClass 7 ScienceQulb e AbbasNo ratings yet

- Year 11 IGCSE Question PaperDocument17 pagesYear 11 IGCSE Question PaperMaitrey TelangNo ratings yet

- Empirical and Molecular Formulae Practice QuestionsDocument3 pagesEmpirical and Molecular Formulae Practice Questionsbilly ogadaNo ratings yet

- Titanium Tetrachloride (Ticl) : Product Data SheetDocument1 pageTitanium Tetrachloride (Ticl) : Product Data SheetJayakumar ANo ratings yet

- 2012 TrialDocument9 pages2012 TrialCin D NgNo ratings yet

- Basic Principles of MetallurgyDocument28 pagesBasic Principles of MetallurgysanjeevNo ratings yet

- Chemical Formula and Naming of CompoundDocument46 pagesChemical Formula and Naming of CompoundMark RamosNo ratings yet

- Jitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetDocument18 pagesJitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetabhishekNo ratings yet

- Cover Booklet KS4 Chemistry 1Document61 pagesCover Booklet KS4 Chemistry 1Peter HoskinsNo ratings yet

- Classification of Chemical ReactionsDocument7 pagesClassification of Chemical Reactionscalew17036No ratings yet

- Precoat Filter Media: Awwa StandardDocument20 pagesPrecoat Filter Media: Awwa StandardErdi ErdoganNo ratings yet

- ASM Calcium Carbonate Technical Data SheetDocument1 pageASM Calcium Carbonate Technical Data SheetAnik AichNo ratings yet

- Experiment 3 Alumina Extraction From Zeolit: (Surjani Rahardjo, 2013)Document8 pagesExperiment 3 Alumina Extraction From Zeolit: (Surjani Rahardjo, 2013)Jafrinta Irma Ruta AstariNo ratings yet

- 2nd Semester (2nd Grading)Document38 pages2nd Semester (2nd Grading)Justine Megan CaceresNo ratings yet

- HKISO-2020-2021 Mock Heat P5fDocument7 pagesHKISO-2020-2021 Mock Heat P5fmanromanokristoff96No ratings yet

- Basic Inorganic ChemistryDocument20 pagesBasic Inorganic ChemistryOMED gardiNo ratings yet

- Types of Chemical ReactionsDocument78 pagesTypes of Chemical ReactionsFerrer AmicaNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Basic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesFrom EverandBasic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesRating: 3 out of 5 stars3/5 (1)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)