Professional Documents

Culture Documents

One Direct Method Statement: Main Hazards Preventative Measures

Uploaded by

Ayu Wanda SaraswatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

One Direct Method Statement: Main Hazards Preventative Measures

Uploaded by

Ayu Wanda SaraswatiCopyright:

Available Formats

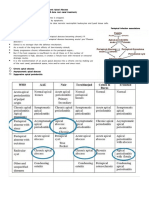

ONE DIRECT METHOD STATEMENT

NUMBER: MS0020

Start Date 01/05/2016

Task / Activity Internal Plastering

Review Date 01/05/2018

Accompanying Risk

Site Address /Location OHG Properties SRA 3, 16, 17, 24

Assessment

Personnel Involved One Direct Operatives Role /Trade Plasters, Multi Trade

Mark Bloxidge – H&S Manager Tel: 07900 160656

Health & Safety

Jessica Langley – H&S Advisor Tel: 07966 348804

Main Hazards Preventative Measures

yy Working at Height yy Operative must be competent to carry out the task

yy Manual Handling yy Operative must have received training and be competent

yy Hazardous Substances to carry out working at height

yy Use of Hand and Power Tools yy Barriers or warning signs to be put in place where

yy Electrocution identified by risk assessment

yy Asbestos yy Operatives must be trained and competent to use hand

tools, power tools

yy Slips, Trips and Falls

yy Do not lift beyond your capabilities, if necessary get help

yy Operatives to confirm location of electrical services

yy Keep work area clean and tidy

Work Equipment yy All plasterers equipment including hand and power tools

and step ladders and hop ups should be kept clean from

yy Trowels, Floats, power

plaster spills to ensure that all makings are visible and

mixing tool

equipment is able to be clearly inspected

yy Handling substances in line with appropriate COSHH

control approach

yy Dispose of waste to the designated area

yy All operatives to read the asbestos information for the

property

yy Wear appropriate PPE where identified

Sequence of Operations for Task

yy Ensure all PPE is being worn yy Ensure area to be worked on is clear of

yy Consult asbestos information for the obstructions, protect any surfaces to prevent

property, report any concerns to supervisor damage, maintain good access and egress

yy Cordon off work area and apply safety yy Ensure wall/ floor surface is structurally

signage as appropriate if practical and stable, flat and consists of a suitable

necessary to do so substrate

OD/HS/2012/V2 Prepared By M Bloxidge (H&S Manager) Date:

ONE DIRECT METHOD STATEMENT

NUMBER: MS0020

yy All Operatives must apply the appropriate yy Mixing should be kept to short duration work

COSHH control approach to the activity or shared between operatives to reduce

yy Mixing of plaster should be carried out as levels of manual handling and repetitive

close as is practical to the work area to strain injuries

avoid excessive manual handling. yy Plaster to be applied to surfaces using hand

yy Power mixing equipment should be visually trowel and finished using hand float

checked prior to use to ensure that is safe to yy Work area to be kept clean and clear as they

use work to prevent slip, trip and fall hazards

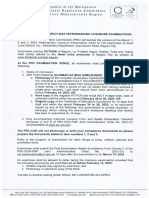

PPE Required

HARD HAT HAND PROTECTION SAFETY VISOR

NO YES NO

HIGH VIZ SAFETY FOOTWEAR DUST MASK

NO YES YES

EYE PROTECTION EAR PROTECTION

YES YES

Environmental Protection Measures

yy Dispose of all waste in designated area or skip provided for waste and in accordance with

manufactures instructions

OD/HS/2012/V2 Prepared By M Bloxidge (H&S Manager) Date:

ONE DIRECT METHOD STATEMENT

NUMBER: MS0020

Hazardous Substances

IRRITANT/ RESPIRATORY

FLAMMABLE

SENSITISER SENSITISER

NO

YES NO

TOXIC CORROSIVE DANGEROUS TO

NO NO THE ENVIRONMENT

NO

GAS UNDER PRESSURE

NO

Emergency procedures

First Aid:

yy First Aid box provided on all vehicles

yy Local arrangements for contacting emergency services to be identified

yy Location or nearest hospital A&E must be known

yy In case of serious accident or injury requiring immediate medical attention call 999

yy Always inform supervisor or H&S Manager of all accidents, incidents and near misses

yy Ensure that accident, incident or near miss is logged

Fire:

yy Fire extinguisher on all vehicles

yy Only attempt to extinguisher f safe to do so

yy Local arrangements for contacting emergency services to be identified

yy Maintain adequate emergency access route in working location at all times

OD/HS/2012/V2 Prepared By M Bloxidge (H&S Manager) Date:

ONE DIRECT METHOD STATEMENT

NUMBER: MS0020

Training & Supervision Permit to work

yy All staff have received H&S Induction training yy N/A

yy All Operatives are supervised

Safety of Other Contractors Refuelling Procedure

or Members of the Public of Plant Machinery

yy Ensure that other contractors are aware

or Equipment

of hazards present

yy Fuel to be carried in appropriate fuel

yy Ensure that work area is secured containers and secured in vans. All plant

yy No works will be left in a dangerous and machinery to be refuelled away from

condition or with risk to themselves, the van, visitors and members of the

contractors, tenants or members of the public and any sources of ignition.

public yy Fuel is to be transferred from the

yy All tools and equipment will be securely proprietary containers by certified fuel

stored or removed from site at the end of transfer unit or through a funnel into the

each working day machine tank.

OD/HS/2012/V2 Prepared By M Bloxidge (H&S Manager) Date:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Method Statement For PlasteringDocument14 pagesMethod Statement For Plasteringjameel100% (1)

- Pediatric Cardiology II Lecture SummaryDocument5 pagesPediatric Cardiology II Lecture SummaryMedisina101No ratings yet

- Safety Risk Assessment Carpentry Safety Risk Assessment CarpentryDocument9 pagesSafety Risk Assessment Carpentry Safety Risk Assessment CarpentryAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument3 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Sra0020 Lone WorkingDocument6 pagesSra0020 Lone WorkingRajesh gpNo ratings yet

- Manual Handling Safety Risk AssessmentDocument6 pagesManual Handling Safety Risk Assessmentgueettaf faresNo ratings yet

- Sra0010 Demolition WorksDocument9 pagesSra0010 Demolition WorksRajesh gpNo ratings yet

- Sra0023 Commercial GasDocument12 pagesSra0023 Commercial GasAyu Wanda SaraswatiNo ratings yet

- Sra0029 Roof Works - Surveying - InspectionsDocument12 pagesSra0029 Roof Works - Surveying - InspectionsAyu Wanda SaraswatiNo ratings yet

- Sra0008 Brickwork and Concrete RepairsDocument9 pagesSra0008 Brickwork and Concrete RepairsAyu Wanda SaraswatiNo ratings yet

- Procedure For Emergency Preparedness and Response: Consolidated Construction Consortium LTDDocument6 pagesProcedure For Emergency Preparedness and Response: Consolidated Construction Consortium LTDAyu Wanda SaraswatiNo ratings yet

- Sra0005 PlumbingDocument10 pagesSra0005 PlumbingRajesh gpNo ratings yet

- Procedure For Internal Audits: Consolidated Construction Consortium LTDDocument5 pagesProcedure For Internal Audits: Consolidated Construction Consortium LTDradhouaneNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Procedure For Control of Records: Consolidated Construction Consortium LTDDocument3 pagesProcedure For Control of Records: Consolidated Construction Consortium LTDAyu Wanda SaraswatiNo ratings yet

- Sra0028 Stress ManagementDocument5 pagesSra0028 Stress ManagementRajesh gpNo ratings yet

- Risk Assessment Vulnerable AdultsDocument4 pagesRisk Assessment Vulnerable AdultsAyu Wanda SaraswatiNo ratings yet

- Legal Requirements Identification ProcedureDocument5 pagesLegal Requirements Identification ProcedureAyu Wanda SaraswatiNo ratings yet

- Procedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresDocument10 pagesProcedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresradhouaneNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Consolidated Construction Consortium LTD: Procedure For Competence Training and AwarenessDocument4 pagesConsolidated Construction Consortium LTD: Procedure For Competence Training and AwarenessAyu Wanda SaraswatiNo ratings yet

- Procedure For Health & Safety Management Programs and Environmental Management ProgramsDocument3 pagesProcedure For Health & Safety Management Programs and Environmental Management ProgramsAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main HazardsDocument4 pagesOne Direct Method Statement: Main HazardsAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Risk Assessment Vulnerable AdultsDocument4 pagesRisk Assessment Vulnerable AdultsAyu Wanda SaraswatiNo ratings yet

- Procedure For Setting Objectives and TargetsDocument3 pagesProcedure For Setting Objectives and TargetsradhouaneNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Electrical - Consumer Unit Method StatmentDocument4 pagesElectrical - Consumer Unit Method StatmentFaisal RazaNo ratings yet

- Safety Systems MinesDocument28 pagesSafety Systems MinesAyu Wanda SaraswatiNo ratings yet

- HIRARC GuideLine From DOSHDocument34 pagesHIRARC GuideLine From DOSHMohd Hadri50% (2)

- One Direct Method Statement: Main Hazards Work EquipmentDocument4 pagesOne Direct Method Statement: Main Hazards Work EquipmentFaisal RazaNo ratings yet

- Dawit Tadesse Fortification AssignmentDocument13 pagesDawit Tadesse Fortification AssignmentDeavoNo ratings yet

- ReportingDocument4 pagesReportingMark CalimlimNo ratings yet

- Project On-Law of Torts Topic - NegligenceDocument10 pagesProject On-Law of Torts Topic - NegligenceSoumya Shefali ChandrakarNo ratings yet

- NCP Self EsteemDocument3 pagesNCP Self EsteemAlfadz AsakilNo ratings yet

- Histology: Diagnosis and Treatment of Chronic Apical AbscessDocument3 pagesHistology: Diagnosis and Treatment of Chronic Apical AbscessPrince AmiryNo ratings yet

- Batangas State University NSTP Project on Community GardeningDocument17 pagesBatangas State University NSTP Project on Community Gardeningjaerald estiocoNo ratings yet

- Impact of COVID-19 On People's Livelihoods, Their Health and Our Food SystemsDocument4 pagesImpact of COVID-19 On People's Livelihoods, Their Health and Our Food Systemsjungkook jeonNo ratings yet

- Uber CEO EmailDocument5 pagesUber CEO EmailKhristopher J. BrooksNo ratings yet

- Case Study of Bronchial Asthma in Acute ExacerbationDocument16 pagesCase Study of Bronchial Asthma in Acute Exacerbationdextroid1290% (29)

- Cpale 2022Document3 pagesCpale 2022Mario ErazoNo ratings yet

- Patient's Profile: Doña Remedios Trinidad Romualdez Medical Foundation, Inc. 2 Semester, S.Y. 2020-2021Document16 pagesPatient's Profile: Doña Remedios Trinidad Romualdez Medical Foundation, Inc. 2 Semester, S.Y. 2020-2021Royce Vincent TizonNo ratings yet

- Conceptual Understanding of OptimismDocument8 pagesConceptual Understanding of OptimismUDITA PARIKHNo ratings yet

- Physiologic Function and Appearance of The NewbornDocument5 pagesPhysiologic Function and Appearance of The NewbornJanelle Cabida SupnadNo ratings yet

- Writing Sample 2Document9 pagesWriting Sample 2api-582848179No ratings yet

- How To Stop Loving Someone Who Doesn't Love You: Part 1 of 4: Giving Yourself SpaceDocument17 pagesHow To Stop Loving Someone Who Doesn't Love You: Part 1 of 4: Giving Yourself SpaceDariz MillerNo ratings yet

- Research Proposal 4Document3 pagesResearch Proposal 4api-385647692No ratings yet

- PAN India Empanelled Hospital List - OICDocument423 pagesPAN India Empanelled Hospital List - OICBHARAT BHUSHANNo ratings yet

- k5 - Sistem Informasi KesehatanDocument29 pagesk5 - Sistem Informasi KesehatanannisaNo ratings yet

- 12 SM 2017 Biology EngDocument206 pages12 SM 2017 Biology EngJaiminGajjar100% (1)

- UNIT5 Technology of Bread MakingDocument12 pagesUNIT5 Technology of Bread MakingS ENo ratings yet

- PRA Tool Box: 6.1. Brief Introduction To PRADocument16 pagesPRA Tool Box: 6.1. Brief Introduction To PRAfaisalNo ratings yet

- Intelligent ConstructionDocument4 pagesIntelligent ConstructionRikesh SapkotaNo ratings yet

- DD - DA Li Ion MSDS U80277 2R2 - SDS 2018Document5 pagesDD - DA Li Ion MSDS U80277 2R2 - SDS 2018lintangscribdNo ratings yet

- Jeenspsu 17Document13 pagesJeenspsu 17GokulVijayGopal G10No ratings yet

- Veterinarians 03-2023Document13 pagesVeterinarians 03-2023PRC BaguioNo ratings yet

- Rare Case of Sirenomelia Congenital AnomalyDocument3 pagesRare Case of Sirenomelia Congenital Anomalymahesh shindeNo ratings yet

- Products Category Pack Size MRP (Inr) : Qnet India Product Price List EFFECTIVE January 1st 2020Document2 pagesProducts Category Pack Size MRP (Inr) : Qnet India Product Price List EFFECTIVE January 1st 2020Gopal SainiNo ratings yet

- IBH 6111 Final PresentationDocument13 pagesIBH 6111 Final PresentationSidney OxboroughNo ratings yet