Professional Documents

Culture Documents

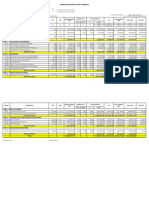

LABOR AND MATERIAL COST BREAKDOWN

Uploaded by

Akil PrabhuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LABOR AND MATERIAL COST BREAKDOWN

Uploaded by

Akil PrabhuCopyright:

Available Formats

MATERIAL LABOR TOTALS

Cost Unit

Unit Material Total Labor Labor Labor Craft Labor Total Total Overhead Sub Cntng Cntng Totals

Description Meas No. Basis Cost Material No. Unit Total Code Rate Labor Labor + Total Total % K$ K$

Units K$ Units Hours Hours $/Hr. K$ Material (LBNL)

NEXT-100 732.6 1,212.1 176.0 1,388.1 22% 304.7 1,693

1 LBNL Contributions 309.2 5,228.0 435.5 744.7 176.0 920.7 25% 232.8 1,153.4

1.1 EDI ( Engineering, Design, Integration) 0.0 2,480.0 222.1 222.1 69.1 291.1 17% 48.5 339.6

1.1.1 Project Integration pe 0.0 1 200 200 ME 94.69 18.9 18.9 5.9 24.8 15% 3.7 28.6

1.1.2 Pressure Vessel Design pe 0.0 1 200 200 ME 94.69 18.9 18.9 5.9 24.8 15% 3.7 28.6

1.1.3 Pressure Vessel Specification pe 0.0 1 160 160 ME 94.69 15.2 15.2 4.7 19.9 15% 3.0 22.8

1.1.4 Pressure Vessel Fab Supervision pe 0.0 1 160 160 ME 94.69 15.2 15.2 4.7 19.9 15% 3.0 22.8

1.1.5 Pressure Vessel Assembly pe 0.0 1 160 160 ME 94.69 15.2 15.2 4.7 19.9 15% 3.0 22.8

1.1.6 Energy Plane Mechanical Design (Cans, PMT bases, cable conduits) pe 0.0 1 200 200 ME 94.69 18.9 18.9 5.9 24.8 15% 3.7 28.6

1.1.7 Field Cage Design (assist TAMU) pe 0.0 1 200 200 ME 94.69 18.9 18.9 5.9 24.8 15% 3.7 28.6

1.1.8 HV feedthrough Design (assist TAMU) pe 0.0 1 100 100 ME 94.69 9.5 9.5 2.9 12.4 15% 1.9 14.3

1.1.9 Tracking Plane Module Design pe 0.0 1 600 600 EE 95.55 57.3 57.3 17.8 75.2 15% 11.3 86.4

1.1.10 " pe 0.0 1 400 400 EI 61.46 24.6 24.6 7.6 32.2 30% 9.7 41.9

1.1.11 Electroluminescent (EL) Plane Design (assist TAMU) pe 0.0 1 100 100 ME 94.69 9.5 9.5 2.9 12.4 15% 1.9 14.3

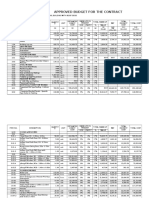

1.2 Energy Plane 196.7 1,848.0 158.1 354.8 75.0 429.8 29% 124.3 554.1

1.2.1 Procurements 173.3 173.3 22.7 196.0 28% 54.2 250.2

1.2.1.1 Sapphire Windows ea 80 vq 1000 80.0 80.0 10.5 90.5 30% 27.1 117.6

1.2.1.2 ITO coating ea 80 vq 100 8.0 8.0 1.0 9.0 20% 1.8 10.9

1.2.1.3 PMTs ea 66 vq 0 0.0 0.0 0.0 0.0 15% 0.0 0.0

1.2.1.4 Helicoflex gaskets ea 140 cp 200 28.0 28.0 3.7 31.7 30% 9.5 41.2

1.2.1.5 PMT base boards and components ea 70 cp 300 21.0 21.0 2.8 23.8 30% 7.1 30.9

1.2.1.6 Test Pressure Vessel components ea 1 cp 1000 1.0 1.0 0.1 1.1 30% 0.3 1.5

1.2.1.7 LED light sources ea 3 cp 100 0.3 0.3 0.0 0.3 10% 0.0 0.4

1.2.1.8 PMT cable Feedthroughs (BNC floating shield 2500VDC ea 65 cp 215 14.0 14.0 1.8 15.8 30% 4.7 20.5

1.2.1.9 Bolts, Shims and Misc. Parts lot 1 pe 1000 1.0 1.0 0.1 1.1 30% 0.3 1.5

1.2.1.10 Cold trap, valves, plumbing and scaffolding for recovery system lot 1 pe 3000 3.0 3.0 0.4 3.4 10% 0.3 3.7

1.2.1.11 Vacuum pump lot 1 pe 3000 3.0 3.0 0.4 3.4 30% 1.0 4.4

1.2.1.12 Helium leak detector lot 1 pe 10000 10.0 10.0 1.3 11.3 10% 1.1 12.4

1.2.1.13 Deuterium light source lot 1 pe 4000 4.0 4.0 0.5 4.5 15% 0.7 5.2

1.2.2 Fabrications 23.4 1,072.0 93.7 117.1 32.2 149.3 30% 44.8 194.0

1.2.2.1 Can Prototype lot 1 se 500 0.5 1 40 40 MS 87.38 3.5 4.0 1.2 5.1 30% 1.5 6.7

1.2.2.2 Test Pressure Vessel lot 1 se 400 0.4 1 40 40 MS 87.38 3.5 3.9 1.1 5.0 30% 1.5 6.5

1.2.2.3 Cans and Lids lot 64 se 200 12.8 64 8 512 MS 87.38 44.7 57.5 15.6 73.1 30% 21.9 95.1

1.2.2.4 PMT heat sinks and base prep lot 64 se 50 3.2 64 1 64 MS 87.38 5.6 8.8 2.2 11.0 30% 3.3 14.2

1.2.2.5 Carrier plate lot 1 se 500 0.5 1 80 80 MS 87.38 7.0 7.5 2.2 9.7 30% 2.9 12.6

You might also like

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Statement of Work AccomplishedDocument29 pagesStatement of Work AccomplishedElline FernandoNo ratings yet

- Approved Budget Cost: I. Stage 1Document66 pagesApproved Budget Cost: I. Stage 1Joel King AzaresNo ratings yet

- 1.1 Construction Progress Up To March 2023Document18 pages1.1 Construction Progress Up To March 2023Pavana KarraNo ratings yet

- Construction of Warehouse in Support To The Dried Cacao Beans Production and MarketingDocument7 pagesConstruction of Warehouse in Support To The Dried Cacao Beans Production and Marketingcarl_orbeNo ratings yet

- Approved Budget For The Contract: Nueva Ecija By-Pass Road ProjectDocument2 pagesApproved Budget For The Contract: Nueva Ecija By-Pass Road ProjectZoilo PaynorNo ratings yet

- Pow 17J00009Document3 pagesPow 17J00009amroussyNo ratings yet

- Slaughter Compound 1.98MDocument2 pagesSlaughter Compound 1.98Mrodelbaon010824No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Pipeline welding consumable calculation sheetDocument10 pagesPipeline welding consumable calculation sheetkeymal9195No ratings yet

- Barzan Templates and Jackets Offshore EPC PMT Costs With Annual Split by Venture - 28 Feb 2008Document5 pagesBarzan Templates and Jackets Offshore EPC PMT Costs With Annual Split by Venture - 28 Feb 2008MarkyNo ratings yet

- Pow 17J00012Document41 pagesPow 17J00012amroussyNo ratings yet

- CE Roby PrimaDocument158 pagesCE Roby PrimaPutri Nikmatulhusna joesrilNo ratings yet

- Gantry Crane-2 (Pyramid Steel Structures Factory) Cost SheetDocument15 pagesGantry Crane-2 (Pyramid Steel Structures Factory) Cost SheetAdeeb ShahzadaNo ratings yet

- Plantilla DimensionamientoDocument243 pagesPlantilla Dimensionamientolaura DuranNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- ScribdDocument13 pagesScribddieeegoix09No ratings yet

- Werner - Financial Model - Final VersionDocument2 pagesWerner - Financial Model - Final VersionAmit JainNo ratings yet

- Lithium-Ion Capacity and CostDocument1 pageLithium-Ion Capacity and CosthuskyjackNo ratings yet

- FCFF Vs FCFE Reconciliation TemplateDocument2 pagesFCFF Vs FCFE Reconciliation TemplateLalit KheskwaniNo ratings yet

- FCFF Vs FCFE Reconciliation Template: Strictly ConfidentialDocument2 pagesFCFF Vs FCFE Reconciliation Template: Strictly ConfidentialvishalNo ratings yet

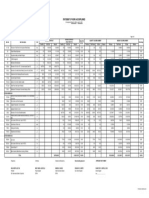

- Summary of Budget For The ContactDocument4 pagesSummary of Budget For The ContactAbusakur HamsaniNo ratings yet

- 9 10. Man Power Equipment ScheduleDocument117 pages9 10. Man Power Equipment ScheduleAngie Lee RomanillosNo ratings yet

- RTKLIB - Porting For Beagle BoardDocument11 pagesRTKLIB - Porting For Beagle Boardwhat zegjeNo ratings yet

- RM CostDocument10 pagesRM CostAndiNo ratings yet

- Weld Consumable Calculation SummaryDocument10 pagesWeld Consumable Calculation SummaryAhmad KamilNo ratings yet

- Road Widening Contract SummaryDocument37 pagesRoad Widening Contract SummaryDennis SagaoNo ratings yet

- Cost Estimate for Platforms and RoadsDocument13 pagesCost Estimate for Platforms and Roadsnaveen yadavNo ratings yet

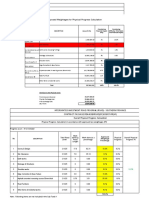

- Proposed Weightages For Physical Progress CalculationDocument2 pagesProposed Weightages For Physical Progress Calculationjayanath nccNo ratings yet

- Resumo Obra Area Sem109Document13 pagesResumo Obra Area Sem109eng_saNo ratings yet

- Experiments (tutorial)Document24 pagesExperiments (tutorial)BAlaNo ratings yet

- Engr. Agatep Engineering Services: Project Title: Proposed Evaporative Condenser Tower (Catwalks, Monkey Lader)Document2 pagesEngr. Agatep Engineering Services: Project Title: Proposed Evaporative Condenser Tower (Catwalks, Monkey Lader)Eli NaguitNo ratings yet

- BOQ - Construction of Power Transmission - Distribution LineDocument14 pagesBOQ - Construction of Power Transmission - Distribution LineDexter QuébecNo ratings yet

- Itemized Cost Revision for Road Improvement Project in Misamis OccidentalDocument1 pageItemized Cost Revision for Road Improvement Project in Misamis OccidentalabigailNo ratings yet

- BBU - Civil FinalDocument2 pagesBBU - Civil FinalRajat KoleyNo ratings yet

- Construction Budget for Multi-Purpose Community CenterDocument60 pagesConstruction Budget for Multi-Purpose Community CenterArjay AletaNo ratings yet

- Cash - Cost - EBITDA 2017-2022 FVDocument7 pagesCash - Cost - EBITDA 2017-2022 FVJulian Brescia2No ratings yet

- New Items and Escalation Due To Which Estimate Has Been Revised (160 KMPH DHN Division)Document2 pagesNew Items and Escalation Due To Which Estimate Has Been Revised (160 KMPH DHN Division)Abhishek JaiswalNo ratings yet

- Leg en D: Construction Project ScheduleDocument6 pagesLeg en D: Construction Project ScheduleSimplicio GoncalvesNo ratings yet

- Project Monitoring - ALL Rev 2.1Document39 pagesProject Monitoring - ALL Rev 2.1Moch FaridNo ratings yet

- Weekly Prod Yance&Leon w36 August 2021 Sej RTTKDocument5 pagesWeekly Prod Yance&Leon w36 August 2021 Sej RTTKTeguh SiswantoNo ratings yet

- Swa1 3Document2 pagesSwa1 3Jezreel FlotildeNo ratings yet

- Pow 17J00072Document47 pagesPow 17J00072Joseph MontalesNo ratings yet

- Dividend Stocks ListDocument4 pagesDividend Stocks ListAnjaiah PittalaNo ratings yet

- FCFF vs. FCFE CompletedDocument1 pageFCFF vs. FCFE CompletedPragathi T NNo ratings yet

- 04 - LoEPP LVM Summary Grid November 2023Document2 pages04 - LoEPP LVM Summary Grid November 2023Bati BotNo ratings yet

- Inlet HR Bar Schedule On WSC 1-p. 1-1Document8 pagesInlet HR Bar Schedule On WSC 1-p. 1-1Benka Korso Waqo SonNo ratings yet

- Evaluation Report Summary For PB02 - PTV Pagadian - Rev1Document42 pagesEvaluation Report Summary For PB02 - PTV Pagadian - Rev1Wesley DahiliNo ratings yet

- APPROVED BUDGET FOR CONSTRUCTION OF DIVERSION ROADDocument48 pagesAPPROVED BUDGET FOR CONSTRUCTION OF DIVERSION ROADamroussyNo ratings yet

- Service Utility Support - 2Document21 pagesService Utility Support - 2marklesterNo ratings yet

- Arbor Lanes Phase 2 - Tower 3: Mango Road, Taguig City: Structural WorksDocument3 pagesArbor Lanes Phase 2 - Tower 3: Mango Road, Taguig City: Structural WorksCyril BayugaNo ratings yet

- CSR SamnaabadDocument11 pagesCSR Samnaabadikhtiyar ali khan ikhtiyarNo ratings yet

- Weekly Report No. 40 FinalDocument1 pageWeekly Report No. 40 FinalOs ManNo ratings yet

- Shed GanttDocument1 pageShed GanttPatrick FanogaNo ratings yet

- Drainage of Las PinasDocument64 pagesDrainage of Las PinasJoji BorromeoNo ratings yet

- Pasalubong Center CADDocument92 pagesPasalubong Center CADVanjerric VillabezaNo ratings yet

- Column Design ReportDocument30 pagesColumn Design Reportokechukwu1benjaminNo ratings yet

- SWA Final BillingDocument1 pageSWA Final BillingJezreel FlotildeNo ratings yet

- SummaryDocument2 pagesSummaryMomie MarquezNo ratings yet

- Worker RequirementDocument1 pageWorker RequirementAkil PrabhuNo ratings yet

- SN Description Total Cost in SAR Mark-Up Sell Price in SAR: Project Risk Pool and InterestDocument1 pageSN Description Total Cost in SAR Mark-Up Sell Price in SAR: Project Risk Pool and InterestAkil PrabhuNo ratings yet

- Finance CostDocument1 pageFinance CostAkil PrabhuNo ratings yet

- Assembly ManpowerDocument6 pagesAssembly ManpowerAkil PrabhuNo ratings yet

- Commercial EstimationDocument1 pageCommercial EstimationAkil PrabhuNo ratings yet

- SN Contingency/Risk % Cost in SAR Cost in USD: Project Risk Pool and InterestDocument1 pageSN Contingency/Risk % Cost in SAR Cost in USD: Project Risk Pool and InterestAkil PrabhuNo ratings yet

- Hydro Test Blind Thickness ChartDocument1 pageHydro Test Blind Thickness ChartAkil Prabhu100% (1)

- Hydro Test Volume Tube Side Left Channel HeadDocument1 pageHydro Test Volume Tube Side Left Channel HeadAkil PrabhuNo ratings yet

- Risk AssesmentDocument1 pageRisk AssesmentAkil PrabhuNo ratings yet

- Electrical Load List for Manufacturing FacilityDocument1 pageElectrical Load List for Manufacturing FacilityAkil PrabhuNo ratings yet

- ASME Calc For Blind FlangeDocument2 pagesASME Calc For Blind FlangeAkil PrabhuNo ratings yet

- ASME Blind Thickness Calculation UG-34Document2 pagesASME Blind Thickness Calculation UG-34Akil PrabhuNo ratings yet

- Material Pipe ListDocument1 pageMaterial Pipe ListAkil PrabhuNo ratings yet

- SL No. Description Material Length M PipesDocument2 pagesSL No. Description Material Length M PipesAkil PrabhuNo ratings yet

- Project Site ARCDocument1 pageProject Site ARCAkil PrabhuNo ratings yet

- Site Load ListDocument1 pageSite Load ListAkil PrabhuNo ratings yet

- Nooter ScopDocument1 pageNooter ScopAkil PrabhuNo ratings yet

- Ammonia Secondary Reforming: By: Gerard B. Hawkins Managing Director, CEODocument10 pagesAmmonia Secondary Reforming: By: Gerard B. Hawkins Managing Director, CEObenonNo ratings yet

- Estiamte For ConstDocument1 pageEstiamte For ConstAkil PrabhuNo ratings yet

- Tube BomDocument1 pageTube BomAkil PrabhuNo ratings yet

- Fabrication site layout and equipment guideDocument1 pageFabrication site layout and equipment guideAkil PrabhuNo ratings yet

- Aop 299314 PDFDocument8 pagesAop 299314 PDFAkil PrabhuNo ratings yet

- Estiamte For LaborDocument1 pageEstiamte For LaborAkil PrabhuNo ratings yet

- Post Weld Heat TreatmentDocument2 pagesPost Weld Heat TreatmentgullenariNo ratings yet

- Ammoniaplantflowsheets 130728184016 Phpapp02 PDFDocument22 pagesAmmoniaplantflowsheets 130728184016 Phpapp02 PDFPeter LiNo ratings yet

- Ammonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEODocument33 pagesAmmonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOAkil PrabhuNo ratings yet

- Design of Boiler Welding For Improvement of LifetiDocument16 pagesDesign of Boiler Welding For Improvement of LifetiAkil PrabhuNo ratings yet

- A Review On Effect of Preheating And/Or Post Weld Heat Treatmemt (PWHT) On Mechanical Behaviour of Ferrous MetalsDocument7 pagesA Review On Effect of Preheating And/Or Post Weld Heat Treatmemt (PWHT) On Mechanical Behaviour of Ferrous MetalsNagarajan PitchandiNo ratings yet

- Welding of Boilers PDFDocument16 pagesWelding of Boilers PDFValentin JonovNo ratings yet

- NBS MonographDocument392 pagesNBS MonographmeloszNo ratings yet

- Well Completion and Stimulation - Chapter 3 Well Performance Analysis-NewDocument56 pagesWell Completion and Stimulation - Chapter 3 Well Performance Analysis-NewsouthliNo ratings yet

- Compositional SimulationDocument35 pagesCompositional SimulationKellen Sanchez100% (1)

- Water Chemistry & DM Plant Rev00Document27 pagesWater Chemistry & DM Plant Rev00AbhiNo ratings yet

- Proposal For Extracting A Drip Irrigation System and ImplementingDocument36 pagesProposal For Extracting A Drip Irrigation System and ImplementingEngr Muhammad Asif Javaid0% (1)

- Gas compressibility factors and propertiesDocument3 pagesGas compressibility factors and propertiesjhchung111No ratings yet

- Neer Project ReportDocument2 pagesNeer Project ReportanimeshbariarNo ratings yet

- Managing Salinity and Waterlogging in The Indus IgcseDocument11 pagesManaging Salinity and Waterlogging in The Indus Igcsecottoncandy1010No ratings yet

- Pressure Vessel Sample CalculationsDocument25 pagesPressure Vessel Sample Calculationsmdreza2001100% (12)

- Module 2 Bernoulli's Equation - ME 319-ME32S3 - Fluid MachineriesDocument8 pagesModule 2 Bernoulli's Equation - ME 319-ME32S3 - Fluid MachineriesOkay Printing100% (1)

- Index: Sr. No. Content Page NoDocument13 pagesIndex: Sr. No. Content Page Nokirti pawarNo ratings yet

- NB 95 - 1) N2 Plan ManualDocument31 pagesNB 95 - 1) N2 Plan Manualionut nicolaeNo ratings yet

- Chlorine Liquefaction ReportDocument12 pagesChlorine Liquefaction ReportPavithran50% (2)

- Compressor power simplified formula explained step-by-stepDocument3 pagesCompressor power simplified formula explained step-by-stepSantosh JayasavalNo ratings yet

- Humidity Conversion Formulas Technical Ebook B210973ENDocument16 pagesHumidity Conversion Formulas Technical Ebook B210973ENarjunchouhan.proNo ratings yet

- Materials Moving Molecules: Membrane DehumidificationDocument2 pagesMaterials Moving Molecules: Membrane DehumidificationSobiyaNo ratings yet

- Group 1Document13 pagesGroup 1MahmudaNo ratings yet

- Refrigeration CapoteDocument51 pagesRefrigeration CapoteMichelle Angela Cabrera GabisNo ratings yet

- Flowmeter DemonstrationDocument24 pagesFlowmeter DemonstrationNajwa Ghazali100% (16)

- W-4, Chap.3-Properties of Pure Substances-2Document31 pagesW-4, Chap.3-Properties of Pure Substances-2سيمو بشيريNo ratings yet

- TCWY PROFILE General PDFDocument36 pagesTCWY PROFILE General PDFhendntdNo ratings yet

- Sewage Sludge GasificationDocument96 pagesSewage Sludge GasificationSupp PrakobkitNo ratings yet

- Lecture 25Document4 pagesLecture 25216435964No ratings yet

- Pump Calculations EquationDocument3 pagesPump Calculations EquationToan LeNo ratings yet

- Water Resources EngineeringDocument3 pagesWater Resources EngineeringSai Charishma100% (1)

- Aeration and Mass Transfer: N DA DC Dy N A Dc/dy DDocument46 pagesAeration and Mass Transfer: N DA DC Dy N A Dc/dy DCamilo Esteban Soto SarayNo ratings yet

- Part II Cases of Piperazine-Activated MDEA and Generic MDEADocument2 pagesPart II Cases of Piperazine-Activated MDEA and Generic MDEAShailesh LohareNo ratings yet

- Water - Dynamic and Kinematic ViscosityDocument2 pagesWater - Dynamic and Kinematic ViscosityjpkedahNo ratings yet

- JC API Plans PosterDocument1 pageJC API Plans PosterDumitrescuNo ratings yet

- MIE210 Property TablesDocument26 pagesMIE210 Property TablesAshraful A. KhanNo ratings yet