Professional Documents

Culture Documents

Make A Scale Electric Guitar: Instructables

Uploaded by

rhinorodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Make A Scale Electric Guitar: Instructables

Uploaded by

rhinorodCopyright:

Available Formats

instructables

Make a Scale Electric Guitar

by drum303

I recently came across a Youtube video where Green Day fan and you want to make a replica of one

someone made three little guitars out of popsicle stick of their guitars, or even a bass. Follow these steps

s. I sometimes make tiny things and I really liked the and you can totally do it without a whole bunch of

video and how it was made. I feel like she did a really expensive tools or equipment. You can probably even

good job and made it seem super easy (it actually do a better job than I did. Continue on to the next step

was) and I felt like I wanted to try it. I used a lot of tips that shows you everything you need to build one.

in the video to make my own tiny guitar and it came You'll be surprised that you probably have most of it

out way better than I had expected. already.

I had made a few videos and instructables in the past Also of note: This isn't particularly a scale model

and kind of wanted to build an overhead camera rig to precisely, as I originally made it whatever size I was

document some of the stuff I've been making so I've comfortable with. Big enough that it wasn't impossible

done just that. Lets make something cool. to work with and small enough to be really cool.

Technically, its right around 1/6 scale, which is called

You can make this. Maybe you have a real guitar and "Barbie" scale in some circles. This is because

want to make a tiny replica. Maybe there is a certain Barbie is more or less 1/6 scale.

guitar you really want, or maybe you are a huge

Make a Scale Electric Guitar: Page 1

https://youtu.be/s2vZtcjfEpU

Download

https://www.instructables.com/ORIG/FXV/JG9U/JP8ZBWM0/FXVJG9UJP8ZBWM0.pdf

…

Step 1: Stuff You'll Need

Materials Super glue

1/4" thick basswood for guitar body (6mm) Silver metallic thread

1/8" thick basswood for guitar neck (3mm) Seed beads - silver if you have them, but they can be

painted.

Polystyrene for pickguard/pickups - I used Evergreen

brand but you can use recycled packaging if you Tools

want.

Metal pins for tuners - I found something called "eye Dremel or other rotary tool with drum sanding bits

pins" for beading. I got mine from Michaels but here is

an AMAZON LINK. Small coping saw or scroll saw

Stick pins for frets 150, 300, and 600 Grit sandpaper

Spray paint - depending on your design Razor/Exacto blade

Silver enamel model paint, for screws/metal parts Small file

Black enamel model paint, for detail work Tweezers

Clear spray enamel - for the clearcoat Masking tape

Wood glue 1/32 drill bit

Make a Scale Electric Guitar: Page 2

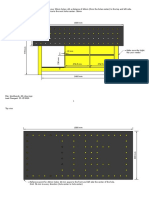

Step 2: The Body

I created a template you can use if you want to make After it is traced on the wood, cut the shape by

a standard Fender Stratocaster shape. Just print it following the line. I used a hand held coping saw but

out, cut it out and trace the shape onto your 1/4" you can use whatever you have. Basswood is super

basswood. I chose basswood because it is really soft soft so it wont take you long at all.

and easy to work with, and they have various sizes

and thicknesses available at most hobby or craft After the body was cut from the basswood, it was

stores. really rough and full of saw marks. First I sanded

around the outside with a Dremel tool fitted with a

small sanding drum. You certainly wouldn't have to at images of the guitar you are recreating. The

do this but it sped up the process of cleaning up the Stratocaster has nice rounded edges all the way

saw marks. around the front and back. Everything is really

smooth. Use the 180 grit to model those features.

If you are familiar with the Stratocaster shape, you Spend some time on this. Even though the basswood

are aware of the part on the back and the other area is soft, this part is really important. Make sure

on the front that is sanded down a bit more (see fig). everything is smooth

I've learned that Fender calls this the "Comfort

Contour Body" If you were wondering. If you are Continue with the 320 and 600 grit papers, often

making this or any other model, be aware of these looking at the photos of the guitar you are modeling.

features. Look for more pictures taken at different angles.

Follow these images as best you can and sand

After I sanded down those areas with the Dremel, I everything until its smooth.

switched to hand sanding with 180 grit. Look closely

Make a Scale Electric Guitar: Page 3

Make a Scale Electric Guitar: Page 4

1

1. Sand down this area 1. Sand down this area

Step 3: The Neck

Making the neck is going to be pretty much the same having to start all over.

process as making the body. Cut out the paper shape

and trace it onto the 1/8" basswood making sure the After it is cut out, sand it just like you did the body

length of the neck goes with the grain. This is how beginning with the 180 grit sandpaper. Take note

real guitars made are and it is important. I cut this one though that the back of a guitar neck is usually a half

out with an Exacto knife. I had trouble cutting it out circle. I did round the back of my neck far more than

with the saw because the straight parts weren't the front, but not nearly half round like a full size

straight enough and the wood is really thin and brittle. guitar. The head is also set back a bit from the neck

The Exacto blade cuts right through the wood going as you can see in the photo. I chose not to do this but

along the grain. Use caution here though because it these would be a few things you could do that would

splits REALLY easy. I suggest making all your cross be more accurate than mine. After getting it nice and

cuts first. I split the first 3 I made and it might take you smooth with the 180 grit, move on to the 320 and then

one or two to get it right as well. If it does split at the to the 600. This shouldn't take long at all.

head though, you can glue it pretty easily without

Make a Scale Electric Guitar: Page 5

1

1. Make sure the wood grain follows the neck.

1. Cut these cross grain cuts first, getting them as deep as possible, if not

completely through.

Make a Scale Electric Guitar: Page 6

Step 4: Cutting a Notch Out of the Body for the Neck

Look at a guitar (or pictures of guitars) and notice that about 1/4th of the thickness of the body and make

the neck and fretboard are just slightly higher than the another cut along the top at the same depth. After

body to allow the strings to move. Hold the neck of you've cut most of the shape, use your exacto or a

your guitar on top of where it belongs on the body. small screwdriver to pry out the piece to allow the

Use a pencil to trace the shape of the neck that neck to be set into the body.

overlaps the body. Use your exacto knife to cut into

the body following the lines you traced. Cut down

Make a Scale Electric Guitar: Page 7

Step 5: Painting the Body

For this guitar I have chosen to do a "sunburst" type towel, similar to staining.

of paint job, although it may not be an exact replica. If

you choose to do a solid color, the process will be The second part of the "sunburst" pattern is the faded

similar. dark part around the outside of the body. To get this

effect, I used a small sponge. Pour out some paint,

The first thing I did was mix up some acrylic paint to "ochre" in this case, and dab your sponge in it. Then

the color I wanted. You may be better off using stain, get most of the paint off the sponge by dabbing it

but I didn't have anything close to the color I wanted further on a piece of news paper or paper plate.

so I made my own with acrylic. It seemed to work just

fine for me. After most of the sponge is dry, carefully dab it

around the perimeter of the guitar, using photos for

I used plenty of water mixed with the paint. Not reference. Make sure you get the sides pretty solid

enough that the wood got wet when i was painting, and the front and back faded evenly.

but it was really thin. This allowed me to paint it on

kind of sloppy and wipe off the excess with paper

Make a Scale Electric Guitar: Page 8

Make a Scale Electric Guitar: Page 9

Step 6: Clearcoat

The first thing I did in preparation for the clear gloss grit sandpaper. This will knock down any bumps or

finish was to glue a piece of scrap to the body where bubbles and make the first coat a bit rough which will

the neck will eventually go. This will help you get a allow the next coat to adhere. make sure you are

nice even coat of clear that will dry really well. careful to wipe off any dust from sanding with a lightly

damp cloth or tack cloth if you have one.

When the glue on your new "handle" is dry you can

move on to painting the clear coat being careful to get Paint a second layer of clearcoat. You will notice this

a light even coat on both the front and back as well as one is much smoother than the first. Be sure to let it

the sides. Make sure that wherever you choose to dry thoroughly before continuing.

paint has adequate lighting and is well ventilated.

These steps would be the same if you were painting If you want to take it even further you could continue

yours a solid color with spray paint. with a few more coats and polishing them with finer

sandpaper or even car polish. There are plenty of

After the first coat, allow the paint to dry thoroughly youtube videos that will help you learn how to do this.

following the instructions on the paint you chose to

use. Then, lightly sand the entire piece with the 600

1. Doesn't look too nice after the first coat

Make a Scale Electric Guitar: Page 10

1

1. Sand with 600 Grit 1. Much better after the second coat

Step 7: PickGuard

The pick guard for the guitar I am building is black on wouldn't worry about it.

the front and back with white sandwiched in between.

To achieve this effect, I am making it out of white After you have it cut out and it fits correctly, sand the

polystyrene and painting it black. If you want a solid front face with the 600 grit sandpaper. This will help

color pick guard, you can make it out of scrap plastic your paint adhere better. Sand the edges a bit too, as

from packaging or whatever you have around. The you may find the exact blade creates sharp edges

polystyrene I use is Evergreen brand that you can get that will need to be knocked down. Thoroughly wipe

at most hobby stores. I keep a fair amount on hand. the piece to remove any dust. Tape a popsicle stick

or scrap piece of wood to the back of the plastic to

Cut out the pickguard from the pattern or use your use as a handle for painting.

own. After cutting it out of the paper, test fit it onto

your guitar body and make any necessary Paint the pick guard with gloss black spray paint. Use

adjustments to make it fit. Then, trace it onto your two coats if necessary and sand with 600 Grit in

chosen plastic material and cut it out with an Exacto between coats. After the piece has dried, sand

blade. Test fit it again and make any necessary around the perimeter edge of the pick guard to reveal

adjustments. This is in case you've slightly over- the white plastic, giving it the two tone look as seen

sanded your guitar body in previous steps. I had to on the real thing. Glue it to the body.

make a few adjustments on each of mine, so I

Make a Scale Electric Guitar: Page 11

1

1. Tape the pickguard to a piece of scrap to aid in painting.

Make a Scale Electric Guitar: Page 12

Step 8: Frets and Tuner Pegs

Take the template that you used to cut out your neck. just press them in farther. The wood is soft enough for

Place it on top of the neck you cut out and use the this.

red lines to mark where the frets are placed on the

fret board. Also use your Exacto knife to make tiny To prepare the neck to receive the frets, use a razor

marks where the tuning pegs go. Just poke the blade blade to cut a tiny slot where each fret will be placed.

through the paper and into the head just a tiny bit. This doesn't have to be too deep. Frets stick above

Then use your Dremel tool and a 1/32 drill bit to make the neck anyways, so this slot is just a spot for the

the holes for the tuning pegs, being careful not to drill frets to sit and somewhere for the glue to adhere. Put

all the way through (but if you do, its not too terrible. a tiny bit of superglue on a small stick pin and glue

You can fix it.) one in each slot. Use something hard to press them

into each of the slots. The glue will quickly soak into

Use your diagonal pliers (or side cutter) to cut 6 the wood, so after it dries enough to hold in there, put

pieces of wire from your beading needles or whatever another bead of glue across each fret. I did the

wire you chose to use for the tuning pegs. Cut these several times so that the frets were almost coated

to about 1/2 inch. I put each of mine in the Dremel with glue. This may take you a few times. Some will

and used a small file to remove the sharp points after fall out immediately and some will fall out in further

cutting them. You want these to be smooth. You steps. Just be patient with it and if they come out, just

could also just sand them down with sandpaper or glue them back in.

just the file if you'd like. Then cut the rough end down

so that when you put them into the hole you just When the glue has dried thoroughly (preferably over

drilled, they stick out about 1/8 of an inch. Test fit night) cut the extra wire off both sides with your side

these before gluing. cutter. Then use a small file or your Dremel tool with

a grinding bit to grind them flush to the neck.

After you have the tuning pegs in, check to make sure

they are even. If any of them stick out too far, you can

Make a Scale Electric Guitar: Page 13

1

1

1. Lightly mark the fret positions along the side of the neck. 1. Punch tiny holes where the tuner pegs will go

1

1

1. Drill 1/32" holes 1. File any sharp points from these pins

1. Carefully glue the pins into the holes

Make a Scale Electric Guitar: Page 14

1

1. Cut thin grooves for the frets following the lines you made earlier

Step 9: Pickups

Cut a 1/8 inch (3mm) wide strip of polystryrene or scrap plastic for the pickups. From that strip, cut three pieces 3/8

inch (10mm) long. Use your Exacto knife or a nail clipper to clip the corners from each piece. This will help you to

shape it using 300 grit sandpaper. Carefully sand the edge of each of the pickups to a uniform rounded shape.

Glue them to the pickguard on the body.

1. Place the finished pickups.

Make a Scale Electric Guitar: Page 15

Step 10: Neck and Back Plates

Cut a 7/16 inch (11mm) by 9/16 inch (15mm) piece of polystyrene for the back plate. Round the corners with 300

grit sandpaper. Then cut a 3/8 inch (10mm) by 1/4 inch (6mm) piece for the neck plate. Round the corners for this

one as well, then use a toothpick to drop a tiny dot of glue to each corner. These dots will represent the neck plate

screws.

1

1

1. Rough neck plate before sanding and detailing 1. Put a tiny dot of white glue on each corner to represent the screws.

These will show better after paint.

Make a Scale Electric Guitar: Page 16

Step 11: Bridge Assembly and Tuners

For the bridge assembly, cut a 3/8 inch (10mm) by silver model paint.

1/8 inch (4mm) rectangle and a smaller 3/8 inch

(10mm) by 1/16 inch (2mm) one. Glue them together After all your parts are dry, glue the bridge to the

at a right angle to represent the bridge. Then cut six body. Then glue the six tuner parts to the head. Cut

tiny squares 1/16 X 1/16 to represent the saddles, six 1/4 inch (6mm) lengths of wire from your beading

which are the small parts the strings come through. needles and glue one up against each of the tuner

Glue these onto the bridge. bodies. When the glue has dried, cut them to even

lengths. Finally glue a silver bead on the end of each

Then, cut six more 3/8 inch (10mm) squares for the piece of wire to represent the tuners.

tuner bodies and paint each of these pieces with

1 1

1. Glue the two pieces together to create the bridge. 1. Cut out six small squares for the tuner bodies.

1. The dots of glue really show now. 1. Glue the tuner bodies to the head.

1. Cut each of these to the same length.

Make a Scale Electric Guitar: Page 17

1. Cut each of these to the same length.

1

1

1. Glue a silver bead onto each one. 1. Closeup of the bridge assembly. Ill need to trim a bit off.

1

1. Bridge

2 2. Saddles

Step 12: Body Detail

Glue the neck plate and back plates to the back of the held at an angle and just pressed it into the body to

body. Paint six black marks on the back plate to get the shape I was looking for. Use an Exacto blade

represent the holes. You could actually drill them, but to clean it up a bit then paint the opening silver.

I noticed that they weren't as noticeable that way.

Note that they are offset to the right slightly. Then use Use the same fine paintbrush to put six dots on each

silver paint to create the tiny screws that hold the of the pickups to represent what I believe are called

back plate on. Note that they are not placed uniformly the "slugs" or the exposed metal parts of the pickups.

either. Then create two screws outside each pickup. Finally,

create the pickguard screws using an image or real

On the front, use your Dremel tool to cut the hole for guitar for reference.

the output jack. I used a triangle shaped cutting bit

Make a Scale Electric Guitar: Page 18

1

1. Finished back plate with screws and holes 1. Cutting the hole for the input jack

1

1

1. Painting the input jack 1. The bridge has been placed and all the screw dots are painted

Step 13: Neck Detail

Glue a thin strip of polystyrene or scrap plastic to the After everything has dried completely, you can glue

top of the head to represent the nut. I used a piece of the neck to the body. I used a glue called E6000. It is

"evergreen" brand half round polystyrene because I thick and heavy and allowed my to make sure I glued

had it from another project. If you use scrap plastic, the neck on perfectly straight while filling in any gaps

paint it white. I might have had.

Make a Scale Electric Guitar: Page 19

1

1

1. This is called the "nut" for some reason. Glue this on and trim the 1. Paint the marker dots on the fretboard

excess.

2

1

1. Glue the neck on

2. Glue the neck on

Step 14: Knobs

I made the knobs from white polymer clay. This is the that I had no idea about the size the knobs should be.

kind that you put in the over at a low temperature for I simply made them to whatever size I thought looked

a while to harden it. right, and measured them after the fact. 5/16 and 3/6

looks right to me.

Roll out two small tubes of clay, one 5/32 inch (5mm)

in diameter and another 3/32 (3mm). Use your Exacto Follow the instructions from your polymer clay to

knife to slice out three small disks from each. Use the bake/cure it. When the pieces have hardened and

back of the exacto knife or any other flat object to thoroughly cooled, glue them to the pickguard on the

press the tiny disks to uniform circles. Then place one body.

of the small ones on top of each of the larger ones,

lightly pressing them together so they will stick. Note

Make a Scale Electric Guitar: Page 20

1

1

1. Cut three of these 1. Cut three smaller ones too.

1 1

1. Place the small one on top of the larger one and lightly press them 1. Glue your knobs on.

together.

Step 15: Strings

Cut six 8-10" lengths of metallic thread for the strings. least two times around the pin, making sure to keep

Glue one piece to each of the saddles on the bridge the tension high. Either hold the extra part of the

paying close attention to the spacing. They need to string until the glue has dried enough to hold it, or you

be evenly spaced so that they will look correct on the can tape it down.

neck and across the nut.

Continue the same steps for the rest of the strings.

After the glue has dried securing the strings to the After the glue has dried, cut the excess string using a

bridge, you can continue with the tuning pins. Put a scissors or razor

dab of glue on the first pin and wrap the first string at

Make a Scale Electric Guitar: Page 21

1

1

1. First string connected 1. All the strings connected

1

1

1. First string connected at the top 1. Connect all the strings!!!

1. Trim off the extra material.

Make a Scale Electric Guitar: Page 22

Step 16: Selector Switch

To create the selector switch, I cut a small slit in the plastic bonded the needle sufficiently. Then use a

pick guard to represent the switch slot. It actually nipper or side cutter to trim off the excess.

wasn't a full slot. I just removed a small slice of paint

there. Then I heated up the tip of a sewing needle I also painted some black details on the knobs to

with a torch. Grab a small pliers to hold the needle. represent the text that painted on the full size

Hold it in the flame and wait until it glows nice and red versions.

and then use the pliers to stick it into the plastic at the

proper angle. No glue is necessary as the melted

1. Selector switch slot 1. FIRE!!

1. Just paint lines and dots here

Now you need to make a little tiny working Marshall amp and have a mini Jam session :)

Make a Scale Electric Guitar: Page 23

You might also like

- Cigar Box GuitarsDocument21 pagesCigar Box GuitarsROUGHRIDER13100% (1)

- Cigar Box Guitar InstructionsDocument4 pagesCigar Box Guitar InstructionsGregNo ratings yet

- Sonny Boy Williamson's Life and Music LegacyDocument6 pagesSonny Boy Williamson's Life and Music LegacyGaurav DharNo ratings yet

- Cardboard ClockDocument5 pagesCardboard ClockleongfoowingNo ratings yet

- Wood Instrument RepairDocument3 pagesWood Instrument RepairKaroly DarabosNo ratings yet

- Ukulele Chord Chart GuideDocument2 pagesUkulele Chord Chart GuideZoltán SiklósiNo ratings yet

- ARIA GUITARS 01eng - Om PDFDocument6 pagesARIA GUITARS 01eng - Om PDFFrank Boz0% (1)

- Soldering Equipment: How To Solder - Soldering TutorialDocument7 pagesSoldering Equipment: How To Solder - Soldering TutorialAnonymous f6goFflg3TNo ratings yet

- 4 17 005 10 0 00Document2 pages4 17 005 10 0 00David HosannaNo ratings yet

- Resonator Guitar Kit: Assembly InstructionsDocument32 pagesResonator Guitar Kit: Assembly InstructionstazzorroNo ratings yet

- Heavy Metal Guitar with Hawaiian EngravingsDocument3 pagesHeavy Metal Guitar with Hawaiian EngravingsAndy GearNo ratings yet

- Blues For Big Nate - Jerry PortnoyDocument2 pagesBlues For Big Nate - Jerry PortnoyLuis Alberto Gostín KrämerNo ratings yet

- Mandolin Workshop With Herman Towles and Fiddle Workshop With Branson RainesDocument1 pageMandolin Workshop With Herman Towles and Fiddle Workshop With Branson RainesJennifer Brown BryanNo ratings yet

- Spring Style 2018Document20 pagesSpring Style 2018New Jersey Jewish StandardNo ratings yet

- Student Guide For Solo-Tuned Harmonica (Part II - Chromatic)Document40 pagesStudent Guide For Solo-Tuned Harmonica (Part II - Chromatic)Drew A EngmanNo ratings yet

- Hammer On and Pull Off PDFDocument4 pagesHammer On and Pull Off PDFRaaghav SinghaniaNo ratings yet

- Instruction SetDocument13 pagesInstruction SetanonannonanonNo ratings yet

- See You in My DreamsDocument5 pagesSee You in My DreamsNoah Kayser-Hirsh100% (1)

- Public Speaking: Harmonica: HistoryDocument1 pagePublic Speaking: Harmonica: HistoryLuis Alberto Gostín KrämerNo ratings yet

- Basic Fingering18cDocument3 pagesBasic Fingering18cSpiros MoumourisNo ratings yet

- Dizi Music NotesDocument4 pagesDizi Music Noteschaitu_ivvalaNo ratings yet

- 36 String Gothic Harp: Musicmaker's KitsDocument29 pages36 String Gothic Harp: Musicmaker's KitsConrad Reyes100% (1)

- Furniture of The Olden Time (1917) PDFDocument508 pagesFurniture of The Olden Time (1917) PDFpatatitoNo ratings yet

- Yamaha Clasic Guitar cg201sDocument6 pagesYamaha Clasic Guitar cg201sCarlos A Negron O100% (1)

- Jazz Guitar Method - Chapter 04 - Basic Guitar TechniquesDocument6 pagesJazz Guitar Method - Chapter 04 - Basic Guitar TechniquesAggelos TsoliatouNo ratings yet

- HowtoMakeaParacordSurvivalBracelet1 PDFDocument10 pagesHowtoMakeaParacordSurvivalBracelet1 PDFchconstruction6153No ratings yet

- Jerry "Boogie" McCainDocument35 pagesJerry "Boogie" McCainDave van BladelNo ratings yet

- Cremona Violins Fo 00 ReadDocument48 pagesCremona Violins Fo 00 ReadSergiu MunteanuNo ratings yet

- CharangoDocument5 pagesCharangoBruno Zanone0% (1)

- Turtle Coaster Knitting PatternDocument4 pagesTurtle Coaster Knitting PatternCindy SNo ratings yet

- Making A Violin NutDocument33 pagesMaking A Violin NutJuan FernandezNo ratings yet

- Major TriadsDocument10 pagesMajor Triadsbuendiainside100% (1)

- Hmmusicfactory Cigar Box GuitarDocument20 pagesHmmusicfactory Cigar Box Guitarcleoslei de fariaNo ratings yet

- 5 - Melodii Pro ZacatecnikyDocument57 pages5 - Melodii Pro ZacatecnikyGrzegorz MaślijewiczNo ratings yet

- Blues Exercises - 12 Killer Blues LicksDocument1 pageBlues Exercises - 12 Killer Blues LicksMariano BottoNo ratings yet

- Tool Rest SVD-110: Positioning of MachineDocument5 pagesTool Rest SVD-110: Positioning of MachineLalo LeloNo ratings yet

- Leather Watch Strap: Food Living Outside Play Technology WorkshopDocument16 pagesLeather Watch Strap: Food Living Outside Play Technology WorkshopSupir TayoNo ratings yet

- How To Paint Swirl A GuitarsDocument4 pagesHow To Paint Swirl A Guitarstoneskupang100% (1)

- 30 Days of BanjoDocument36 pages30 Days of BanjoNickita Rogozhin100% (1)

- Liedjes 1950-2000Document24 pagesLiedjes 1950-2000Ilja van LuijkNo ratings yet

- CLASSICAL GUITAR METHOD Available NOW! Harry Pellegrin Author, Musician, Recording Artist Guitar Lessons Schenectady NY Captiol AreaDocument9 pagesCLASSICAL GUITAR METHOD Available NOW! Harry Pellegrin Author, Musician, Recording Artist Guitar Lessons Schenectady NY Captiol AreatanguerodelacruzNo ratings yet

- Ergonomics Guidance for Guitar PlayersDocument1 pageErgonomics Guidance for Guitar PlayerssibieNo ratings yet

- Dulcimer Workshop With Dean EadesDocument4 pagesDulcimer Workshop With Dean EadesJennifer Brown BryanNo ratings yet

- Calypso: Exploring The Sounds of Calypso!Document11 pagesCalypso: Exploring The Sounds of Calypso!dr0alexanderNo ratings yet

- The Dead South song tuning guide and tabsDocument3 pagesThe Dead South song tuning guide and tabsTadeoNo ratings yet

- MerleTravis IllSeeYouInMyDreamsDocument2 pagesMerleTravis IllSeeYouInMyDreamsAlex LNo ratings yet

- Kravik Lyre Rosette FittingDocument2 pagesKravik Lyre Rosette Fittingmking_6No ratings yet

- Esercizi Carter StyleDocument4 pagesEsercizi Carter StyleEnrico CrosatoNo ratings yet

- Ewe Lamb DiaperDocument2 pagesEwe Lamb DiaperwelcomehomefarmNo ratings yet

- Lazy WalkdownDocument5 pagesLazy WalkdownPoss HumNo ratings yet

- Fender guitar manual features top specsDocument38 pagesFender guitar manual features top specsAlexandre AmparoNo ratings yet

- Theory of Western Music 1Document11 pagesTheory of Western Music 1Prithvi KadamNo ratings yet

- No Woman No Cry - by Bob Marley Ukulele Tabs On UkuTabsDocument3 pagesNo Woman No Cry - by Bob Marley Ukulele Tabs On UkuTabsAzraaei AzaharuddinNo ratings yet

- Dimensions of the Fajardo/Armstrong flute wedgeDocument1 pageDimensions of the Fajardo/Armstrong flute wedgemike vidal100% (1)

- Hymns: Ancient AND ModernDocument1,059 pagesHymns: Ancient AND Modern29r5pjjjjqNo ratings yet

- Charlie Built His Acoustic GuitarDocument56 pagesCharlie Built His Acoustic GuitarRosa OliveiraNo ratings yet

- Accordi BanjoDocument10 pagesAccordi BanjoAndrea TuroneNo ratings yet

- Cigar Box Guitar: Tools Used in This ProjectDocument10 pagesCigar Box Guitar: Tools Used in This Projectbpearson02311132No ratings yet

- Semi Acoustic Electric Guitar From ScratchDocument28 pagesSemi Acoustic Electric Guitar From ScratchIverso BatistaNo ratings yet

- Drill Perpendicular: InstructablesDocument5 pagesDrill Perpendicular: InstructablesrhinorodNo ratings yet

- Wood RackDocument1 pageWood RackrhinorodNo ratings yet

- Workbensh 2D DrawingsDocument10 pagesWorkbensh 2D DrawingsrhinorodNo ratings yet

- Modern Parsons Coffee Table DIYDocument11 pagesModern Parsons Coffee Table DIYrhinorodNo ratings yet

- Updated DIY woodworkbench planDocument14 pagesUpdated DIY woodworkbench planrhinorod100% (1)

- Clamp Rack Plan PDFDocument3 pagesClamp Rack Plan PDFrhinorodNo ratings yet

- Modern Rocking Horse!Document1 pageModern Rocking Horse!Abdul RosyidNo ratings yet

- Coat-Rack GrinwoodDocument8 pagesCoat-Rack GrinwoodKVVenkatasubramanianNo ratings yet

- Folding Dining Table SEO-Optimized TitleDocument11 pagesFolding Dining Table SEO-Optimized TitleIvica TomljanovicNo ratings yet

- TUM Friday Fix 01.09.2017Document2 pagesTUM Friday Fix 01.09.2017rhinorodNo ratings yet

- Making A Modern Walnut Wood Wallet Business Card HDocument8 pagesMaking A Modern Walnut Wood Wallet Business Card HrhinorodNo ratings yet

- Mitre Bridle Joint For Picture Frames: We Will NeedDocument9 pagesMitre Bridle Joint For Picture Frames: We Will NeedrhinorodNo ratings yet

- Mini Shipping Crates: InstructablesDocument12 pagesMini Shipping Crates: InstructablesrhinorodNo ratings yet

- Making The Fanciest Beer Koozie You Ever SeenDocument7 pagesMaking The Fanciest Beer Koozie You Ever SeenrhinorodNo ratings yet

- Beautiful Eating Spoons From Firewood: Craft Wooden Spoons on VacationDocument7 pagesBeautiful Eating Spoons From Firewood: Craft Wooden Spoons on VacationrhinorodNo ratings yet

- Giant Outdoor Robot: by Dvda2108Document28 pagesGiant Outdoor Robot: by Dvda2108rhinorodNo ratings yet

- TUM Friday Fix 03.11.2017Document3 pagesTUM Friday Fix 03.11.2017rhinorodNo ratings yet

- TUM Friday Fix 01.02.2019Document2 pagesTUM Friday Fix 01.02.2019rhinorodNo ratings yet

- TUM Friday Fix 03.08.2018Document2 pagesTUM Friday Fix 03.08.2018rhinorodNo ratings yet

- TUM Friday Fix 01.07.2016Document2 pagesTUM Friday Fix 01.07.2016Rod HyattNo ratings yet

- TUM Friday Fix 03.03.2017Document2 pagesTUM Friday Fix 03.03.2017Rod HyattNo ratings yet

- TUM Friday Fix 04.08.2017Document3 pagesTUM Friday Fix 04.08.2017rhinorodNo ratings yet

- Advice From My GrandpaDocument1 pageAdvice From My GrandparhinorodNo ratings yet

- TUM Friday Fix 02.06.2017Document2 pagesTUM Friday Fix 02.06.2017Rod HyattNo ratings yet

- Felix DennisDocument4 pagesFelix DennisrhinorodNo ratings yet

- TUM Friday Fix 02.02.2018Document2 pagesTUM Friday Fix 02.02.2018rhinorodNo ratings yet

- TUM Friday Fix 04.05.2018Document1 pageTUM Friday Fix 04.05.2018rhinorodNo ratings yet

- TUM Friday Fix 03.02.2017Document2 pagesTUM Friday Fix 03.02.2017Rod HyattNo ratings yet

- TUM Friday Fix 01.06.2019Document2 pagesTUM Friday Fix 01.06.2019rhinorodNo ratings yet

- UNESCO World Heritage Sites in India Taj MahalDocument68 pagesUNESCO World Heritage Sites in India Taj MahalVlad AdomnicaiNo ratings yet

- San Juan National High School 1st Periodical test in TLE 10 (Fashion AccessoriesDocument3 pagesSan Juan National High School 1st Periodical test in TLE 10 (Fashion AccessoriesJohn AdonaNo ratings yet

- Weft Knitting PrincipleDocument11 pagesWeft Knitting PrincipleTamanna AhmedNo ratings yet

- Local Environment Phrasal Verbs Complex SentencesDocument3 pagesLocal Environment Phrasal Verbs Complex Sentenceskhong co ten KhongNo ratings yet

- Sample Pattern: Kwik - SewDocument6 pagesSample Pattern: Kwik - Sewelena_luna100% (1)

- Cinnamon The Little Deer: by ZipzipdreamsDocument10 pagesCinnamon The Little Deer: by ZipzipdreamsElicia Oñate100% (2)

- Free Knitting Pattern Lion Brand Wool-Ease® Thick & Quick® Extra Easy, Extra Fabulous SweaterDocument4 pagesFree Knitting Pattern Lion Brand Wool-Ease® Thick & Quick® Extra Easy, Extra Fabulous SweaterMadalina CNo ratings yet

- Doc665499546 609562607Document4 pagesDoc665499546 609562607Brittany RamirezNo ratings yet

- Chubby Milky CowDocument10 pagesChubby Milky CowCarlos Alexis Arteaga Gómez90% (10)

- 04 Train en PDFDocument120 pages04 Train en PDFRonicito MujicaNo ratings yet

- Anna Lositskaya - KittiesDocument21 pagesAnna Lositskaya - KittiesLu Palaver100% (2)

- Clown PennywiseDocument16 pagesClown Pennywisegomez julieta100% (2)

- The Complete Guide to Crochet BasicsDocument115 pagesThe Complete Guide to Crochet BasicsLeonor Morales100% (1)

- History of Embroidery Pitoy MorenoDocument7 pagesHistory of Embroidery Pitoy MorenoChuck SalibaNo ratings yet

- Amigurumi Spider Pattern RavelryDocument5 pagesAmigurumi Spider Pattern RavelryLu Orphão100% (1)

- Harmony Guide ColorworkDocument8 pagesHarmony Guide ColorworkRena Vergou0% (1)

- Mama's Garden: FabricsDocument4 pagesMama's Garden: FabricsCreek LiteracyNo ratings yet

- Art PresentationDocument33 pagesArt PresentationPeppoNo ratings yet

- Tommy La RanaDocument38 pagesTommy La RanaYasmin Perez100% (3)

- Topaz 9-Inch SquareDocument2 pagesTopaz 9-Inch SquareANo ratings yet

- DoroginaDocument27 pagesDoroginamin vale 19No ratings yet

- Annealingschedule CimDocument3 pagesAnnealingschedule CimMaria Louisa WesselsNo ratings yet

- MONOFOLHA 216 EN Out 2019Document4 pagesMONOFOLHA 216 EN Out 2019eyoliveNo ratings yet

- Objectives: Passion Awareness AppreciationDocument14 pagesObjectives: Passion Awareness AppreciationElisha TanNo ratings yet

- Post-Neolithic Shell Beads From Ille Cave, El Nido, PalawanDocument26 pagesPost-Neolithic Shell Beads From Ille Cave, El Nido, PalawanCarl SoriaNo ratings yet

- Favorite Baby Hat PatternsDocument19 pagesFavorite Baby Hat PatternsstephsewsNo ratings yet

- Granny Square Bucket Hat - M22020 FBTQ. v1664806391730 ZraavgDocument5 pagesGranny Square Bucket Hat - M22020 FBTQ. v1664806391730 ZraavgDrBhagyashree BhatNo ratings yet

- WyvernDocument32 pagesWyvernBetzayda Chavez100% (1)

- Granny Square Crochet For Beginners UK Terms PDF by Shelley Husband 2015.compressedDocument51 pagesGranny Square Crochet For Beginners UK Terms PDF by Shelley Husband 2015.compressedȘtefana Huţupașu100% (1)

- Bead Stair ActivitiesDocument2 pagesBead Stair ActivitiesMac YmacNo ratings yet