Professional Documents

Culture Documents

Understanding Silica-3

Uploaded by

Ahmed FoudaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Understanding Silica-3

Uploaded by

Ahmed FoudaCopyright:

Available Formats

Loss Control TIPS

Technical Information Paper Series

Innovative Safety and Health Solutions SM

Understanding Silica: Health Hazards,

Standards, and Sampling Issues

Sources, Properties, and Uses

Any discussion of “silica” has to start with a few definitions. Silica can take several different forms, and

the term is applied (and sometimes misapplied) to very different materials. Free silica (SiO2) and

silicates, or combined silica (SiO3), have substantially different chemical compositions and present

different health hazards.

Free silica (SiO2) can take two separate forms: crystalline and amorphous. Both represent significantly

different health concerns. Silicates can include many relatively nontoxic compounds, including sodium

silicate (water glass), calcium metasilicate, portland cement, kaolin clay, or perlite. On the other hand,

some silicates such as mica, talc, asbestos, feldspar, and soapstone have potentially toxic properties. Not

all forms of silica exhibit the same degree of toxicity, so it is essential to understand the type of silica

present in order to determine its degree of hazard. For further information, refer to the Threshold Limit

Values (TLV) published by the American Conference of Governmental Industrial Hygienists or other

reliable references.

Amorphous forms of silica do not present the serious health hazard associated with the crystalline forms.

Examples of amorphous silica include glass, diatomaceous earth (uncalcined), precipitated silica, and

silica gel.

Silica or silicates can occur naturally and are also manufactured. It is reasonable to expect crystalline

silica content in almost any naturally-occurring mineral or other substance which has been removed from

the ground. Dust from sand, coal, graphite, slate, clay, sandstone, shale, pumice, flint, diatomite or glacial

deposits are all possible candidates for crystalline silica exposures.

The terms crystalline and amorphous silica apply to the chemical silicon dioxide (SiO2). Crystalline silica

exists in several different mineral forms, including quartz, cristobalite, and tridymite. Other materials that

may contain appreciable amounts of quartz include fused silica, silica flour, and tripoli.

The primary source of crystalline silica is quartz, a mineral found in nearly all mineral deposits; it is an

important component of common rocks such as granite and sandstone.

Understanding Silica: Health Hazards, Standards, and Sampling Issues Page 1

© 2002 The Hartford Loss Control Department

TIPS S 580.480

Sand contains large amounts of quartz and is used in the glass and pottery industry as well as in

production of brick, mortar, and abrasives (for example, concrete, sand paper, sand blasting). In its finely

divided form (silica flour), it is added to soaps, paints, and porcelains.

The two minerals known as cristobalite and tridymite usually occur together, most commonly in volcanic

rock in California, Colorado, and Mexico. These two minerals can also be manufactured by heating silica

(either crystalline or amorphous) to high temperatures. This process occurs in calcining diatomaceous

earth; the resulting products are used in insulation, filters, and furnace linings.

Industries and products which use crystalline silica include abrasives, abrasive blasting, boiler scaling,

cement production, ceramics, coal mining and milling, fillers (paints, rubber, etc), foundry work, glass

manufacture, insulation production, metal mining and milling, mining, quarrying, tunneling, nonmetallic

mining and milling, plastic manufacturing (as a filler), pottery making, refractories, road working, rubber

manufacturing (as a filler), sandblasting, scouring powder, tile and clay production, and vitreous

enameling.

Health Hazards

It is impossible to generalize about the health hazard potential of any dust of unknown composition.

References in Material Safety Data Sheets may give hints as to whether the material in question is silica

or a silicate, or whether it is crystalline or amorphous silica, or none of the above. Because some silicates

are harmless and others are not, explore this aspect fully.

Crystalline silica can damage the lungs. Of primary concern are respirable silica dust particles (those that

are sufficiently small to penetrate into the deep recesses of the lung). Health hazards associated with

excessive exposure to respirable crystalline silica include silicosis and lung cancer. Employees who

develop silicosis are also at increased risk of developing tuberculosis, although tuberculosis is not directly

caused by exposure to silica. The rate of tuberculosis has long been known to be higher among those who

have silicosis, and may occur at any stage of the disease. There are also case studies of short but profound

exposures to very fine forms of crystalline silica producing a condition known as "acute silicosis.”

Silicosis symptoms are often not initially apparent; a victim’s exposure may continue for decades before

he or she experiences respiratory difficulties. By then, significant damage may have occurred, including

classic silicosis or progressive massive fibrosis. Several agencies, including the International Agency for

Research on Cancer, the German MAK Commission, and the American Conference of Governmental

Industrial Hygienists, have concluded that respirable crystalline silica dust exposures and the

development of silicosis are associated with an increased risk of lung cancer, tuberculosis, or both.

Standards

The United States Occupational Safety and Health Administration (OSHA) and the American Conference

of Governmental Industrial Hygienists (ACGIH) have established different standards for respirable

crystalline silica.

The current ACGIH standard, or Threshold Limit Value (TLV), for respirable quartz is the more

conservative of the two, at 0.1 milligrams per cubic meter (mg/m3). (In 1999, ACGIH published a Notice

of Intended Change for quartz to reduce the TLV to 0.05 mg/m3.)

Understanding Silica: Health Hazards, Standards, and Sampling Issues Page 2

© 2002 The Hartford Loss Control Department

TIPS S 580.480

OSHA’s Permissible Exposure Limit (PEL) uses a different method; it requires the following formula to

determine the PEL for each sample taken, the PEL is different for each sample. The respirable dust

concentration (in mg/m3) is then compared to the individual PEL for each sample to determine exposure.

PEL Respirable Silica = 10 mg/m3

% Quartz +2

As a practical matter, the OSHA PEL and the ACGIH TLV are identical when the material being sampled

is 100% quartz. Both are twice as high as the proposed TLV.

Note that the permissible exposure limit and TLVs for silica (other than quartz) such as cristobalite and

tridymite are 0.05 milligrams per cubic meter, half the quartz value. At this time, there is no proposal to

lower the TLVs for either cristobalite or tridymite.

If the material being used contains less than 1% silica, or if it is amorphous silica, then ACGIH’s

Particulate Not Otherwise Classified (PNOC) standard applies.

Because of the significance of the health effects, The Hartford recommends adherence to the proposed

ACGIH Threshold Limit Value of 0.05 mg/m3 for respirable quartz dust and the existing TLV of 0.05

mg/m3 for respirable dust of cristobalite or tridymite.

Sampling Issues

Respirable dust measurements are more practical than total dust measurements in making a meaningful

estimate of the health hazard potential associated with exposure to silica. The standard sampling

methodology for total dust collects particles of all sizes, which can bias sample results (both negatively

and positively) during measurement of silica concentrations.

To collect respirable dust samples, use a size-selective collection device, usually a cyclone separator. This

device separates particles larger than 10 microns (not considered respirable) from those fewer than 10

microns (as defined by OSHA under 29 CFR 1910.1001, Table Z3, footnote e.) It is essential that the

collection device be operated at the flow rate stipulated by the manufacturer. Higher or lower flow rates

will directly impact the efficiency of the device. (The Hartford uses two types of cyclone separators, but

most often the MSA 10-millimeter nylon cyclone, which requires a flow rate of 1.7 liters/minute.)

Samples are collected on pre-weighed 5 micron PVC filters in a 2-piece, 37-millimeter cassette.

In some limited situations, a major drawback to the analytical procedure employed by some laboratories

is the inability to differentiate among the various types of silica. Some methods cannot distinguish quartz

from cristobalite or tridymite, nor can they distinguish quartz from amorphous silica. In short, with some

methods, all silica (silicon dioxide) is reported regardless of its form or structure. In order to identify

combinations of silica or to assess unknown material, conduct an x-ray diffraction. But be aware that x-

ray diffraction alone cannot distinguish quartz from amorphous silica.

Because the TLV and PEL differ, it is imperative that you know which standard is going to be applied

prior to requesting laboratory analysis.

Understanding Silica: Health Hazards, Standards, and Sampling Issues Page 3

© 2002 The Hartford Loss Control Department

TIPS S 580.480

Sampling Methodology

In most sampling methods, a pre-weighed, PVC, 5 micron filter is placed into a cyclone apparatus face

down, so that the ribbed outlet side is facing up and towards the tubing leading to the pump. Adjust the

flow rate to the manufacturer’s specification and check it at least once each hour. Re-adjust the flow only

if it appears that the flow rate has increased or decreased more than 10%.

Since only the respirable dust is being collected, it will be necessary to take samples for a longer time to

ensure that sufficient material is obtained for analysis. To obtain meaningful results from the chosen

laboratory, collect respirable dust samples for a minimum of five hours, and preferably during the entire

shift. Obviously, if conditions are such that dust loadings appear high, shorter collection times are

permitted, but sampling for at least five hours should be the goal.

Control Options

If the exposure approaches levels of respirable silica dust at or in excess of the TLV/PEL, consider

control options. Fundamental principles of industrial hygiene indicate that the most effective measures are

likely to be substitution of a less hazardous material for silica or the use of engineering controls to remove

respirable silica dust from the air.

Where possible, use effective engineering controls or other dust suppression methods to bring the

airborne levels of respirable crystalline silica below an acceptable exposure level, such as the proposed

TLV of 0.05 mg/m3.

In circumstances where, despite using the best technology, airborne levels of respirable crystalline silica

dust cannot be brought into compliance with the exposure limit, worker(s) must be protected adequately,

either through isolation of the employee(s) or through administrative controls. As a last resort, and as an

interim method to protect employee health, an appropriate respiratory protection program should be

implemented. Note that respirator users must comply with OSHA’s Respiratory Protection Standard (29

CFR 1910.134).

Exposed workers also need to receive regular medical evaluations to determine whether they are

developing adverse health effects. These examinations should include initial and periodic chest x-rays,

pulmonary function tests, and a complete physical examination. If medically warranted, it may be

necessary to remove a worker from the hazardous environment.

Eliminating the use of silica is possible in some industrial processes where a suitable, less toxic material

exists. The use of sand in abrasive blasting is one example of a process for which a number of substitutes

are available. Commercially available abrasives (such as Zeolite and “black beauty”) may be good

substitutes for sand. Substitutes should also be considered for the production and commercial use of silica

flour, the very finely divided, highly purified form of crystalline silica. Silica flour is often used as an

abrasive where other less toxic substitutes exist. In some instances, cristobalite can be replaced by similar

refractory materials that are less toxic.

In hard rock mining, quarrying, stone crushing, and heavy construction, workers are exposed to dusts

generated from naturally occurring quartz. In these circumstances, more stringent preventive measures

(e.g., wet methods, ventilation) are needed to minimize exposures and reduce the risk of silicosis.

Understanding Silica: Health Hazards, Standards, and Sampling Issues Page 4

© 2002 The Hartford Loss Control Department

TIPS S 580.480

References

1. National Institute of Occupational Safety and Health. Occupational Respiratory Diseases (NIOSH

86-102), “Silicosis” and “Acute Silicosis,” September 1986, pp. 219-241.

2. American Conference of Governmental Industrial Hygienists. Documentation of Threshold Limit

Values, Silica, Crystalline – various forms.

3. OSHA website, technical links, Silica-Crystalline (www.osha.gov).

4. Greaves, Ian, A. “Not-So-Simple Silicosis: A Case for Public Health Action,” American Journal of

Industrial Medicine 37: 245-251, 2000.

5. Chan, Chi Kuen, et al. “Lung Cancer Mortality Among a Cohort of Men in a Silicotic Register.”

Journal of Occupational and Environmental Medicine 42 (1): 69-75, January 2000.

6. National Institutes of Health. Eighth Report on Carcinogens. “Silica, Crystalline (Respirable Size).”

For more information, contact your local Hartford agent or your Hartford Loss Control Consultant.

Visit The Hartford’s Loss Control web site at http://www.thehartford.com/corporate/losscontrol/

This document is provided for information purposes only. It is not intended to be a substitute for individual legal counsel or advice on

issues discussed within. Readers seeking resolution of specific legal issues or business concerns related to the captioned topic

should consult their attorneys and/or insurance representatives.

Understanding Silica: Health Hazards, Standards, and Sampling Issues Page 5

© 2002 The Hartford Loss Control Department

TIPS S 580.480

You might also like

- The Adult Psychodiagnostic Chart 2012 1.7 PDFDocument3 pagesThe Adult Psychodiagnostic Chart 2012 1.7 PDFMF LeblancNo ratings yet

- Limestone MSDSDocument6 pagesLimestone MSDSSamuel GaétanNo ratings yet

- A Guide On Health Hazards & Their Control in Wafer Fabrication FacilitiesDocument42 pagesA Guide On Health Hazards & Their Control in Wafer Fabrication FacilitiesDarrenGCGNo ratings yet

- Silica VitreousDocument49 pagesSilica VitreousLuu XiaoNo ratings yet

- Bioceramic Materials in Clinical EndodonticsFrom EverandBioceramic Materials in Clinical EndodonticsSaulius DrukteinisNo ratings yet

- Silica Summary of Data Reported and Evaluation - WHO (IARC) PDFDocument24 pagesSilica Summary of Data Reported and Evaluation - WHO (IARC) PDFJuan Carlos Guerrero RNo ratings yet

- Silica Sand 2Document10 pagesSilica Sand 2Charles Dewey BandaNo ratings yet

- Chapter RDocument21 pagesChapter RmanoharandaNo ratings yet

- Abra 508Document23 pagesAbra 508Kiatchai IttivikulNo ratings yet

- Amorphous SilicaDocument2 pagesAmorphous SilicaAnteneh TadesseNo ratings yet

- 10 Must Knows Words Related To Silica DustDocument3 pages10 Must Knows Words Related To Silica DustGRTNo ratings yet

- Silicosis: SeminarDocument11 pagesSilicosis: SeminarFelipe Barbosa CordeiroNo ratings yet

- The MAK Collection For Occupational Health and Safety - 2012 - Silica Amorphous MAK Value Documentation 1991Document23 pagesThe MAK Collection For Occupational Health and Safety - 2012 - Silica Amorphous MAK Value Documentation 1991Anteneh TadesseNo ratings yet

- Crystalline Silica Final May 2013Document6 pagesCrystalline Silica Final May 2013Riston Belman SidabutarNo ratings yet

- Material Safety Data Sheet: Section 1 - Product Identification and Company IdentificationDocument9 pagesMaterial Safety Data Sheet: Section 1 - Product Identification and Company IdentificationecoscribdNo ratings yet

- Chemical Properties of SiliconDocument3 pagesChemical Properties of SiliconMuhammad Fajrul IkshanNo ratings yet

- Material Safety Data Sheet: MSDS: Limestone and DolomiteDocument6 pagesMaterial Safety Data Sheet: MSDS: Limestone and DolomiteMisr RaymondNo ratings yet

- Silicosis - UpToDateDocument44 pagesSilicosis - UpToDateyuliaNo ratings yet

- Silica EnglishDocument2 pagesSilica EnglishRatu PermataNo ratings yet

- Crystalline Silica Dust Determination in Limestone Aggregate Quarries in GreeceDocument6 pagesCrystalline Silica Dust Determination in Limestone Aggregate Quarries in GreeceIoannis KapageridisNo ratings yet

- MSDS - Tuff-Krete HD - Part DDocument6 pagesMSDS - Tuff-Krete HD - Part DAl GuinitaranNo ratings yet

- Life Cycle Inventory-Sodium SilicatesDocument6 pagesLife Cycle Inventory-Sodium SilicatessourabhtheoneNo ratings yet

- SilicappDocument10 pagesSilicappapi-217912133No ratings yet

- (International Journal of Occupational Medicine and Environmental Health) Occupational Exposure Assessment For Crystalline Silica Dust Approach in Poland and WorldwideDocument23 pages(International Journal of Occupational Medicine and Environmental Health) Occupational Exposure Assessment For Crystalline Silica Dust Approach in Poland and WorldwideRaden Ananda NurimanNo ratings yet

- Silicon Dioxide WikiDocument14 pagesSilicon Dioxide WikiSanchez Camargo MarioNo ratings yet

- MSDS C030 Silica Flour V - 0.3Document8 pagesMSDS C030 Silica Flour V - 0.3Cementation StimulationNo ratings yet

- QuartzDocument6 pagesQuartzaamarawanshaneelNo ratings yet

- Astm D7126Document2 pagesAstm D7126syarifuddin100% (2)

- Microelectronics L2 (Wafer Preperation)Document11 pagesMicroelectronics L2 (Wafer Preperation)algiteanNo ratings yet

- Silica SandDocument7 pagesSilica SandHuru HaraNo ratings yet

- Minerals 06 00121Document23 pagesMinerals 06 00121Mohammad Gulam KibriahNo ratings yet

- Worker Exposure To Silica During Countertop Manufacturing, Finishing and InstallationDocument8 pagesWorker Exposure To Silica During Countertop Manufacturing, Finishing and InstallationShahid BhattiNo ratings yet

- Silicosis An UpdateDocument14 pagesSilicosis An UpdateLaras KinasihNo ratings yet

- Silica in Construction: Kyle Horwarth CM 365 2/27/2019Document51 pagesSilica in Construction: Kyle Horwarth CM 365 2/27/2019Kyle HorwarthNo ratings yet

- Overview of Sol-Gel Science and Technology: by Sandra K. YoungDocument24 pagesOverview of Sol-Gel Science and Technology: by Sandra K. YoungFrank E. InscoreNo ratings yet

- Liquid Sodium SilicatesDocument5 pagesLiquid Sodium SilicatesJavad MousavyNo ratings yet

- Respiratory Diseases Among Dust Exposed WorkersDocument19 pagesRespiratory Diseases Among Dust Exposed WorkersAR MalikNo ratings yet

- All 14202Document13 pagesAll 14202sukiyantoNo ratings yet

- Rapid Set Repair MaterialDocument7 pagesRapid Set Repair Materialsam damsNo ratings yet

- Use of Coagulants To Reduce Crud by Colloidal SilicaDocument11 pagesUse of Coagulants To Reduce Crud by Colloidal SilicaJose Eduardo Osuna AraizaNo ratings yet

- REACH Safety Information Sheet For StainlessDocument11 pagesREACH Safety Information Sheet For StainlessShaik Mohammed HaikhalNo ratings yet

- Material Safety Data Sheet For CementDocument6 pagesMaterial Safety Data Sheet For Cementjohan tindiNo ratings yet

- PresentationDocument10 pagesPresentationapi-348897864No ratings yet

- Geological Overview of Whitesilica SandsDocument38 pagesGeological Overview of Whitesilica SandsenjaegerNo ratings yet

- Guide Printing - Business and Industry - Queensland GovDocument23 pagesGuide Printing - Business and Industry - Queensland GovIvanRomanovićNo ratings yet

- BlastingDocument4 pagesBlastingvinaye212No ratings yet

- Environmental Management in Indian Chlor-Alkali IndustriesDocument28 pagesEnvironmental Management in Indian Chlor-Alkali Industriessivas54No ratings yet

- Chloride Stress Corrosion Cracking of 300 Series Stainless SteelDocument5 pagesChloride Stress Corrosion Cracking of 300 Series Stainless SteelhboodhaiNo ratings yet

- Crystalline Silica Dust 2Document2 pagesCrystalline Silica Dust 2Serdal SözüneerNo ratings yet

- Msds p500 NagpurDocument7 pagesMsds p500 NagpurAnkur BarsainyaNo ratings yet

- Occupational Health Aspects of Quartz in Bituminous Coal Fly Ash in Israel 2009Document21 pagesOccupational Health Aspects of Quartz in Bituminous Coal Fly Ash in Israel 2009Rani Nasrasyam ZalmaNo ratings yet

- SilicosisDocument1 pageSilicosisAlvin Garcia PalancaNo ratings yet

- Politehnica University of Bucharest Faculty of Engineering in Foreign LanguagesDocument5 pagesPolitehnica University of Bucharest Faculty of Engineering in Foreign LanguagesLuizaNo ratings yet

- 41 - 2 - New Orleans - 03-96 - 0568Document6 pages41 - 2 - New Orleans - 03-96 - 0568gloriaNo ratings yet

- Part A-12-Wood Dust Allergies - Q&ADocument8 pagesPart A-12-Wood Dust Allergies - Q&Afernanda1rondelliNo ratings yet

- Czochralski Process - Wikipedia, The Free Encyclopedia PDFDocument5 pagesCzochralski Process - Wikipedia, The Free Encyclopedia PDFSaikat PayraNo ratings yet

- MSDS Cementitous Materials SafetyDocument6 pagesMSDS Cementitous Materials SafetyMade YennyNo ratings yet

- Basics On SiliconeDocument70 pagesBasics On Siliconesmritinarayan100% (2)

- Material Safety Data Sheet: (Granite)Document4 pagesMaterial Safety Data Sheet: (Granite)paNo ratings yet

- Calicium Silicate InsulationDocument2 pagesCalicium Silicate Insulationrajkamal eshwarNo ratings yet

- Concentration, Sources and Health Effects of Silica in Ambient Respirable Dust of Jharia Coalfields Region, IndiaDocument11 pagesConcentration, Sources and Health Effects of Silica in Ambient Respirable Dust of Jharia Coalfields Region, IndiaLabManager ESPAKNo ratings yet

- PDS Technofoam PT 01 - HFC-1Document2 pagesPDS Technofoam PT 01 - HFC-1Ahmed FoudaNo ratings yet

- 10.1002 Macp.201000748Document33 pages10.1002 Macp.201000748Ahmed FoudaNo ratings yet

- PDS Technofoam PT 01 - Hfc.Document2 pagesPDS Technofoam PT 01 - Hfc.Ahmed FoudaNo ratings yet

- 400 Q PDFDocument91 pages400 Q PDFAhmed FoudaNo ratings yet

- NT90004212Document58 pagesNT90004212Jelena ĆukNo ratings yet

- Chapter 1Document62 pagesChapter 1Ashenafi PaulosNo ratings yet

- Social Science Class 10 Understanding Economic DevelopmentDocument93 pagesSocial Science Class 10 Understanding Economic DevelopmentkannansesNo ratings yet

- CV - Mahbub MishuDocument3 pagesCV - Mahbub MishuMahbub Chowdhury MishuNo ratings yet

- Herbicides ToxicityDocument51 pagesHerbicides ToxicityAdarshBijapurNo ratings yet

- The Pale Blood HuntDocument92 pagesThe Pale Blood HuntRafael JunioNo ratings yet

- Organ SystemsDocument2 pagesOrgan SystemsArnel LaspinasNo ratings yet

- Steps To Reduce Drug Abuse 1800 11 0031 National Toll Free Drug de Addiction Helpline NumberDocument4 pagesSteps To Reduce Drug Abuse 1800 11 0031 National Toll Free Drug de Addiction Helpline NumberimranNo ratings yet

- Neurobiologic Theories and PsychopharmacologyDocument2 pagesNeurobiologic Theories and Psychopharmacologymyer pasandalanNo ratings yet

- Centrifugal ChillerDocument24 pagesCentrifugal ChillerARUL SANKARANNo ratings yet

- HS-Rev.00 Hazardous Substance - Chemical Assessment SheetDocument2 pagesHS-Rev.00 Hazardous Substance - Chemical Assessment Sheetlim kang haiNo ratings yet

- Dapus FixDocument2 pagesDapus FixIkrima MuhdarmuhallyNo ratings yet

- DR John Chew (SPMPS President) PresentationDocument50 pagesDR John Chew (SPMPS President) PresentationdrtshNo ratings yet

- What Is ISO 22000 S. 2005?: An OverviewDocument23 pagesWhat Is ISO 22000 S. 2005?: An OverviewMario Norman B. CelerianNo ratings yet

- PHIL 125: Practical Logic: University of Alberta Sam Hillier, Fall 2013Document12 pagesPHIL 125: Practical Logic: University of Alberta Sam Hillier, Fall 2013Harry WeiNo ratings yet

- MENTAL HEALTH NURSING ExamDocument5 pagesMENTAL HEALTH NURSING ExamSurkhali BipanaNo ratings yet

- Pitbull StatementDocument4 pagesPitbull StatementThe Citizen NewspaperNo ratings yet

- Climbing Training Log - TemplateDocument19 pagesClimbing Training Log - TemplateKam Iqar ZeNo ratings yet

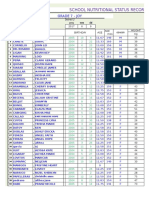

- School Nutritional Status Record: Grade 7 - JoyDocument4 pagesSchool Nutritional Status Record: Grade 7 - JoySidNo ratings yet

- Darrells ResumeDocument5 pagesDarrells Resumeapi-273253154No ratings yet

- PSC Question BankDocument9 pagesPSC Question BankFaisal qblp100% (29)

- Aeon 4000 SDSDocument13 pagesAeon 4000 SDSmarcos luqueNo ratings yet

- Export of SpicesDocument57 pagesExport of SpicesJunaid MultaniNo ratings yet

- Eular References For Website 2015Document240 pagesEular References For Website 2015Antonio BernalNo ratings yet

- Et CareDocument15 pagesEt CarePaulo GarciaNo ratings yet

- Bioethics SeminarDocument1 pageBioethics Seminarapi-24500288No ratings yet

- Sterile Potassium Chloride 10%, 15% and 20% W/V Concentrate For Solution For InfusionDocument1 pageSterile Potassium Chloride 10%, 15% and 20% W/V Concentrate For Solution For InfusionMatthew ParsonsNo ratings yet

- Dunkin DonutsDocument2 pagesDunkin DonutszerpthederpNo ratings yet

- DSM 5Document33 pagesDSM 5Grace Marie100% (2)