0% found this document useful (0 votes)

62 views6 pagesAssembly Manpower

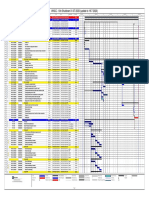

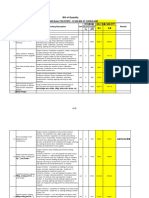

The document provides details of the fabrication process for a boiler, including 26 steps and estimated man hours and costs for each. It lists fabrication tasks like positioning parts, welding panels and pipes, hydrotesting, and loading the completed boiler onto a truck. It also provides estimated man hours and costs for the roles of fabricator, welder, rigger, helper and QA/QC personnel for each step.

Uploaded by

Akil PrabhuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

62 views6 pagesAssembly Manpower

The document provides details of the fabrication process for a boiler, including 26 steps and estimated man hours and costs for each. It lists fabrication tasks like positioning parts, welding panels and pipes, hydrotesting, and loading the completed boiler onto a truck. It also provides estimated man hours and costs for the roles of fabricator, welder, rigger, helper and QA/QC personnel for each step.

Uploaded by

Akil PrabhuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd