Professional Documents

Culture Documents

On The Mechanical Stability: of Inclined Wellbores

Uploaded by

Dayro Ramirez TOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On The Mechanical Stability: of Inclined Wellbores

Uploaded by

Dayro Ramirez TCopyright:

Available Formats

On the Mechanical Stability

of Inclined Wellbores

Shaohua Zhou,' R.R. Hillis, and Mike Sandiford, U. of Adelaide (Australia)

Summary this may not be the case near the surface, particularly in areas of ex-

Consideration of the stress field around an arbitrarily oriented bore- treme topography, it has since been confirmed by numerous in-situ

hole shows that in an extensional stress regime (av> OH> ah), well- stress measurements, 12-14 and is further supported by the vast ma-

bores parallel to the direction of minimum horizontal principal jority of intraplate crustal earthquake focal mechanisms. IS In this

stress are the least prone to compressive shear failure (breakout). paper, we assume that the principal stresses in the upper few kilome-

The most stable deviation angle (from the vertical) depends on the ters of the Earth's crust generally act in the vertical and two orthogo-

ratio of the horizontal principal stresses to the vertical stresses, and nal horizontal directions.

the higher the ratio oH/av, the higher the deviation angle for mini- Based on this assumption, and the assumption that rock is isotrop-

mizing breakout. In a strike-slip stress regime (OH> av >Oh), hori- ic and behaves like a linear elastic material up to the point of failure,

zontal wells are the least prone to breakout, and the higher the ratio an analytical solution of the stress field around an arbitrarily ori-

oH/av, the closer the drilling direction should be to the azimuth of ented borehole can be obtained.16-20 The following summarizes the

OH· stress solution and coordinate system used in this paper.

A new compressive shear failure criterion, which is a combina- For an arbitrarily oriented borehole, the rotation of the stress ten-

tion of the effective strength concept and the Drucker-Prager criteri- sor from the global in-situ coordinate system to a local borehole

on, is proposed for quantifying the stresses at which borehole break- coordinate system (Fig, 1) is given by21

out occurs. The lowest mud weight, at and below which breakout

will occur, can be predicted by combining this criterion with the sin2ß cos2 ß cos2 a cos2 ß sin2a

stress field around an arbitrarily oriented borehole. The highest mud O sin a2

cos2a

weight at and above which a tensional or hydraulic fracture is in- cos2ß sin2ß cos2 a sin2ß sin2a

duced can be predicted by combining the tensile strength of the

O - sin a cos a sin ß sin a cos a sinß

rocks of the wellbore wall with the stress field around an arbitrarily

oriented borehole. For the in-situ stress environments considered, - sinßcosß sinß cos ß cos2 a sinß cosß sin2a

the optimallY oriented inclined well bore is less prone to breakout O - sinacosacosß sina cosa cosß

(i.e., allows a lower mud weight) and tensional or hydraulic fracture

(i.e., supports a higher mud weight) than a vertical well.

av}

Introduction ~: . . (I)

{

It has been widely recognized that highly deviated, extended-reach

and horizontal wells can offer economic benefits through lower

Following these equations, the stress field at the wall of the bore-

field development costs, faster production rates, and higher recov-

hole is given by

ery factors. I ,2 However, inclined and horizontal wells may be prone

to mechanical instability problems associated with the in-situ stress Or = ßp, (2)

field. Hence, an understanding and analytical design capability to

manage wellbore stability in high in-situ stress fields should help

Oe = 0, + 0, - 2(ox - 0,.) cos 28 - 4fX).sin 28 - !'lp, .. (3)

realize the full benefits offered by current and emerging inclined

well drilling technology.

Much progress has recently been made toward the determination (4)

of the magnitude and orientation of in-situ stress in the crust, in par-

ticular, by borehole breakout analyses and hydraulic fracturing

fez' = 2( - fxzsin8 + fyzcos8), (5)

techniques including modified leak-offtests.3-g With knowledge of

the in-situ stress field, the most stable inclined well trajectory can

be designed. In this paper, the concept of minimum stress anisotropy f re = O, (6)

around the inclined wellbore wall is introduced. The condition of

minimum stress anisotropy can be used to determine an optimum and frz, = O. (7)

drilling direction and deviation angle. In this study, an elastic analyt-

Based on the above equations, the effective principal stresses on

ical approach is adopted for mode ling the stress field of deviated

the borehole wall (which are orthogonal to each other) in the local

wells in various stress regimes. By combining the effective strength

borehole coordinate system can be expressed by

concept9 with the widely used Drucker-Prager failure criterion,1O a

new failure criterion for rocks is presented and tested with available

rock strength data, Appropriate mud weights for mechanically

stable wells can be determined based on this criterion.

Stress Field Around an Arbitrarily Oriented Borehole O2 = !(oe + Oz,) - !¡(oe - O} + 4f~z" (9)

The three principal stresses are usually oriented vertically and hori-

zontally because the Earth's surface is a free surface.ll Although

and 03 = Or' (la)

'Now at Geologicallnsl., U. of Copenhagen (Denmark). The above solutions assume that the effective fluid pressure in the

Copyright 1996 Society of Petroieum Engineers borehole is the effective minimum principal stress. However, if this

pressure is sufficiently high (such as in the generation of hydraulic

Original SPE manuscript received for review Jan. 20, 1994. Revised manuscript received

Nov. 28, 1995. Paper (SPE 28176) peer approved Jan. 24. 1996. fractures), it may become the intermediate principal stress.

SPE Drilling & Completion, June 1996 67

stability. The octachedral shear stress is used here because it is a crit-

ß ical controlling factor on the stress level at failure.22-25

The shear stress anisotropy, Rs as defined in Eq. Il, is a function

of the effective principal stress ratios nh( =Oh/Ov) and nH( = oH/av),

the Poisson's ratio, Y, of the material, and effective well pressure,

!'lp. So for a given Y and !'lp, Rs can be uniquely determined by devi-

y ation angle from the vertical,ß, and the drilling direction, a, in a spe-

cified nh and nH. The effective principal stress ratios, nh and nH,

uniquely define the tectonic stress regime, according to Anderson

8 faulting mechanism.11 For instance, nh < nH < I indicates ex ten-

x

sional stress regime, while nh < I < nH indicates strike-slip stress re-

gime, and I < nh < nH indicates compressional stress regime. There-

fore, a critical stable condition can be determined if the tectonic

stress regime is known (i.e., the orientation and magnitudes of OH

and ah)'

The stable configurations, as given by an optimum set of the devi-

A / Oh ation angle, ß, from the vertical and the drilling direction, a, with

respect to the azimuth of the maximum horizontal principal stress,

of deviated wells in various tectonic stress environments are defined

to be those in which the stress anisotropy as defined in Eq. II is

minimized. In what follows, only extensional and strike-slip stress

regimes are considered because compressive stress regimes exist in

very few sedimentary basins.4-8

° B

The calculated stable conditions for an extensional stress regime

show that the stable drilling direction is always parallel to the azi-

muth of the minimum horizontal principal stress ah, and that the op-

Fig. 1-Borehole orientation and coordinate system used in this

study. timum deviation angles (Fig. 2) depend on the ratio of the horizontal

principal stresses to the vertical stresses. In general, the deviation

angle is controlled by both nH and nh. The higher the stress ratio nH,

Stable Drilling Direction and Deviation Angle

the higher the deviation angle required for maximizing stability. At

To define an optimum drilling direction and deviation angle, a use- a given nh, the deviation angle increases with nH. In addition, for

ful parameter (Rs), called shear stress anisotropy around the well- some cases where both horizontal principal stresses are equal in

bore wall, is defined by magnitude, vertical wells (ß = 0°) would be most stable in terms of

stress anisotropy around the borehole. When nH = I, the well should

f oC/(max) - f ouCmin) be drilled horizontally (i.e., ß = 90°) for maximizing stability. The

R, = foc,(min) (Il)

stress anisotropy, associated with the most stable condition, is gen-

erally less than 15% (without excess fluid pressure in the wellbore),

where fact is the octahedral shear stress,21 and foct(max) and

and for nh > 0.2, the stress anisotropy is always less than 5%.

foc/(min) are the maximum and minimum values of the octahedral

The calculated stable conditions for a strike-slip stress regime

shear stress around the wellbore wall, respectively. A number of

suggest that the deviation angles should always be 90° (horizontal

measurements could be used to define the stress anisotropy around wells), and that the drilling directions (Fig. 3) with respect to the azi-

the wellbore, e.g., mean principal stress, maximum principal stress, muth of OH are controlled by the stress ratios (nh and nH ).The higher

or octahedral shear stress. Intuitively, a measurement of the stress the ratio nH, the closer the drilling direction should be to the OH azi-

anisotropy should incorporate all stress factors that control wellbore muth. When nh = I, the well should be drilled along the azimuth of

0.2 0.4 0.6 0.8 1.0

0.0 .~ 1.0 0.2

1.0~~ ~~ 2.0 ~O

!

004

~

0.6 0.8

I

1.0

2.0

::J3~~~

1 ,.r-'

----

~ en

Ô

~

II OA~ ~~ ,/[

¡OB

L

06

004

Ô

~

J~~ \\u::

:r: I~ 1A~ ~ "- \ \ \ \~ 104

e

e

~'

0.2 Region not applicable L 0.2

1.2J ~

~\\11.2

0.0 ' 0.0 1.0~~

0.0 0.2 0.4 0.6 0.8 0415~'-1

10 0.0 i 0.2 i .6 0.8 1.0 .0

Fig, 2-Deviation angle from the vertical at which the stress ani- Fig. 3-Drilling direction with respect to OH at which the stress

sotropy around the well wall is minimized in extensional stress anisotropy around the well wall is minimized in strike-slip stress

regimes with tlp=O and v=O.25. The drilling direction (a) is regimes with tlp = Oand v = 0.25. The deviation angle (13) is equal

equal to 90° in all cases. to 90° in all cases.

68 SPE Drilling & Completion, June 1996

2 2 2

I 7 I 2 t------~-----___tl 2 I I 2

lzumi sandstone Shirahama sandstone (Takahashl & Koide, 1989)

(Takahashi & Koide, 19891

8 8 8

B B ."

......,

Il-' 1 Il-' 1

1 1 1

(o, + O 1°2 + 03) 13Co (o, + O 1 02 + 03) I 3Co (o, +0.102 + 03) 13Co

2 2

I I 2 I I 2

Solenhofen Limestone (Magi, 1971) Dunham Dolomite (Magi, 1971)

3

i :> I 2

Mizuho trachyte (Magi. 1972)

o

O 8 8

B

Il-' 1

Fig. 4-Rock strength data, derived from the published experimental results under the polyaxial states of compresSiOn.25,35,37

OH (i.e., a = 0°). In general, the calculated minimum stress anisotro- sive stresses occurred at a critical value of the effective shear strain

py is less than 20% (without excess fluid pressure in the wellbore), energy. The adoption of their criterion has led to much more suc-

and for nh > 0.4, the stress anisotropy is always less than 5%. cessful predictions of rock strength.Z2-Z4 Use ofWiebols and Cook's

Poisson's ratio v has been taken to be 0.25 in the above calcula- criterion in the study of borehole breakouts has recently been suc-

tions; a change of the Poisson's ratio by ± O. I has a minimal effect cessfully made.6 However, the mathematical formula used to calcu-

on the stress field of deviated wells. Hence, the value of Poisson's late failure stresses in a polyaxial state of compression in the effec-

ratio selected is not critical for this study. tive strain energy criterion are complex. Given the fact that there is

no universal law governing the level of stress at rock failure, it is

Failure Criteria of Rocks often desirable to develop simple and workable models, based on

both empirical studies and theoretical analyses of the physical

The drilling direction, a, and deviation angle, ß, that minimize the

mechanisms of fracture initiation and propagation, to predict rock

shear stress anisotropy of inclined wellbore in the ex tensional and

strength. We propose a new criterion for compressive rock failure,

strike-slip stress regimes were discussed in the previous section.

which is a combination of the effective strength concept9 with the

However, to make quantitative predictions of the borehole fluid

widely used Drucker-Prager failure criterion.1O This criterion can be

pressure (mud weight) required to prevent compressive shear fail-

also regarded as a simplified form of a general yield function pro-

ure of the wellbore wall (breakout) and tensional or hydraulic frac-

posed by Desai,32 who postulated that rock failure could be gov-

ture in the optimum (or any other) drilling trajectory, one needs to

erned by a yield function expressed as a polynomial of the three

further consider the mechanisms of breakout and hydraulic fracture

stress invariants, J¡, }Z, and 1}. A truncated form of Desai's yield

and develop an appropriate failure criteria. Borehole breakouts are

function is adopted here, that is, the yield function is simply given

spalled regions centered on the azimuth of the least horizontal prin-

by f(JI,}z) = O, on the basis that only JI and}z, have obvious physi-

cipal stress for vertical wells and are generally formed by compres-

cal significance, being directly related to the dilatational and distor-

sive shear failure.26-29 Comparison between field observations

tional elastic strain energy, respectively,21 Our new yield function

from borehole breakouts and theoretical predictions has shown that

is expressed by

the Mohr-Coulumb criterion tends to underestimate the stability

(i.e., the rock strength),30 while recent laboratory tests on hollow

cylinders have demonstrated that the circumscribed Drucker-Prager

fi' = A + Bll + elT, (I2)

criterion (another version of the extended von Mises criterion) tends

to underestimate the rock strength at small stresses and overesti- where J2'h(- _

foct)

_

- 3'I j( al - 03

)2 + (.al - O2

)2 + (O2 - 03

)2

mate the rock strength at large stresses.31 Wiebols and Cook9 pro- and J¡ = (al +02 + 03)13. Here the constants A, B, and C are deter-

posed an effective strain energy criterion for rock failure. They as- mined such that Eq. 12 is constrained by rock strengths under both

sumed that a rock contained a large number of randomly distributed triaxial and biaxial compression. In the triaxial state of stress (i.e.,

pre-existing cracks, and rock failure under any system of compres- Oz = 03 ), the rock strength is given by al = Co + q a3, where Co is

SPE Drilling & Completion, June 1996 69

o 1 2 3 5 n 2

41 I 4

A: 03 / Co = 0.0

B : 03 / Co = 0.1 b = 0.68

e: 03 / Co = 0.2 µ = 0.567

O: 03 / Co = 0.3 A: 03 /Co =O

e

3J 4J B: 03 / Co = 0.1 ---

-- L 4

/

~ 3

e : 03 I Co = 0.2

-- --

/

o

() - - -- - - / B

-- /

--

Ó

J .~'

/ I~'

/

/;iII"

/

,-

.......... -------.........""

.. ::,.. - - - _ .....

-'.'/0

,/

/

e

...

.. .. /

/

/

/

L 2

o

()

-- '1

- - -----

- -- - - -

,- - - - -

,, , ,- - - --

- ---

, --

A

L 3

t5 - - ---

-

/

/

/

2J y--'" ~

)i ~ 2

/ B

/

/ solid line = experimental model

/ / long-dash = Wiebols and Cook's model

/ short-dash = new model

/

o I" I o

o 2 3

Not applicable region

Fig. S-Comparison of failure models with coefficient of internal

friction µ = 0.567 and stress slope b = 0.68: the experimental

o

o 2

derived criterion,35 the effective strain energy criterion,9 and the

criterion proposed in this paper.

the uniaxial compressive strength, and q = (jI+µï + µ)

2

. In Fig. 6-Comparison of failure models with coefficient of internal

friction µ = 0.6: Mohr-Coulomb criterion (long dash line), the ex-

the biaxial state of stress (i.e., al = 02), the rock strength is given by

tended von Mises criterion (short dash line), and the criterion

al = Cl + q03, where Cl is the biaxial plane strength.9 By substitut- proposed in this paper (solid line).

ing the above conditions plus the uniaxial rock strength (al = Co,

02 = 03 = O) into Eq. 12, it can be found that

breakout types,38-40 (2) it is a much simpler analytical expression

than the original equations of Wiebols and Cook9 for predicting

!ï8 [CI-CO+(q-I)03 q-l] rock strength in the polyaxial state of stress 01 > Oz > 03, and (3)

C = 2cI - Co + (q - 1)03 2c] - Co + (2q + 1)03 - 2 + q

available laboratory rock strength tests are more consistent with the

new model predictions (Fig. S). Therefore, for the quantitative for-

ward modeling of borehole mechanical stability in the following

B = fi ~.(q - I) _ 1[

3 2co + (2 + q)03]C

section we use the criterion given by Eq. 12 to predict compressive

rock failure and breakout generation around wellbores.

A=-c

fi Co

--B--C

cö

Mud Weights for Mechanically Stable Deviated Wells

3 o 3 9'

A measure of the borehole stability can be made by defining an ef-

Currently available rock strength data are gathered and replotted fective failure stresslO as

in terms of octahedral stress and a modified mean confining stress

to test the proposed failure criterion. The results shown in Fig. 4 j'{~ff = Jr;Ockfailure

- Jr;"'rehole' ...........•.......... (13)

clearly indicate that octahedral stress at failure is a linear function

of the modified mean confining stress.33-3? Fig. 5 shows the new whereJr;ockfailureis the rock shear strength evaluated using Eq. 12,

model prediction, in comparison with the experimentally based and J~~orehole is the octahedral shear stress at the point on the bore-

model (Magi empirical criterion) and Wiebols and Cook's criterion. hole wall under consideration, calculated by using Eqs. I through

It can be seen that the new criterion provides a better prediction than 10. A positive value of the effective failure stress indicates a stable

that ofWiebols and Cook's criterion. The new model result deviates condition, and a negative value indicates an unstable or failed condi-

very little from the experimental result except at near biaxial state tion. Based on the concept of the effective failure stress as defined

of compression. in Eq. 13, the lower limit for borehole fluid pressure (mud weight),

Fig. 6 shows a comparison of the Mohr-Coulomb criterion, the i.e., the minimum borehole fluid pressure required to avoid com-

extended van Mises criterion, and the proposed criterion. In a poly- pressive shear failure, can be calculated for a given well trajectory.

axial state of stress, the prediction made by the new criterion is Borehole fluid pressure must not be so high as to cause hydraulic

greater than that given by the Mohr-Coulomb criterion and general- fracturing and associated fluid loss caused by high mud weight. The

ly less than that given by the extended van Mises criterion. Our pro- upper limit for borehole fluid pressure can be calculated based on

posed failure criterion has a number of advantages: (I) it takes into the assumption that hydraulic fracturing occurs when the minimum

account most stress loading conditions associated with various effective principal stress becomes tensile and equal to rock tensile

70 SPE Drilling & Completion, June 1996

1.0 1.5 2.0 2.5 3.0 1.0 1.5 2.0 2.5 3.0

O O I I O

I

short dash:;:: vertical well 01

short dash = vertical weU I

longdash = deviatedwell long dash = deviated weill

I

r

I

I

I

Upper

.. Upper \ "

; Bound

"

I

I" Bound

I' I \

I Lów~Bound

I" \

\\ I

\

1\ I I

\\ I I

\\ I

~ \\ I

2

Ê

~

-"

\

\

.r: 2 l 2

'1 ., ,,

I'. I \ ,

Ö. .r: ,

Q) I" I Ö. I

O I'. I

Q)

I ' ,

I'

O

I "

I',

I

""

I I

"

Lower Bound I

I, I

I', 1

\'\

I'

3J I 3

I' I 3 L 3

I: 1

I' I

I' I

I'

\

I

I', I

\: I

I: I

4 I: 4 I I

4 I 4

1.0 1.5 2.0 2.5 3.0

1.0 1.5 2.0 2.5 3.0

equivalent drilling mud density (g/cm'3)

equivalent drilling mud density (g/cm'3)

Fig. 7-Mud weight stability profile for vertical and optimally de- Fig. 8-Mud weight stability profile for vertical and optimally de-

viated wells for stress ratios nH = 0.9 and nh = 0.5 and effective viated wells for stress ratios nH = 1.1 and nh = 0.5. The deviated

vertical stress gradient = 12 MPalkm. The rock strength parame- well trajectory (a = 55° and ß = 90°) is that given by the optimum

ters are Co = 20 MPa (uniaxial compressive rock strength), drilling direction and deviation angle as shown in Fig. 3 for the

µ = 0.6 (coefficient of internal friction), and T= O (tensile given stress ratios nH and nh' The diagram is otherwise the same

strength). The deviated well trajectory (a = 90° andß = 55°) is that as in Fig. 7.

given by the optimum set of drilling direction and deviation

angle as shown in Fig. 2 for the given stress ratios nH and nh'

mum deviation angle and drilling direction. Based on a new com-

Pore pressure is assumed to be hydrostatic. It should be men-

tioned that there is no compressive shear failure at shallow

pressi ve rock failure criterion presented here, our predictions on

depth less than 1 km for the given stress field and rock strength mud weight stability profiles show that, contrary to intuitive ex-

parameters. The recommended upper mud weight for the de- pectation, regions of high tectonic stress anisotropy may produce a

viated well is given by the overburden pressure (Le., bulk rock more stable environment for inclined wells than vertical wells. Ob-

density of 2.22 glcm3 derived from the given effective vertical viously, mechanical stability will not generally be the primary factor

stress and pore pressure), hence, in this case horizontal fracture in selecting well trajectory. For example, deviated wells may be tar-

would be readily induced by excessive mud weight (see text for

geted to access reservoirs remote from surface facilities or oriented

further discussion).

such as to maximize intersection with open natural fractures. The

methodology presented here allows mechanically safe mud weight

strength.ll Such rock tensile strength can be derived from the un-

limits to be determined for a well in any trajectory. It should be noted

confined compressive strength (i.e., T= Co/I2, based on the ex-

that it has been shown elsewhere42 that the well trajectory that maxi-

tended Griffith criterion) or directly measured by extended leakoff

mizes intersection with open, natural, or hydraulically induced frac-

test. However, for previously fractured rocks, T= O, and this value

ture is consistent with the optimum drilling direction and deviation

is used in our calculations to provide an upper limit for mud weight.

angle in both the extensional and the strike-slip stress regimes where

In addition, to avoid horizontal hydraulically induced fractures, the

0.9<nH<I.1.

mud weight should not be higher than the overburden pressure.2lAI

The conclusion herein applies only to isotropic rocks with linear

Hence, the upper mud weight limit is taken as the lower of the values

elasticity up to the point of failure. In the real earth, the rock proper-

of bulk rock density or that calculated from the tangential stress de-

ties are often complex because of various geological processes.43

scribed above.

As examples, the lower and upper mud weight limits for wells For material with a Young's modulus depending on the effective

drilled in the optimum trajectories with respect to mechanical stabil- mean stress, the stress field around a well has been shown to be low-

ity in two tectonic stress regimes have been calculated (Figs. 7 and er than the prediction based on linear elasticity.44-45 From the stabil-

8). In a tectonic stress regime of relati vely large anisotropy, well bore ity point of view, this would tend to increase the stability of the de-

mechanical stability can be improved by inclined wells drilled with viated wells because of the reduction of stress concentration around

optimum drilling direction and deviation angle. High in-situ stresses a wellbore. Temperature fluctuations associated with mud circula-

may create a less stable environment for vertical wells. The mud tion during drilling will not influence the stress anisotropy around

weight stability field associated with the optimum drilling direction the wellbore because the temperature effect should alter the tangen-

and deviation angle, much wider than that for vertical wells, shows tial and vertical stresses by an equal amount. However, rock proper-

the importance of drilling trajectory to the mechanical stability of ties may be altered as a result of temperature changes, which may

the well bore. increase or reduce the possibility of mechanical failure, depending

on the actual effect on the rock properties.43

Conclusions

Nomenclature

In this paper, we have presented a straightforward methodology to

deal with the mechanical stability of inclined wells. It has been Co = uniaxial rock compressive strength, mlLtZ,

shown that mechanical stability can be improved by adopting opti- MPa

SPE Drilling & Completion, June 1996 71

Cl = biaxial plane strength, mlLt2, MPa 5. Moos, D. and Zoback. MD.: "Utilization of Observations of Wellbore

JI = mean effective confining stress, mlLt2, MPa Failure To Constrain the Orientation and Magnitude of Crustal Stresses:

Application to Continental, Deep Sea Drilling Project. and Ocean Drill-

nh = ratio of the effective minor horizontal

ing Program Boreholes," 1. Geophys. Res. (1990) 95, 9305-9325.

principal stress to the effecti ve vertical

6. Vernik, L. and Zoback. M.O.: "Estimation of Maximum Horizontal

stress

Principal Stress Magnitude From Stress-Induced Wellbore Breakouts in

nH = ratio of the effective major horizontal the Cajon Pass Scientific Research Borehole," 1. Geophys. Res. (1992)

principal stress to the effective vertical 97,5109-5119.

stress 7. Hillis, R. and Williams, A.: 'The Stress Field of the North West Shelf

ßp = excess fluid pressure in the borehole (i.e., mud and Wellbore Stability," APEA 1. (1993) 33,373-385.

pressure less pore pressure in the formation), 8. Enever, J.R.: "Case Studies of Hydraulic Fracture Stress Measurement

in Australia," Comprehensive Rock Engineering. J.A. Hudson (ed.) Per·

mlLt2, MPa

gamon Press (1993) 3, 497-531.

Rs = shear stress anisotropy around the wellbore

9. Wiebols, G.A. and Cook, N.G.W.: "An Energy Criterion forthe Strength

wall of Rock in Polyaxial Compression," Jnt. 1. Rock Mech. Min. Sei. (1968)

T= rock tensile strength, mlLt2, MPa 5,529-549.

a = the angle between OH and the projection 10. Bradley, W.B.: "Failure of Inclined Boreholes," Trans .. ASME (1979)

of the bore hole axis onto the horizontal 101,232-239.

1I. Anderson, E.M.: The Dynamics of Faulting and Dyke Formation, (sec-

plane

ond edition), Oliver and Boyd, London (195 I) 206.

ß= the angle between the borehole axis and the

12. Obert, L.: "Determination of Stress in Rock-A State of the Art Re-

vertical direction port," ASTM, Special Technical Publication (1967) No. 429.

8 = polar angle in the borehole cylindrical 13. Greiner, G.: "In-Situ Stress Measurements in Southwest Germany."

coordinate system Tectonophysics (1975) 29, 49-58.

µ = coefficient of internal friction 14. Gysei, M.: "In-Situ Stress Measurements of the Primary Stress State in

the Sonnenberg Tunnel in Lucerne, Switzerland," Tectonophysics

v= Poisson's ratio

(1975) 29, 301-314.

OH = effective major horizontal principal stress, 15. Zoback, M.L. et al.: "Global Patterns of Tectonic Stress," Nature (1989)

mlLt2, MPa 341,291-298.

Oh = effective minor horizontal principal stress, 16. Hiramatsu, Y and Oka, Y: "Determination of the Stress in Rock Unaf-

mlLtZ, MPa fected by Boreholes or Drifts From Measured Strains or Deformations,"

Jnt. J. Rock Mech. Min. Sci. (1968) 5, 337-353.

Or, oe, Oz', Oe;z'.

17. Fairhurst, c.: "Methods of Determining In-Situ Rock Stress at Great

Orf). Orz' = stress tensor in the borehole cylindrical

Depths," TRI·68, Missouri River Div. Corps of Engineers (1968).

coordinate system, mlLtZ, MPa 18. Aadnoy, B.S. and Chenevert, M.E.: "Stability of Highly Inclined Bore-

av = effective vertical stress, mlLtZ, MPa holes," SPEDE (1987) 2, 364-374.

ox, ay, o;z.Oxy, 19. Mastin, L.: "Effect of Borehole Deviation on Breakout Orientations," J.

Geophys. Res. (1988) 93, 9t87-9195.

oxz 0vz = stress tensor in the borehole Cartesian

20. Baumgatner, J., Carvalho, J. and McLennan, J.: "Fracturing Deviated

. . coordinate system, mlLtZ, MPa

Wells: An Experimental Laboratory Approach," Rock at Great Depth,

al = effective maximum principal stress in the V. Maury and D. Fourmaintraux (eds.) (1989) 929-937.

borehole cylindrical coordinate system, 21. Jaeger, J.e. and Cook, N.: Fundamentals of Rock Mechanics, Methuen

mlLtZ, MPa and Co. Ltd., London (1969) 513.

02 = effective intermediate principal stress in the 22. Paterson, M.S.: Experimental Rock Deformation-The Brittle Field,

bore hole cylindrical coordinate system, Springer- Verlag, Berlin (1978) 254. •

mlLtZ, MPa 23. Hoek, E. and Brown, ET: Underground Excavations in Rock, Institu-

tion of Mining and Metallurgy, London (1980) 527.

03 = effective minimum principal stress in the

24. Brady, B.H.G. and Brown, ET.: Rock Mechanicsfor Underground Min·

borehole cylindrical coordinate system,

ing, George Allen & Unwin (1985) 527.

mlLt2, MPa 25. Takahashi, M. and Koide, H.: "Effect of the Intermediate Principal

fact (= J~') = octahedral shear stress, mlLt2, MPa Stress on Strength and Deformation Behavior of Sedimentary Rocks at

the Depth Shallower than 2000 m," Rock at Great Depth, V. Maury and

D. Fourmaintraux (eds.) (1989) 19-26.

Acknowledgments

26. Gough, DJ. and Bell, J.S.: "Stress Orientations From Oil-Well Fractures

This study was supported by the Australian Petroleum Cooperative in Alberta and Texas," Can. 1. Earth Sei. (1981) 18,638-645.

Research Centre (APCRC). Two anonymous reviewers are thanked 27. Gough, DJ. and Bell, J.S.: "Stress Orientations From Borehole Wall

for their helpful comments, with which this manuscript has been im- Fractures With Examples From Colorado, East Texas. and Northern

proved significantly. Canada," Can. J. Earth Sei. (1982) 19,1358-1370.

28. Bell, J.S. and Gough, DJ.: "Northeast-Southwest Compressive Stress in

Alberta: Evidence From Oil Wells," EPSL (1979) 45, 475-482.

References

29. Bell, J.B. and Babcock, E.A.: "The Stress Regime of the Western Cana-

1. Land, W.J. and Jett, M.B.: "High Expectations for Horizontal Drilling dian Basin and Implications for Hydrocarbon Production," Bull., Cando

Becoming Reality," Oil Field J. (Sept. 24, 1990) 7(}""79. Petrol. GeaI. (1986) 34, 364-378.

2. Joshi, S.O.: "Overview and Application of Horizontal Wells," Geologi· 30. Hansen, K.S.: "Comparison Between Field Observations and Theory

cal Aspects of Horizontal Drilling, R.O. Fritz, M.K. Hom, and S.O. Jo- for Stress-Induced Borehole Ellipticity," Rack Mechanics as a Multidis·

shi (eds.), AAPG Cont. Educ. Course Note Ser. (1991) 33, 51-64. ciplinary Science, J-P. Roegiers (eds.) (1991) 995-1003.

3. Zoback, M.D. et al.: "Wellbore Breakouts and In-Situ Stress," J. Geo- 31. Addis, M.A. and Wu, B.: "The Role of the Intermediate Principal Stress

phys. Res. (1985) 90, 5523-5530. in Wellbore Stability Studies: Evidence From Hollow Cylinder Tests,"

4. Barton, C.A., Zoback, M.O., and Burns, K.L.: "In-Situ Stress Orienta- Preprint Proceedings of the 34th US. Symposium on Rock Mechanics

tion and Magnitude at the Fenton Geothermal Site, New Mexico, Deter· (1993) 57-60.

mined From Wellbore Breakouts," Geophys. Res. Let!. (1988) 15, 32. Desai, C.S.: "A General Basis for Yield, Failure, and Potential Functions

467-470. in Plasticity," Jntl. J. Num. Ana. Meth, in Geomech. (1980) 4, 361-375.

72 SPE Drilling & Completion, June 1996

33. Mogi, K.: "Effect ofthe Intermediate Principal Stress on Rock Failure," SI Metric Conversion Factors

1. Geophys. Res. (1967)72,5117-5131.

in. x 2.54* E + 00 = cm

34. Mogi, K.: "Fracture and Flow Of Rocks Under High Triaxial Compres-

in.3 x 1.638 706 E+Ol =cm3

sion," J. Geophys. Res. (1971) 76,1255-1269.

mile x 1.609 344* E + 00 = km

35. Magi, K.: "Effect of the Triaxial Stress System on the Failure of Dolo-

mite and Limestone," Tectonophysics (197 I) 11, I I 1-127. psi x 6.894 757 E + 00 = kPa

36. Magi, K.: "Fracture and Flow of Rocks," Tectollophysics (1972) 13, ·Conversion factor is exact. SPEDC

541-568.

37. Magi, K.: "Rock Fracture," Ann. Rev. Earth Planet. Sei. (1973) 1,

63-84. Shaohua Zhou was appointed lecturer in geophysics at the

38. Guenot, A. and Santarelli, FJ.: "Borehole Stability: A New Challenge Geological Inst., U. of Copenhagen in 1994. His main research

for an Old Problem," Key Questions ill Rock Mechanics. P.A. Cundall. interests are in solid earth geophysics and geodynamics. Shao-

R.L. Sterling, and A.M. Starfield (eds.) (1988) 453-460. hua holds an MS degree in applied geophysics from Chengdu

39. Guenot, A.: "Borehole Breakouts and Stress Fields,"/lltl. J. Rock. Mech. C. of Geology (in China) and a PhD degree in geophysics from

Sei. Geomech. Abstr. (1989) 26,185-195. Adelaide U. Richard Hilliswas appointed lecturer in exploration

40. Plumb, R.A.: "Fracture Patterns Associated With Incipient Wellbore geophysics at Adelaide U. in 1992. His main research interests

Breakouts," Rock at Great Depth, V. Maury and D. Fourmaintraux are in contemporary stressesand sedimentary basin dynamics.

(eds.) (1989) 761-768. He holds a BSdegree in geology from London U. and a PhD de-

41. Hubbert, M.K. and Willis, D.G.: "Mechanics of Hydraulic Fracturing," gree in geology from Edinburgh U. Mike Sandiford iscurrently a

J. Pet. Tech. (1957) 9,153-168. senior lecturer at Adelaide U. Hismain research interests include

42. Zhou, S., Hillis, R. and Sandiford, M.: "A Study of the Design of In- structural and metamorphic geology, Iithospheric dynamics,

clined Wellbores With Respect to Both Mechanical Stability and Frac- and solid earth geophysics. He holds a PhD degree in geology

ture Intersection, and lts Application to the Australian North West from Melbourne U.

Shelf," 1. Appl. Geophys. (1994) 32, 293-304.

43. Fjaer, E. et al.: Petroleum Related Rock Mechanics, Developments in

Petroleum Science. Elsevier (1992) 33, 338.

44. Santarelli, EJ., Brown, ET .. and Maury, v.: "Analysis of Borehole

Stress Using Pressure-Dependent, Linear Elasticity," Inti. J. Rock Mech.

Min. Sei. & Geomech. Abstr. (1986) 23, 445-449.

45. Fama, M.E.D. and Brown. ET: "Influence of Stress Dependent Elastic

Moduli on Plane Strain Solutions for Boreholes," Rock at Great Depth.

V. Maury and D. Fourmaintraux (eds.) (1989) 819-826. Zhou Sandiford

SPE Drilling & Completion. June 1996 73

You might also like

- Introduction to the Theory of Shells: Structures and Solid Body MechanicsFrom EverandIntroduction to the Theory of Shells: Structures and Solid Body MechanicsNo ratings yet

- 1994 JAppGZhouDocument12 pages1994 JAppGZhouDulce LopezNo ratings yet

- Unique Geotechnical Problems at Hydro Projects Deere0001Document7 pagesUnique Geotechnical Problems at Hydro Projects Deere0001Selçuk GülarıNo ratings yet

- SPE 136989 Mechanical Stability Analysis of Directional Wells: A Case Study in Ahwaz OilfieldDocument10 pagesSPE 136989 Mechanical Stability Analysis of Directional Wells: A Case Study in Ahwaz OilfieldMuhammad S. RaniYahNo ratings yet

- Upper-Bound Solution For Seismic Bearing Capacity of Shallow Foundations Near A SlopeDocument6 pagesUpper-Bound Solution For Seismic Bearing Capacity of Shallow Foundations Near A SlopeHUGINo ratings yet

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (4)

- International Journal of Mining Science and TechnologyDocument10 pagesInternational Journal of Mining Science and TechnologyDEEPESH KUMARNo ratings yet

- Basic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandBasic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4 out of 5 stars4/5 (4)

- Lecture 20Document10 pagesLecture 20فردوس سليمانNo ratings yet

- Determining Stress Orientation and Magnitude in Deep WellsDocument28 pagesDetermining Stress Orientation and Magnitude in Deep WellsDiego RangelNo ratings yet

- Fault-Valve Behavior and The Hydrostatic-Lithostatic Fluid Pressure InterfaceDocument4 pagesFault-Valve Behavior and The Hydrostatic-Lithostatic Fluid Pressure InterfaceSergio Paucar MoreyraNo ratings yet

- Borehole GeophysicsDocument4 pagesBorehole Geophysicsfaten adelNo ratings yet

- Saikumar Docx5Document13 pagesSaikumar Docx5Sai Kumar Goud SudhavenaNo ratings yet

- Stresses Around UndergroundDocument41 pagesStresses Around UndergroundNhật LêNo ratings yet

- Stress and Stability of Coal Ribs and PillarsDocument12 pagesStress and Stability of Coal Ribs and Pillarspradhith kattaNo ratings yet

- International Journal of Rock Mechanics and Mining Sciences: Raúl Castro, Ren e G Omez, Matthew Pierce, Juan CanalesDocument11 pagesInternational Journal of Rock Mechanics and Mining Sciences: Raúl Castro, Ren e G Omez, Matthew Pierce, Juan CanalesNicolás SilvaNo ratings yet

- Induced Pore Pressures During Pile-Driving OperationsDocument5 pagesInduced Pore Pressures During Pile-Driving OperationsTri TruongNo ratings yet

- Melo Et Al. - Forces On Plunge Pool Slabs - Influence of Joint Location and WidthDocument12 pagesMelo Et Al. - Forces On Plunge Pool Slabs - Influence of Joint Location and Widthigor774No ratings yet

- 1 s2.0 S1878522013000489 Main - 2Document5 pages1 s2.0 S1878522013000489 Main - 2Febry RomarioNo ratings yet

- Seismic Design of Earth Retaining StructuresDocument9 pagesSeismic Design of Earth Retaining StructuresMehul JethvaNo ratings yet

- Arma12 601 BLecampion - VFDocument9 pagesArma12 601 BLecampion - VFaxel.tokoNo ratings yet

- Development of Filament Wound Composite Isotensoidal Pressure Vessels - Lei Zu2014Document6 pagesDevelopment of Filament Wound Composite Isotensoidal Pressure Vessels - Lei Zu2014Hiến Đinh VănNo ratings yet

- Goldman1967 (B)Document8 pagesGoldman1967 (B)LUIS GRANDANo ratings yet

- Persentasi Bearing Capacity of Deep Foundation in SandDocument39 pagesPersentasi Bearing Capacity of Deep Foundation in SandAwal AwalmansurNo ratings yet

- Hydraulic Fracture Initiation and Propagation From Wellbore With Oriented PerforationDocument17 pagesHydraulic Fracture Initiation and Propagation From Wellbore With Oriented PerforationLok Bahadur RanaNo ratings yet

- International Journal of Rock Mechanics and Mining SciencesDocument10 pagesInternational Journal of Rock Mechanics and Mining SciencesheydaripostNo ratings yet

- Tuck RevisedDocument16 pagesTuck RevisedSaiSudhakar MamidipakaNo ratings yet

- Rock Strength Parameters From Annular Pressure While Drilling and Dipole Sonic Dispersion AnalysisDocument14 pagesRock Strength Parameters From Annular Pressure While Drilling and Dipole Sonic Dispersion Analysisfajar agung setiawanNo ratings yet

- Design of Flat Roof Tunnels and Caverns by Use of The Multi-Jointed Voussoir Beam TheoryDocument8 pagesDesign of Flat Roof Tunnels and Caverns by Use of The Multi-Jointed Voussoir Beam TheorywolvesyNo ratings yet

- Journal of Natural Gas Science and Engineering: Fei Yin, Deli GaoDocument7 pagesJournal of Natural Gas Science and Engineering: Fei Yin, Deli GaoJuan MNo ratings yet

- Improved Methodology For Estimating Seismic Coefficients For TheDocument12 pagesImproved Methodology For Estimating Seismic Coefficients For TheMalik RizwanNo ratings yet

- Dorecasting Vulnerability of Deep Extraction Level Excavations To Draw Cindiced Cave LoadsDocument8 pagesDorecasting Vulnerability of Deep Extraction Level Excavations To Draw Cindiced Cave LoadsAlexander ArdilesNo ratings yet

- Three-D stability analysis of Kom El-Shoqafa catacombsDocument8 pagesThree-D stability analysis of Kom El-Shoqafa catacombsJorge AndradeNo ratings yet

- Spe 89 Pa PDFDocument13 pagesSpe 89 Pa PDFSteeven RezabalaNo ratings yet

- Fulltext-13 (10) Aydan Kawamoto 1992 Flexural TopplingDocument23 pagesFulltext-13 (10) Aydan Kawamoto 1992 Flexural TopplingRodrigo Peluci de FigueiredoNo ratings yet

- Davis Et Al (1980) Stability of Shallow TunnelsDocument20 pagesDavis Et Al (1980) Stability of Shallow TunnelsRAJAT PURWARNo ratings yet

- 10 1680@p3is 15562 0030Document9 pages10 1680@p3is 15562 0030taher ahmedNo ratings yet

- Plastic - Collapse at Pipes and Vessels PDFDocument19 pagesPlastic - Collapse at Pipes and Vessels PDFElias KapaNo ratings yet

- Retaining WallDocument11 pagesRetaining Wallardi rahadianNo ratings yet

- Ghosh - Rock Stress Measurements For Underground ExcavationsDocument9 pagesGhosh - Rock Stress Measurements For Underground ExcavationsnumspyNo ratings yet

- H Theoretical Study of Three-Dimensional Combustion Instability in Liquid-Propellant Rocket EnginesDocument9 pagesH Theoretical Study of Three-Dimensional Combustion Instability in Liquid-Propellant Rocket EnginesAIEIMANo ratings yet

- A General Earth Pressure Theory: Une Théorie Générale de La Poussée de TerreDocument5 pagesA General Earth Pressure Theory: Une Théorie Générale de La Poussée de TerreAnonymous ImoZI0363No ratings yet

- Improving Fracture Permeability Prediction by Combining Geomechanics and DiagenesisDocument7 pagesImproving Fracture Permeability Prediction by Combining Geomechanics and DiagenesisOscar Javier ArevaloNo ratings yet

- Stability Analysis of A Slurry Trench in Cohesive-Frictional SoilsDocument13 pagesStability Analysis of A Slurry Trench in Cohesive-Frictional SoilsVetriselvan ArumugamNo ratings yet

- DTMB 1959 1311Document34 pagesDTMB 1959 1311S M BNo ratings yet

- The Influence of Vertical Fractures Intercepting Active and Observation Wells On Interference TestsDocument12 pagesThe Influence of Vertical Fractures Intercepting Active and Observation Wells On Interference Testsleonelz6aNo ratings yet

- Vrakas2016-Reaction Curve ReprofileDocument10 pagesVrakas2016-Reaction Curve Reprofilejuan muneraNo ratings yet

- Rock Engineering Rock Engineering Practice & Design Practice & DesignDocument37 pagesRock Engineering Rock Engineering Practice & Design Practice & Designjmhs31No ratings yet

- A Fracture Mechanic Analysis of The Effect of Backfill On Stability of Cut and Fill MineDocument11 pagesA Fracture Mechanic Analysis of The Effect of Backfill On Stability of Cut and Fill MineShashank SharmaNo ratings yet

- Froude-Krylov Force CoefficientDocument20 pagesFroude-Krylov Force CoefficientLazaros NtoanidisNo ratings yet

- Calculation Procedures For Installation of Suction CaissonsDocument34 pagesCalculation Procedures For Installation of Suction Caissonslollyb100% (1)

- Well Stimulation On The Basis of Preliminary Triaxial Tests of Reservoir RockDocument7 pagesWell Stimulation On The Basis of Preliminary Triaxial Tests of Reservoir Rockعلي صباحNo ratings yet

- Practical Strength Criterion For Coal Mine Roof Support Design in Laminated Soft RocksDocument8 pagesPractical Strength Criterion For Coal Mine Roof Support Design in Laminated Soft Rockspradhith kattaNo ratings yet

- Sheet 3Document2 pagesSheet 3hishamlashennNo ratings yet

- Strength of Pressure Vessels With Ellipsoidal HeadsDocument8 pagesStrength of Pressure Vessels With Ellipsoidal Headsنصرالدين ادريسNo ratings yet

- SETTLEMENT COMPUTATIONDocument10 pagesSETTLEMENT COMPUTATIONNhân NguyễnNo ratings yet

- B Ed 3 Sem Physics Teaching Group C Science 1 Paper 1 Summer 2018Document3 pagesB Ed 3 Sem Physics Teaching Group C Science 1 Paper 1 Summer 2018Rrr KkkNo ratings yet

- When Ceramic Sociology Meets Material SCDocument10 pagesWhen Ceramic Sociology Meets Material SCJosé Renato TeixeiraNo ratings yet

- SK716 Pengintegrasian Mekanisme Nilai Karbon (English)Document13 pagesSK716 Pengintegrasian Mekanisme Nilai Karbon (English)Isti HanifahNo ratings yet

- Saej401v002 PDFDocument6 pagesSaej401v002 PDFLuis LujanoNo ratings yet

- Communications in Algebra: On The U-Invariant of P-Adic Function FieldsDocument9 pagesCommunications in Algebra: On The U-Invariant of P-Adic Function FieldsKarim ZahidiNo ratings yet

- Thermal Performance of Air-Cooled Condensing Units by CFD SimulationDocument2 pagesThermal Performance of Air-Cooled Condensing Units by CFD SimulationFauziah JeraiNo ratings yet

- Fair Directory 02-2016Document44 pagesFair Directory 02-2016Ravichandran SNo ratings yet

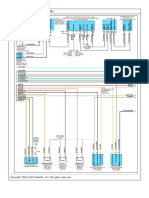

- Fault Codes: STO U AndriivDocument3 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- Understanding of AVO and Its Use in InterpretationDocument35 pagesUnderstanding of AVO and Its Use in Interpretationbrian_schulte_esp803100% (1)

- NTPC Training ReportDocument83 pagesNTPC Training ReportAbhishek Mittal100% (2)

- Seminar Application of Nitrous Oxide in AutomobilesDocument20 pagesSeminar Application of Nitrous Oxide in AutomobilesSaikat BadyakarNo ratings yet

- Textile Internship Report AlokDocument39 pagesTextile Internship Report AlokRahul TelangNo ratings yet

- SteelsDocument72 pagesSteelsLLNo ratings yet

- Differential Equations CookbookDocument2 pagesDifferential Equations CookbookAugustinZNo ratings yet

- Stereochemistry MSCDocument29 pagesStereochemistry MSCBapu Thorat50% (2)

- A Robust Firearm Identification Algorithm ProposalDocument7 pagesA Robust Firearm Identification Algorithm ProposalEuneel EscalaNo ratings yet

- Detecting Oil Spills from Remote SensorsDocument7 pagesDetecting Oil Spills from Remote SensorsFikri Adji Wiranto100% (1)

- 0610 m16 QP 62Document12 pages0610 m16 QP 62faryal khanNo ratings yet

- Welcome Students!: Week 8 (3 Quarter)Document28 pagesWelcome Students!: Week 8 (3 Quarter)Erika Lloren Luyun-GaliaNo ratings yet

- Script For TSB GRDDocument9 pagesScript For TSB GRDJuvel OrquinazaNo ratings yet

- HydrotherapyDocument7 pagesHydrotherapyGialys MoretaNo ratings yet

- Random Variate Generation-1Document21 pagesRandom Variate Generation-1Christian Delas AlasNo ratings yet

- Computer Engineering SyllabusDocument47 pagesComputer Engineering SyllabusLily ChanNo ratings yet

- Air release plug and lifting lug details for 15 MVA 66/11.55 kV transformer radiatorDocument1 pageAir release plug and lifting lug details for 15 MVA 66/11.55 kV transformer radiatorshravan Kumar SinghNo ratings yet

- Diagrama 4 AMBIENT AIR TEMPER..Document1 pageDiagrama 4 AMBIENT AIR TEMPER..Gustavo PérezNo ratings yet

- Chapter-1: Introduction of The StudyDocument21 pagesChapter-1: Introduction of The StudyViswanathanNo ratings yet

- FT Aeroterme GEADocument15 pagesFT Aeroterme GEACrisTimNo ratings yet

- Let Us Be HappyDocument2 pagesLet Us Be HappyMarjule DechavezNo ratings yet

- OrlDocument186 pagesOrlMuli MaroshiNo ratings yet