Professional Documents

Culture Documents

Detailed Specification PE Casing Jacket With Standard UIP System 1) General

Uploaded by

Mina MagdyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detailed Specification PE Casing Jacket With Standard UIP System 1) General

Uploaded by

Mina MagdyCopyright:

Available Formats

DETAILED SPECIFICATION

PE casing jacket with

®

Standard UIP System

1) General

The pipe shall be insulated using the unique U.I.P.® factory insulation process, as supplied by Urecon

Ltd., complete with integral conduit for electric heat trace cable (if required). Insulation of associated

joints, fittings and accessories shall be as per Urecon's recommendations, depending on the size and

type of pipe involved. The product shall be manufactured in accordance to ISO 9001-2000 Standards, or

approved equal.

2) Pipe and casing preparation

Pipe and casing shall be cleaned of surface dust or dirt, if necessary, to insure adhesion of the foam to

the pipe and casing surface. The pipe and/or polyethylene casing may be treated by sand blasting,

application of a chemical foam-bonding compound, or by flame to enhance adhesion, as deemed

necessary by Urecon and project requirements.

3) Heat tracing conduit(s)

Heat tracing conduit(s) shall consist of an extruded molding and shall be applied to the pipe prior to

application of the insulation. The conduit(s) will be securely fastened to the pipe to prevent the ingress of

foam therein during the insulation process. All conduit shall be checked after insulating to insure they are

not plugged. The ends shall be sealed prior to shipping to prevent any foreign material from entering the

conduit while in transit or during installation.

4) Insulation

a) Material: rigid polyurethane foam, factory applied.

b) Thickness: 50 mm (2 in.) or as required.

c) Density: (ASTM D 1622) 35 to 48 kg/m3 (2.2 to 3.0 lbs/ft3 ).

d) Closed cell content: (ASTM D 2856) 90%, minimum.

e) Water absorption: (ASTM C272) 4.0% by volume.

0 2 0

f) Thermal conductivity: (ASTM C518) 0,020 to 0,026 W/m C (0.14 to 0.17 Btu in/ft hr F).

5) System properties

a) System compressive strength: (modified ASTM D 1621 with casing jacket) approximately 690 to

1379 kPa (100-200 lbs/in2 ), varies with pipe diameter.

b) Core pipe service temperature range: from -45o to 930C (-490 to 200oF ); the overall factory insulated

system limitations are dependant on core pipe type and application. Call your Urecon representative

for details.

PE Casing Specs with standard UIP system, Feb. 2010 1

6) Outer PE jacket

The outer protective jacket on the casing system shall consist of black P.E. UV inhibited, factory applied

as per the following specifications:

a) Cell classification =234360C for PE, ASTM D3350

b) Minimum 2% carbon black, well dispersed

c.) Minimum recommended PE casing jacket thicknesses (for above grade applications)-

Jacket OD <or = 300mm (12”) @ 3,17 mm (125 mil)

Jacket OD 300mm (12”) to < or = 600mm (24”) @ 3,81 mm (150 mil)

Jacket OD > 600mm (24”) @ 4,44mm (175 mil)

*other jacket thicknesses are available upon request

7 a) Insulated pipe joints (above ground)

Insulated pipe joints shall consist of prefabricated rigid polyisocyanurate or urethane foam half shells

supplied complete with either:

3,17 – 6,35 mm (0.125 to 0.250 in.) wall split casing, stainless steel bands and band-it clips. This

Urecon Slipjoint allows for expansion and contraction by having one end fixed while the other end is free

to slide.

Canusa Superseal® heat shrink wrap

For more demanding or waterproof applications, a heat-shrinkable expanded cross linked

polyethylene casing is available in lieu of the split casing. This is the Urecon Mec-Seal joint kit.

b) Insulated pipe joints (buried)

Insulated pipe joints shall consist of prefabricated rigid polyisocyanurate or urethane foam half shells

supplied complete with wrap-around adhesive lined heat-shrink sleeves, as supplied by Urecon. The

heat- shrink sleeves shall overlap the insulation jacket by a minimum of 75 mm (3 in.) on either side of

the joint providing a waterproof seal. For more demanding or critical applications, a Urecon Mec-Seal

Joint kit should be considered.

8) Insulation for fittings

a.) Field applied insulation kits:

Insulation kits for fittings shall consist of rigid polyisocyanurate or urethane foam insulation with a fully

bonded polymer protective coating on all exterior and interior surfaces, including ends. Kits to be

supplied complete with silicone caulking for seams, stainless steel attachment straps and clips, and

heat-shrink sleeves or butyl mastic tape to seal between pipe and insulation kit.

i) Rigid Polyisocyanurate or urethane foam insulation

PE Casing Specs with standard UIP system, Feb. 2010 2

.1 Density (ASTM D1622) 27 to 32 kg/m 3 (1.7 to 2.0 lbs/ft3).

2

.2 Compressive strength (ASTM D1621) 131 to 158 kPa (19 to 23 lbs/in ) .

.3 Closed cell content 90%, minimum.

.4 Water absorption: (ASTM C272) 4.0% by volume.

.5 K factor: (ASTM C 518) 0,027 W/m0C, (0.19 Btu • in/ft2 • hr • 0F).

.6 Thickness to match pipe insulation thickness.

ii) Polymer Coating, Urecon BL-100-20EP

.1 Two component high density polyurethane coating, black in color.

3

.2 Density 1170 kg/m3 (73 lbs/ft ).

.3 Durometer D scale 60.

2

.4 Tensile strength 11,100 kPa (1610 lbs/in ).

.5 Tear strength 26,5 N/mm (151 lbs/in).

.6 Thickness 2.54mm (100mils)outside surfaces; 0,51 mm (20 mils) inside surfaces.

b.) Factory insulated fittings-

Fittings to be factory insulated must either be bell X spigot in configuration or have adequately long legs

on each end to allow for joining in the field.

Each fitting shall be insulated with urethane foam as described in section #4 above, and the jacket shall

be either-

2.54mm (100 mil) polymer coating with the physical characteristics as described in (8 a.ii) above

-OR-

mitered / fused PE casing with a minimum thickness as the PE jacket on the factory insulated pipe.

9) Electric Tracing System

The electric tracing system and associated controls shall be as per the manufacturer's recommendations

with particular attention being paid to the watt densities applied through conduits on plastic pipes. All

tracing cables and related accessories to be CSA approved and comply with CSA heat-tracing standard

C22.2 No. 130.2-93. Standard of acceptance is Urecon’s Thermocable or approved equal. Please

contact your Urecon representative for further details and design assistance.

Note: -Physical characteristics are nominal and may vary depending on pipe type and diameter (Revised Feb. 2010).

PE Casing Specs with standard UIP system, Feb. 2010 3

You might also like

- Piping & Equipt Insulation - RevDocument7 pagesPiping & Equipt Insulation - RevLuis Gabriel BautistaNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- C610 PDFDocument4 pagesC610 PDFGLADYS2714No ratings yet

- Insulation SpecDocument16 pagesInsulation Specsandesh100% (1)

- Pipe Insulation Section OverviewDocument8 pagesPipe Insulation Section OverviewManjunath ShettyNo ratings yet

- Astm C547Document7 pagesAstm C547Javier Orna100% (1)

- Asme II Part D Metric 2019Document1,262 pagesAsme II Part D Metric 2019José GarcíaNo ratings yet

- Products and Services CatalogueDocument34 pagesProducts and Services CatalogueDOC LABNo ratings yet

- Specification For Pressure Vessel Plates, Carbon Steel, Low-And Intermediate-Tensile StrengthDocument4 pagesSpecification For Pressure Vessel Plates, Carbon Steel, Low-And Intermediate-Tensile StrengthLeandro Marinho100% (1)

- Indo Nickel Mining and Industry Move ForwardDocument29 pagesIndo Nickel Mining and Industry Move Forwardone_peaceNo ratings yet

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDocument7 pagesASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastNo ratings yet

- 2A?Djkhkcu: Insulation & LiningsDocument4 pages2A?Djkhkcu: Insulation & LiningsbenssjNo ratings yet

- Connections in Steel StructuresDocument4 pagesConnections in Steel StructuresLorna BacligNo ratings yet

- API 580 Closed Book Question AnalysisDocument16 pagesAPI 580 Closed Book Question AnalysisAdriana MarcelaNo ratings yet

- Ep-Gis 36-320 - b05Document77 pagesEp-Gis 36-320 - b05Matteo ColomboNo ratings yet

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeDocument22 pagesTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshNo ratings yet

- 3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPDocument24 pages3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPAnonymous 4kYNmixNo ratings yet

- 11kV - 3-C - 300 - AL - Cable - Specification Final PDFDocument18 pages11kV - 3-C - 300 - AL - Cable - Specification Final PDFShubham BaderiyaNo ratings yet

- M2 - Manual PDFDocument0 pagesM2 - Manual PDFFlorinHanu100% (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Detailed Specification Detailed Specification: GeneralDocument3 pagesDetailed Specification Detailed Specification: GeneralRamachandran SundararamanNo ratings yet

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDocument7 pagesPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1No ratings yet

- Special Specification 4604 Stay CablesDocument15 pagesSpecial Specification 4604 Stay CablesAbok Cai NginumNo ratings yet

- TROSTEN Mechanical Specification - AHUDocument6 pagesTROSTEN Mechanical Specification - AHUBalaji JenarthananNo ratings yet

- SECTION 15081: Ductwrap - Doc 1Document2 pagesSECTION 15081: Ductwrap - Doc 1geverett2765No ratings yet

- Mechanical Insulation Standards at UT AustinDocument8 pagesMechanical Insulation Standards at UT Austinrizviabbas2012No ratings yet

- Afico Pipe Insulation PDFDocument4 pagesAfico Pipe Insulation PDFHusni HayathNo ratings yet

- Guide - Foam Glass InsulationDocument25 pagesGuide - Foam Glass InsulationChristian DoriaNo ratings yet

- 66 KV Cable and AccessoriesDocument4 pages66 KV Cable and AccessoriesSandip AhireNo ratings yet

- Armaflex Insulation + Fire Rated DuctworkDocument7 pagesArmaflex Insulation + Fire Rated DuctworkGiải Pháp Cơ ĐiệnNo ratings yet

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Document5 pagesEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783No ratings yet

- (ERECTION PROCEDURE Insulation-Lagging) - BiddingDocument5 pages(ERECTION PROCEDURE Insulation-Lagging) - BiddingnuntaricherdchaiNo ratings yet

- (ERECTION PROCEDURE Insulation-Lagging) - Bidding 0Document5 pages(ERECTION PROCEDURE Insulation-Lagging) - Bidding 0nuntaricherdchaiNo ratings yet

- Duct InsulationDocument9 pagesDuct Insulationphyolwin ooNo ratings yet

- Section-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPEDocument5 pagesSection-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPESandeep SharmaNo ratings yet

- Technical SpecificationDocument7 pagesTechnical SpecificationrohitctppNo ratings yet

- Cap Ngam 240mm2 Cach Dien Xlpe Hay EprDocument7 pagesCap Ngam 240mm2 Cach Dien Xlpe Hay EprMinh VienNo ratings yet

- Cross-Linked Polyethylene Insulated Thermoplastic Sheathed Cables-SpecificationDocument22 pagesCross-Linked Polyethylene Insulated Thermoplastic Sheathed Cables-SpecificationSuresh SharmaNo ratings yet

- Tica SpecDocument29 pagesTica SpecCong ThanhNo ratings yet

- Cables Specifications VFDocument13 pagesCables Specifications VFraiutkarshNo ratings yet

- 80080-TCH-0000-SP-003_SIGNED-Coating ProcedureDocument7 pages80080-TCH-0000-SP-003_SIGNED-Coating ProcedurePaul NieNo ratings yet

- Fan Coil UnitsDocument2 pagesFan Coil UnitsAhmadNo ratings yet

- Polyethylene InsulationDocument2 pagesPolyethylene InsulationJeghi100% (1)

- Water Agencies' Standards Standard SpecificationsDocument9 pagesWater Agencies' Standards Standard SpecificationsAdelChNo ratings yet

- SECTION 15083: Pipeing Insulation 15083Document8 pagesSECTION 15083: Pipeing Insulation 15083fatREVITNo ratings yet

- Technical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 ScopeDocument22 pagesTechnical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 Scopethomas chinNo ratings yet

- GS 50PG 4PDDocument8 pagesGS 50PG 4PDSalvador Loyola TreviñoNo ratings yet

- Exhibit B-30 InsulationDocument7 pagesExhibit B-30 Insulationsethu1091No ratings yet

- Cathodic Protection 2015Document21 pagesCathodic Protection 2015ainunNo ratings yet

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530No ratings yet

- 3m qtII 5623kDocument4 pages3m qtII 5623kcerachuckNo ratings yet

- RegulationDocument15 pagesRegulationLuzhengyeNo ratings yet

- Fibrous Glass Duct SystemDocument4 pagesFibrous Glass Duct SystemJFBD BuildersNo ratings yet

- Chiller Tech3 - EIL DelhiDocument3 pagesChiller Tech3 - EIL DelhibmanojNo ratings yet

- 15 1 3 Mechanical InsulationDocument7 pages15 1 3 Mechanical Insulationfarshan296015No ratings yet

- Tech Specs 1Document22 pagesTech Specs 1headqcNo ratings yet

- Opgw SpecificDocument21 pagesOpgw SpecificASH TVNo ratings yet

- 941 - 82A1 Rev.: 0 Date: May, 2006: Enap Refineria Bio-Bio Interconexiones Unidad DGC External Insulation Hot ServiceDocument24 pages941 - 82A1 Rev.: 0 Date: May, 2006: Enap Refineria Bio-Bio Interconexiones Unidad DGC External Insulation Hot Servicepablo padronNo ratings yet

- Styrofoam (English)Document21 pagesStyrofoam (English)Krish DoodnauthNo ratings yet

- CSC XxxxixDocument10 pagesCSC XxxxixAshish bhattNo ratings yet

- PAL Polyurethane Panel Spec 31102008Document4 pagesPAL Polyurethane Panel Spec 31102008Mohd Fahmie Bin MustapaNo ratings yet

- ZTT Technical Spec for Duct & Direct Buried Optical CableDocument8 pagesZTT Technical Spec for Duct & Direct Buried Optical CableEnzo del PradoNo ratings yet

- Share 'Compliance 5-6-7 ADSS FiberDocument6 pagesShare 'Compliance 5-6-7 ADSS FiberShashank SaxenaNo ratings yet

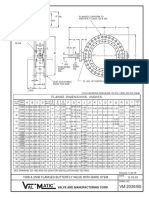

- Cast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscDocument3 pagesCast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscMina MagdyNo ratings yet

- FM-CR FlgaDocument4 pagesFM-CR Flgamdkhan17No ratings yet

- Fawwas SpecsDocument1 pageFawwas SpecsHassan SleemNo ratings yet

- ASME B16.20 Gasket Dimensions: Standard Standard With Inner RingDocument1 pageASME B16.20 Gasket Dimensions: Standard Standard With Inner RingMina MagdyNo ratings yet

- Flex-Valve CatalogDocument20 pagesFlex-Valve CatalogMina MagdyNo ratings yet

- Grinnell Mechanical Products Figure 61 Flange Adapter For Joining Copper Tubing (CTS) Installation / Assembly InstructionsDocument2 pagesGrinnell Mechanical Products Figure 61 Flange Adapter For Joining Copper Tubing (CTS) Installation / Assembly InstructionsMina MagdyNo ratings yet

- Flanges: Figure 71 Flange Adapter (ANSI Class 125/150)Document2 pagesFlanges: Figure 71 Flange Adapter (ANSI Class 125/150)Mina MagdyNo ratings yet

- Olets PricelistDocument4 pagesOlets Pricelistangelufc99No ratings yet

- Ethafoam 600 Polyethylene Foam: Density 6.0 PCF (96.1 KG/M) Maximum Loading 10.0 Psi (69 Kpa) Color NaturalDocument2 pagesEthafoam 600 Polyethylene Foam: Density 6.0 PCF (96.1 KG/M) Maximum Loading 10.0 Psi (69 Kpa) Color NaturalMina MagdyNo ratings yet

- Performance Foam Product InformationDocument2 pagesPerformance Foam Product InformationMina MagdyNo ratings yet

- Ethafoam M5 Polyethylene Foam: Density 10.0 PCF (160.2 KG/M) Maximum Loading 20.0 Psi (138 Kpa) Color BlackDocument2 pagesEthafoam M5 Polyethylene Foam: Density 10.0 PCF (160.2 KG/M) Maximum Loading 20.0 Psi (138 Kpa) Color BlackMina MagdyNo ratings yet

- Ethafoam 400 Polyethylene Foam: Density 4.0 PCF (64.1 KG/M) Maximum Loading 5.0 Psi (34.5 Kpa) Color Black, NaturalDocument2 pagesEthafoam 400 Polyethylene Foam: Density 4.0 PCF (64.1 KG/M) Maximum Loading 5.0 Psi (34.5 Kpa) Color Black, NaturalMina MagdyNo ratings yet

- Plain End Fittings: Figure 914 & 924Document1 pagePlain End Fittings: Figure 914 & 924Mina MagdyNo ratings yet

- Comparing 3-Piece Y-Lateral Fittings: NPS, and SDR's Between 6.3 and 17, Will, at Minimum, 126%Document1 pageComparing 3-Piece Y-Lateral Fittings: NPS, and SDR's Between 6.3 and 17, Will, at Minimum, 126%Mina MagdyNo ratings yet

- Vitaulic Style 44Document3 pagesVitaulic Style 44joseNo ratings yet

- Lap Joint Stub End PDFDocument2 pagesLap Joint Stub End PDFBowo Edhi WibowoNo ratings yet

- Style 28 Coupling: Applied Vic-Ring SystemDocument4 pagesStyle 28 Coupling: Applied Vic-Ring SystemMina MagdyNo ratings yet

- Quickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsDocument4 pagesQuickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsMina MagdyNo ratings yet

- Vitas Check Valves Full OpeningDocument4 pagesVitas Check Valves Full OpeningMina MagdyNo ratings yet

- Flexible High Pressure Coupling For Applied Vic-Ring SystemsDocument4 pagesFlexible High Pressure Coupling For Applied Vic-Ring SystemsMina MagdyNo ratings yet

- Standard Flexible Coupling: Carbon Steel Pipe - Grooved CouplingsDocument4 pagesStandard Flexible Coupling: Carbon Steel Pipe - Grooved CouplingsMina MagdyNo ratings yet

- Cast Steel Swing Check Valve: Class 150 - Bolted CapDocument3 pagesCast Steel Swing Check Valve: Class 150 - Bolted CapMina MagdyNo ratings yet

- High Performance Butterfly Valves: Corrosion ResistantDocument3 pagesHigh Performance Butterfly Valves: Corrosion ResistantMina MagdyNo ratings yet

- Fluorogold PDFDocument14 pagesFluorogold PDFnileshmadankarNo ratings yet

- VM 2030 BS - 11 20 09Document1 pageVM 2030 BS - 11 20 09Mina MagdyNo ratings yet

- CPVC BrochureDocument8 pagesCPVC BrochureMina MagdyNo ratings yet

- Cast Carbon Steel Check Valve: Class 150Document1 pageCast Carbon Steel Check Valve: Class 150Mina MagdyNo ratings yet

- 3306 SnubberDocument4 pages3306 SnubberMina MagdyNo ratings yet

- Building Connections That Last: Anvil BrandsDocument4 pagesBuilding Connections That Last: Anvil BrandsMina MagdyNo ratings yet

- Manual Arc Welding of Titanium Alloy Hardware Process SpecificationDocument20 pagesManual Arc Welding of Titanium Alloy Hardware Process SpecificationFaiz NanafiNo ratings yet

- 1-Phase TransformerDocument21 pages1-Phase TransformerVishnuNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Proforma Invoice: No Picture Description EXW Price/Set (USD) Quantity (SET) Total Amount (USD)Document1 pageProforma Invoice: No Picture Description EXW Price/Set (USD) Quantity (SET) Total Amount (USD)Juan José Ac MayNo ratings yet

- C: T F F: Orrosion AND Abrasion HE Inal RontierDocument3 pagesC: T F F: Orrosion AND Abrasion HE Inal Rontier1977julNo ratings yet

- SuperChute Manual November 2017Document127 pagesSuperChute Manual November 2017Terry CheungNo ratings yet

- English For Welding 1Document188 pagesEnglish For Welding 1MOSES7 WISE100% (1)

- Test Booklet: Steel StructuresDocument6 pagesTest Booklet: Steel StructuresICE Group of Education BhopalNo ratings yet

- Mil L 46010BDocument18 pagesMil L 46010BaguNo ratings yet

- Contact: Non-Ferrous Metals & Ferro Alloys - TradingDocument4 pagesContact: Non-Ferrous Metals & Ferro Alloys - TradingYakup AVCINo ratings yet

- Remote Laser Welding With High Power Fiber LasersDocument8 pagesRemote Laser Welding With High Power Fiber LasersOnderNo ratings yet

- Rail Brochure 1Document58 pagesRail Brochure 1Tengku Azaha Tengku IsmailNo ratings yet

- GDCS Bandlock2 LiteratureDocument2 pagesGDCS Bandlock2 LiteratureFilipNo ratings yet

- Henco Multilayer Pipe: GAS Heating Sanitary Underfloor HeatingDocument4 pagesHenco Multilayer Pipe: GAS Heating Sanitary Underfloor HeatingSaurabh KumarNo ratings yet

- 4th Question Experimental TechniquesDocument10 pages4th Question Experimental TechniquesHayaa KhanNo ratings yet

- Corrosion Properties of 2219Document100 pagesCorrosion Properties of 2219Maaz ZafarNo ratings yet

- Emaco S73: Thixotropic Fibre Reinforced, Polymer Repair MortarDocument2 pagesEmaco S73: Thixotropic Fibre Reinforced, Polymer Repair MortarFrancois-No ratings yet

- PIAZZA TRENCH GRATINGS FOR HOLY HARAM MAKKAH EXPANSIONDocument5 pagesPIAZZA TRENCH GRATINGS FOR HOLY HARAM MAKKAH EXPANSIONwooderNo ratings yet

- Door Schedule: D1 D2 D3 D5 D4Document1 pageDoor Schedule: D1 D2 D3 D5 D4Geni RapsanjaniNo ratings yet

- TCR Engineering Services Profile 2010Document50 pagesTCR Engineering Services Profile 2010aayasirNo ratings yet

- Dr. Kishor Kumar Gajrani: IIIT DM Kancheepuram, ChennaiDocument12 pagesDr. Kishor Kumar Gajrani: IIIT DM Kancheepuram, Chennaim sriNo ratings yet

- WAIN Easy CatalogDocument18 pagesWAIN Easy CatalogAarsol AdvanceNo ratings yet

- UL Listing For Copper Bonded RodsDocument2 pagesUL Listing For Copper Bonded RodsPraveen BoshettiNo ratings yet