Professional Documents

Culture Documents

CSTR 1 Prelab

CSTR 1 Prelab

Uploaded by

Dyako D TaherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSTR 1 Prelab

CSTR 1 Prelab

Uploaded by

Dyako D TaherCopyright:

Available Formats

CHEG 3128 – Chemical Engineering Junior Laboratory

Spring 2017 – CSTR 1 Prelab

In Chemical Engineering classes, we often talk about the continuously stirred tank reactors

(CSTRs), which are cornerstone unit operations for mixing and reactions in industry. One of the

core assumptions in the CSTR model is instantaneous homogeneous mixing. Intuition tells us that

it is impossible to achieve this type of perfect mixing. Mass transport issues (laminar flow regimes,

vortexing, back mixing, dead zones, short circuiting, etc.) all influence the degree of mixing in the

reactor. In this laboratory, we will explore the various factors that influence mixing through:

1. In class lecture and discussion; and

2. Hand-on experimentation with pre-designed and assembled CSTR stations

However, before you arrive to class to perform the lab, there are a few tasks that should be

completed in order to be adequately prepared to take part in our discussion.

1. Purchase at least 16oz of 5% white distilled vinegar

2. Download and install the NeuLog software that controls the pH sensor

3. Familiarize yourself with the NeuLog software and user guide

4. Read about steady state mass balances in “Elementary Principles of Chemical Processes”,

either the 3rd or 4th Ed, Section 4.2.

5. Read about non steady-state mass balances in “Elementary Principles of Chemical

Processes”, 3rd Edition Sections 11.1-11.2 or 4th Edition Sections 10.1-10.2.

6. Review Acid-Base equilibrium and pKa’s from your chemistry textbook and/or:

https://www.av8n.com/physics/ph-versus-concentration.htm

In this portion of the lab, we will investigate the mixing properties of a pre-assembled CSTR with

a given impeller at a constant speed. The tracer species in this study will be protons that come

from the dissociation of acetic acid in water. The proton concentration in the CSTR exit will be

continuously monitored using a NeuLog pH sensor. Below is an abbreviated procedure:

1. Adjust the inlet flowrate of tap water until a steady state CSTR volume between 3.5 and

4.0 gallons is achieved

2. Introduce a known volume of 5% acetic acid into the reactor as a pulse input

3. Monitor the pH change over time

4. Perform steps 2-3 at least 3 times, introducing fresh acetic acid only after the concentration

(pH) levels off near the initial value (this will take 10-20 minutes per addition)

5. Remove all of the water from the system and rinse thoroughly

6. Disconnect experimental setup and return it to its storage location

7. Clean your laboratory station before leaving

There will be a laboratory assignment posted to Husky CT that provides detail regarding how to

prepare the lab report, including discussion and data analysis, as well as the other tasks that will

need to be completed before the group’s assigned time for the second part of this lab (shown as

CSTR 2 in the Course Schedule).

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Basics of Concrete Repair and Structural StrengtheningDocument65 pagesBasics of Concrete Repair and Structural StrengtheningEdmond ChowNo ratings yet

- ASTM C 593-06 - Standard Specification For Fly Ash and Other Pozzolans For Use With LimeDocument5 pagesASTM C 593-06 - Standard Specification For Fly Ash and Other Pozzolans For Use With Limeluisenriq33100% (1)

- CG ScienceDocument60 pagesCG ScienceAgnes G. Arguilles TaladtadNo ratings yet

- Chme 401 Chemical Engineering Laboratory Ii Experiment 401-4 Chemical Reactors ObjectiveDocument4 pagesChme 401 Chemical Engineering Laboratory Ii Experiment 401-4 Chemical Reactors ObjectiveDyako D TaherNo ratings yet

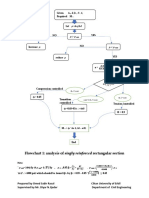

- Flowchart For Design Reinfoced Concrete 2017 PDFDocument7 pagesFlowchart For Design Reinfoced Concrete 2017 PDFDyako D TaherNo ratings yet

- Batch CSTR ExperimentDocument5 pagesBatch CSTR ExperimentDyako D TaherNo ratings yet

- FigureDocument1 pageFigureDyako D TaherNo ratings yet

- Alternate Operating Methods For Improving The Performance of Continuous Stirred Tank ReactorsDocument33 pagesAlternate Operating Methods For Improving The Performance of Continuous Stirred Tank ReactorsDyako D TaherNo ratings yet

- Subject: Material Science & MetallurgyDocument26 pagesSubject: Material Science & MetallurgyDyako D TaherNo ratings yet

- CIVIL ENGINEER DYAKO Diyar 1995 PDFDocument2 pagesCIVIL ENGINEER DYAKO Diyar 1995 PDFDyako D TaherNo ratings yet

- Flowchart (Deflection) PDFDocument4 pagesFlowchart (Deflection) PDFDyako D TaherNo ratings yet

- Dyako Dyar Tahir: Experince and andDocument2 pagesDyako Dyar Tahir: Experince and andDyako D TaherNo ratings yet

- Introduction To Materials Science and Engineering: Mr. Pem PhakvisethDocument38 pagesIntroduction To Materials Science and Engineering: Mr. Pem PhakvisethDyako D TaherNo ratings yet

- AA - SensomicsDocument15 pagesAA - Sensomicsmuhammad ekaNo ratings yet

- Board Assignment - AminesDocument5 pagesBoard Assignment - AminesHarsh GuptaNo ratings yet

- Influence of Impurities in Cathodic Copper On The Ductility of Copper WiresDocument8 pagesInfluence of Impurities in Cathodic Copper On The Ductility of Copper WiresvitordeleteNo ratings yet

- Unit 2 Solutions: Points To RememberDocument15 pagesUnit 2 Solutions: Points To RememberHarpreet kaurNo ratings yet

- VT No: 1Document12 pagesVT No: 1JithuJohnNo ratings yet

- Estudo 1Document8 pagesEstudo 1Jerusa Pacheco SampaioNo ratings yet

- NGL CT 1 0000 Pi SP 2002 D3 PDFDocument26 pagesNGL CT 1 0000 Pi SP 2002 D3 PDFAnonymous cVnKDdhNo ratings yet

- Effects of Spiral Diameter On The Bond Stress-Slip Relationship in Grouted Sleeve Connector - SeyedDocument17 pagesEffects of Spiral Diameter On The Bond Stress-Slip Relationship in Grouted Sleeve Connector - Seyedseyed jamal aldin HosseiniNo ratings yet

- DPP-13 (Coordination Compound) PDFDocument3 pagesDPP-13 (Coordination Compound) PDFAvishek BiswasNo ratings yet

- Alfacaus: Cleaning Agent For Heat ExchangersDocument2 pagesAlfacaus: Cleaning Agent For Heat ExchangerssijinjoyNo ratings yet

- Neutron Activation Analysis: Engineering Physics 4U04-NuclearDocument10 pagesNeutron Activation Analysis: Engineering Physics 4U04-NuclearDinusha LokuliyanaNo ratings yet

- Plumb Conc.Document28 pagesPlumb Conc.Muhammad AwaisNo ratings yet

- Pollution of Air and WaterDocument3 pagesPollution of Air and WaterChampuNo ratings yet

- Arabian DieselDocument1 pageArabian DieselArabian DieselNo ratings yet

- The Invisible Blanket: BIG IDEA: The AtmosphereDocument50 pagesThe Invisible Blanket: BIG IDEA: The AtmosphereggggangNo ratings yet

- Experiment 5 - Enzymes Part IiDocument6 pagesExperiment 5 - Enzymes Part IiHalleli CastilloNo ratings yet

- On The Applicability of Flory-Huggins Theory To Ternary Starch-Water-Solute SystemsDocument10 pagesOn The Applicability of Flory-Huggins Theory To Ternary Starch-Water-Solute SystemsjuarsrdNo ratings yet

- X Brief Review of NanocompositeDocument9 pagesX Brief Review of NanocompositeNUR KHOLISH ALI FAHMINo ratings yet

- ShamimfinalDocument6 pagesShamimfinalvimalNo ratings yet

- 4147ictte384 PDFDocument6 pages4147ictte384 PDFKandasamy AsohanNo ratings yet

- Study of Furnace Operations - Walking Beam FurnaceDocument47 pagesStudy of Furnace Operations - Walking Beam FurnaceGkNo ratings yet

- Solar Powered Air Conditioner For Car in Parking Condition Under The SunDocument12 pagesSolar Powered Air Conditioner For Car in Parking Condition Under The SunPRANAV PATILNo ratings yet

- Periodic Properties of The Elements 608817Document3 pagesPeriodic Properties of The Elements 608817Kumar nayakNo ratings yet

- Root Zone Method For Treatment of Waste Water-Ijaerdv04i0289634Document7 pagesRoot Zone Method For Treatment of Waste Water-Ijaerdv04i0289634Editor IJAERDNo ratings yet

- Introducccion A La Ciencia de Los PolimerosDocument155 pagesIntroducccion A La Ciencia de Los PolimerosRoss LoveNo ratings yet

- Pds Li5plusDocument2 pagesPds Li5plusTimmyJuriNo ratings yet

- PHY SCI DLP Q3 Week 2Document15 pagesPHY SCI DLP Q3 Week 2Radish CucumberNo ratings yet