Professional Documents

Culture Documents

Analysis and Design of Sump and Overhead Tank and Usage of Sensors in Residential Apartment in Nanganallur Chennai IJERTV5IS090590

Uploaded by

sathishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis and Design of Sump and Overhead Tank and Usage of Sensors in Residential Apartment in Nanganallur Chennai IJERTV5IS090590

Uploaded by

sathishCopyright:

Available Formats

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 09, September-2016

Analysis and Design of Sump and Overhead Tank

and Usage of Sensors in Residential Apartment in

Nanganallur, Chennai.

Yashwwanth Krishna Gunasekaran, Abhishek Senthil, Harshit R Jain

Department of Civil Engineering

SRM University, Kattankulathur

Chennai, Tamil Nadu, India.

Abstract- The Sumps and Overhead tanks are those A water tank is used to store water to tide over the daily

Hydraulic structures that are used to store water, liquid requirement. In the construction of concrete structure for the

petroleum, petroleum products and similar liquids. The force storage of water and other liquids the imperviousness of

analysis of the tanks is about the same irrespective of the concrete is most essential .The permeability of any uniform

chemical nature of the product. All tanks are designed as crack

and thoroughly compacted concrete of given mix proportions

free structures to eliminate any leakage. These structures plays

a crucial role in storing water which can be used in various day- is mainly dependent on water cement ratio .The increase in

to-day activities mostly in urban regions especially in water cement ratio results in increase in the permeability .The

Residential apartments which happens to be this project. decrease in water cement ratio will therefore be desirable to

The Float Sensor unit is responsible for sensing the decrease the permeability, but very much reduced water

level of water and sound the alarm when the level of water is cement ratio may cause compaction difficulties and prove to

about to over flow or the tank is nearly empty. The presence of be harmful also. Design of liquid retaining structure has to be

sensor unit helps in maintaining the level of water throughout based on the avoidance of cracking in the concrete having

the day and it also helps in uninterrupted supply of water in regard to its tensile strength. The risk of cracking can also be

many commercial buildings and residential apartments.

minimized by reducing the restraints on free expansion or

The necessity of water is rapidly increasing now-a-days

and this situation cannot be helped only by increasing the source contraction of the structure. And the usage of sensors will

but also by saving the water from wastage. More water is wasted help to avoid the wastage of water which is more important

by over flow from tanks and this is due to human negligence. now-a-days.

This can be avoided by the implementation of sensors. This is a OBJECTIVES

small step towards the bright future. To make a study about the design and analysis of

water tanks.

Keywords- Hydraulic Structures; leakage; force analysis;

Float Sensor Unit; sensors; crack free structures To make a study about the guidelines for the design

of liquid retaining structure according to IS Code.

INTRODUCTION

The Sumps and Overhead tanks are those Hydraulic To know about the design philosophy for the safe

structures that are used to store water, liquid petroleum, and economical design of water tank and sump and

petroleum products and similar liquids. The force analysis of applying a circuit in it.

the tanks is about the same irrespective of the chemical nature

of the product. All tanks are designed as crack free structures To develop programs for the design of water tank of

to eliminate any leakage. These structures plays a crucial role flexible base and rigid bae and the underground tank

in storing water which can be used in various day-to-day to avoid the tedious calculations.

activities mostly in urban regions especially in Residential

apartments which happens to be this project. In the end, the usage of sensors and circuit board for

the prevention of water wastage.

The Float Sensor unit is responsible for sensing the level SCOPE

of water and sound the alarm when the level of water is about

It helps us to design and analyze overhead tank or a

to over flow or the tank is nearly empty. The presence of

sump of any dimension for any residential or

sensor unit helps in maintaining the level of water throughout

commercial building.

the day and it also helps in uninterrupted supply of water in

It helps us to find the overall demand and per capita

many commercial buildings and residential apartments.

demand for a particular area.

And the implementation of sensors and circuit

boards helps us to gain few knowledge about

application of sensors.

Wastage of water can be avoided and enables the

usage of water only for appropriate needs.

IJERTV5IS090590 www.ijert.org 701

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 09, September-2016

METHODOLOGY Table 1 Structure Descriptions

SUMP DIMENSIONS

Here, the methodology consists of various steps where we

understand the process from planning the project, analysis Length 4m

and the design. The methodology of the project is shown as a

flow chart in the below figure. Breadth 3m

Height 3m

OVERHEAD TANK DIMENSIONS

Length 4m

Breadth 2m

Height 5m

Per Capita Demand: Per Capita Demand is defined as the

average annual consumption of water for a particular

population in particular area. It includes domestic, industrial,

fire and theft demands.

P.C.D =

From the above formula we found the total annual

consumption of water in Kadhirkammam Apartments to be

Fig: Flow chart of Methodology

19710 l per day.

SOFTWARES/EQUIPMENT USED

The software / equipment used in the project work ANALYSIS AND DESIGN OF SUMP

is: With respect to the plan of the sump, structure is made with

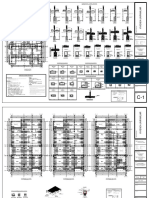

AutoCAD 2016: Overviews of overhead tanks and the help of nodes, beams, plates and surface elements.

sumps have been drawn with the help of this Loads which are acting on the sump are Dead Load,

software. This software will help us to observe the Hydraulic Load and Soil Load.

overhead tank and sump from the top and will make AutoCAD Diagram: The following AutoCAD diagram shows

sure that the dimensions of these tanks are correct. the overview of Sump in the below figure.

STAAD Pro: Analysis of overhead tanks and sump

has been done with the help of this software. The

bending moment and shear force diagrams are the

outcomes and they have been studied.

GENERAL

This project is done according to the Indian Standards and the

requirements regarding the project should be kept in mind.

The average annual daily consumption for the people living

in Kadhirkamam apartments has been calculated. And with

the help of STAAD Pro analysis of sump and overhead tank

is done and bending moment and shear force analysis has

been studied. Design of overhead tank and sump has been

done according to the obtained analysis report.

Building Description: The proposed overhead tank and sump

is in Kadhirkamam apartments situated at Nanganallur, Fig.2. Overview of Sump

Chennai. The dimensions of the sump and overhead tank are

shown in following table.

IJERTV5IS090590 www.ijert.org 702

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 09, September-2016

Analysis Results: The following results include the 3- Design of Sump

dimensional diagram of the sump and diagram explaining

dead load and hydraulic load acting on the sump. Given

Capacity of the tank = 24000 litres

= 24

Free board = 0.2 m

Depth of tank = 3 m

Length of tank = 4 m

Height of tank = 3 m

Storage height = 3 - 0.2

= 2.8 m

Area =

=

Two Conditions

1. Tank Full

Fig.4. 3-D view of Sump

M =

H = 2.8 m

Υ = 10 m

M =

= 36.586 KNm

T =

=

= 42 KN

For M 20 and Fe 415

Q = 1.16 , j = 0.87

M = Qb

36.586 x = 1.16 x 1000 x

d = 177.45 mm

= 178 mm (approx.)

Fig.3. Dead and Hydraulic Load acting

D = d + cover(30 mm) +

= 178 + 30 +

= 214 mm

Ast = 36.586 x

=

= 1575.01

Using 12 mm bars

Spacing =

=

= 71.74

= 70 mm c/c

Fig.5. Deflection and Shear on y and z

IJERTV5IS090590 www.ijert.org 703

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 09, September-2016

Minimum requirements AutoCAD Diagram: The following AutoCAD diagram shows

the overview of Overhead tank in the below figure.

Ast (min) =

= 513.6

Proving 8 mm bars for distribution

=

= 139.68

= 140 mm

Check for Tension (T)

Consider 1 m height of the well,

Tensile stress induced =

=

= 0.19 N/ < 1.2 N/

Hence Safe.

2. Tank Empty

M =

( = angle of repose)

Fig.6. Overview of Overhead Tank

=

Analysis Results: The following results includes the 3-

= = 18.29 KNm

dimensional diagram of the sump and diagram explaining

Ast = wind load acting on the sump.

=

= 1575.01

Using 12 mm bars

Spacing =

= 71.74 mm

Provide distribution reinforcement horizontally in

both faces @ 140 mm.

Spacing = 2 x 140

= 280 mm

Provide 8 mm bars @ 250 mm.

ANALYSIS AND DESIGN OF O.H TANK

With respect to the plan of the overhead tank structure is

made with the help of nodes, beams, plates and surface

elements.

Loads which are acting on the sump are Dead Load, Fig.8. 3-D view of Overhead Tank

Hydraulic Load and Wind Load.

IJERTV5IS090590 www.ijert.org 704

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 09, September-2016

Dimensions of Tank

Height = 3 + 0.2

= 3.2 m

(L\B) = 2m

Long walls are designed at vertical cantilevers and

short walls as spanning horizontally between long

walls.

Maximum bending moment at base of,

Long walls =

=

= 53.52 KNm

Fig.7. Wind load acting on Z- direction

d =

=

= 213 mm

Use 16 mm diameter bars and 25 mm clear cover

Overall depth = 246 mm

Effective depth = 213 mm

Therefore,

Ast =

= 4454 mm

Spacing of 16 mm bars =

= 93.2 mm

Fig.9. Deflection and axial force on Tank

Adopt 16 mm diameter bars at 95 mm c\c. Spacing

Design of Overhead Tank towards the top is increased to 170 mm c\c for the

Given top 1 m.

Capacity of the tank = 24000 litres

= 24 Intensity of pressure 1 m above base is:

Free board = 0.2 m p =

Depth of tank = 2 m = 9.8(3-1)

Length of tank = 4 m = 19.61 KN/m2

Height of tank = 3 m Direct tension in long walls ,

Grade of concrete = M20 grade T =

Permissible Stress

= 19.6 KN

= 8.33 N/

= 200 N/ Ast = =

Modular ratio, m = 196 mm2

But minimum area

=

= 0.3% =( x 246 x 1000)

= 0.314

= 738 mm2

j = 1-

Spacing of 10 mm diameter bars =

= 1 – 0.314/3 ( ) = 108 mm

= 0.895

Provide 10 mm diameter bars at 200 mm c\c on both faces.

k = 0.5( x n x j)

= 1.1708

IJERTV5IS090590 www.ijert.org 705

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 09, September-2016

Design of Short Walls INSTALLATION OF SENSOR

The Sensor used to fine the level of water is Float Sensor.

p = 19.6 KN/m2

Detectors are place near the bottom of the tank and almost at

Effective span of horizontally spanning slab

the top of the tank.

= (2 + 0.24)

= 2.24 m

Bending moment (Corner section)

=

=

= 8.342 KNm

Tension transferred per metre height of short wall

= (19.6 x 1)

= 19.6 KN

Therefore,

Ast =

=

Fig.10. Float switch in OFF condition

= 345 mm2

Spacing of 10 mm bars =

= 228 mm

Adopt 16 mm bars at 230 mm centres. At mid span section

the bending moment is (PL2/24) and hence provide 10 mm

diameter bars at 460 mm centres away from the water face.

Design for Cantilever effect of Short wall

Maximum Bending moment

= (0.5 x 10 x 3 x 1/3)

= 5 KNm

Effective depth (using 10 mm bars)

= (213 – 25 – 10 – 5)

= 173 mm

Fig.11. Float switch in ON condition

Therefore,

Ast = A ball will be allowed to float in water and ball floats at the

surface of the water. If the level of water gets changed, the

= 304 mm2

position of ball changes too. By that way, if the water either

But 0.3% of gross area =( x 1000 x 246) goes below the detector level or increases above the detector

= 738 mm2 in the top, the sensor will sound alarm. So that the wastage of

Therefore, water can be prevented by overflowing and always to keep a

Spacing of 10 mm diameter bars = constant amount of water in the tank always which helps in

= 108 mm uninterrupted supply.

CONCLUSION

Adopt 10 mm diameter bars at 200 mm c\c on both During the course of the research, sufficient knowledge on

faces in the vertical direction. planning and designing the Overhead tank and Sump on

different software such as STAAD. Pro and AUTOCAD have

been implemented. This particular knowledge enriched us in

various circumstances and taught us varied methods to look

into this study. The Standard codes required for the design of

Overhead tank and Sump have been obtained from Indian

IJERTV5IS090590 www.ijert.org 706

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 09, September-2016

Standard Provisions. Per capita demand has been calculated

which helped us know about the water consumption in a

residential apartment and further helped in designing the tank

and sump. Sensors’ applications and their wide varieties have

been studied and conclusion has been made regarding the

correct use of sensors in a particular situation. Usage of

sensors has reduced many difficulties that arose during earlier

circumstances.

ACKNOWLEDGMENTS

The authors would like to place on record, our grateful thanks

to the Department of Civil Engineering, SRM University

Kattankulathur for providing all facilities and help in carrying

out this project. The authors are also grateful for their

encouragement and support during the course of this

research.

REFERENCES

[1] Sudhir K Jain and Sudhir Medhekar et. al. (2014), General

provisions and Buildings Pvt. Ltd. at Mumbai.

[2] Dr. B.C Punia, Dr. Ashok K Jain & Dr. Arun K Jain et. al.

(2014), “Theory of Structures”, Laxmi Publications Pvt. Ltd.,

Delhi.

[3] IS 456: 2000 – Plain and Reinforced Concrete – Code of

Practice.

[4] IS 875 (Part 1):1987 – Code of practice for design loads (other

than earthquake for buildings and structures).

[5] IS SP 7 : 2005- National Building Code (NBC).

IJERTV5IS090590 www.ijert.org 707

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

You might also like

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Non-destructive Testing and Evaluation of Civil Engineering StructuresFrom EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacNo ratings yet

- Iot Based Water Management SystemDocument10 pagesIot Based Water Management SystemdeekshaNo ratings yet

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Intelligent Water Leakage Controller Using Raspberry PIDocument2 pagesIntelligent Water Leakage Controller Using Raspberry PIEditor IJTSRDNo ratings yet

- Report On Water Level Indicator With Alarm 211 (1) .Docx GavDocument21 pagesReport On Water Level Indicator With Alarm 211 (1) .Docx Gavdavidmwass96No ratings yet

- Sensors Transducers Innovative Design of Dam Water Level SensorDocument8 pagesSensors Transducers Innovative Design of Dam Water Level SensorMarel Orlando Rivera LopezNo ratings yet

- Review Paper On Water Leakage Detection in Pipes Using SensorsDocument4 pagesReview Paper On Water Leakage Detection in Pipes Using SensorsAmeen Ahmed0% (1)

- Design and Analysis of Intez Type Water Tank Using SAP 2000 SoftwareDocument7 pagesDesign and Analysis of Intez Type Water Tank Using SAP 2000 SoftwareIJRASETPublicationsNo ratings yet

- Microcontroller Based Water Level Indicator and Controller: June 2017Document3 pagesMicrocontroller Based Water Level Indicator and Controller: June 2017NandhiniNo ratings yet

- Research Paper On Irrigation Engineering PDFDocument4 pagesResearch Paper On Irrigation Engineering PDFafeavbpwg100% (3)

- IJCRT2006368Document10 pagesIJCRT2006368oscarNo ratings yet

- Storage Tank Design - 5Document10 pagesStorage Tank Design - 5Riyan EsapermanaNo ratings yet

- Microcontroller Based Water Level Indicator and ControllerDocument2 pagesMicrocontroller Based Water Level Indicator and ControllerSaikiran RaoNo ratings yet

- Water Tank Monitoring System IJERTCONV7IS08030Document4 pagesWater Tank Monitoring System IJERTCONV7IS08030K PRIYADARSHINI 21MVD1083No ratings yet

- Sana'a University Faculty of Engineering Mechatronics Engineering DepartmentDocument6 pagesSana'a University Faculty of Engineering Mechatronics Engineering DepartmentMohammed SalehNo ratings yet

- OTC-25111-MS Evaluation of A Composite Device With An Embedded Non-Intrusive Water Cut Sensing Platform For Production Tubing and Well CompletionsDocument9 pagesOTC-25111-MS Evaluation of A Composite Device With An Embedded Non-Intrusive Water Cut Sensing Platform For Production Tubing and Well CompletionsLeon ZidaneNo ratings yet

- Irjet V5i11255 PDFDocument5 pagesIrjet V5i11255 PDFRamkumar KumaresanNo ratings yet

- 23hp JRP Kbpintzwatertank1 9-2-2014Document10 pages23hp JRP Kbpintzwatertank1 9-2-2014rajinder_hpiphNo ratings yet

- International Journal of Engineering Research and General Science (IJERGS), Volume 1, Issue 1Document57 pagesInternational Journal of Engineering Research and General Science (IJERGS), Volume 1, Issue 1Pragyan Bhattarai100% (1)

- Revised ECEA200-1L Group4-1Document38 pagesRevised ECEA200-1L Group4-1Reynard Kevin FranciscoNo ratings yet

- Analytical Study On Self Closing Flood Barrier Using Ansys IJERTCONV3IS16005Document4 pagesAnalytical Study On Self Closing Flood Barrier Using Ansys IJERTCONV3IS16005ManivannanNo ratings yet

- Ri Ha Definitivo InglesDocument16 pagesRi Ha Definitivo InglesPopoola Olalekan MansoorNo ratings yet

- Water Level Controller Using Ultrasonic SensorDocument8 pagesWater Level Controller Using Ultrasonic SensorIJRASETPublicationsNo ratings yet

- Storm Water Management-IJRASETDocument4 pagesStorm Water Management-IJRASETIJRASETPublicationsNo ratings yet

- Declaration: "Comparative Study of Flood Protection Devices"Document34 pagesDeclaration: "Comparative Study of Flood Protection Devices"Jec SarmientoNo ratings yet

- Poc Slide f1004Document8 pagesPoc Slide f1004Kuhaan GaneshNo ratings yet

- Other Technical Details: 1. Origin of The ProposalDocument7 pagesOther Technical Details: 1. Origin of The ProposalDeeba SNo ratings yet

- Underwater Surveillance DeviceDocument8 pagesUnderwater Surveillance DeviceIJRASETPublicationsNo ratings yet

- IoT Based Water Management System Using Arduino PDFDocument3 pagesIoT Based Water Management System Using Arduino PDFgraveNo ratings yet

- Fin Irjmets1653546359Document5 pagesFin Irjmets1653546359ekalrudy20No ratings yet

- A Review On Arduino Based Automatic Water Pump Level Adjustment and Monitoring SystemDocument6 pagesA Review On Arduino Based Automatic Water Pump Level Adjustment and Monitoring SystemIJRASETPublicationsNo ratings yet

- Standpost DesignDocument93 pagesStandpost Designdeerws anaparthiNo ratings yet

- Water Flow SystemDocument21 pagesWater Flow SystemSuriya RaghavanNo ratings yet

- A Microcontroller Based Water Level Indicator Using Radio Frequency RF Technology and Ultrasonic Sensor1Document6 pagesA Microcontroller Based Water Level Indicator Using Radio Frequency RF Technology and Ultrasonic Sensor1amey salunke100% (1)

- Leak Detection in Water-Distribution Pipe System: June 2018Document5 pagesLeak Detection in Water-Distribution Pipe System: June 2018Sai PhanindraNo ratings yet

- Review On Liquid-Level Measurement and Level Transmitter Using Conventional and Optical TechniquesDocument14 pagesReview On Liquid-Level Measurement and Level Transmitter Using Conventional and Optical TechniquesMang KrisnoNo ratings yet

- A Rational Approach To Septic Tank Design: March 2012Document12 pagesA Rational Approach To Septic Tank Design: March 2012Jannatun NaimNo ratings yet

- Review Paper On Water Monitoring and Leakage DetectionDocument2 pagesReview Paper On Water Monitoring and Leakage DetectionManjul KothariNo ratings yet

- Water Saving TweetyDocument22 pagesWater Saving TweetyIJRASETPublicationsNo ratings yet

- Sea Water Converted Into Usable and Emergency Drinkable WaterDocument7 pagesSea Water Converted Into Usable and Emergency Drinkable WaterIJRASETPublicationsNo ratings yet

- Analysis and Design of An In-Pipe System For Water Leak DetectionDocument10 pagesAnalysis and Design of An In-Pipe System For Water Leak DetectionEvergloss Pte LtdNo ratings yet

- Maheshwari 1996-InfiltrometerDocument7 pagesMaheshwari 1996-InfiltrometerErin WalkerNo ratings yet

- Section 2 ProjectDocument23 pagesSection 2 ProjectAlex manNo ratings yet

- Fabrication of Automatic Water Tap Control SystemDocument41 pagesFabrication of Automatic Water Tap Control SystemjohnsonNo ratings yet

- Civil Design Guide: Daily Water Use EstimateDocument16 pagesCivil Design Guide: Daily Water Use EstimatermugilNo ratings yet

- Review On Comparative Analysis of Water Tank Rest On GroundDocument6 pagesReview On Comparative Analysis of Water Tank Rest On GroundIJRASETPublicationsNo ratings yet

- Design-Rcc Over Head TankDocument82 pagesDesign-Rcc Over Head Tankjay_p_shah60% (5)

- Okeligho Mike Iruoghene: Adjustment and Error Analysis For Control Network For Dam Deformation Monitoring by GpsDocument114 pagesOkeligho Mike Iruoghene: Adjustment and Error Analysis For Control Network For Dam Deformation Monitoring by Gpsmikey2011100% (1)

- Storage Tank Design - 2Document9 pagesStorage Tank Design - 2Riyan EsapermanaNo ratings yet

- Water Level Indicator PDFDocument4 pagesWater Level Indicator PDFKeith brylleNo ratings yet

- 3 - Water Level Indicator PDFDocument4 pages3 - Water Level Indicator PDFNaga Ravindra PamarthiNo ratings yet

- Final Report Awfs1Document30 pagesFinal Report Awfs1Sahana ReddyNo ratings yet

- Automated Water Distribution System and Theft Detection-Ijaerdv04i0476640Document4 pagesAutomated Water Distribution System and Theft Detection-Ijaerdv04i0476640nayeem banuNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeFrom EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeRating: 4 out of 5 stars4/5 (2)

- Plain Pile DesignDocument1 pagePlain Pile Designeco protectionNo ratings yet

- Ultimate Load Carrying Capacity of An Under Reamed Piles 1Document1 pageUltimate Load Carrying Capacity of An Under Reamed Piles 1eco protection100% (1)

- Ultimate Load Carrying Capacity of An Under Reamed Piles 1Document1 pageUltimate Load Carrying Capacity of An Under Reamed Piles 1eco protection100% (1)

- Footing J1922018 v1Document15 pagesFooting J1922018 v1eco protectionNo ratings yet

- Column Design by JDocument48 pagesColumn Design by Jeco protectionNo ratings yet

- Footing J17218 (Recovered)Document9 pagesFooting J17218 (Recovered)eco protectionNo ratings yet

- Individual Footings (17.12.09) EDIT by J3Document32 pagesIndividual Footings (17.12.09) EDIT by J3eco protectionNo ratings yet

- Bridge Engineering 1916 PDFDocument1,207 pagesBridge Engineering 1916 PDFeco protectionNo ratings yet

- Chapter3rigidbodies EquivalentsystemsofforcesDocument205 pagesChapter3rigidbodies Equivalentsystemsofforceseco protectionNo ratings yet

- Design of FootingDocument13 pagesDesign of Footingeco protectionNo ratings yet

- 11 Stat 6 Measures of DispersionDocument17 pages11 Stat 6 Measures of Dispersioneco protectionNo ratings yet

- Static Analysis of G+2 Institutional Building in Bhopal: Aakash Saxena, S S KushwahDocument9 pagesStatic Analysis of G+2 Institutional Building in Bhopal: Aakash Saxena, S S Kushwaheco protectionNo ratings yet

- Hydrodynamic SBRDocument17 pagesHydrodynamic SBReco protectionNo ratings yet

- Plasti-Fab, Inc. Fiberglass Gate BrochureDocument4 pagesPlasti-Fab, Inc. Fiberglass Gate BrochurePlasti-Fab100% (1)

- Lobby Vision BroDocument5 pagesLobby Vision BroPearl JamNo ratings yet

- Comprehensive Electrical System Maintenance ChecklistsDocument12 pagesComprehensive Electrical System Maintenance ChecklistsFarrukh Nadeem100% (1)

- Central in ADocument18 pagesCentral in AJorge A. Moreno PitonesNo ratings yet

- Dell Poweredge: Resolve Cpu 1 or 2 Has An Internal Error (Cpu Ierr) On ServersDocument2 pagesDell Poweredge: Resolve Cpu 1 or 2 Has An Internal Error (Cpu Ierr) On ServersNadir ShahzadNo ratings yet

- Electrical Installation - DIAGRAMS & DRAWINGSDocument10 pagesElectrical Installation - DIAGRAMS & DRAWINGSgteklayNo ratings yet

- HW4Document3 pagesHW40123456789abcdefgNo ratings yet

- Error Code StandardizationDocument1 pageError Code StandardizationMichael McDonaldNo ratings yet

- Technical ManualDocument140 pagesTechnical ManualHajar Suwantoro100% (1)

- Adfsnl'a Sfns Afa SfasDocument2 pagesAdfsnl'a Sfns Afa SfasRoyAndrew GarciaNo ratings yet

- Mengatasi Masalah Eror Saat Kita Memanggil LocalhostDocument3 pagesMengatasi Masalah Eror Saat Kita Memanggil LocalhostdarwinNo ratings yet

- EN25F80 8 Megabit Serial Flash Memory With 4kbytes Uniform SectorDocument32 pagesEN25F80 8 Megabit Serial Flash Memory With 4kbytes Uniform SectoradyanNo ratings yet

- Metalworks Clip-In and Clip-In Swing Down Ceilings: General Installation InstructionsDocument2 pagesMetalworks Clip-In and Clip-In Swing Down Ceilings: General Installation InstructionsSunil Dinanath JoshiNo ratings yet

- Roman ArchitectureDocument15 pagesRoman ArchitecturelavanyaNo ratings yet

- Proy. C - Completo - 2018Document12 pagesProy. C - Completo - 2018Gosbony SKNo ratings yet

- Vocabulary Builder Book-1Document15 pagesVocabulary Builder Book-1jeravi84No ratings yet

- Malteri WEBDocument219 pagesMalteri WEBAnonymous LjQllpNo ratings yet

- HP Secure Erase For Imaging and PrintingDocument11 pagesHP Secure Erase For Imaging and PrintingSukrat SharmaNo ratings yet

- Raspberry Pi Command Line Audio PDFDocument8 pagesRaspberry Pi Command Line Audio PDFSteve AttwoodNo ratings yet

- BCA RailingsDocument6 pagesBCA RailingsLee Chih FeiNo ratings yet

- Kolban's Book On C.H.I.P.Document317 pagesKolban's Book On C.H.I.P.thiagocabral88No ratings yet

- LMDocument19 pagesLMlittledanmanNo ratings yet

- ST KPS 10Document2 pagesST KPS 10ecosistemisolariNo ratings yet

- Soft Copy Laporan Sandcone Gudang - JIIPEDocument2 pagesSoft Copy Laporan Sandcone Gudang - JIIPEardaloevera_63818328No ratings yet

- Exexsum PDFDocument16 pagesExexsum PDFMaria Cristina PonceNo ratings yet

- Daylight Design of BuildingsDocument54 pagesDaylight Design of Buildingsm_popovicNo ratings yet

- Ansys Platform Support Strategy Plans February 2019Document3 pagesAnsys Platform Support Strategy Plans February 2019Nicola PieriNo ratings yet

- Somerset Classic Brochure Adams Family FloorsDocument3 pagesSomerset Classic Brochure Adams Family FloorsTerriNo ratings yet

- Working With Database Tables Student VersionDocument12 pagesWorking With Database Tables Student VersionSuresh babuNo ratings yet

- BR Knauf Ceiling Solutions Vario Design ENDocument9 pagesBR Knauf Ceiling Solutions Vario Design ENAshraf AbdellatefNo ratings yet