Professional Documents

Culture Documents

Technical Data Actuator Controls: General Information

Technical Data Actuator Controls: General Information

Uploaded by

Medjahdi RafikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Actuator Controls: General Information

Technical Data Actuator Controls: General Information

Uploaded by

Medjahdi RafikCopyright:

Available Formats

AC 01.

Technical data Actuator controls

General information

Actuator controls AC 01.2 for controlling multi-turn actuators of the SA/SAR type range and part-turn actuators of the SQ/SQR .2 type range.

Features and functions

Power supply Standard voltages AC:

3-phase AC current 1-phase AC current

Voltages/frequencies Voltages/frequencies

Volt 208 220 230 240 440 460 480 575 600 Volt 110, 115, 120 220, 230, 240

Hz 60 60 60 60 60 60 60 60 60 Hz 60 50/60

Special voltages AC:

3-phase AC current 1-phase AC current

Voltages/frequencies Voltages/frequencies

Volt 220 230 240 380 400 415 500 525 575 660 690 Volt 208

Hz 50 50 50 50 50 50 50 50 50 50 50 Hz 60

Permissible variation of mains voltage: ±10 %

Permissible variation of mains voltage: ±30 % (option)

Permissible variation of mains frequency: ±5 %

Special voltages DC: (on request)

DC current

Voltages

Volt 24 48 60 110 125 220 250

Permissible voltage deviation: (on request)

External supply of the electronics 24 V DC: +20 %/–15 %, or 115 V AC: +20 %/–15 %

(option) Current consumption for 24 V DC version: Basic version approx. 250 mA, with options up to 500 mA

Current consumption for 115 V AC version: Approx. 160 mA

External power supply must have reinforced insulation against mains voltage in accordance with IEC 61010-1 and

may only be supplied by a circuit limited to 150 VA in accordance with IEC 61010-1.

Current consumption Current consumption of controls depending on mains voltage:

For permissible variation of mains voltage of ±10 %:

100 to 120 V AC = max. 740 mA

208 to 240 V AC = max. 400 mA

380 to 500 V AC = max. 250 mA

515 to 690 V AC = max. 200 mA

For permissible variation of mains voltage of ±30 %:

100 to 120 V AC = max. 1,200 mA

208 to 240 V AC = max. 750 mA

380 to 500 V AC = max. 400 mA

515 to 690 V AC = max. 400 mA

Overvoltage category Category III according to IEC 60364-4-443

Rated power Actuator controls are designed for rated motor power (refer to Electrical data Multi-turn or Part-turn actuators)

Switchgear Standard: Reversing contactors (mechanically and electrically interlocked) for

AUMA power classes A1/A2

Options: Reversing contactors (mechanically and electrically interlocked) for AUMA power class A3

Thyristor unit for mains voltage up to 600 V AC for AUMA power classes B1, B2 or up to 500 V AC

for AUMA power class B3 (recommended for modulating actuators)

The reversing contactors are designed for a lifetime of 2 million starts. For applications requiring a high number of

starts, we recommend the use of thyristor units.

For the assignment of AUMA power classes, please refer to Electrical data Multi-turn or Part-turn actuators.

Control inputs 6 digital inputs: OPEN, STOP, CLOSE, EMERGENCY (via opto-isolator, OPEN, STOP, CLOSE with one common and

EMERGENCY without common, respect minimum pulse duration for modulating actuators).

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y004.678/065/us Issue 1.15 Page 1/5

AC 01.2

Technical data Actuator controls

Control voltage/current consumption Standard: 24 V DC, current consumption: approx. 10 mA per input

for control inputs

Options: 48 V DC, current consumption: approx. 7 mA per input

60 V DC, current consumption: approx. 9 mA per input

115 V DC, current consumption: approx. 15 mA per input

100 – 120 V AC, Current consumption: approx. 15 mA per input

All input signals must be supplied with the same potential.

Status signals Standard: 6 programmable output contacts:

(output signals) - 5 potential-free NO contacts with one common, max. 250 V AC, 1 A (resistive load)

Default configuration: End position CLOSED, end position OPEN, selector switch REMOTE,

torque fault CLOSE, torque fault OPEN

- 1 potential-free change-over contact, max. 250 V AC, 5 A (resistive load)

Default configuration: Collective fault signal (torque fault, phase failure, motor protection

tripped)

Analog output signal for position feedback

- Galvanically isolated position feedback 0/4 – 20 mA (load max. 500 Ω)

Options: 6 programmable output contacts:

- 5 change-over contacts with one common, max. 250 V AC, 1 A (resistive load), 1 poten-

tial-free change-over contact, max. 250 V AC, 5 A (resistive load)

12 programmable output contacts:

- 10 potential-free NO contacts, 5 with one common each, max. 250 V AC, 1 A (resistive

load), 2 potential-free change-over contacts, max. 250 V AC, 5 A (resistive load)

6 programmable output contacts:

- 6 potential-free change-over contacts without one common, per contact max. 250 V AC, 5

A (resistive load)

10 programmable output contacts:

- 10 potential-free change-over contacts without one common, per contact max. 250 V AC, 5

A (resistive load)

6 programmable output contacts:

- 4 self-latching potential-free NO contacts with one common, max. 250 V AC, 1 A (resistive

load), 1 potential-free NO contact, max. 250 V AC, 1 A (resistive load), 1 potential-free

change-over contact, max. 250 V AC, 5 A (resistive load)

6 programmable output contacts:

- 4 self-latching potential-free NO contacts, max. 250 V AC, 1 A (resistive load), 2 poten-

tial-free NO contacts, max. 250 V AC, 1 A (resistive load),

12 programmable output contacts:

- 8 self-latching potential-free NO contacts, max. 250 V AC, 1 A (resistive load), 2 poten-

tial-free NO contacts, max. 250 V AC, 1 A (resistive load), 2 potential-free change-over

contacts, max. 250 V AC, 5 A (resistive load)

12 programmable output contacts:

- 8 self-latching potential-free NO contacts, max. 250 V AC, 1 A (resistive load), 4 poten-

tial-free NO contacts, max. 250 V AC, 1 A (resistive load),

All output signals must be supplied with the same potential.

Voltage output Standard: Auxiliary voltage 24 V DC: max. 100 mA for supply of control inputs, galvanically isolated from inter-

nal voltage supply.

Option: Auxiliary voltage 115 V AC: max. 30 mA for supply of control inputs, galvanically isolated from inter-

nal voltage supply

Auxiliary voltage 115 V AC: max. 150 mA for supply of control inputs/optional equipment, galvani-

cally isolated from internal voltage supply

Auxiliary voltage 115 V AC: max. 100 VA for supply of control inputs/optional equipment, galvanically

isolated from internal voltage supply

Analog output Option: 2 analog outputs:

With position transmitter option: Output of travel, torque or output speed as continuous values

between 0/4 and 20 mA

Analog input Option: 2 analog inputs:

With positioner/process controller option: Input of actual position value/actual process value as con-

tinuous values between 0/4 and 20 mA

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y004.678/065/us Issue 1.15 Page 2/5

AC 01.2

Technical data Actuator controls

Local controls Standard: Selector switch: LOCAL - OFF - REMOTE (lockable in all three positions)

Push buttons: OPEN, STOP, CLOSE, RESET

- Local STOP

The actuator can be stopped via push button STOP of local controls if the selector switch is

in position REMOTE (not activated when leaving the factory).

6 indication lights:

- End position and running indication CLOSED (green), torque fault CLOSE (blue), motor

protection tripped (yellow), torque fault OPEN (violet), end position and running indication

OPEN (red), Bluetooth (blue)

Large graphic LD display, with 200 x 100 pixels: illuminated

Display language: English (can be programmed to display other languages upon request)

Option: 6 indication lights:

- End position and running indication CLOSED (yellow), torque fault CLOSE (red), motor

protection tripped (red), torque fault OPEN (red), end position and running indication OPEN

(green), Bluetooth (blue)

Bluetooth communication interface Bluetooth class II chip, version 2.1: with a range up to 32 feet (10 m) in industrial environments, supports the SPP

Bluetooth profile (Serial Port Profile).

Required accessories: AUMA CDT (Commissioning and Diagnostic Tool for Windows-based PC)

Application functions Standard: Selectable type of seating, limit or torque seating for end position OPEN and end position

CLOSED

Torque by-pass: Adjustable duration (with adjustable peak torque during start-up time)

Start and end of stepping mode as well as ON and OFF times: can be set individually for direc-

tions OPEN and CLOSE, 1 to 1,800 seconds

Any 8 intermediate positions: can be set between 0 and 100 %, reaction and signal behavior

programmable

Running indication blinking: can be set

Options: Positioner:

- Position setpoint via analog inputs 0/4 – 20 mA

- Programmable behavior on loss of signal

- Automatic adaptation of dead band (adaptive behavior selectable)

- Split range operation

- MODE input for selecting between open-close and setpoint control

PID process controller: with adaptive positioner, via 0/4 – 20 mA inputs for process setpoint and

actual process value

Multiport valve: up to 12 positions, signals (pulse or edge)

Automatic deblocking: up to 5 operation trials, travel time in opposite direction can be set

Static and dynamic torque recording for both rotation directions with torque measurement

flange as additional accessory

Safety functions Standard: EMERGENCY operation (programmable behavior)

- Digital input: Low active

- Reaction can be selected: Stop, run to end position CLOSED, run to end position OPEN, run

to intermediate position

- Torque monitoring can be by-passed during EMERGENCY operation

- Thermal protection can be by-passed during EMERGENCY operation (only in combination

with thermal switch within actuator, not with PTC thermistor).

Options: Enabling local controls via digital input Enable LOCAL: Thus, actuator local push button operation

can be enabled or disabled remote digital input Enable LOCAL.

Interlock for main/by-pass valve: Enabling the operation commands OPEN or CLOSE via two

digital inputs

EMERGENCY Stop push button (latching): interrupts electrical operation, irrespective of the

selector switch position.

PVST (Partial Valve Stroke Test): programmable to check the function of both actuator and actua-

tor controls: Direction, stroke, operation time, reversing time

Lockable cover for local controls with/without viewing glass, for protection against vandalism.

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y004.678/065/us Issue 1.15 Page 3/5

AC 01.2

Technical data Actuator controls

Monitoring function Valve overload protection: adjustable, results in switching off and generates fault signal

Motor temperature monitoring (thermal monitoring): results in switching off and generates fault indication

Monitoring the heater within actuator: generates warning signal

Monitoring of permissible on-time and number of starts: adjustable, generates warning signal

Operation time monitoring: adjustable, generates warning signal

Phase failure monitoring: results in switching off and generates fault signal

Automatic correction of rotation direction upon wrong phase sequence (3-ph AC current)

Diagnostic function Electronic device ID with order and product data

Logging of operating data: A resettable counter and a lifetime counter each for:

- Motor running time, number of starts, torque switch trippings in end position CLOSED, limit switch trippings

in end position CLOSED, torque switch trippings in end position OPEN, limit switch trippings in end position

OPEN, torque faults CLOSE, torque faults OPEN, motor protection trippings

Time-stamped event report with history for setting, operation and faults:

- Status signals according to NAMUR recommendation NE 107: "Failure", "Function check", "Out of specifica-

tion", "Maintenance required"

Torque characteristics (for version with MWG in actuator):

- 3 torque characteristics (torque-travel characteristic) for opening and closing directions can be saved sepa-

rately.

- Torque characteristics stored can be shown on the display.

Motor protection evaluation Standard: Monitoring the motor temperature in combination with thermal switches within actuator motor

Options: Thermal overload relay in controls combined with thermal switches within actuator

PTC tripping device in combination with PTC thermistors within actuator motor

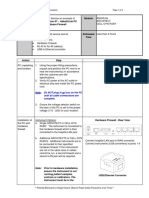

Electrical connection Standard: AUMA plug & socket connector with screw-type connection

Options: Terminals or crimp connection

Gold-plated control plug (sockets and plugs)

Threads for cable entries Standard: NPT-threads

Options: PG-threads, G-threads, metric threads

Further options for version with MWG in actuator

Setting of limit and torque switches via local controls

Torque feedback signal Galvanically isolated analog output 0/4 – 20 mA (load max. 500 Ω)

Wiring diagram (basic version) TPCA-3A2-1C1-A000 TPA00R100-0I1-000

Service conditions

Use Indoor and outdoor use permissible (not permissible for use in potentially hazardous locations)

Mounting position Any position

Installation altitude ≤ 2,000 m above sea level

> 2,000 m above sea level on request

Ambient temperature Standard: –22 °F to 158 °F (–30 °C to +70 °C)

Options: –76 °F to 140 °F (–60 °C to +60 °C), extreme low temperature version

Low temperature versions incl. heating system for connection to external power supply 230 V AC or

115 V AC.

Humidity Up to 100 % relative humidity across the entire permissible temperature range

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y004.678/065/us Issue 1.15 Page 4/5

AC 01.2

Technical data Actuator controls

Enclosure protection according to Standard: IP68 (NEMA 4X/ 6P) with AUMA 3-phase AC motor/1-phase AC motor

EN 60529 For special motors, differing enclosure protection is possible

Option: DS Terminal compartment additionally sealed against interior (double sealed)

According to AUMA definition, enclosure protection IP68 meets the following requirements:

Depth of water: maximum 26 ft (8 m) head of water

Duration of continuous immersion in water: Max. 96 hours

Up to 10 operations during continuous immersion

Modulating duty is not possible during continuous immersion.

Pollution degree to IEC 60664-1 Pollution degree 4 (when closed), pollution degree 2 (internal)

Vibration resistance IEC 60068-2-6 1 g, from 10 Hz to 200 Hz

Resistant to vibration during start-up or for failures of the plant.

However, a fatigue strength may not be derived from this. (Not valid in combination with gearboxes)

Corrosion protection Standard: KS Suitable for use in areas with high salinity, almost permanent condensation, and high

pollution.

Options: KX Suitable for use in areas with extremely high salinity, permanent condensation, and high

pollution.

Coating Double layer powder coating

Two-component iron-mica combination

Color Standard: AUMA silver-gray (similar to RAL 7037)

Option: Available colors on request

Accessories

Wall bracket For AC 01.2 mounting separately from the actuator, including plug & socket connector, connecting cable on request

Recommended for high ambient temperatures, difficult access, or heavy vibration during service.

Cable length between actuator and AC 01.2 max. 328 ft (100 m). (Not suitable for version with potentiometer in

the actuator.) Instead of the potentiometer, the actuator has to be equipped with an electronic position transmitter.

(Cable length for non-intrusive version with MWG in the actuator max. 328 ft (100 m) requires separate data cable

for MWG.)

Programming software AUMA CDT (Commissioning and Diagnostic Tool for Windows-based PC)

Torque measurement flange DMF Accessory for torque measurement for SA/SAR 07.2 to SA/SAR 16.2

Further information

Weight Approx. 15 lbs [7 kg] (with AUMA plug & socket connector)

Directives and compliances Canadian Standards Association (CSA): (C22.2)

Electromagnetic Compatibility (EMC): (2014/30/EU)

Low Voltage Directive: (2014/35/EU)

Machinery Directive: (2006/42/EC)

Reference documents Brochure Electric actuators for industrial valve automation

Dimensions Multi-turn actuators with AUMATIC integral controls

Dimensions Part-turn actuators with AUMATIC integral controls

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y004.678/065/us Issue 1.15 Page 5/5

You might also like

- Alstom 12" LED Flashing Light AssemblyDocument24 pagesAlstom 12" LED Flashing Light AssemblyDJNo ratings yet

- Technical Data Actuator Controls: General InformationDocument5 pagesTechnical Data Actuator Controls: General InformationTiennghia BuiNo ratings yet

- TD Ac2 enDocument6 pagesTD Ac2 enPtbbi TubanNo ratings yet

- TD Ac2 enDocument6 pagesTD Ac2 enmohamed abourayaNo ratings yet

- TD Ac2 Hart enDocument7 pagesTD Ac2 Hart enengineer.humgNo ratings yet

- TD WirelesshartDocument8 pagesTD WirelesshartManzoor AnsariNo ratings yet

- AM 01.1/AM 02.1: Technical Data Actuator ControlsDocument3 pagesAM 01.1/AM 02.1: Technical Data Actuator ControlsLuis MedinaNo ratings yet

- AM 01.1/AM 02.1: Technical Data Actuator ControlsDocument3 pagesAM 01.1/AM 02.1: Technical Data Actuator ControlsYousif Elsadig YousifNo ratings yet

- TD Ac2 Profinet enDocument6 pagesTD Ac2 Profinet enengineer.humgNo ratings yet

- n204 k8dt-vw 1-Phase Overvoltage Undervoltage Relay Datasheet enDocument14 pagesn204 k8dt-vw 1-Phase Overvoltage Undervoltage Relay Datasheet enhamparan nightwatchNo ratings yet

- Datasheet ASW 45-50-60K LT G3 Series en 0124 WebDocument2 pagesDatasheet ASW 45-50-60K LT G3 Series en 0124 WebSilas Carneiro MoreiraNo ratings yet

- Ultron NT 20 To 4000kVA - DatasheetDocument2 pagesUltron NT 20 To 4000kVA - DatasheetAnil RajputNo ratings yet

- UpsDocument8 pagesUpsrahu111112000100% (2)

- Motor Controllers AC Semiconductor Motor Controller Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - BDocument4 pagesMotor Controllers AC Semiconductor Motor Controller Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - BAbdul Aziz KhanNo ratings yet

- 100W Triple Output Switching DC Power Supplies: ApplicationsDocument3 pages100W Triple Output Switching DC Power Supplies: ApplicationsbillNo ratings yet

- Specifications - 700-HD RelaysDocument1 pageSpecifications - 700-HD RelaysArif KhanNo ratings yet

- 6EP13363BA10 Datasheet enDocument5 pages6EP13363BA10 Datasheet enNirmal KumarNo ratings yet

- Datasheet ASW 3K-6K-S-G2 Series 0922 - Global EN - WebDocument2 pagesDatasheet ASW 3K-6K-S-G2 Series 0922 - Global EN - WebRadu Paul SorinNo ratings yet

- B Protect 8 S10 4pp en LowDocument4 pagesB Protect 8 S10 4pp en LowirawanheriNo ratings yet

- Datasheet ASW 3 5K S Series 0722global EN - WebDocument2 pagesDatasheet ASW 3 5K S Series 0722global EN - Webalexe.alexandru90No ratings yet

- LC1D09U7: Product DatasheetDocument4 pagesLC1D09U7: Product DatasheetJan Richardo GultomNo ratings yet

- SMA HIghpower Peak3 Product Datasheet EN 100 20Document2 pagesSMA HIghpower Peak3 Product Datasheet EN 100 20Michel GuerreroNo ratings yet

- Nj-Pa/Pd: Powerful Power Supply Unit To Supply Stable Power To The NJ-series ControllerDocument8 pagesNj-Pa/Pd: Powerful Power Supply Unit To Supply Stable Power To The NJ-series ControllerKevin MoralesNo ratings yet

- Datasheet Inverter 75K 80K 100K 110K EN - 0124 - WebDocument2 pagesDatasheet Inverter 75K 80K 100K 110K EN - 0124 - WebDandara MartinsNo ratings yet

- Nj-Pa/Pd: Powerful Power Supply Unit To Supply Stable Power To The NJ-series ControllerDocument8 pagesNj-Pa/Pd: Powerful Power Supply Unit To Supply Stable Power To The NJ-series ControllerKevin MoralesNo ratings yet

- Nj-Pa/Pd: Powerful Power Supply Unit To Supply Stable Power To The NJ-series ControllerDocument8 pagesNj-Pa/Pd: Powerful Power Supply Unit To Supply Stable Power To The NJ-series ControllerKevin MoralesNo ratings yet

- Datasheet SHP100 150 20 ENDocument2 pagesDatasheet SHP100 150 20 ENpowerabsolut myanmarNo ratings yet

- XW+ Hybrid Inverter/charger: One Solution For Global Power NeedsDocument2 pagesXW+ Hybrid Inverter/charger: One Solution For Global Power NeedsAlexander Zabala MNo ratings yet

- Gutor - UPS PXP Technical DataDocument4 pagesGutor - UPS PXP Technical DatajokotsNo ratings yet

- Single-Phase Voltage Relay: K8Ab-VwDocument13 pagesSingle-Phase Voltage Relay: K8Ab-VwRuddy MariusNo ratings yet

- Altistart 48 - ATS48C41Y PDFDocument5 pagesAltistart 48 - ATS48C41Y PDFServicios electronicos ncpNo ratings yet

- CT SizingDocument24 pagesCT SizingGanesh SantoshNo ratings yet

- LC1D32M7: Product DatasheetDocument3 pagesLC1D32M7: Product DatasheetFeritNo ratings yet

- Manual Well Sprinten EvolutionDocument54 pagesManual Well Sprinten EvolutionCatalinNo ratings yet

- Electric Installation RequirementsDocument10 pagesElectric Installation RequirementsRogerio CastroNo ratings yet

- Sofar 5kwDocument2 pagesSofar 5kwGustavo CarvalhoNo ratings yet

- EPCOS Thyristor Duty SwitchingDocument3 pagesEPCOS Thyristor Duty SwitchingMohaned Kamal HassanNo ratings yet

- Avr As440 Datasheet: 1.product DescriptionDocument7 pagesAvr As440 Datasheet: 1.product DescriptionAnonymous vqsuRyNo ratings yet

- Datasheet ASW 3K 6K S G2 Series Global en 0124 WebDocument2 pagesDatasheet ASW 3K 6K S G2 Series Global en 0124 WebomairyNo ratings yet

- LC1D123UDDocument3 pagesLC1D123UDRichard SullivanNo ratings yet

- Current and Voltage Controls 3-Phase AC Max. Current Control Type S 178Document3 pagesCurrent and Voltage Controls 3-Phase AC Max. Current Control Type S 178Felipe FarfanNo ratings yet

- Product Data Sheet 6EP1334-3BA00: Sitop Psu200M 10 A Stabilized Power Supply INPUT: 120/230-500 V AC OUTPUT: 24 V DC/10 ADocument4 pagesProduct Data Sheet 6EP1334-3BA00: Sitop Psu200M 10 A Stabilized Power Supply INPUT: 120/230-500 V AC OUTPUT: 24 V DC/10 AHari HaranNo ratings yet

- Series: 800W DC Power SuppliesDocument6 pagesSeries: 800W DC Power Suppliesneparun16No ratings yet

- 6MD85 Short TimeDocument1 page6MD85 Short Timesanjana.jayakrishnanNo ratings yet

- 7SL 86 - BurdenDocument1 page7SL 86 - Burdenananda krishnaNo ratings yet

- Voltage Monitoring Series SM 800: Ordering InformationDocument3 pagesVoltage Monitoring Series SM 800: Ordering Informationkarthik achudhanNo ratings yet

- Technical Specification: Item 4 / C-1270306 / Sludge Treatment Substation Item DescriptionDocument3 pagesTechnical Specification: Item 4 / C-1270306 / Sludge Treatment Substation Item Descriptionanse1No ratings yet

- Altistart 48 - ATS48D75YDocument5 pagesAltistart 48 - ATS48D75YWilliam Lema VistínNo ratings yet

- Equipos de Potencia Mision Critica PDFDocument20 pagesEquipos de Potencia Mision Critica PDFjuancanicNo ratings yet

- 6EP13333BA10 Datasheet enDocument3 pages6EP13333BA10 Datasheet enalpha1ahNo ratings yet

- Delivery ProgramDocument7 pagesDelivery ProgramEduardo Mateo ArdilNo ratings yet

- Three-Phase Asymmetry and Phase-Sequence Phase-Loss Relay: K8Ab-PaDocument7 pagesThree-Phase Asymmetry and Phase-Sequence Phase-Loss Relay: K8Ab-PaKeerthi Vasan SNo ratings yet

- 6EP13333BA10 Datasheet enDocument5 pages6EP13333BA10 Datasheet enmikexanderNo ratings yet

- MFA350 :: ROAL Living EnergyDocument7 pagesMFA350 :: ROAL Living EnergyMinhNo ratings yet

- AC Semiconductor Motor Controller Types RSE.. - BDocument4 pagesAC Semiconductor Motor Controller Types RSE.. - Bpayolin77No ratings yet

- Ds Eum 050sxxxdx Rev.ADocument15 pagesDs Eum 050sxxxdx Rev.AFrancisco PizarroNo ratings yet

- 6EP71336AE000BN0 Datasheet enDocument3 pages6EP71336AE000BN0 Datasheet enVăn Công LêNo ratings yet

- vfm100 SeriesDocument3 pagesvfm100 SeriesElviraNo ratings yet

- Voltage Regulator For Generators: Instruction Manual V1.3.1Document20 pagesVoltage Regulator For Generators: Instruction Manual V1.3.1fahad pirzadaNo ratings yet

- Schneider Electric TeSys-Deca-contactors LC1D115M7Document7 pagesSchneider Electric TeSys-Deca-contactors LC1D115M7Le GiathanhNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Tpca-1b2-1c2-A000tpa00r100-0i1-000 - S Rev-011Document1 pageTpca-1b2-1c2-A000tpa00r100-0i1-000 - S Rev-011Medjahdi RafikNo ratings yet

- Maintenance Preventive / Preventive Maintenance Lot Rep QT REF DesignationDocument1 pageMaintenance Preventive / Preventive Maintenance Lot Rep QT REF DesignationMedjahdi RafikNo ratings yet

- Wiring Diagram Selection: Y004.868/003/en Issue 1.16 Page 1/5Document5 pagesWiring Diagram Selection: Y004.868/003/en Issue 1.16 Page 1/5Medjahdi RafikNo ratings yet

- Scada TutorialDocument4 pagesScada TutorialMedjahdi RafikNo ratings yet

- Html.Document2 pagesHtml.Medjahdi RafikNo ratings yet

- Inkjet Vs Laser PrinterDocument4 pagesInkjet Vs Laser PrinteriamvishalNo ratings yet

- Level and Viscotherm From Reeds Vol 10 Instrumentation and Control Systems - NodrmDocument12 pagesLevel and Viscotherm From Reeds Vol 10 Instrumentation and Control Systems - Nodrmprashant manhasNo ratings yet

- 84 Roundness E 2112 READ AccretechDocument94 pages84 Roundness E 2112 READ Accretechcavoixanh89No ratings yet

- Equipment List - OrheiDocument1 pageEquipment List - OrheighenaNo ratings yet

- Class B (SOLAS) Emergency PackDocument2 pagesClass B (SOLAS) Emergency Packjessie pulidoNo ratings yet

- Osisense XM Xmlb020c2s12Document6 pagesOsisense XM Xmlb020c2s12Iman FaisalNo ratings yet

- Project Name Suburb StateDocument28 pagesProject Name Suburb StateSopsky SalatNo ratings yet

- Optical DiskDocument16 pagesOptical DiskÃtïkûr Rãhmâñ ShàónNo ratings yet

- SubStation Major Equipment and Their FunctionsDocument51 pagesSubStation Major Equipment and Their FunctionsRonieboy Baliber CairoNo ratings yet

- Notes On Tripping RelaysDocument7 pagesNotes On Tripping RelaysSenthil KumarNo ratings yet

- ISA 800-005 Option 7Document3 pagesISA 800-005 Option 70sman MczNo ratings yet

- Double Enveloping Worm Gear Sets PDFDocument36 pagesDouble Enveloping Worm Gear Sets PDFOzan SümenNo ratings yet

- Quick Reference Guide: IC260L/D DUO IC261L/D DUO (Firmware Rel. 1.9)Document64 pagesQuick Reference Guide: IC260L/D DUO IC261L/D DUO (Firmware Rel. 1.9)Ivaylo TodorovNo ratings yet

- Ficha Técnica Interruptores TermomagnéticosDocument4 pagesFicha Técnica Interruptores TermomagnéticosJosé IturvideNo ratings yet

- The Essential Entrelec - Cat - enDocument76 pagesThe Essential Entrelec - Cat - engeekboxcaruaruNo ratings yet

- Lesson Plan - Electrical Tools and EquipmentDocument2 pagesLesson Plan - Electrical Tools and Equipmentwels berdNo ratings yet

- Water Cooled Manual IOM120229 1.10Document76 pagesWater Cooled Manual IOM120229 1.10Robinson Jimenez100% (1)

- Inspiron 14 3467 Laptop Service Manual en UsDocument108 pagesInspiron 14 3467 Laptop Service Manual en UskalteNo ratings yet

- Rate List - ResidentialDocument2 pagesRate List - ResidentialSales PNo ratings yet

- 2Kv Hdfpc-Dlo, Rhh/Rhw-2 & Rw90: Flexible Stranded Rope-Lay Class I Tinned Copper Per ASTM B33 and B172Document3 pages2Kv Hdfpc-Dlo, Rhh/Rhw-2 & Rw90: Flexible Stranded Rope-Lay Class I Tinned Copper Per ASTM B33 and B172gerrzen64No ratings yet

- Connector Selector PDFDocument64 pagesConnector Selector PDFEduardo David100% (1)

- AWH Catalog Connections Edition 1.1 enDocument80 pagesAWH Catalog Connections Edition 1.1 enrisbo12No ratings yet

- Cheklist Harian-Hydrant-GedungDocument1 pageCheklist Harian-Hydrant-GedungBAIDARUSEDONo ratings yet

- Shop Inspection & Test procedure-GVK-1Document7 pagesShop Inspection & Test procedure-GVK-1Sungil ChoiNo ratings yet

- Battlestrike Force of Resistance CheatsDocument2 pagesBattlestrike Force of Resistance CheatsRyan AguilarNo ratings yet

- Inpak EN Catalogue-20200206-170232814Document12 pagesInpak EN Catalogue-20200206-170232814mck_medoNo ratings yet

- Rtd4Al: RTD Temperature Sensor For Temperature Measurement Up To 900°F (482°C)Document2 pagesRtd4Al: RTD Temperature Sensor For Temperature Measurement Up To 900°F (482°C)gabrielpmendesNo ratings yet

- Ap-3000 SM 53-36819.01 PDFDocument89 pagesAp-3000 SM 53-36819.01 PDFTheophile Nkouaa Kouedja100% (1)

- Kenaikan Harga Obat Per 1 Oktober 2015 NO. Nama Obat Rajal RanapDocument2 pagesKenaikan Harga Obat Per 1 Oktober 2015 NO. Nama Obat Rajal RanapJuon Vairzya AnggraeniNo ratings yet