Professional Documents

Culture Documents

Written Assesment in Splicing - Joining Electrical Conductor

Uploaded by

MARY ANN NUCEJAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Written Assesment in Splicing - Joining Electrical Conductor

Uploaded by

MARY ANN NUCEJACopyright:

Available Formats

Splicing/Joining

Electrical Conductor

Written Assessment

TECHNICAL EDUCATION AND SKILLS DEVELOPMENT AUTHORITY

Qualifications and Standards Office – Curriculum and Training Aids Division

Information Sheet 01

Identifying Splices and Joints

1. Joining and splicing of electrical conductor plays a very important role in the field of

electricity. Some experts say, “there is no better conductor than the unjoined or unspliced

conductor”, unfortunately, any wiring installation is impossible to accomplish without cutting

the conductor for a certain length and then join or splice together afterwards to satisfy the

desired connection for the operation of the circuitry. Therefore, an electrician must be

equipped with proper technical skills in this activity

2. The Philippine Electrical Code relative to electrical joints and splices specifies that conductors

must be spliced or joined as to both mechanically and electrically secure prior to soldering.

3. The code emphasizes that the joint or splice must be secured mechanically and electrically.

Loose connection due to improper joining/splicing of conductor may lead to a big problem a

few months after the commissioning, especially if the spliced conductor carries huge amount of

electric current. The connection will generate heat that will cause the joined conductor to

expand and thereby increasing the gap between the surfaces which then lead to arcing.

4. Joint is the tying together of two single

wire conductors so that the union will be

good both mechanically and electrically.

5. Splice is the interlaying of the strands of

two stranded conductors so that the

union will be good both mechanically

and electrically.

6. Rat Tail or Pig Tail - This kind of joint

is commonly used to joint two or more

conductor inside the junction box. It is

suitable for service where there is no

mechanical stress as where wires are to

be connected in an outlet box, switch or

conduit fitting.

Learning Element: Splicing/Joining Electrical Conductor 2

Information Sheet 01

7. Bell Hanger’s Joint (Western Union

Short Tie). This joint is commonly used

to join continuous run conductor where

the tensile stress is not too great, such as

conductors inside conduit bodies.

8. Western Union Long Tie - The

modified form of bell hanger’s joint,

made in the same way as the latter with

the exception that a number of twists is

to make it more efficient mechanically

as the tensile stress brought on this joint

is considerable.

9. Turn Back Joint (Through Fixture

Joint) - This joint is use to connect two

continuous run conductor under extreme

tension.

10. Duplex Joint - Duplex wire joint is used

where twin wire is employed, that is

two-wire cables. It consists of two bell

hanger’s joints spaced so that they do

not come opposite each other.

11. Tap Joint - Tap is the connection of the

end of one wire to some point along the

run of another wire. There are various

taps to meet different conditions.

12. Plain tap joint-is use where the tap wire

is under considerable tensile stress.

13. Knotted Tap-is used where the tap wire

is under heavy tensile stress.

14. Aerial Tap-is used as temporary taps

usually done in constructions sites. The

easy twist will facilitate tap wire

Learning Element: Splicing/Joining Electrical Conductor 3

Information Sheet 01

movement.

15. Double cross joint-the same application

as plain tap do, the only difference is

that this tap a combination of two plain

taps place side by side with each other..

16. Duplex cross joint-a two tap wire turned

simultaneously and is used where the

two tap wire is under heavy tensile

stress.

17. Running Butt Splice - Running butts

link to splices formed by butting

together the end of two cable lengths to

extend the run or length of circuit.

Running butt splices are classified as

single wrapped splice and multi

wrapped splice.

18. Single Wrapped Splice This splice is

used for large wire (14 mm2 and larger)

because it is easier to wrapped a single

wire at a turn than to wrapped them all

at once.

19. Multi Wrapped Splice - This method

of wrapping is generally used on small

cables because the strands are flexible

and all can be wrapped in one operation.

A three strand cable is selected so as to

clearly show the method of wrapping

Learning Element: Splicing/Joining Electrical Conductor 4

Information Sheet 01

20. Tap Splices - These are made when the

end of one stranded conductor is to be

connected at some point along the run of

another stranded conductor. They are

classified as ordinary, split and y-splice.

21. Ordinary tap splice

22. Split tap splice-This splice is used for

large wire (14 mm2 and larger) because

it is easier to wrapped a single wire at a

turn than to wrapped them all at once.

23. Y-splice- This method of wrapping is

generally used on small cables because

the strands are flexible and all can be

wrapped in one operation.

Learning Element: Splicing/Joining Electrical Conductor 5

Self Check 01

Identifying Splices and joints

IDENTIFICATION:

Direction: Identify the following splices and joints and describe their applications.

1. 2.

3. 4.

5. 6.

7. 8.

9. 10.

11. 12.

Learning Element: Splicing/Joining Electrical Conductor 6

Information Sheet 02

Stripping Electrical Conductor

1. In preparing insulated conductors for

making joints or splices, the insulation must

first be removed from each conductor a

proper distance depending upon the type of

joint or splice to be made.

2. For smaller size of wires a wire stripper can

be use to remove the insulation.

3. A stripping knife or electrician knife can be

use to remove insulation of bigger

conductors.

4. When using electrician’s knife, hold the

blade so that it will lie almost flat with

the wire to avoid groove or nicking.

NOTE: Don't stretch the insulation

when you are stripping the

conductors otherwise the

stretched part will be thinner

and give less insulation

protection.

Learning Element: Splicing/Joining Electrical Conductor 7

Information Sheet 02

5. The stripped conductor should look like

this.

6. Do not place the blade of the knife

perpendicular to the conductor.

7. The groove or nick lessens the ampacity

of the conductor.

8. The conductor will be cut easily through

accidental bending during joining or

splicing

9. Scrape or clean the surface of the

conductor lightly with the knife to

ensure good contact between wires.

Learning Element: Splicing/Joining Electrical Conductor 8

Job Sheet 08

Learning Element: Splicing/Joining Electrical Conductor 9

You might also like

- 1st Quarter Examination in MAPEH 10 Final Docx - 100242Document6 pages1st Quarter Examination in MAPEH 10 Final Docx - 100242Punang National High School 309166No ratings yet

- 2 Quarter Summative Assessment 2 in Mapeh 10: Name: - Grade/Section: - ScoreDocument4 pages2 Quarter Summative Assessment 2 in Mapeh 10: Name: - Grade/Section: - ScoreKate MaryNo ratings yet

- 2nd Quarter MAPEH 10Document12 pages2nd Quarter MAPEH 10Celia Rose Dumile LingayaNo ratings yet

- 2ndQ Pandemic Summative Test in MAPEH-10Document4 pages2ndQ Pandemic Summative Test in MAPEH-10Reymundo PenialaNo ratings yet

- Mapeh ReviewerDocument9 pagesMapeh ReviewerJulianne FNo ratings yet

- Mine Gases (Part 1)Document15 pagesMine Gases (Part 1)Melford LapnawanNo ratings yet

- Bid Submission SheetDocument3 pagesBid Submission SheetARSE100% (1)

- Lesson For SpreadsheetsDocument69 pagesLesson For SpreadsheetsCrisna Rivera PundanoNo ratings yet

- Audi Navigation System Plus - MMI Operating ManualDocument100 pagesAudi Navigation System Plus - MMI Operating ManualchillipaneerNo ratings yet

- Mapeh 10 Second Quarter ExamDocument3 pagesMapeh 10 Second Quarter ExamLILYBETH QUEMADA0% (1)

- Operational Business Suite Contract by SSNIT Signed in 2012Document16 pagesOperational Business Suite Contract by SSNIT Signed in 2012GhanaWeb EditorialNo ratings yet

- Second Grading Exam in MAPEH-10Document4 pagesSecond Grading Exam in MAPEH-10Reymundo PenialaNo ratings yet

- Reviewer MapehDocument11 pagesReviewer MapehVan BatirNo ratings yet

- MEdia and Information Sources QuizDocument1 pageMEdia and Information Sources QuizRizi Mae Codal100% (5)

- Summative Test q1 Arts g10 No TimeDocument26 pagesSummative Test q1 Arts g10 No TimeAlbert Ian CasugaNo ratings yet

- 1.1 Cruz v. DENR PDFDocument7 pages1.1 Cruz v. DENR PDFBenBulacNo ratings yet

- 2nd Quarter Final 10 MercuryDocument2 pages2nd Quarter Final 10 MercuryJoram Ray Obiedo100% (1)

- Quarter 2 Lesson 1 in Arts 10Document17 pagesQuarter 2 Lesson 1 in Arts 10milk teaNo ratings yet

- Mapeh 10 Lect 2nd Quarter ACTIVE RECREATIONDocument15 pagesMapeh 10 Lect 2nd Quarter ACTIVE RECREATIONCindy PontillasNo ratings yet

- English 10: Quarter 4 - Module 2 Giving Technical and Operational DefinitionsDocument21 pagesEnglish 10: Quarter 4 - Module 2 Giving Technical and Operational DefinitionsDdeow grtilNo ratings yet

- Music 10: 1 Quarterly Assessment (Mapeh 10 Written Work)Document4 pagesMusic 10: 1 Quarterly Assessment (Mapeh 10 Written Work)Kate Mary50% (2)

- 1st Quarter Summative Test in Music 10Document7 pages1st Quarter Summative Test in Music 10Niño Embile DellomasNo ratings yet

- Mapeh Scrapbook ContentsDocument9 pagesMapeh Scrapbook ContentsGrace P.No ratings yet

- 1Q Exam in Mapeh 10Document4 pages1Q Exam in Mapeh 10Dianne Mae DagaNo ratings yet

- Second Quarter Exam 22-23Document7 pagesSecond Quarter Exam 22-23Marife GuadalupeNo ratings yet

- English Week 4Document7 pagesEnglish Week 4Desiree Anne Balisi CuregNo ratings yet

- 1st Periodical Mapeh 10Document5 pages1st Periodical Mapeh 10Darren MendozaNo ratings yet

- Arts 10 - 3Q 3bDocument17 pagesArts 10 - 3Q 3bErra Peñaflorida - Pedro100% (1)

- Answer Sheet Module 4Document3 pagesAnswer Sheet Module 4Jakecob Mejillano JacobNo ratings yet

- MAPEH (Music) : Quarter 3: Week 5 & 6Document22 pagesMAPEH (Music) : Quarter 3: Week 5 & 6Allinas NathalieNo ratings yet

- G10 - Q2 - Module 1Document10 pagesG10 - Q2 - Module 1Sherilyn Dotimas BugayongNo ratings yet

- G10 Q2 Music Module 6 - For Reg - L EditingDocument11 pagesG10 Q2 Music Module 6 - For Reg - L EditingSALGIE SERNALNo ratings yet

- 3rd Q Music10Document23 pages3rd Q Music10Charlie Puth100% (1)

- Q4 Arts 10 Module 2Document15 pagesQ4 Arts 10 Module 2anthonneacNo ratings yet

- Mapeh 10 Module (Week 4) QTR 2Document12 pagesMapeh 10 Module (Week 4) QTR 2Marjorie Palma0% (1)

- Quarter 1 - Module 1b Modern Art (Abstract Expressionism, Pop Art and Contemporary Art Forms)Document16 pagesQuarter 1 - Module 1b Modern Art (Abstract Expressionism, Pop Art and Contemporary Art Forms)Maria Rose Tariga AquinoNo ratings yet

- Health Reviewer Grade 10 2nd QuarterDocument4 pagesHealth Reviewer Grade 10 2nd QuarterImelda CambelNo ratings yet

- LERMA 3rd Quarter ULAS-Health-10-Q3-Week-4Document15 pagesLERMA 3rd Quarter ULAS-Health-10-Q3-Week-4Lerma EstoboNo ratings yet

- Mapeh 10 2nd Quarter - 100632Document5 pagesMapeh 10 2nd Quarter - 100632Punang National High School 309166No ratings yet

- Quarter 4 Music 10 Week 6Document6 pagesQuarter 4 Music 10 Week 6Keith MacalamNo ratings yet

- Quarter Ii - Periodical Examination (1-60)Document4 pagesQuarter Ii - Periodical Examination (1-60)ELIAS DE MESANo ratings yet

- First Grading TestDocument20 pagesFirst Grading TestHoney Rose TimtimNo ratings yet

- Q1 Mathematics 10 - Module 5Document17 pagesQ1 Mathematics 10 - Module 5Angela SolivioNo ratings yet

- Module in Mapeh 10: Healthcare Providers and Fraudulent ServicesDocument4 pagesModule in Mapeh 10: Healthcare Providers and Fraudulent ServicesChristian Gonzales Laron100% (1)

- First Quarter Summative Test in English 10: San Ildefonso National High School English DepartmentDocument9 pagesFirst Quarter Summative Test in English 10: San Ildefonso National High School English Departmentramonito cruzNo ratings yet

- Mapeh 10: Health - Grade 10 Quarter 1 - Module 1: Consumer HealthDocument5 pagesMapeh 10: Health - Grade 10 Quarter 1 - Module 1: Consumer HealthBea Valerie GrislerNo ratings yet

- Arts WorksheetDocument12 pagesArts WorksheetApr CelestialNo ratings yet

- Answer Key For 2nd Quarterly Exam - SCIENCE10Document9 pagesAnswer Key For 2nd Quarterly Exam - SCIENCE10Donna T. Duaso100% (1)

- Health 10 Module 1Document15 pagesHealth 10 Module 1Kate BatacNo ratings yet

- S10 Diagnostic Answer KeyDocument15 pagesS10 Diagnostic Answer KeyNanette MoradoNo ratings yet

- Science Answers Q2 M 1Document4 pagesScience Answers Q2 M 1Krisha RosalesNo ratings yet

- Health10 - Q1 - Module1b (FOR TEACHER)Document26 pagesHealth10 - Q1 - Module1b (FOR TEACHER)AshleyNo ratings yet

- G10 1st PERIODICAL TEST MAPEH10 TQDocument5 pagesG10 1st PERIODICAL TEST MAPEH10 TQMaricel LajeraNo ratings yet

- Reviewer Sa Grade 10 Science 2nd PTDocument2 pagesReviewer Sa Grade 10 Science 2nd PTHelen Grace Llemos CabalagNo ratings yet

- Steps in Planning and Drafting Your Speech: Type Equation HereDocument2 pagesSteps in Planning and Drafting Your Speech: Type Equation HereJemima Camilosa ClomaNo ratings yet

- MAPEH ReviewerDocument12 pagesMAPEH ReviewerCassandra Jeurice UyNo ratings yet

- Summative Test in Music 92ND Quarter)Document2 pagesSummative Test in Music 92ND Quarter)Jovelyn TakilidNo ratings yet

- G10 MAPEH 1st PTDocument2 pagesG10 MAPEH 1st PTJethromelech RodriguezNo ratings yet

- 2nd Quarter Reviewer in ScienceDocument3 pages2nd Quarter Reviewer in Sciencecali annaNo ratings yet

- 1st Quarter Summative Test MapehDocument2 pages1st Quarter Summative Test Mapehkim nicdaoNo ratings yet

- Health: Worksheet No.3Document7 pagesHealth: Worksheet No.3melvin ynionNo ratings yet

- Grade 10 Reviewer in MAPEHDocument4 pagesGrade 10 Reviewer in MAPEHLoraine Antonette CupoNo ratings yet

- Quarter 3 Reading Materials in MusicDocument6 pagesQuarter 3 Reading Materials in MusicElisha HernandezNo ratings yet

- Grade 10 Quarter 2 Module 3 - Qualitative CharacteristicsDocument14 pagesGrade 10 Quarter 2 Module 3 - Qualitative CharacteristicsAlljhon Dave Joshua MagnoNo ratings yet

- Secondary Music 10 Q2 Week1Document11 pagesSecondary Music 10 Q2 Week1Mer LynNo ratings yet

- Splicing - Joining Electrical ConductorDocument35 pagesSplicing - Joining Electrical ConductorMARY ANN NUCEJANo ratings yet

- css10 Week 5Document8 pagescss10 Week 5lesterNo ratings yet

- M98 PVT 051 7546.bakDocument96 pagesM98 PVT 051 7546.bakmarkbillupsNo ratings yet

- Metabolic SyndromeDocument4 pagesMetabolic SyndromeNurayunie Abd HalimNo ratings yet

- OL2068LFDocument9 pagesOL2068LFdieselroarmt875bNo ratings yet

- Class B Digital Device Part 15 of The FCC RulesDocument7 pagesClass B Digital Device Part 15 of The FCC RulesHemantkumarNo ratings yet

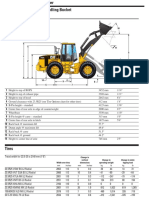

- Cat It62hDocument4 pagesCat It62hMarceloNo ratings yet

- Sinamics gm150 sm150 Catalog d12 02 2020 enDocument238 pagesSinamics gm150 sm150 Catalog d12 02 2020 enGo andWatchNo ratings yet

- ABES Engineering College, Ghaziabad Classroom Photograph: (Ramanujan Block, First Floor)Document21 pagesABES Engineering College, Ghaziabad Classroom Photograph: (Ramanujan Block, First Floor)Avdhesh GuptaNo ratings yet

- Project Proposal - Articulation SessionsDocument8 pagesProject Proposal - Articulation SessionsJhay-are PogoyNo ratings yet

- Review of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)Document12 pagesReview of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)RHIAN B.No ratings yet

- Inkt Cables CabinetsDocument52 pagesInkt Cables CabinetsvliegenkristofNo ratings yet

- Security Enhancement in 2016 SQL ServerDocument21 pagesSecurity Enhancement in 2016 SQL ServerAtul SharmaNo ratings yet

- Beijing-Michael PageDocument71 pagesBeijing-Michael Pagejohndavsg8022No ratings yet

- Thermo King Tool Catalog Part 2Document53 pagesThermo King Tool Catalog Part 2Alb NewgateNo ratings yet

- The Truth About Customer ExperienceDocument11 pagesThe Truth About Customer Experienceaksr27No ratings yet

- Art and Culture KSG IndiaDocument4 pagesArt and Culture KSG IndiaAbhishek SinghNo ratings yet

- Group9 SecADocument7 pagesGroup9 SecAshivendrakadamNo ratings yet

- Lucero Flores Resume 2Document2 pagesLucero Flores Resume 2api-260292914No ratings yet

- Gist of FIEO ServicesDocument1 pageGist of FIEO Servicessanjay patraNo ratings yet

- National Geographic - April 2020 PDFDocument160 pagesNational Geographic - April 2020 PDFIbn ZubairNo ratings yet

- Transformative Change at PPLDocument24 pagesTransformative Change at PPLAli A. KhokhArNo ratings yet

- Modeling Cover Letter No ExperienceDocument7 pagesModeling Cover Letter No Experienceimpalayhf100% (1)

- Es 590Document35 pagesEs 590Adnan BeganovicNo ratings yet