Professional Documents

Culture Documents

Document Ref: Date: 05/08/2020 Psb/Pqp/Qap Rev. No: Project Quality Manual Quality Assurance Plan

Uploaded by

Nizam PodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Document Ref: Date: 05/08/2020 Psb/Pqp/Qap Rev. No: Project Quality Manual Quality Assurance Plan

Uploaded by

Nizam PodCopyright:

Available Formats

DOCUMENT REF : PANAROMIC SDN BHD DATE : 05/08/2020

PSB/PQP/QAP REV. NO :

PROJECT QUALITY MANUAL

QUALITY ASSURANCE PLAN

1. PLANNING

As part of overall planning, the master work programme shall be provided and

produced using Microsoft Project indicating the schedule for each activity

throughout the contract period.

The document pertaining to master work programme to be issued separately.

2. ENVIRONMENTAL SAFETY & HEALTH AND TRAFFIC MANAGEMENT

The following documents shall be produced separately as part of Contractual

and Regulatory requirements

Environmental Management Plan

Safety & Health Plan

The Documents pertaining to the above are issued separately

3. PROCESS CONTROL

All activities shall have adequate control and coordination :

Processes are performed by suitably qualified and experienced

personnel.

Equipment used shall be suitable for the processes, in good conditioned,

maintained and approved by the SO.

Materials shall be procured in a controlled manner and approved by the

SO.

Processes shall be performed in accordance with construction drawings,

Technical specification and method statement and inspected using

inspection and test plan.

Documentation systems shall be available for identification that the

processes have been carried out.

PROJECT QUALITY MANUAL I Page 9 of 13

DOCUMENT REF : PANAROMIC SDN BHD DATE : 05/08/2020

PSB/PQP/QAP REV. NO :

PROJECT QUALITY MANUAL

6.0. QUALITY ASSURANCE PLAN

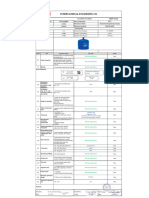

4. INSPECTION AND TESTING

Inspection and Test Plan shall be produced to reflect specific requirements,

point of test, personnel responsible for test. The Inspection and Test Plan shall

comply client Quality Management System (the ‘SPK’)

Inspection and test shall be carried out where appropriate during different

stages of work i.e. Receiving of Materials and components, during process or

upon completion of process.

Records to demonstrate that product and areas of work have passed or failed

inspection or test will be maintained by the appropriate site representatives.

5. CONTROL OF NON-CONFORMING PRODUCT/ACTIVITY

Non-conformity identified during receiving of materials component or

equipment shall prevented from inadvertent use or installation. Notice of Non-

conforming shall be issued and the reviews and disposition of the non-

conforming product shall be recorded as a quality record.

6. CONTROL OF NON-CONFORMING REPORT AND CORRECTIVE ACTION

Non-Conformity identified during the progress of works shall be controlled via

Non-Conformance Report (NCR) issued to concerned parties. The records of

this non-conformity shall be maintained in a Non-Conformance Register.

Non-Conformance shall be promptly investigated, documented, evaluated and

corrected in order to prevent recurrence. Corrective Action shall be conducted

within stipulated time and monitored to ensure their adequacy and

effectiveness.

PROJECT QUALITY MANUAL I Page 10 of 13

DOCUMENT REF : PANAROMIC SDN BHD DATE : 05/08/2020

PSB/PQP/QAP REV. NO :

PROJECT QUALITY MANUAL

QUALITY ASSURANCE PLAN

7. CONTROL OF RECORDS

Quality records are documents that provided objective evidence of compliance

with specified requirements. They include but not limited to :

Inspection and Test Records

Equipment List and Calibration Records

Drawings and Specifications

Materials and Goods Flow Records

Technical Records (E.g. Survey Data, Material Certificate)

All Kind of project related correspondence.

Customer and Third Party Complaints.

Arrangement for the archiving of specific records to comply with both Clients

and Regulatory requirements shall be identified and controlled.

PROJECT QUALITY MANUAL I Page 11 of 13

You might also like

- PM Project Quality Plan 8-7-2012Document27 pagesPM Project Quality Plan 8-7-2012XozanNo ratings yet

- Typical Traffic Management Plan - VSDDocument1 pageTypical Traffic Management Plan - VSDNizam Pod100% (2)

- Inspection ControlDocument10 pagesInspection ControlIvan D. RiveraNo ratings yet

- Method Statement For LV & Control Cable Laying at NGPD SiteDocument13 pagesMethod Statement For LV & Control Cable Laying at NGPD SitebabjihanumanthuNo ratings yet

- E-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality PlanDocument26 pagesE-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality Planmahesh100% (1)

- Quality HUB India Training Topics and DurationDocument2 pagesQuality HUB India Training Topics and DurationPrakash kumarTripathiNo ratings yet

- Quality Assurance For Service IndustriesDocument16 pagesQuality Assurance For Service IndustriesDr Srinivasan Nenmeli -K100% (11)

- Method Statement For Installatio of Water Booster PumpsDocument9 pagesMethod Statement For Installatio of Water Booster PumpsDiana Abu Hassan Hatoum100% (1)

- Stone Pitching and Rip-Rap SpecificationDocument0 pagesStone Pitching and Rip-Rap SpecificationNgoka EliesikiaNo ratings yet

- ISO 10064-6-2009 Code of Inspection Practice - Part 6 Bevel Gear Measurement Methods (Đo Bánh Răng Côn)Document42 pagesISO 10064-6-2009 Code of Inspection Practice - Part 6 Bevel Gear Measurement Methods (Đo Bánh Răng Côn)Màu Đen Cuộc SốngNo ratings yet

- Supplier Quality Management System A Complete Guide - 2020 EditionFrom EverandSupplier Quality Management System A Complete Guide - 2020 EditionNo ratings yet

- Method Statement For Construction of Trapezoidal CanalDocument30 pagesMethod Statement For Construction of Trapezoidal CanalAmila Priyadarshana Dissanayake80% (5)

- Common Quality Assurance PlanDocument3 pagesCommon Quality Assurance PlanQASWA ENGINEERING IMRANNo ratings yet

- Asq What Is A Quality PlanDocument3 pagesAsq What Is A Quality PlanCloud RedfieldNo ratings yet

- Municipal ABE Department OrdinanceDocument20 pagesMunicipal ABE Department Ordinancejeffrey100% (3)

- Communication Plan TemplateDocument6 pagesCommunication Plan TemplateHussain ElarabiNo ratings yet

- GEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceDocument20 pagesGEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceUmair Awan100% (1)

- Quality Awareness 2020Document14 pagesQuality Awareness 2020Remya100% (1)

- Blasting Painting ProcedureDocument4 pagesBlasting Painting ProcedureRyanNo ratings yet

- Cost of QualityDocument30 pagesCost of QualityrkshpanchalNo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- QAP Plan For Biratnagar AirportDocument20 pagesQAP Plan For Biratnagar AirportNirmal bhandariNo ratings yet

- Quality Management System GuidanceDocument3 pagesQuality Management System GuidanceAnonymous 3tOWlL6L0UNo ratings yet

- Great Man-Made River Quality AuditingDocument8 pagesGreat Man-Made River Quality Auditingscriptd_ozd3nNo ratings yet

- Piping Systems Srac 1994Document6 pagesPiping Systems Srac 1994maheshNo ratings yet

- Inspection and Testing Plan (Itp) Item: Instruments Air PipingDocument9 pagesInspection and Testing Plan (Itp) Item: Instruments Air PipingNguyen DienNo ratings yet

- Financial Crisis - Group 6Document8 pagesFinancial Crisis - Group 6Anonymous ZCvBMCO9No ratings yet

- Inspection OF Painting, Coating, Wrapping & LiningDocument45 pagesInspection OF Painting, Coating, Wrapping & LiningsreekanthNo ratings yet

- Annex A - Index of Quality ProceduresDocument1 pageAnnex A - Index of Quality ProceduresFendi AchmadNo ratings yet

- Quality Management PlanDocument18 pagesQuality Management Planraditanka aobakweNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- Quality Management System ManualDocument26 pagesQuality Management System ManualtalhaNo ratings yet

- CAT - Duo Cone Seal InstructionsDocument26 pagesCAT - Duo Cone Seal Instructionsford62b100% (2)

- Instrument: InspectionDocument5 pagesInstrument: InspectionToby MerchantNo ratings yet

- Qa QCDocument10 pagesQa QCBrain Dee Tech LtdNo ratings yet

- Rftmdc6a PDFDocument17 pagesRftmdc6a PDFShakeebNo ratings yet

- Job Description - Senior Welding InspectorDocument3 pagesJob Description - Senior Welding InspectorJennifer FrenchNo ratings yet

- Quality BasicsDocument18 pagesQuality BasicsCamyChinNo ratings yet

- Quality Assessment ProcedureDocument3 pagesQuality Assessment ProcedureAlina OnţaNo ratings yet

- PMPT Itp 010Document3 pagesPMPT Itp 010hz135874No ratings yet

- Customer Complains and Audit FormsDocument6 pagesCustomer Complains and Audit FormsAhmad AzrilNo ratings yet

- QMS ProceduresDocument1 pageQMS Proceduressurenu89No ratings yet

- Quality Metrics Project ManagementDocument8 pagesQuality Metrics Project Managementselinasimpson1501No ratings yet

- Quality InductionDocument15 pagesQuality InductionaleemmurtazaNo ratings yet

- COPQDocument8 pagesCOPQJocelyn Garcia100% (1)

- CH 2Document18 pagesCH 2suresh84123No ratings yet

- Guide to Separator Inspection and OptimisationDocument25 pagesGuide to Separator Inspection and OptimisationRawat67% (3)

- Quality Assurance in Construction Definition 150617Document20 pagesQuality Assurance in Construction Definition 150617Andre IrawanNo ratings yet

- Project CommunicationDocument7 pagesProject CommunicationJavadNurIslamiNo ratings yet

- Inspection and Testing To Ensure The Quality of End Product in Construction WorksDocument5 pagesInspection and Testing To Ensure The Quality of End Product in Construction WorksensafepsNo ratings yet

- Quality System ManualDocument50 pagesQuality System ManualrajshakeeNo ratings yet

- Flow Chart-3. Internal NCRDocument1 pageFlow Chart-3. Internal NCRMubashir KhanNo ratings yet

- Maintenance of Overhead Transmission LinesDocument23 pagesMaintenance of Overhead Transmission LinesWilmark R. Cahilig75% (4)

- BNV6200 - Individual Honors Project - Research Proposal - Coursework 01 - 22212876Document52 pagesBNV6200 - Individual Honors Project - Research Proposal - Coursework 01 - 22212876Ahmed Ansaf100% (1)

- Quality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanDocument4 pagesQuality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanJoannesHuseanNo ratings yet

- Codes For Automatic Ultrasonic Testing (AUT) of Pipeline Girth WeldsDocument18 pagesCodes For Automatic Ultrasonic Testing (AUT) of Pipeline Girth WeldsjangdiniNo ratings yet

- Contrat Jesa 4582K/12: Annex N Quality RequirementsDocument33 pagesContrat Jesa 4582K/12: Annex N Quality RequirementsoundilahmedNo ratings yet

- Quality Control and Quality Assurance in Building ConstructionDocument9 pagesQuality Control and Quality Assurance in Building ConstructionAbdul JabbarNo ratings yet

- Rehabilitation and Upgrading of Pakpattan Canal, Khadir Branch and Pakpattan Islam Link Contract: PCSBIP/ICB-01Document53 pagesRehabilitation and Upgrading of Pakpattan Canal, Khadir Branch and Pakpattan Islam Link Contract: PCSBIP/ICB-01yashas sNo ratings yet

- Sudheer Sudhakaran: Top Level AssignmentsDocument3 pagesSudheer Sudhakaran: Top Level AssignmentsAjay KumarNo ratings yet

- CREC Construction Inspection Equipment ProcedureDocument3 pagesCREC Construction Inspection Equipment ProcedureStephen David GozunNo ratings yet

- PQP Vs ISO 9001 Clauses List PDFDocument1 pagePQP Vs ISO 9001 Clauses List PDFVpln Sarma100% (1)

- Quality Management PlanDocument1 pageQuality Management PlanKen LeeNo ratings yet

- QM-QA-QC Basic Infos, LinksDocument8 pagesQM-QA-QC Basic Infos, LinksbehringerzsoltNo ratings yet

- 02 QA Procedures 18Document12 pages02 QA Procedures 18JohnNo ratings yet

- AB-518b Quality Manual and Audit ChecklistDocument24 pagesAB-518b Quality Manual and Audit ChecklistStan Lee PaulsonNo ratings yet

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthNo ratings yet

- Qms Guidelines Appendix A 0Document3 pagesQms Guidelines Appendix A 0BranErikNo ratings yet

- Building Strong: Rick Reese, P.EDocument16 pagesBuilding Strong: Rick Reese, P.EOsama GhannamNo ratings yet

- IR No CE-C1352 Witness to test concrete cubes (compressive strength at 7 days) for containment of pump in DS6. - ف뻵£شDocument1 pageIR No CE-C1352 Witness to test concrete cubes (compressive strength at 7 days) for containment of pump in DS6. - ف뻵£شNassim SabriNo ratings yet

- ISO 9001 Certified Precision MachiningDocument21 pagesISO 9001 Certified Precision Machiningqmicertification100% (2)

- Dinesh Qa-Qc EngineerDocument6 pagesDinesh Qa-Qc EngineerDinesh SomwanshiNo ratings yet

- A Project ReportDocument13 pagesA Project ReportRahul SehgalNo ratings yet

- 06 Breakout D-Quality Risk Management-Key MessagesDocument26 pages06 Breakout D-Quality Risk Management-Key MessagesAhmad KhreisatNo ratings yet

- Qa-Qc Plan For Sharq R-0aDocument163 pagesQa-Qc Plan For Sharq R-0akbldamNo ratings yet

- National Institute of Construction Management and ResearchDocument14 pagesNational Institute of Construction Management and Researchsimple_aniNo ratings yet

- SGI-R.08.17 Rev 0 - Quality Plan DBNRDocument26 pagesSGI-R.08.17 Rev 0 - Quality Plan DBNRLUISNo ratings yet

- Practice of Implementation of Quality Assurance Plan in NepalDocument8 pagesPractice of Implementation of Quality Assurance Plan in Nepalyamanta_rajNo ratings yet

- List Machinery & PlantDocument2 pagesList Machinery & PlantNizam PodNo ratings yet

- List of Machinery & EquipmentDocument2 pagesList of Machinery & EquipmentNizam PodNo ratings yet

- Earthfill and Rockfill Construction GuideDocument32 pagesEarthfill and Rockfill Construction GuidesamNo ratings yet

- Automatic Shut-Off Valves (Also Known As Excess Flow Valves, EFV) For Air or Nitrogen ServiceDocument7 pagesAutomatic Shut-Off Valves (Also Known As Excess Flow Valves, EFV) For Air or Nitrogen ServiceDarwin DarmawanNo ratings yet

- Standard Documents: BGXB02008Document33 pagesStandard Documents: BGXB02008Ricardo F.A.No ratings yet

- NS - QAP-001 - Quality Assurance Provisions (QAPs) v6 - 0Document36 pagesNS - QAP-001 - Quality Assurance Provisions (QAPs) v6 - 0Suleman KhanNo ratings yet

- Maintain Hand ToolsDocument10 pagesMaintain Hand ToolskreamerNo ratings yet

- CPD KCC (Ons) T 3301Document30 pagesCPD KCC (Ons) T 3301khurram ijazNo ratings yet

- NRC Inspection ManualDocument4 pagesNRC Inspection Manualelsayed abdemagiedNo ratings yet

- Pdvsa: Material Technical SpecificationDocument14 pagesPdvsa: Material Technical SpecificationAryelys PadillaNo ratings yet

- Import Procedures by Food GroupDocument108 pagesImport Procedures by Food GroupFAUZANNo ratings yet

- Final Draft Pren 1709: European Standard Norme Européenne Europäische NormDocument19 pagesFinal Draft Pren 1709: European Standard Norme Européenne Europäische Normandre_c_guerraNo ratings yet

- TSPi Workbook 20041202Document37 pagesTSPi Workbook 20041202Knows LeeNo ratings yet

- KTF-standard ENGDocument60 pagesKTF-standard ENGkazdanoNo ratings yet

- ITP-3005 - A01 - SajopDocument12 pagesITP-3005 - A01 - SajopSkinhead TvNo ratings yet

- Final Inspection ReportDocument9 pagesFinal Inspection Reporthamza hameedNo ratings yet

- P166 NSE TS MS MEP MECH 00001 02 Raft Piping Drainage System - BDocument27 pagesP166 NSE TS MS MEP MECH 00001 02 Raft Piping Drainage System - Bgiginbabujohn.spotsNo ratings yet

- 74 Samss 001Document7 pages74 Samss 001getravi1886No ratings yet