Professional Documents

Culture Documents

Features: Quarter Brick DC/DC Power Module 18 75V In, 12V/20A Out, 240W

Uploaded by

Alex BlagikhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Features: Quarter Brick DC/DC Power Module 18 75V In, 12V/20A Out, 240W

Uploaded by

Alex BlagikhCopyright:

Available Formats

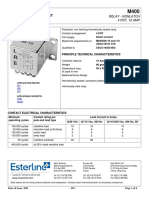

Q36SR12020

240W 1/4th Brick DC/DC Power Modules

FEATURES

Electrical

High efficiency: 93% @ 12V/20A

Industry standard footprint and pin-out

Fixed frequency operation

OTP, Input UVLO, Output OVP

Output OCP Hiccup mode

Output voltage trim range: -10%~+10%

Monotonic startup into normal and pre-biased

loads

2250V isolation and basic insulation

No minimum load required

No negative current during power or enable

on/off

Mechanical

Size:

w/o heat-spreader

58.4x36.8x11.7mm (2.30”x1.45”x0.46”)

with heat-spreader

58.4x36.8x12.7mm (2.30”x1.45”x0.50”)

Q36SR12020 Soldering Methods

Wave soldering

Quarter Brick DC/DC Power Module Hand soldering

18~75V in, 12V/20A out, 240W

Safety & Reliability

ISO 9001, TL 9000, ISO 14001, QS 9000,

OHSAS18001 certified manufacturing

Q36SR12020, Quarter Brick, 18V~75Vin input, single output, isolated facility

DC/DC converters, are the latest offering from a world leader in power UL/cUL 60950-1 (US & Canada)

systems technology and manufacturing ― Delta Electronics, Inc. With

creative design technology and optimization of component placement,

these converters possess outstanding electrical and thermal

OPTIONS

performance, as well as extremely high reliability under highly stressful

Negative or positive logic remote On/Off

operating conditions. Typical efficiency of the 12V/20A module is greater Through hole with heat-spreader

than 93%.

APPLICATIONS

Optical Transport

Data Networking

Communications

Servers

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P1

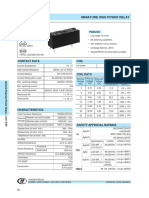

TECHNICAL SPECIFICATIONS

(TA=25°C, airflow rate=300 LFM, Vin=48Vdc, nominal Vout unless otherwise noted.)

PARAMETER NOTES and CONDITIONS Q36SR12020

Min. Typ. Max. Units

ABSOLUTE MAXIMUM RATINGS

Input Voltage Vdc

Continuous 0 80 Vdc

Transient (100ms) 100ms 100 Vdc

Operating Ambient Temperature -40 85 °C

Storage Temperature -55 125 °C

Input/Output Isolation Voltage 2250 Vdc

INPUT CHARACTERISTICS

Operating Input Voltage 18 48 75 Vdc

Input Under-Voltage Lockout

Turn-On Voltage Threshold 16 17 18 Vdc

Turn-Off Voltage Threshold 15 16 17 Vdc

Lockout Hysteresis Voltage 0.3 1 1.8 Vdc

Maximum Input Current 100% Load, 18Vin 17.2 A

No-Load Input Current Vin=48V,Io=0A 100 mA

Off Converter Input Current Vin=48V 10 mA

Inrush Current (I2t) 1 A2s

Input Reflected-Ripple Current P-P thru 12µH inductor, 5Hz to 20MHz 20 mA

Input Voltage Ripple Rejection 120 Hz 50 dB

OUTPUT CHARACTERISTICS

Output Voltage Set Point Vin=48V, Io=Io.max, Tc=25°C 11.82 12.00 12.18 Vdc

Output Voltage Regulation

Load Regulation Io=Io, min to Io, max ±3 ±15 mV

Line Regulation Vin=18V to 75V ±3 ±15 mV

Temperature Regulation Tc=-40°C to 110°C ±120 mV

Total Output Voltage Range Over sample load, line and temperature 11.64 12.00 12.36 V

Output Voltage Ripple and Noise 5Hz to 20MHz bandwidth

Peak-to-Peak Full Load, 1µF ceramic, 10µF tantalum 100 mV

RMS Full Load, 1µF ceramic, 10µF tantalum 25 mV

Operating Output Current Range Vin=18V to75V 0 20 A

Operating Output Current Range

DYNAMIC CHARACTERISTICS

Output Voltage Current Transient Vin=48V, 10µF Tan & 1µF Ceramic load cap, 0.1A/µs

Positive Step Change in Output Current 75% Io.max to 50% Io.max 550 mV

Negative Step Change in Output Current 50% Io.max to 75% Io.max 550 mV

Settling Time (within 1% Vout nominal) 200 µs

Turn-On Transient

Start-Up Time, From On/Off Control 35 mS

Start-Up Time, From Input 35 mS

Output Capacitance (note1) Full load; 5% overshoot of Vout at startup 0 5000 µF

EFFICIENCY

100% Load Vin=24V 93.5 %

100% Load Vin=48V 93.0 %

60% Load Vin=48V 92.0 %

ISOLATION CHARACTERISTICS

Input to Output 2250 Vdc

Isolation Resistance 10 MΩ

Isolation Capacitance 1000 pF

FEATURE CHARACTERISTICS

Switching Frequency 260 KHz

ON/OFF Control, Negative Remote On/Off logic

Logic Low (Module On) Von/off 0.8 V

Logic High (Module Off) Von/off 2.4 5 V

ON/OFF Control, Positive Remote On/Off logic

Logic Low (Module Off) Von/off 0.8 V

Logic High (Module On) Von/off 2.4 5 V

ON/OFF Current (for both remote on/off logic) Ion/off at Von/off=0.0V 1 mA

Leakage Current (for both remote on/off logic) Logic High, Von/off=5V

Output Voltage Trim Range(note 2) Pout ≦ max rated power, Io ≦ Io.max -10 10 %

Output Voltage Remote Sense Range Pout ≦ max rated power, Io ≦ Io.max 10 %

Output Over-Voltage Protection Over full temp range; % of nominal Vout 115 140 %

GENERAL SPECIFICATIONS

MTBF Io=80% of Io, max; Ta=25°C, normal input,600FLM 3.0 M hours

Weight Without heat spreader 45.5 grams

Weight With heat spreader 61.1 grams

Over-Temperature Shutdown (Without heat Refer to Figure 19 for Hot spot 1 location (48Vin,80%

135 °C

spreader) Io, 200LFM,Airflow from Vin+ to Vin-)

Over-Temperature Shutdown (With heat spreader) Refer to Figure 22 for Hot spot 2 location (48Vin,80% Io,

120 °C

200LFM,Airflow from Vin+ to Vin-)

Over-Temperature Shutdown (NTC resistor) Refer to Figure 19 for NTC resistor location 130 °C

Note: Please attach thermocouple on NTC resistor to test OTP function, the hot spots’ temperature is just for reference.

Note1: For applications with higher output capacitive load, please contact Delta.

Note2: Trim down range -10% for 18Vin ~75Vin, Trim up range +10% for 20Vin ~ 75Vin.

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P2

ELECTRICAL CHARACTERISTICS CURVES

TA=25°C

Figure 1: Efficiency vs. load current for minimum, nominal, and Figure 2: Power dissipation vs. load current for minimum,

maximum input voltage at 25°C nominal, and maximum input voltage at 25°C

Figure 3: Typical full load input characteristics at room

temperature

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P3

ELECTRICAL CHARACTERISTICS CURVES

For Negative Remote On/Off Logic

Figure 4: Turn-on transient at full rated load current (resistive Figure 5: Turn-on transient at zero load current (10 ms/div).

load) (10 ms/div). Vin=48V. Top Trace: Vout, 3.0V/div; Bottom Vin=48V. Top Trace: Vout: 3.0V/div, Bottom Trace: ON/OFF

Trace: ON/OFF input, 3V/div input, 3V/div

Figure 6: Output voltage response to step-change in load Figure 7: Output voltage response to step-change in load

current (50%-75%-50% of Io, max; di/dt = 0.1A/µs; Vin is 24v). current (50%-75%-50% of Io, max; di/dt = 0.1A/µs; Vin is 48v).

Load cap: 10µF tantalum capacitor and 1µF ceramic capacitor. Load cap: 10µF tantalum capacitor and 1µF ceramic capacitor.

Top Trace: Vout (0.5V/div, 500us/div), Bottom Trace:Iout Top Trace: Vout (0.5V/div, 500us/div), Bottom Trace: Iout

(5A/div). Scope measurement should be made using a BNC (5A/div). Scope measurement should be made using a BNC

cable (length shorter than 20 inches). Position the load between cable (length shorter than 20 inches). Position the load between

51 mm to 76 mm (2 inches to 3 inches) from the module 51 mm to 76 mm (2 inches to 3 inches) from the module

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P4

ELECTRICAL CHARACTERISTICS CURVES

Figure 8: Test set-up diagram showing measurement points for Figure 9: Input Terminal Ripple Current, ic, at full rated output

Input Terminal Ripple Current and Input Reflected Ripple current and nominal input voltage (Vin=48V) with 12µH source

Current. impedance and 33µF electrolytic capacitor (1A/div, 5us/div)

Note: Measured input reflected-ripple current with a simulated

source Inductance (LTEST) of 12 μH. Capacitor Cs offset

possible battery impedance. Measure current as shown above

Copper Strip

Vo(+)

SCOPE RESISTIVE

10u 1u

LOAD

Vo(-)

Figure 10: Input reflected ripple current, is, through a 12µH Figure 11: Output voltage noise and ripple measurement test

source inductor at nominal input voltage (Vin=48V) and rated setup

load current (20 mA/div, 5us/div)

Figure 12: Output voltage ripple at nominal input voltage Figure 13: Output Voltage Ripple and Noise at nominal input

(Vin=48V) and rated load current (50 mV/div, 2us/div).Load voltage and max load current (20 mV/div, 2us/div)

capacitance: 1µF ceramic capacitor and 10µF tantalum Load cap: 1µF ceramic capacitor and 10µF tantalum capacitor.

capacitor. Bandwidth: 20 MHz. Scope measurements should be Bandwidth: 20MHz.

made using a BNC cable (length shorter than 20 inches).

Position the load between 51 mm to 76 mm (2 inches to 3

inches) from the module

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P5

DESIGN CONSIDERATIONS

Input Source Impedance

Basic insulation based on 75 Vdc input is provided between the

input and output of the module for the purpose of applying

The impedance of the input source connecting to the DC/DC insulation requirements when the input to this DC-to-DC

power modules will interact with the modules and affect the converter is identified as TNV-2 or SELV. An additional

stability. A low ac-impedance input source is recommended. If evaluation is needed if the source is other than TNV-2 or SELV.

the source inductance is more than a few μH, we advise

adding a 100 μF electrolytic capacitor (ESR < 0.7 Ω at 100 When the input source is SELV circuit, the power module

kHz) mounted close to the input of the module to improve the meets SELV (safety extra-low voltage) requirements. If the

stability. input source is a hazardous voltage which is greater than 60

Vdc and less than or equal to 75 Vdc, for the module’s output to

Layout and EMC Considerations meet SELV requirements, all of the following must be met:

The input source must be insulated from the ac mains by

Delta’s DC/DC power modules are designed to operate in a reinforced or double insulation.

wide variety of systems and applications. For design

assistance with EMC compliance and related PWB layout The input terminals of the module are not operator

issues, please contact Delta’s technical support team. An accessible.

external input filter module is available for easier EMC

compliance design. Below is the reference design for an A SELV reliability test is conducted on the system where

input filter tested with Q36SR12020 to meet class A in the module is used, in combination with the module, to

CISSPR 22. ensure that under a single fault, hazardous voltage does

not appear at the module’s output.

Schematic

When installed into a Class II equipment (without grounding),

spacing consideration should be given to the end-use

installation, as the spacing between the module and mounting

surface have not been evaluated.

The power module has extra-low voltage (ELV) outputs when

all inputs are ELV.

This power module is not internally fused. To achieve optimum

safety and system protection, an input line fuse is highly

recommended. The safety agencies require a Fast-acting fuse

Figure 14-1: Recommended Input Filter

with 50A maximum rating to be installed in the ungrounded

lead. A lower rated fuse can be used based on the maximum

inrush transient energy and maximum input current.

Soldering and Cleaning Considerations

Post solder cleaning is usually the final board assembly

process before the board or system undergoes electrical

testing. Inadequate cleaning and/or drying may lower the

reliability of a power module and severely affect the finished

circuit board assembly test. Adequate cleaning and/or drying is

especially important for un-encapsulated and/or open frame

type power modules. For assistance on appropriate soldering

and cleaning procedures, please contact Delta’s technical

support team.

Figure 14-2: Test Result of EMC

25C, 48Vin, full load, Green line is quasi peak mode and blue

line is average mode.

Safety Considerations

The power module must be installed in compliance with the

spacing and separation requirements of the end-user’s safety

agency standard, i.e., UL60950-1(2nd Edition), CAN/CSA

C22.2 NO. 60950-1-07(2nd Edition) and IEC 60950-1: 2005

(2nd Edition), if the system in which the power module is to be

used must meet safety agency requirements.

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P6

FEATURES DESCRIPTIONS

Over-Current Protection Remote Sense

The modules include an internal output over-current protection Remote sense compensates for voltage drops on the output

circuit, which will endure current limiting for an unlimited by sensing the actual output voltage at the point of load.

duration during output overload. If the output current exceeds The voltage between the remote sense pins and the output

the OCP set point, the modules will automatically shut down, terminals must not exceed the output voltage sense range

and enter hiccup mode. given here:

For hiccup mode, the module will try to restart after shutdown. [Vo(+) – Vo(–)] – [SENSE(+) – SENSE(–)] ≤ 10% × Vout

If the over current condition still exists, the module will shut

down again. This restart trial will continue until the This limit includes any increase in voltage due to remote

over-current condition is corrected. sense compensation and output voltage set point

adjustment (trim).

Over-Voltage Protection Vi(+) Vo(+)

Conduct resistance

The modules include an internal output over-voltage Sense(+)

protection circuit, which monitors the voltage on the output

terminals. If this voltage exceeds the over-voltage set point, ON/OFF trim Rload

the module will shut down, and enter in hiccup.

Sense(-)

For hiccup mode, the module will try to restart after shutdown. Vi(-) Vo(-)

If the over voltage condition still exists, the module will shut

down again. This restart trial will continue until the

over-voltage condition is corrected.

Figure 16: Effective circuit configuration for remote

sense operation

Over-Temperature Protection

If the remote sense feature is not used to regulate the

The over-temperature protection consists of circuitry that output at the point of load, please connect SENSE(+) to

provides protection from thermal damage. If the temperature Vo(+) and SENSE(–) to Vo(–) at the module.

exceeds the over-temperature threshold the module will shut

down, and enter in hiccup. The output voltage can be increased by both the remote

sense and the trim; however, the maximum increase is the

For hiccup mode, the module will try to restart after shutdown. larger of either the remote sense or the trim, not the sum of

This restart trial will continue until the over-temperature both.

condition is corrected.

When using remote sense and trim, the output voltage of

Remote On/Off the module is usually increased, which increases the power

output of the module with the same output current.

The remote on/off feature on the module can be either

negative or positive logic. Negative logic turns the module on Care should be taken to ensure that the maximum output

during a logic low and off during a logic high. Positive logic power does not exceed the maximum rated power.

turns the modules on during a logic high and off during a

logic low.

Output Voltage Adjustment (TRIM)

Remote on/off can be controlled by an external switch

between the on/off terminal and the Vi(-) terminal. The To increase or decrease the output voltage set point,

switch can be an open collector or open drain. connect an external resistor between the TRIM pin and

the SENSE(+) or SENSE(-). The TRIM pin should be left

For negative logic if the remote on/off feature is not used, open if this feature is not used.

please short the on/off pin to Vi(-). For positive logic if the

remote on/off feature is not used, please leave the on/off pin

floating.

Vi(+) Vo(+)

Sense(+)

ON/OFF trim Rload

Sense(-)

Vi(-) Vo(-)

Figure 17: Circuit configuration for trim-down

(decrease output voltage)

Figure 15: Remote on/off implementation

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P7

FEATURES DESCRIPTIONS

If the external resistor is connected between the TRIM and

SENSE (-) pins, the output voltage set point decreases.

The external resistor value required to obtain a percentage

of output voltage change △% is defined as:

511

Rtrim down 10 .2 K

Ex. When Trim-down -10% (12V×0.9=10.8V)

511

Rtrim down 10 .2 K 40 .9 K

10

Figure 18: Circuit configuration for trim-up (increase

output voltage)

If the external resistor is connected between the

TRIM and SENSE (+) the output voltage set point

increases. The external resistor value required to

obtain a percentage output voltage change △% is

defined as:

5 .11 Vo (100 ) 511

Rtrim up 10 .2 K

1.225

Ex. When Trim-up +10% (12V×1.1=13.2V)

5.11 12 (100 10 ) 511

Rtrim up 10 .2 489 .3K

1.225 10 10

The output voltage can be increased by both the

remote sense and the trim, however the maximum

increase is the larger of either the remote sense or the

trim, not the sum of both.

When using remote sense and trim, the output voltage

of the module is usually increased, which increases

the power output of the module with the same output

current.

Care should be taken to ensure that the maximum

output power of the module remains at or below the

maximum rated power.

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P8

THERMAL CONSIDERATIONS

Thermal management is an important part of the system design. To ensure proper, reliable operation, sufficient cooling of the

power module is needed over the entire temperature range of the module. Convection cooling is usually the dominant mode of

heat transfer.

Hence, the choice of equipment to characterize the thermal performance of the power module is a wind tunnel.

Thermal Testing Setup

Delta’s DC/DC power modules are characterized in heated vertical wind tunnels that simulate the thermal environments

encountered in most electronics equipment. This type of equipment commonly uses vertically mounted circuit cards in cabinet

racks in which the power modules are mounted.

The following figure shows the wind tunnel characterization setup. The power module is mounted on a 185mmX185mm,105μm

(3Oz),6 layers’ test PWB and is vertically positioned within the wind tunnel. The space between the neighboring PWB and the top

of the power module is constantly kept at 6.35mm (0.25’’).

FANCING PWB PWB

MODULE

AIR VELOCITY

AND AMBIENT

50.8(2.00")

TEMPERATURE

SURED BELOW

THE MODULE

AIR FLOW

Note: Wind Tunnel Test Setup Figure Dimensions are in millimeters and (Inches)

Figure 19: Wind Tunnel Test Setup

Thermal Derating

Heat can be removed by increasing airflow over the module. To enhance system reliability, the power module should always be

operated below the maximum operating temperature. If the temperature exceeds the maximum module temperature, reliability of

the unit may be affected.

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P9

THERMAL CONSIDERATIONS

Thermal Curves (without heat-spreader)

Thermal Curves (without heat-spreader)

AIRFLOW

NTC RESISTOR AIRFLOW

HOT SPOT 2

HOT SPOT 1

Figure 20: Hot spot1 & NTC resistor temperature measurement Figure 23: Hot spot2 temperature measurement location.

locations. The allowed maximum hot spot1 temperature is defined at The allowed maximum hot spot2 temperature is defined at 100℃

120℃

Q36SR12020(Standard) Output Power vs. Ambient Temperature and Air Velocity

Output Power(W) @Vin = 24V (Transverse Orientation) Q36SR12020(Standard) Output Power vs. Ambient Temperature and Air Velocity

Output Power(W) @Vin = 24V (Transverse Orientation,with Heat Spreader)

240

240

200

Natural 200

Natural

Convection

Convection

160 100LFM

160 100LFM

200LFM

200LFM

300LFM

120 300LFM

120

400LFM 400LFM

80 500LFM

500LFM

80

600LFM

600LFM

40

40

0

25 30 35 40 45 50 55 60 65 70 75 80 85 0

Ambient Temperature (℃) 25 30 35 40 45 50 55 60 65 70 75 80 85

Ambient Temperature (℃)

Figure 21: Output current vs. ambient temperature and air velocity Figure 24: Output current vs. ambient temperature and air velocity

@Vin=24V (Transverse Orientation, Airflow direction from Vin+ to @Vin=24V (Transverse Orientation, Airflow direction from Vin+ to Vin-,

Vin-, without heat spreader) with heat spreader)

Q36SR12020(Standard) Output Power vs. Ambient Temperature and Air Velocity

Output Power(W) @Vin = 48V (Transverse Orientation) Q36SR12020(Standard) Output Power vs. Ambient Temperature and Air Velocity

Output Power(W) @Vin = 48V (Transverse Orientation,with Heat Spreader)

240

240

200

200 Natural

Natural

Convection

Convection

160 100LFM

100LFM 160

200LFM 200LFM

120 300LFM

120 300LFM

400LFM 400LFM

80

80

500LFM 500LFM

40 600LFM

40

600LFM

0

25 30 35 40 45 50 55 60 65 70 75 80 85 0

Ambient Temperature (℃) 25 30 35 40 45 50 55 60 65 70 75 80 85

Ambient Temperature (℃)

Figure 22: Output current vs. ambient temperature and air velocity Figure 25: Output current vs. ambient temperature and air velocity

@Vin=48V (Transverse Orientation, Airflow direction @Vin=48V (Transverse Orientation, Airflow direction from Vin+ to

from Vin+ to Vin-, without heat spreader) Vin-, with heat spreader)

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P10

MECHANICAL DRAWING

Mechanical Drawing (with heat-spreader)

For modules with through-hole pins and the optional heat-spreader, they are intended for wave soldering assembly onto system

boards; please do not subject such modules through reflow temperature profile.

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P11

MECHANICAL DRAWING

Mechanical Drawing (without heat-spreader)

Pin No. Name Function

1 +Vin Positive input voltage

2 ON/OFF Remote ON/OFF

3 -Vin Negative input voltage

4 -Vout Negative output voltage

5 -Sense Negative remote sense

6 Trim Output voltage trim

7 +Sense Positive remote sense

8 +Vout Positive output voltage

Pin Specification:

Pins 1-3,5-7 1.00mm (0.040”) diameter

Pins 4 & 8 2. 1.50mm (0.060”) diameter

Note:All pins are copper alloy with matte tin(Pb free) plated over Ni under-plating.

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P12

MECHANICAL DRAWING

Recommended Pad Layout (Through-hole Module)

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P13

MANUFACTURE CONSIDERATION

Soldering method

Generally, as the most common mass soldering method for the solder attachment, wave soldering is used for through-hole power

modules and reflow soldering is used for surface-mount ones. Delta recommended soldering methods and process parameters are

provided in this document for solder attachment of power modules onto system board. SAC305 is the suggested lead-free solder

alloy for all soldering methods.

Reflow soldering is not a suggested method for through-hole power modules due to many process and reliability concerns. If you

have this kind of application requirement, please contact Delta sales or FAE for further confirmation.

Wave Soldering (Lead-free)

Delta’s power modules are designed to be compatible with single-wave or dual wave soldering. The suggested soldering process

must keep the power module’s internal temperature below the critical temperature of 217℃ continuously. The recommended

wave-soldering profile is shown in following figure.

Note: The temperature is measured on solder joint of pins of power module.

Recommended Temperature Profile for Lead-free Wave Soldering

The typical recommended (for double-side circuit board) preheat temperature is 115+/-10℃ on the top side (component side) of the

circuit board. The circuit-board bottom-side preheat temperature is typically recommended to be greater than 135℃ and preferably

within 100 ℃ of the solder-wave temperature. A maximum recommended preheat up rate is 3℃ /s. A maximum recommended

solder pot temperature is 255+/-5℃ with solder-wave dwell time of 3~6 seconds. The cooling down rate is typically recommended

to be 6℃/s maximum.

Hand Soldering (Lead Free)

Hand soldering is the least preferred method because the amount of solder applied, the time the soldering iron is held on the joint,

the temperature of the iron, and the temperature of the solder joint are variable. The recommended hand soldering guideline is listed

in Table below. The suggested soldering process must keep the power module’s internal temperature below the critical temperature

of 217℃ continuously.

Table Hand-Soldering Guideline

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P14

PART NUMBERING SYSTEM

Q 36 S R 120 20 N R F A

Number

Form Input Output Output ON/OFF Pin

Of Product Series RoHS Option Code

Factor Voltage Voltage Current Logic Length

Outputs

Q - 1/4 36 - S - Single R - Regular 120 - 12V 20- 20A N - Negative R - 0.170” Space - RoHS 5/6 A – Standard Functions

P- Positive N - 0.146” F - RoHS 6/6 H-with heat spreader

Brick 18V~75V

(Lead Free)

MODEL LIST

Model Name Input Output Eff. @ 100% Load

Q36SR12020NRFA 18V~75V 17.2A 12V 20A 93.0% @ 48Vin

Q36SR12020NRFH 18V~75V 17.2A 12V 20A 93.0% @ 48Vin

Default remote On/Off logic is negative and pin length is 0.170”.

For different remote On/Off logic and pin length, please refer to part numbering system above or contact your local sales office.

For modules with through-hole pins and the optional heat-spreader, they are intended for wave soldering assembly onto system

boards; please do not subject such modules through reflow temperature profile.

CONTACT US:

Website: www.deltaww.com/dcdc Email: dcdc@deltaww.com

USA: Europe: Asia & the rest of world:

Telephone: Telephone: +31-20-655-0967 Telephone: +886 3 4526107

East Coast: 978-656-3993 Fax: +31-20-655-0999 Ext. 6220~6226

West Coast: 510-668-5100 Fax: +886 3 4513485

Fax: (978) 656 3964

WARRANTY

Delta offers a two (2) year limited warranty. Complete warranty information is listed on our web site or is available upon request

from Delta.

Information furnished by Delta is believed to be accurate and reliable. However, no responsibility is assumed by Delta for its use,

nor for any infringements of patents or other rights of third parties, which may result from its use. No license is granted by

implication or otherwise under any patent or patent rights of Delta. Delta reserves the right to revise these specifications

Datasheet E-mail: dcdc@deltaww.com

DS_Q36SR12020_06042019 http://www.deltaww.com/dcdc

P15

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Delta Electronics:

Q36SR12020NRFA Q36SR12020NRFH

You might also like

- Ds E48sp12020nrfaDocument16 pagesDs E48sp12020nrfaVishwakarma EnterprisesNo ratings yet

- Quarter Brick DC/DC Power Module 36 75V In, 12V / 42A Out, 500WDocument26 pagesQuarter Brick DC/DC Power Module 36 75V In, 12V / 42A Out, 500WdeccNo ratings yet

- MU320 Merging Unit: Analog and Digital, Fast and Accurate: Fully-Integrated Merging Unit For Process Bus ApplicationsDocument2 pagesMU320 Merging Unit: Analog and Digital, Fast and Accurate: Fully-Integrated Merging Unit For Process Bus ApplicationsMohamedNo ratings yet

- Delphi Series H48SC3R325, 85W Half Brick Family DC/DC Power Modules: 48V In, 3.3V/25A OutDocument13 pagesDelphi Series H48SC3R325, 85W Half Brick Family DC/DC Power Modules: 48V In, 3.3V/25A OutRODRIGO ALVES DA COSTANo ratings yet

- 74 MP100 TD enDocument5 pages74 MP100 TD enBa DuyNo ratings yet

- EBVW025A0B Barracuda Series DC-DC Converter Power Modules: FeaturesDocument18 pagesEBVW025A0B Barracuda Series DC-DC Converter Power Modules: FeaturesABHINASH MAHOR ee12b068No ratings yet

- CET Power - Datasheet ALTO 230vac - 2014 v1Document2 pagesCET Power - Datasheet ALTO 230vac - 2014 v1Tengkureza DKSHNo ratings yet

- M400 D4N 003Document19 pagesM400 D4N 003Mian FahimNo ratings yet

- RelêDocument3 pagesRelênelsongomessantosNo ratings yet

- Skai 90 A2 Gd06-Wci 14282034Document12 pagesSkai 90 A2 Gd06-Wci 14282034nishant_dreamviewerNo ratings yet

- PCB Relay: NRP - 17 - C - 12DDocument2 pagesPCB Relay: NRP - 17 - C - 12DZaman SahibNo ratings yet

- SV48 26 225 2 PDFDocument6 pagesSV48 26 225 2 PDFamit singhNo ratings yet

- JQX 68FDocument2 pagesJQX 68FCarlos AguiarNo ratings yet

- TR24-SR-T US Technical Data Sheet: Modulating, Non-Spring Return, 24 V, For DC 2... 10 V or 4... 20 MaDocument2 pagesTR24-SR-T US Technical Data Sheet: Modulating, Non-Spring Return, 24 V, For DC 2... 10 V or 4... 20 Manicolas sNo ratings yet

- 25kW 208V, 1000Vdc String Inverters For North America: Key FeaturesDocument2 pages25kW 208V, 1000Vdc String Inverters For North America: Key FeaturesFERNANDOLANNo ratings yet

- Ys 6235Document2 pagesYs 6235pabloperezmtz1No ratings yet

- CPS SCA25KTL-DO-US-480 Datasheet July-10-2020Document2 pagesCPS SCA25KTL-DO-US-480 Datasheet July-10-2020Luis Alberto Serrano MesaNo ratings yet

- SQM48T20025 NBB0Document33 pagesSQM48T20025 NBB0Gabriel RacovskyNo ratings yet

- Pip-Msd TDocument1 pagePip-Msd TTakudzwa CeeNo ratings yet

- Relé Tianbo 5V PDFDocument3 pagesRelé Tianbo 5V PDFjhonny gonzalezNo ratings yet

- Contact Data Characteristics: 100A Power Latching RelayDocument3 pagesContact Data Characteristics: 100A Power Latching RelaySeendal Khan JokhioNo ratings yet

- DS 20230615 SG8800UD-MV-20 Datasheet V15 ENDocument2 pagesDS 20230615 SG8800UD-MV-20 Datasheet V15 ENPRADEEP SNo ratings yet

- Relafy 30 Amps T Typfe RelfayDocument2 pagesRelafy 30 Amps T Typfe RelfayMarudhasalamMarudhaNo ratings yet

- Switching Power Supply Redundant ModuleDocument3 pagesSwitching Power Supply Redundant ModuleAaron Ibarra San DiegoNo ratings yet

- FW250H1 and FW300H1 Power Modules: DC-DC Converters 36 To 75 VDC Input, 24 VDC Output 250 W To 300 WDocument20 pagesFW250H1 and FW300H1 Power Modules: DC-DC Converters 36 To 75 VDC Input, 24 VDC Output 250 W To 300 WJuan Pablo RiquelNo ratings yet

- Power Supply 360WDocument4 pagesPower Supply 360WandreNo ratings yet

- QT20 241Document23 pagesQT20 241memzueNo ratings yet

- EPEVER Datasheet XTRADocument3 pagesEPEVER Datasheet XTRAGem RNo ratings yet

- Se Three Phase Inverter With Setapp Configuration DatasheetDocument2 pagesSe Three Phase Inverter With Setapp Configuration DatasheetAleksa GrubacNo ratings yet

- Ld20 Series: 20W, Ac-Dc ConverterDocument5 pagesLd20 Series: 20W, Ac-Dc ConverterAnonymous QqyLDoW1No ratings yet

- DC-AC Inverter: 2 Year WarrantyDocument1 pageDC-AC Inverter: 2 Year WarrantySaleem MuhammadNo ratings yet

- DatasheetDocument2 pagesDatasheetSebas EcharteNo ratings yet

- RM-ST180 Jan 2021Document2 pagesRM-ST180 Jan 2021Jorge Rodriguez AlvaradoNo ratings yet

- Output V Low Test: Single Supply Profile VibrationsDocument2 pagesOutput V Low Test: Single Supply Profile VibrationsCarlos GomezNo ratings yet

- Three Phase DIN-Rail Digital Energy Meter Model:SDE430-C 1000ADocument3 pagesThree Phase DIN-Rail Digital Energy Meter Model:SDE430-C 1000AOmar FarhatNo ratings yet

- Arb24 SRDocument2 pagesArb24 SRJuanNo ratings yet

- EPEVER Datasheet XTRADocument3 pagesEPEVER Datasheet XTRADiego Steven Rayo VillamizarNo ratings yet

- PS3000W-48V Rev2Document4 pagesPS3000W-48V Rev2Juan Enrique Castillo CanoNo ratings yet

- Mornsun 500 VACTODCDocument6 pagesMornsun 500 VACTODCvahid hajihasaniNo ratings yet

- HDF 2415 DDocument2 pagesHDF 2415 Dศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet

- 2S7B 3upDocument5 pages2S7B 3upJlavieraNo ratings yet

- 300 500microDocument2 pages300 500microproficientsolarhuaweiNo ratings yet

- iPowerCube Outedoor Power Cabinet ICC1000-A1-E5 (72kVA, 01075825) Datasheet 01 - (20210218)Document4 pagesiPowerCube Outedoor Power Cabinet ICC1000-A1-E5 (72kVA, 01075825) Datasheet 01 - (20210218)Ride AlongNo ratings yet

- CC-E Series: Feature BenefitDocument2 pagesCC-E Series: Feature BenefitchiquicikNo ratings yet

- EV500 Series DC ContactorDocument8 pagesEV500 Series DC ContactorDIEGO VICENTE SANCHEZNo ratings yet

- Cps Sca25ktl Do Us 208 Datasheet Aug 7 2020 CSM 2020Document2 pagesCps Sca25ktl Do Us 208 Datasheet Aug 7 2020 CSM 2020lalo rivasNo ratings yet

- TP03AL220S03LSW 2W 85-265VAC Input 3.3VDC OutputDocument3 pagesTP03AL220S03LSW 2W 85-265VAC Input 3.3VDC OutputtoppowerNo ratings yet

- 1md8a 3upDocument3 pages1md8a 3upDirson Volmir WilligNo ratings yet

- Isolated 48VDC/24VDC ConverterDocument3 pagesIsolated 48VDC/24VDC ConverterOPENWIFI MIKROTIKNo ratings yet

- TP10AC - 2017 10W 4KV Isolation Wide Input AC/DC ConvertersDocument3 pagesTP10AC - 2017 10W 4KV Isolation Wide Input AC/DC ConverterstoppowerNo ratings yet

- RM2048XE: 2.0kW 48V DC Modular RectifiersDocument2 pagesRM2048XE: 2.0kW 48V DC Modular Rectifiersalways_975382984100% (2)

- Wpg-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Document4 pagesWpg-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Gopal HegdeNo ratings yet

- Jameco Part Number 95038ISOCOM: Distributed byDocument4 pagesJameco Part Number 95038ISOCOM: Distributed bymejmakNo ratings yet

- Ds 241120.123xx - ds3 1 2 1Document2 pagesDs 241120.123xx - ds3 1 2 1Boris BondarenkoNo ratings yet

- Description: Zero-Volt Switching Triac DriverDocument4 pagesDescription: Zero-Volt Switching Triac DriverTheo GrahamNo ratings yet

- Datasheet TSI BravoDocument2 pagesDatasheet TSI BravoMax TapiaNo ratings yet

- Datasheet ReleDocument2 pagesDatasheet ReleGuillermo Pocovi L.No ratings yet

- Solid q50 Denind 1808 V11webDocument2 pagesSolid q50 Denind 1808 V11webNinditya NugrohoNo ratings yet

- Electrochemistry, PPT 3Document33 pagesElectrochemistry, PPT 3Ernest Nana Yaw AggreyNo ratings yet

- Advanced Power System-I (Department Elective-I)Document4 pagesAdvanced Power System-I (Department Elective-I)Palak AriwalaNo ratings yet

- GT Load Effect On HRSGDocument3 pagesGT Load Effect On HRSGsatishchemeng100% (1)

- Coal Fired Power Plant PDFDocument1 pageCoal Fired Power Plant PDFboyzes100% (2)

- MMC 16101 - Positive Displacement Pump - 01Document19 pagesMMC 16101 - Positive Displacement Pump - 01HET DEDHIANo ratings yet

- Unit 2B.1Document16 pagesUnit 2B.1PualeilehuaNo ratings yet

- Fire Retardant Research PaperDocument2 pagesFire Retardant Research Paperapi-318759920No ratings yet

- Sample Questions - Chapter 22Document4 pagesSample Questions - Chapter 22Rasel IslamNo ratings yet

- Kiln Thruster LogicDocument3 pagesKiln Thruster LogicSameer kumar GOGOI0% (1)

- KBR Catalytic Olefins TechnologyDocument2 pagesKBR Catalytic Olefins TechnologyTomasz OleckiNo ratings yet

- DynaPack Adhesive Supply UnitDocument2 pagesDynaPack Adhesive Supply UnitITWDynatecNo ratings yet

- Antenna Theory TutorialDocument20 pagesAntenna Theory TutorialAbhicruiserNo ratings yet

- Pulley Systems Printed Handout - HeilmanDocument46 pagesPulley Systems Printed Handout - HeilmanGerman ToledoNo ratings yet

- Chapter 2-Measuring InstrumentDocument28 pagesChapter 2-Measuring InstrumentsaravananNo ratings yet

- Kids Picv1Document7 pagesKids Picv1Karthikeyan SankarrajanNo ratings yet

- Subject:-Engineering Thermodynamics Topic: - First Law of ThermodynamicsDocument78 pagesSubject:-Engineering Thermodynamics Topic: - First Law of Thermodynamicsuday kiran thagirchi100% (1)

- Bomba KSB Etablock y Etaline SYDocument4 pagesBomba KSB Etablock y Etaline SYParis AnabelNo ratings yet

- Ad00267v Ledeen BrochureDocument28 pagesAd00267v Ledeen Brochureetd_1988No ratings yet

- ICT Jalna Campus Booklet PDFDocument36 pagesICT Jalna Campus Booklet PDFUmesh khadkeNo ratings yet

- Chemical KineticsDocument3 pagesChemical Kineticsvivek daveNo ratings yet

- 24" (61 CM) Electric Single and Double Built-In Oven: Product Model Series Overall DimensionsDocument1 page24" (61 CM) Electric Single and Double Built-In Oven: Product Model Series Overall DimensionsHewa PCNo ratings yet

- M Arch (LA) PDFDocument27 pagesM Arch (LA) PDFmonsNo ratings yet

- 1559038005845442000Document171 pages1559038005845442000Patel IbrahimNo ratings yet

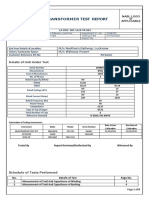

- Transformer Test Report: LA DOC. NO: LA-R-TR-003Document8 pagesTransformer Test Report: LA DOC. NO: LA-R-TR-003mayur dhandeNo ratings yet

- 844K 4WD Loader PIN 1DW844K D642008 Replacement Parts GuideDocument3 pages844K 4WD Loader PIN 1DW844K D642008 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- Eng Sicor Catalogue GearlessDocument52 pagesEng Sicor Catalogue GearlessEmeka Pius OramunwaNo ratings yet

- Elements Periodic TableDocument168 pagesElements Periodic TablejackzhangNo ratings yet

- Manual - BigMuff - Green RussianDocument10 pagesManual - BigMuff - Green RussianBen KussauerNo ratings yet

- Mechanical EngineeringDocument1 pageMechanical EngineeringManjunatha EikilaNo ratings yet

- LCM FormatDocument2 pagesLCM FormatSIMANTA KUMAR SAHUNo ratings yet