Professional Documents

Culture Documents

Scan20200923 07570736

Scan20200923 07570736

Uploaded by

hoby christian0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

SCAN20200923_07570736

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageScan20200923 07570736

Scan20200923 07570736

Uploaded by

hoby christianCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

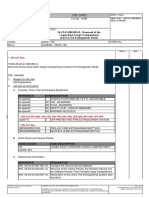

64 | MAINTENANCE & ENGINEERING

vd oo aa @

cant

= To cea [Sheer Re oem alone] meme T+

es Sa a a ee ee

ee a ee

a are me

mandatory and optional fields. Each

screen of the TLP cannot be signed off

until all mandatory fields are completed.

‘The customer can decide which fields

they wish to make mandatory during the

configuration and setup process, and then

this is managed within eCentral8. This

‘means that the input of vital information

cannot be missed in operation

“In addition, we have a few clever

ways of ensuring data is entered

correctly,” continues Boyd. “Where

possible, we compare pilo-entered data

‘with schedule information and ACARS

feeds. Ifthe information entered docs not

match, for example, the ight-scheduled

‘O00! times, iis highlighted in amber

and a warning message is displayed.”

For other areas such as refuelling,

ETLELB software also assists with

‘mathematical calelations. This can save

time for fighe crews during aircraft TATS.

“Fuel bowser uplifs can be calculated

from the pre-rfucl, departure and

specific gravity data, then displayed next

to the fcid where the information has to

be entered,” adds Boyd. “Again, in

eTechLog8, a warming message in amber

is displayed ifthe uplift entered is very

different to the calculated amount. An

auditing feature on eCentral8 compares

data with an authoritative source and

flags anything that falls ouside an

acceptable tolerance. This can then be

‘manually audited or corrected before

being allowed to flow into che M&E

system.”

‘With ULTRAMAIN ELE, the techlog

is now accessed via an iPad. “The system

can be set up so both the light ew and

the mechanic on the aircraft can be

looking atthe same techlog on separate

devices,” explains Stone “We have

proprietary technology to make sure

every iPad is synced and thae there is

‘rece Cnc

always a master copy.”

“In this system, access to the ELB

requires logging into the aircraft techlog

‘on each device,” continues Stone. “The

airlines ean also fix a device to that

aircraft. If flight crew are issued with

‘personal devices a different set of

authentications would happen. These will

differ from customer to customer,

depending on individual policy and

regulations. One option isto have a QR.

code on the flight deck to register and

access the correct aircraft log book.”

=

Defect reporting

‘While the aircraft isin operational

service all defers ae controlled through

che arerafrtechlog andlor cabin logs.

“This is diferent to heavy maintenance

cavironments where the MRO's own

paperwork willbe used to clear the

defects.

Defects reported ‘online’ are a result

of scheduled maintenance inspections or

in-service operational sues. Depending

on their nature, defects ean be rectified

immediatly, dfered asa carried

forward defer (CFD) for future

rectification, or categorised as nimum

equipment lise (MEL) items. MEL listed

defects may sll be referred to as 2 CFD,

bye set time lmits and operational

sestitions wil be applied to them.

‘Addivonaly, durin line maintenance

defec reporting the defer originator s

noted. “Defect classification codes are

‘sed within OASES to distinguish

winether the defect was recorded bythe

pilot, the ground crew, or the cabin

rev” explains David Pusey, projecs

‘lector at OASES, “The coding is user

definable, but sypically PIREP (plot

feports) MAREP (maintenance reports —

raised from pre-ight and line checks)

Defects ae recorded by closifaton ces to

clstngush he originator Common code

groupings are Pot reports (PREP),

Maintenance reports (MAREP), and Cabin

reports.

and cabin reports are used. By using

coding, defects can be filtered for

information gathering and reporting

purposes. For instance, only the defects

originating from PIREPs will form part of

the in-flight reliability statistics

reporting.”

For paper-based techlog entries,

interaction with the M&E system is via

‘manual entry of the TLP information into

the system. This will raise, detail and

electronically control the defect for the

aircraft records, time recording, parts

ordering, and defect closure.

‘While using an ETL, defects will be

automatically entered into the MBE.

system via the interfaces described, when

‘connectivity is available both on the

‘ground or in fight.

“When a defect is recorded,

TechLog$ will automatically be flagged

asa MAREP or PIREP, depending on

‘when during flight or tarnaround the

defect has been recorded,” explains Boyd,

“For example, if a defect is recorded by

the flight crew before the fight has been

completed, it will be registered

automatically asa PIREP. After the flight

has been completed and engineers are

raising defecs, these will be registered as

a MAREE. Users can overrule the flag as,

required. eTechLog8 will artempe to

‘transmit the defect ifa connection is

available o the M&E system. In fight

this will be achievable ifthe airceaft has

WIFI enabled for cockpit use.”

Issue. un 2038

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Echannel Tech Pub DownloadDocument12 pagesEchannel Tech Pub Downloadhoby christianNo ratings yet

- Del Is LendsDocument56 pagesDel Is Lendshoby christianNo ratings yet

- ZL 141Document1 pageZL 141hoby christianNo ratings yet

- Compresseur 100L 5.5CV Triphasé GGA - Sanifer - CopieDocument3 pagesCompresseur 100L 5.5CV Triphasé GGA - Sanifer - Copiehoby christianNo ratings yet

- Hocking Locator 2 Price 1Document1 pageHocking Locator 2 Price 1hoby christianNo ratings yet

- COMPRESSEUR 7.5 KW, 300 L EKO POWER PRODUCT 2010301005 - Batimax - CopieDocument2 pagesCOMPRESSEUR 7.5 KW, 300 L EKO POWER PRODUCT 2010301005 - Batimax - Copiehoby christianNo ratings yet

- Sonatest Wave Price 1Document1 pageSonatest Wave Price 1hoby christianNo ratings yet

- Thories Du ManagementDocument4 pagesThories Du Managementhoby christianNo ratings yet

- Scan20200923 07563765Document1 pageScan20200923 07563765hoby christianNo ratings yet

- Copie de Content Calendar and Plan TemplateDocument2 pagesCopie de Content Calendar and Plan Templatehoby christianNo ratings yet

- IC Sales Management Dashboard Template Free FR2Document105 pagesIC Sales Management Dashboard Template Free FR2hoby christianNo ratings yet

- Tendance de Dépenses de Budget1Document14 pagesTendance de Dépenses de Budget1hoby christianNo ratings yet

- IC Project Management Dashboard Template Free FR2Document18 pagesIC Project Management Dashboard Template Free FR2hoby christianNo ratings yet

- JIC 32-42-55 CHK 10000: CHECK OF BRAKE Assy For Damages, Leak and WearDocument3 pagesJIC 32-42-55 CHK 10000: CHECK OF BRAKE Assy For Damages, Leak and Wearhoby christianNo ratings yet

- Job Card: Mpd-Task: ATLAS - A340Document9 pagesJob Card: Mpd-Task: ATLAS - A340hoby christianNo ratings yet

- Job Card: MPD-TASK: 324200-01 ATLAS - A340Document6 pagesJob Card: MPD-TASK: 324200-01 ATLAS - A340hoby christianNo ratings yet

- Job Card: 21-23-98-920-851-A - Replacement of The Filter Elements of The Smoke Extraction SystemDocument6 pagesJob Card: 21-23-98-920-851-A - Replacement of The Filter Elements of The Smoke Extraction Systemhoby christianNo ratings yet