Professional Documents

Culture Documents

Zebra Machinist Mixer Manual: Requirements

Uploaded by

carlos cisnerosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zebra Machinist Mixer Manual: Requirements

Uploaded by

carlos cisnerosCopyright:

Available Formats

Zebra Skimmers Corp.

Zebra Machinist Mixer

Zebra Machinist Mixer

®

Requirements

Manual

• Minimum of 25 psi continuous operating water pressure

• Maximum 500 SUS coolant concentrate viscosity

• USE DISCHARGE HOSE PROVIDED. Longer lengths will less-

en concentration or provide none at all.

• Use proper fittings for water input and output. Restriction of

either will reduce vacuum pressure. Required fitting sizes are

noted below.

• Keep drum upright

Installation Instructions

1. Configure the standpipe to fit your concentrate container type.

Use both standpipes and the coupler for tote applications. You

may need to re- move and reattach the check valve to the lower

end of the standpipe configuration.

2. Remove the bung cap from the concentrate container.

3. Insert the required length standpipe into the container and

screw bushing into the 2” female thread in drum. Tighten the

set screw.

4. Unfasten the breather cap from the concentrate lid.

5. Connect the included shut-off valve to the mixer head.

6. Connect the water line to the shut-off valve using the proper sized fitting (see chart below).

7. Attach the 40” discharge hose, provided. Longer lengths will lessen concentration output. If delivering

mix through a garden hose, for instance, a proportioning pump is required.

8. Open the water valve, and after emulsion is dispensed, check the proportion with a refractometer, then

adjust the dial as necessary. Once the dial setting has been determined, secure with the locknut located

below the dial.

• Dial settings are for reference only. Varying water pressure and fluid viscosities will produce different

mixing ratios.

• Turning the dial clockwise (right) will bottom out the needle valve onto its seat in the mixer body, pre-

venting coolant concentrate from entering the mixing chamber. At this point, the number zero should

be in-line with the pointer.

• Turning the dial counter-clockwise (left) will open the inlet orifice permitting increasing amounts of

cool- ant concentrate to enter the mixing chamber.

• Maximum ratio delivered with four full turns of the dial.

Part# Ratio Range % Range GPM Fitting In Fitting Out Application

MIX0327 15:1 - 45:1 0-7% 3 3/8” 1/2” Pail, Barrel or Tote

MIX03725 8:1 - 35:1 0-25% 3 3/8” 1/2” Pail, Barrel or Tote

MIX03725SS 8:1 - 35:1 0-25% 3 3/8” 1/2” Pail, Barrel or Tote

MIX1027 15:1 - 45:1 0-7% 10 1/2” 3/4” Pail, Barrel or Tote

MIX10725 8:1 - 35:1 0-25% 10 1/2” 3/4” Pail, Barrel or Tote

MIX10725SS 8:1 - 35:1 0-25% 10 1/2” 3/4” Pail, Barrel or Tote

SS models for caustic concentrate

Machinist Mixer Manual Zebra Skimmers Corp.

Troubleshooting

Low Concentrations or None at All

1. Check the discharge hose. If you are NOT using the hose we provided, make sure you are using NO

MORE than 40” of discharge hose, with a minimum UNINTERRUPTED ID of 1/2” for 3 gpm models,

and 3/4” for 10 gpm models. Make sure that the hose has no kinks or other obstructions. If delivering

mix through a garden hose, for instance, a proportioning pump is required.

2. Examine the check valve at the bottom of the standpipe. Debris can keep it open, allowing concentrate

to drain back into the drum. The check ball should be below the valve’s set screw.

3. Check the water pressure. Our equipment requires a minimum pressure of 25 psi. TEST: Using the mix-

er with needle valve closed, fill a pail of known volume and time it. If you can fill a 1 gallon pail in 20

seconds there is enough pressure for our 3 gpm unit. If you can fill a 1 gallon pail in 6 seconds there is

enough pressure for our 10 gpm unit.

4. The needle-valve (dial) is numbered as a guide only. It does not indicate proportions. Turning the dial

clockwise reduces coolant concentrate ratio.

5. Check the coolant concentrate level in the drum. You may be running out.

6. Check the viscosity of the coolant concentrate. Our equipment is designed for up to 500 SUS at 100° F.

(SUS=saybolt universal seconds). 500 SUS is about the same as SAE30 motor oil.

Water Draining into Concentrate Container

1. Shut water ball valve off (check valve on end of standpipe is not rated to hold fluid under pressure).

2. Check water ball valve for cracks or damage.

3. If using a solenoid valve, install it on inlet before water supply (check valve on end of standpipe is not

rated to hold fluid under pressure).

Concentrate Siphoning from Container

1. Remove discharge hose from output holding container or sump.

2. Verify concentrate container’s breather hole is open.

3. Verify that the check valve is free of debris.

Warranty

• Lifetime warranty on all parts.

• Any use of this product outside the suggested parameters will void all warranties.

If you have any questions or require product support,

please contact 888-249-4855

Visit

www.CoolantMaintenance.com

for clean coolant tips

Zebra Skimmers

Corporation

Copyright 2013 © ZSC • Zebra Skimmers Corp. • PO Box 833 • Chagrin Falls, OH 44022 • 888-249-4855 • www.ZebraSkimmers.com

Printed in the USA • Revised February 2008 • Information is correct as of the date printed. We reserve the right to change any information without notice.

Page 2 888.249.4855 • www.ZebraSkimmers.com • Zebra Skimmers Corporation

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Input Data: CMM 040/063 U 150 71B14 SZDX M1 UB1 0.37kW 4p 3ph 60Hz T1Document4 pagesInput Data: CMM 040/063 U 150 71B14 SZDX M1 UB1 0.37kW 4p 3ph 60Hz T1carlos cisnerosNo ratings yet

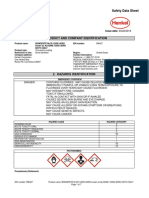

- Product and Company Identification: Safety Data SheetDocument7 pagesProduct and Company Identification: Safety Data Sheetcarlos cisnerosNo ratings yet

- Safety Data Sheet Bonderite C-IC 624 MOD (Deoxidine 624 MOD)Document8 pagesSafety Data Sheet Bonderite C-IC 624 MOD (Deoxidine 624 MOD)carlos cisnerosNo ratings yet

- Oak Draw 505 - MsdsDocument7 pagesOak Draw 505 - Msdscarlos cisnerosNo ratings yet

- Safety Data Sheet Bonderite C-IC 624 MOD (Deoxidine 624 MOD)Document8 pagesSafety Data Sheet Bonderite C-IC 624 MOD (Deoxidine 624 MOD)carlos cisnerosNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- InstallationDirective C13 IvecoDocument60 pagesInstallationDirective C13 Ivecoblaktion0% (1)

- MacRoy G PDFDocument60 pagesMacRoy G PDFJuan Pablo NavasNo ratings yet

- 01 Check Valve Mini CatalogDocument50 pages01 Check Valve Mini Catalognemi90No ratings yet

- Pressure Transients in Water EngineeringDocument559 pagesPressure Transients in Water EngineeringvasuNo ratings yet

- MOFFETTDocument72 pagesMOFFETTtanjossNo ratings yet

- 9working Hydraulic System - ENGLISG-G9165Document58 pages9working Hydraulic System - ENGLISG-G9165George Jhonson100% (3)

- A100 Absorber Ecoflow System User ManualDocument32 pagesA100 Absorber Ecoflow System User ManualInformes biosertecNo ratings yet

- 2hr DistributionSystemsBrandedDocument107 pages2hr DistributionSystemsBrandedLê Văn Thế QuangNo ratings yet

- IOM - iHTDocument50 pagesIOM - iHTkarun agrawalNo ratings yet

- ValvesDocument82 pagesValvespuru55980No ratings yet

- Listado de RepuestoDocument9 pagesListado de RepuestoRodrigo Andres CeledonNo ratings yet

- Chemical Injection Quills Nozzle: FeaturesDocument1 pageChemical Injection Quills Nozzle: FeaturesAmjad HaniNo ratings yet

- WHO VBC 89.970 enDocument24 pagesWHO VBC 89.970 en'ucha' SikumbangNo ratings yet

- Maersk Boston Machinery Manual PDFDocument412 pagesMaersk Boston Machinery Manual PDFCeban Eugeniu100% (1)

- Fichas Tecnicas Tyco Amd-2Document4 pagesFichas Tecnicas Tyco Amd-2Isaac Yull AguilarNo ratings yet

- HK12 04 09Document123 pagesHK12 04 09layetajNo ratings yet

- 2 - B+L - Pump - Level 2Document87 pages2 - B+L - Pump - Level 2riin100% (2)

- Alarm Check Valve Model JDocument8 pagesAlarm Check Valve Model JDirham NuriawangsaNo ratings yet

- D155 Hydraulic SystemDocument39 pagesD155 Hydraulic SystemReza SyailendraNo ratings yet

- Fassi Crane: Use and MaintenanceDocument49 pagesFassi Crane: Use and MaintenanceDaniel MihailaNo ratings yet

- S10332300-3003 - 0 Process MeasurmentDocument27 pagesS10332300-3003 - 0 Process Measurmentappril26No ratings yet

- Dismantling ProcedureDocument23 pagesDismantling ProcedureNeil FerrerNo ratings yet

- Ch. 7 PDFDocument26 pagesCh. 7 PDFrezaNo ratings yet

- TFP1305 07 2005Document8 pagesTFP1305 07 2005mohammadazraiNo ratings yet

- LC-2010 Maintenance Training (Customer) PDFDocument109 pagesLC-2010 Maintenance Training (Customer) PDFDhiraj SagarNo ratings yet

- Prefabricated Pumping Stations of Lowara A Xylem BrandDocument48 pagesPrefabricated Pumping Stations of Lowara A Xylem Brandgeorge_efstratiadisNo ratings yet

- Aircraft System 1 - Pneumatic SystemDocument14 pagesAircraft System 1 - Pneumatic SystemAndreas.G100% (1)

- Model M05 Non-Metallic Design Level 2: Service & Operating ManualDocument33 pagesModel M05 Non-Metallic Design Level 2: Service & Operating ManualTrungGVNo ratings yet

- Rita MachineryDocument203 pagesRita MachineryGheorghe CristianNo ratings yet

- TestDocument22 pagesTestAbdul WaheedNo ratings yet