Professional Documents

Culture Documents

Fosroc Conbextra EPGP: Constructive Solutions

Uploaded by

Vincent JavateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fosroc Conbextra EPGP: Constructive Solutions

Uploaded by

Vincent JavateCopyright:

Available Formats

Fosroc Conbextra EPGP constructive solutions

Multi-purpose, epoxy resin grout

Uses Properties

For free flow grouting where the mechanical properties, low Pot life : 2 hrs. @ 25ºC

permeability and chemical resistance of the hardened grout 1 hr. @ 35ºC

are of the highest order. Typical applications include : Maximum flow 100mm : 1000mm with 35mm gap

! Heavy duty support to large structural elements. head @ 35ºC 1800mm with 70mm gap

Water penetration : Nil (after 7 days)

! Supporting dynamic and/or mobile loads. DIN 1048: Part 5 :1991

! Pile top encapsulation. Rapid chl. permeability : Negligible

AASHTO T 277-83

Advantages Compressive strength : 80 N/mm2 @ 7 days

@ 35ºC. (BS 6319 : Part 2)

! High flexural strength and adhesion to substrate ensures Flexural strength . : 17 N/mm2 @ 7 days

excellent performance under dynamic operating (BS 6319 : Part 3)

conditions. Tensile strength . : 12 N/mm2 @ 7 days

! Simple mixing followed by high early strength allows (BS 6319 : Part 7)

minimum down time and early commissioning of plant.

Application instructions

! Withstands attack by a wide range of chemicals, acids

and alkalis, as well as water and frost. Preparation

! High compressive, flexural and tensile strengths ensure Underplate grouting

durability and long-term service life. The unrestrained surface area of the grout must be kept to a

! Very low permeability ensures integrity as part of a minimum. Generally, the gap between the perimeter formwork

waterproofing system. and the plate edge should not exceed 75 mm on the pouring

side and 25 mm on the opposite side. Formwork on the flank

Description sides should be kept tight to the plate edge. Air pressure

relief holes should be provided to allow venting of any isolated

Conbextra EPGP solvent-free epoxy resin grout is designed high spots.

for grouting of gap widths of 20-80 mm. It is supplied as a

three component system consisting of epoxy base, epoxy Formwork

hardener and specially graded aggregate. The components The formwork should be constructed to be leak-proof as

are supplied in the correct mix proportions designed for Conbextra EPGP is a free flow grout. This can be achieved by

whole pack mixing on site and no other materials should be using foam rubber strip or mastic sealant beneath the

added. constructed formwork and between joints.

Specification Foundation surface

Where shown on the contract documents, the epoxy resin, This must be free from oil, grease, or any loosely adherent

free flow grout shall be Conbextra EPGP by Fosroc. The material. If the concrete surface is defective or has laitence,

cured material shall exhibit a minimum compressive strength it must be cut back to a sound base. Bolt holes or fixing

of 80 N/mm2; a minimum flexural strength of 17 N/mm2 and pockets must be blown clean of any dirt or debris.

a minimum tensile strength of 12 N/mm2 when tested after 7 Base plate

days in accordance with BS 6319. The water penetration

shall be Nil after 7 days, when tested in accordance with DIN If delay is likely before placing steel base plates, it is

1048 : Part 5 : 1991. recommended that the underside and edge are coated with

Nitoprime 25* primer to prevent rust formation and ensure

Conbextra EPGP

bonding with the Conbextra EPGP grout. Nitoprime 25 can

be applied directly onto newly cleaned steel surfaces even if

they are damp. All surfaces must be substantially dry. All free

standing water must be removed.

Fosroc Conbextra EPGP

Mixing Storage

The entire contents of the hardener should be poured into the Conbextra EPGP has a shelf life of 12 months if kept in a dry,

base container and mixed until homogeneous. Place the cool store in the original unopened package.

mixed base and hardener into a suitable forced action mixer

making sure that the entire volume is poured in. Add the Precautions

aggregate and mix for 2-3 minutes or until uniform colour is

Health and safety

achieved.

Some people are sensitive to epoxy resin so gloves and a

Placing

barrier cream such as Kerodex 71, Rozalex 9, Debba-Wet

Place the grout within the pot life of the material. After this Work or similar should be used when handling these products.

time, unused material will have stiffened and should be If contact with the resin occurs, it must be removed before it

discarded. hardens with a resin removing cream such as Kerocleanse

22 or Rozalex 42. Follow by washing with soap and water.

Continuous grout flow is essential. Sufficient grout must be

Do not use solvent. The use of goggles is recommended but

available prior to starting and the time taken to pour a batch

should accidental eye contamination occur, wash thoroughly

must be regulated to the time taken to prepare the next one.

with plenty of clean water and seek medical treatment

Pouring should be from one side of the void to eliminate air immediately.

entrapment. The hydrostatic head must be maintained at all

Fire

times so that a continuous grout front is achieved.

Nitoprime 25 and Fosroc Solvent 102 are flammable. No

Cleaning

smoking. Use in well ventilated areas away from sources of

All tools and equipment should be cleaned with Fosroc heat and naked flames.

Solvent 102* immediately after use.

Flash points

Limitation Nitoprime 25 : 39ºC

Fosroc Solvent 102 : 33ºC

- For underplate grouting, failure to adhere to “Instructions

for use”, may result in cracking & edge uplifting. Technical support

High temperature working Fosroc offers a comprehensive technical support service to

For temperatures above 35ºC, special procedures need to specifiers, end users and contractors. It is also able to offer

be adopted, refer to your local Fosroc office for further advice. on-site technical assistance, an AutoCAD facility and

dedicated specification assistance in locations all over the

Estimating world.

Supply For further information on any of the services or other products

offered by Fosroc, please consult your local Fosroc office, as

Conbextra EPGP : 14 litre packs

below.

Nitoprime 25 : 1 and 4 litre packs

Fosroc Solvent 102 : 5 litre packs

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for

the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to

obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

Qatar, Tadmur telephone: 4432365 fax: 4419517 email: qatar@fosroc.com

UAE/0042/07/H

You might also like

- Conbextra EPGPDocument2 pagesConbextra EPGPm.elsanee.cubicNo ratings yet

- Conbextra EP120: High Strength, Epoxy Resin GroutDocument2 pagesConbextra EP120: High Strength, Epoxy Resin GroutzulfikarNo ratings yet

- Conbextra EP10TG PDFDocument2 pagesConbextra EP10TG PDFAcho SupraholicNo ratings yet

- Conbextra EP10: High Strength, Epoxy Resin GroutDocument3 pagesConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajNo ratings yet

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavateNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicNo ratings yet

- 10 Conbextra EP10Document2 pages10 Conbextra EP10ahmad wildaanNo ratings yet

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument1 pageConbextra EP10 : High Strength, Epoxy Resin GroutminedataNo ratings yet

- Nitomortar ELDocument4 pagesNitomortar ELMansoor AliNo ratings yet

- Conbextra EP75 PDFDocument4 pagesConbextra EP75 PDFsaroat moongwattanaNo ratings yet

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocument2 pagesFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateNo ratings yet

- TDS Nitobond EP India4Document3 pagesTDS Nitobond EP India4SHIVANSHUNo ratings yet

- Fosroc Supercast EPTDocument2 pagesFosroc Supercast EPTArun KumarNo ratings yet

- Fosroc Conbextra EP75: Constructive SolutionsDocument2 pagesFosroc Conbextra EP75: Constructive SolutionsmangjitNo ratings yet

- Conbextra EP75 PDFDocument3 pagesConbextra EP75 PDFKhaerul SidikNo ratings yet

- Conbextra EP40 UAEDocument2 pagesConbextra EP40 UAEjasonNo ratings yet

- Conbextra EP75: High Strength, Epoxy Resin GroutDocument4 pagesConbextra EP75: High Strength, Epoxy Resin GroutHamkarNo ratings yet

- Fosroc Nitomortar EL: Constructive SolutionsDocument4 pagesFosroc Nitomortar EL: Constructive SolutionsVincent JavateNo ratings yet

- TDS Conbextra EP10 IndiaDocument3 pagesTDS Conbextra EP10 IndiaBabla SNo ratings yet

- Conbextra EP75: High Strength, Epoxy Resin GroutDocument4 pagesConbextra EP75: High Strength, Epoxy Resin GroutVikas Singh ChandelNo ratings yet

- Fosroc Thioflex 600Document3 pagesFosroc Thioflex 600lutfiNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPMuhammad ShoaibNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicNo ratings yet

- Expangrout AGDocument2 pagesExpangrout AGPMG04 EKLNo ratings yet

- Conbextra PDocument4 pagesConbextra Pm.elsanee.cubicNo ratings yet

- Renderoc HB25: Constructive SolutionsDocument4 pagesRenderoc HB25: Constructive SolutionsDoby YuniardiNo ratings yet

- Conbextra EP300Document4 pagesConbextra EP300abhay_joshi2002No ratings yet

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument2 pagesConbextra EP10 : High Strength, Epoxy Resin GroutBudhi KurniawanNo ratings yet

- Datasheet File Conbextra GP PremixDocument4 pagesDatasheet File Conbextra GP PremixLftea AdiNo ratings yet

- (PDS) Conbextra GPDocument4 pages(PDS) Conbextra GPSheena GardnerNo ratings yet

- Conbextra EP: T T T T T TDocument4 pagesConbextra EP: T T T T T TFeri Oktara IrawanNo ratings yet

- Supercast EPT UAEDocument2 pagesSupercast EPT UAEsriatul2006No ratings yet

- Quickmast 341Document2 pagesQuickmast 341osama mohNo ratings yet

- Conbextra EP150 UAEDocument4 pagesConbextra EP150 UAEjasonNo ratings yet

- TDs - Emaco R101Document3 pagesTDs - Emaco R101Venkata RaoNo ratings yet

- Conbextra Ep300 PDFDocument4 pagesConbextra Ep300 PDFUa AnyanhunNo ratings yet

- Conbextra EP75 PlusDocument4 pagesConbextra EP75 Plusm.elsanee.cubicNo ratings yet

- Nitomortar ELDocument4 pagesNitomortar ELmilanbrasinaNo ratings yet

- Conbextra GPXtraDocument4 pagesConbextra GPXtraJoshua EkoNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- Combextra GP ExtraDocument4 pagesCombextra GP ExtrailhamNo ratings yet

- TDS Conbextra GP VNDocument4 pagesTDS Conbextra GP VNShahanis NabilaNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Fosroc Conbextra P: Constructive SolutionsDocument4 pagesFosroc Conbextra P: Constructive SolutionsVincent JavateNo ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Conbextra GP PDFDocument4 pagesConbextra GP PDFPrabowo SandiNo ratings yet

- Conbextra HF - Grout For Tank Gaps PDFDocument4 pagesConbextra HF - Grout For Tank Gaps PDFEngr.Mohammed KhaledNo ratings yet

- Renderoc RG: Constructive SolutionsDocument3 pagesRenderoc RG: Constructive Solutionsmohammad khabibNo ratings yet

- Nitoflor EPU100Document4 pagesNitoflor EPU100Allan DerickNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDPritha DasNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarNo ratings yet

- Renderoc HSDocument2 pagesRenderoc HSMansoor AliNo ratings yet

- Nitocote EpuDocument4 pagesNitocote EpumohamedbossilyNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Fosroc Colpor 200: Constructive SolutionsDocument4 pagesFosroc Colpor 200: Constructive Solutionsarwin dela cruzNo ratings yet

- Nitocote EP405Document4 pagesNitocote EP405mangjitNo ratings yet

- Fosroc Dekguard E2000: (Also Known As Nitocote FBC)Document4 pagesFosroc Dekguard E2000: (Also Known As Nitocote FBC)Tejinder KumarNo ratings yet

- Nitocote EpsDocument4 pagesNitocote EpsmangjitNo ratings yet

- Fosroc Nitocote NT402: Constructive SolutionsDocument4 pagesFosroc Nitocote NT402: Constructive SolutionsVJ QatarNo ratings yet

- Nitoseal Debonding Tape AgfDocument1 pageNitoseal Debonding Tape AgfVincent JavateNo ratings yet

- Fosroc Bitucell: Constructive SolutionsDocument2 pagesFosroc Bitucell: Constructive SolutionsIna RoseNo ratings yet

- Barrel GunDocument1 pageBarrel GunVincent JavateNo ratings yet

- Fosroc Nitocote EP410: Constructive SolutionsDocument4 pagesFosroc Nitocote EP410: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote PE135 PDFDocument2 pagesNitocote PE135 PDFSuresh BabuNo ratings yet

- Fosroc Dekguard S: Constructive SolutionsDocument4 pagesFosroc Dekguard S: Constructive SolutionsshazibNo ratings yet

- Fosroc Nitocote NT550: Constructive SolutionsDocument4 pagesFosroc Nitocote NT550: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Nitocote SN502: Constructive SolutionsDocument2 pagesFosroc Nitocote SN502: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote Primer SealerDocument2 pagesNitocote Primer SealerVJ QatarNo ratings yet

- Fosroc Nitocote SN522: Non Staining Water RepellentDocument2 pagesFosroc Nitocote SN522: Non Staining Water RepellentDasha DosftNo ratings yet

- Nitocote CM210Document4 pagesNitocote CM210sivakumar ramaiahNo ratings yet

- Fosroc Nitocote EN901: Constructive SolutionsDocument4 pagesFosroc Nitocote EN901: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Dekguard AC: Constructive SolutionsDocument4 pagesFosroc Dekguard AC: Constructive SolutionsVJ QatarNo ratings yet

- MNVTFRDF 0UDocument4 pagesMNVTFRDF 0UTarek TarekNo ratings yet

- Fosroc Nitocote HT120: Constructive SolutionsDocument4 pagesFosroc Nitocote HT120: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Nitocote HEX: Constructive SolutionsDocument4 pagesFosroc Nitocote HEX: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Dekguard PU: Constructive SolutionsDocument4 pagesFosroc Dekguard PU: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote sr3000Document4 pagesNitocote sr3000VJ QatarNo ratings yet

- Brush BondDocument4 pagesBrush BondGibbs PerNo ratings yet

- Fosroc Brushbond FLXIII: Constructive SolutionsDocument2 pagesFosroc Brushbond FLXIII: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Dekguard EP302: Water Based, Epoxy Resin Primer For Dekguard PUDocument2 pagesFosroc Dekguard EP302: Water Based, Epoxy Resin Primer For Dekguard PUVJ QatarNo ratings yet

- Fosroc Nitocote ET402: Constructive SolutionsDocument4 pagesFosroc Nitocote ET402: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Nitocote EP403: Constructive SolutionsDocument4 pagesFosroc Nitocote EP403: Constructive SolutionsVJ QatarNo ratings yet

- Galva FroidDocument2 pagesGalva FroidChrill DsilvaNo ratings yet

- Fosroc Dekguard Filler: Acrylic, Intercoat Pin Hole FillerDocument2 pagesFosroc Dekguard Filler: Acrylic, Intercoat Pin Hole FillerVincent JavateNo ratings yet

- Module 10 MagnetismDocument22 pagesModule 10 MagnetismJojimar JulianNo ratings yet

- 04 Samss 041Document6 pages04 Samss 041Moustafa BayoumiNo ratings yet

- Prediction of Adhesion and Wetting From Lewis Acid Base MeasurementsDocument6 pagesPrediction of Adhesion and Wetting From Lewis Acid Base MeasurementsGabriel MendivilNo ratings yet

- 1-2019 - Investigation of Crosslinking, Mechanical - by SiO2 - Thiên VươngDocument15 pages1-2019 - Investigation of Crosslinking, Mechanical - by SiO2 - Thiên VươngPhạm HàNo ratings yet

- Hvac Brochure - FinalDocument9 pagesHvac Brochure - FinalAmrut Prasade100% (1)

- 15 - CreepDocument41 pages15 - Creepgosaye desalegnNo ratings yet

- Direct Analysis Method TipsDocument25 pagesDirect Analysis Method Tipsbobmarley20161934No ratings yet

- NX Nastran DesktopDocument5 pagesNX Nastran DesktopThanakorn VichiensamuthNo ratings yet

- Design Introduction AirframeDocument27 pagesDesign Introduction Airframekarthiks12008658No ratings yet

- SpecificationsDocument1 pageSpecificationssiddheartttNo ratings yet

- Transparent Concrete Concept by Replacing Fine Aggregate of Waste Glass by Using Admixture in Optical FibreDocument8 pagesTransparent Concrete Concept by Replacing Fine Aggregate of Waste Glass by Using Admixture in Optical FibreInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- CRL Srs Standoff Railing System: CRL Glass Rail Standoff Fittings Rs0B20 W/ Rectangular Back PlateDocument8 pagesCRL Srs Standoff Railing System: CRL Glass Rail Standoff Fittings Rs0B20 W/ Rectangular Back PlateHanmant OulkarNo ratings yet

- AISC Design Guide 1 - Errata-Column Base Plates - 2nd Edition PDFDocument6 pagesAISC Design Guide 1 - Errata-Column Base Plates - 2nd Edition PDFसौरव डेNo ratings yet

- Liquid Crystalline Polymers PDFDocument19 pagesLiquid Crystalline Polymers PDFdevilturn7050% (2)

- Autoclave CatalogueDocument12 pagesAutoclave CataloguecristianoclemNo ratings yet

- 2016 Cau Caesar II CoolingDocument21 pages2016 Cau Caesar II CoolingGentelmanOnlyNo ratings yet

- Ceramic TileDocument4 pagesCeramic TilewalidNo ratings yet

- Umer Associates Builders, Engineers & Contructors: Abstract of Quantities SR - No Description Unit Earthwork/ExcavationDocument4 pagesUmer Associates Builders, Engineers & Contructors: Abstract of Quantities SR - No Description Unit Earthwork/ExcavationSaqib Ali100% (1)

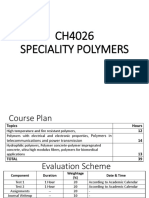

- Speciality PolymersDocument63 pagesSpeciality PolymersChini ChineeNo ratings yet

- Double Glazing ManualDocument19 pagesDouble Glazing ManualullwnNo ratings yet

- Petronas Technical Standards: Design Requirement For Non-Permanent Onshore WorksDocument16 pagesPetronas Technical Standards: Design Requirement For Non-Permanent Onshore WorksFirdausi FauziNo ratings yet

- Halaba Poly Technic ColllegeDocument36 pagesHalaba Poly Technic ColllegeFikru TesefayeNo ratings yet

- Kitz Complete Ball Valve Catalog PDFDocument132 pagesKitz Complete Ball Valve Catalog PDFDinifaanNo ratings yet

- Exit ExamDocument70 pagesExit ExamHaymanot MelakuNo ratings yet

- Is 1904Document24 pagesIs 1904Able KuriakoseNo ratings yet

- Bueco Clean Room AHUDocument26 pagesBueco Clean Room AHUHENRY100% (1)

- MasterSeal 940 TDSDocument4 pagesMasterSeal 940 TDSbayuargad100% (1)

- HVAC Design Handbook PDFDocument783 pagesHVAC Design Handbook PDFMustafa FalihNo ratings yet

- 1083ch7 16 PDFDocument27 pages1083ch7 16 PDFmelosz100% (1)