Professional Documents

Culture Documents

Design of Masonry Structures: Dr. Ratnesh Kumar Associate Professor

Uploaded by

Arunsai Gilla0 ratings0% found this document useful (0 votes)

21 views31 pagesOriginal Title

DMS Lecture 5

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views31 pagesDesign of Masonry Structures: Dr. Ratnesh Kumar Associate Professor

Uploaded by

Arunsai GillaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 31

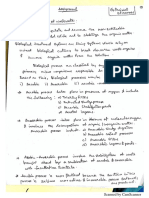

DESIGN OF MASONRY

STRUCTURES

Dr. Ratnesh Kumar

Associate Professor

Department of Applied Mechanics

VNIT NAGPUR, www.vnit.ac.in

Department of Applied Mechanics, VNIT NAGPUR

Slenderness: Introduction

The axial capacity of a masonry wall decreases with increasing

wall height.

For slender walls, this decrease in capacity can be associated

with elastic buckling.

But, for most practical wall heights, lower capacity is the

result of material failure under the combination of axial load

and bending.

For all walls, additional bending moments are caused by

deflection of the walls.

This was the case of reinforced concrete columns many years

ago.

Department of Applied Mechanics, VNIT NAGPUR 2

Because, the main function of the walls was to carry axial

compression.

Methods were developed to directly account for decreased

capacity due to slenderness.

Typically, the slenderness effect was introduced by multiplying

the section capacity by the reduction factor R so that

𝑃𝑠𝑙𝑒𝑛𝑑𝑒𝑟 = 𝐴𝑚 𝐹𝑚 𝑅

Initially, this type of factor was expressed in terms of height to

thickness ratio ℎ 𝑡

But, to include both hollow and solid masonry, the

slenderness ratio has generally been changed to height to

radius of gyration ratio ℎ 𝑟

Where 𝑟 = 𝐼 𝐴

Department of Applied Mechanics, VNIT NAGPUR 3

From the Euler buckling equation,

π2 𝐸𝐼

𝑃𝑐 =

ℎ2

Substituting 𝐴𝑟 2 = 𝐼 and dividing by 𝐴 gives

π2 𝐸

𝑓𝑚 𝑐𝑟𝑖𝑡𝑖𝑐𝑎𝑙 =

ℎ 𝑟 2

As a result, the ratio ℎ 𝑡 or ℎ 𝑟 has been related to the

reduction in capacity due to slenderness.

Alternatively, wall tests and computer modeling have shown

that bending moments in the wall significantly influence the

effect of slenderness.

Department of Applied Mechanics, VNIT NAGPUR 4

Other factors that contribute to make the rotational

prediction of the effects of slenderness very complex are as

follows:

The presence

Location

Amount of reinforcement

Rotational restraint at the top and bottom of the wall

Application of forces normal to the surface of the wall

Tensile strength

Variation in modulus of elasticity

Long term creep

Shrinkage

Department of Applied Mechanics, VNIT NAGPUR 5

Effective length:

When a wall has more than-one opening such that there is no

opening within a distance of H/8 from a cross wall and wall

length between openings are not columns by definition.

The design of the wall should be based on the value of SR

obtained from the consideration of height or length,

whichever is less.

Department of Applied Mechanics, VNIT NAGPUR 6

Effective height:

H is the height of wall between center of support in case of

RCC slabs and timber floors.

In case of footings or foundation block, height (H) is measured

from top of footing or foundation block.

In case of roof truss, height (H) is measured up to bottom of

the tie beam.

In case of. beam and slab construction, height should be

measured from center of bottom slab to center of top beam.

Referring above points, strictly speaking actual height of a

wall for the purpose of working out its effective height should

be taken to be the clear distance between the supports.

Department of Applied Mechanics, VNIT NAGPUR 7

However, in the Code it has been given as the height between

center of supports.

Which is in accordance with the provisions of British Standard

CP-I I I : Part 2 : 1970 as well as Australian Standard 1640-

1974.

Since thickness of floors is generally very small as compared

to height of floors, this method of reckoning actual height will

not make any appreciable difference in the end results.

One could, therefore, take actual height as given in the Code

or clear distance between supports as may be found

convenient to use in calculations.

When thickness of a wall bonded to a pier is at least two-

thirds the thickness of the pier measured in the same

direction, the wall and pier may be deemed to act as one

structural element.

Department of Applied Mechanics, VNIT NAGPUR 8

In this case we may design the element just as a wall

supporting a concentrated load, taking advantage of the

increase in the supporting area due to the pier projection.

In case thickness of wall is less than 2/3 of the thickness of

pier, we have to design the pier just like a column.

For which permissible stress is less because of greater

effective height and further supporting area will be only that

of the pier.

That is, without getting any benefit in design of the adjoining

walls on either side.

However in case, the wall and piers are supporting a

distributed load, we would get the advantage of stiffening

effect of piers as given below.

Department of Applied Mechanics, VNIT NAGPUR 9

For solid walls adequately bonded into piers/buttresses,

effective thickness for determining slenderness ratio based on

effective height.

Effective height shall be the actual thickness of wall multiplied

by stiffening coefficient as given in Table below.

No modification in effective thickness, however, shall be made

when slenderness ratio is to be based on effective length of

walls.

Department of Applied Mechanics, VNIT NAGPUR 10

Department of Applied Mechanics, VNIT NAGPUR 11

In case of columns actual height should be taken as the clear

height of a column between supports as illustrated in Figure

below.

Department of Applied Mechanics, VNIT NAGPUR 12

Effect of opening in wall:

An RCC slab bearing on a wall is assumed to provide full

restraint to the wall while a timber floor comprising timber joints

planking is assumed to provide only partial restraint.

The clause makes stipulations for reckoning effective

height of columns formed by openings in a wall for the two

cases:

a) when wall has full restraint at top and bottom

b) when wall has partial restraint at top and bottom. These two

cases are illustrated in Figure below

Department of Applied Mechanics, VNIT NAGPUR 13

Department of Applied Mechanics, VNIT NAGPUR 14

In the case of (b), if height of neither opening exceeds 0.5H,

wall masonry would provide some support to the column

formed by openings in the direction parallel to the wall.

For this reason effective height for the axis perpendicular to

the wall is taken as Hand

Otherwise it is to be taken as 2H. For the direction

perpendicular to the wall.

There is a likelihood of a situation when no joist rests on the

column formed between the openings.

Thus effective height is taken as 2H that is, for a column

having no lateral support at the top.

Department of Applied Mechanics, VNIT NAGPUR 15

Slenderness Ratio:

Point 1

Under a vertical load a wall would buckle either around a

horizontal axis parallel to the length of the wall or around a

vertical axis as illustrated in Figure below.

Buckling is resisted by horizontal supports such a floors and

roofs, as well as by vertical supports such as cross walls, piers

and buttresses.

Thus capacity of the walls to take vertical loads depends both

on horizontal supports that is, floor or roof as well as on

vertical supports that is, cross walls, piers and buttresses.

However, for the sake of simplicity and erring on safe side,

lesser of the two slenderness ratios, namely, one derived from

height.

Department of Applied Mechanics, VNIT NAGPUR 16

The other derived from length is taken into consideration for

determining permissible stresses in masonry walls, thus

ignoring strengthening effect of other supports.

Department of Applied Mechanics, VNIT NAGPUR 17

Point 2

In case of columns, there will be two values of SR as illustrated

in Figure below.

For the purpose of design, higher of the two values is taken

into account since column will buckle around that axis with

reference to which the value of SR is critical, that is, greater.

Department of Applied Mechanics, VNIT NAGPUR 18

Point 3

Load carrying capacity of a masonry member depends upon

its slenderness ratio.

As this ratio increases, crippling stress of the member gets

reduced because of limitations of workmanship and elastic

instability.

A masonry member may fail, either due to excessive stress or

due to buckling (see Figure below).

According to Sahlin for materials of normal strength with SR

less than 30, the load carrying capacity of a member at

ultimate load is limited by stress.

While for higher value of SR failure is initiated by buckling.

Department of Applied Mechanics, VNIT NAGPUR 19

Department of Applied Mechanics, VNIT NAGPUR 20

Further, mode of failure of a very short member having h/r

ratio of less than 4 is predominantly through shear action,

While with h/r = 4 or more, failure is by vertical tensile

splitting.

From consideration of structural soundness and economy of

design.

Most codes control the maximum slenderness ratio of walls

and columns so as to ensure failure by excessive stress rather

than buckling.

Department of Applied Mechanics, VNIT NAGPUR 21

Point 4

Limiting values of SR are less for masonry built in lime mortar,

as compared to that built in cement mortar.

Because the former, being relatively weaker, is more liable to

buckling.

Similarly, values of maximum SR are less for taller buildings

since imperfections in workmanship in regard to verticality are

likely to be more pronounced in case of taller buildings.

Limiting values of SR for column is less than that of walls

because a column can buckle around either of the two

horizontal axes.

While walls can buckle around horizontal axis only.

Department of Applied Mechanics, VNIT NAGPUR 22

Point 5

Since slenderness of a masonry element increases its

tendency to buckle, permissible compressive stress of an

element is related to its slenderness ratio.

It is determined by applying Stress reduction factor (ks) as

given in Table below

Strictly speaking full value of stress reduction factor is

applicable only for central one-fifth height of the member

bottom support.

In practice however for the sake of simplicity in design

calculations, stress reduction factor is applied to the masonry

throughout its storey height

Department of Applied Mechanics, VNIT NAGPUR 23

Department of Applied Mechanics, VNIT NAGPUR 24

For designing masonry for a particular storey height, generally

stress is worked out at the section just above the bottom

support assuming it to be maximum at that section.

Theoretically critical section in a storey occurs at a height 0.6

H above the bottom support.

Thus provisions of the Code and the design procedure in

question, as commonly followed, is an approximation, that

errs on the safe side.

Department of Applied Mechanics, VNIT NAGPUR 25

Point 6

Increase in permissible compressive stress for walls subjected

to concentrated loads:

When a wall is subjected to a concentrated load

A load being taken to be concentrated when area of

supporting walls equals or exceeds three times the bearing

area.

Certain increase in permissible compressive stress may be

allowed because of dispersal of the load.

Since, according to the present state of art, there is diversity

of views in regard to manner and extent of dispersal, design of

walls subjected to concentrated load may, therefore, be

worked out as per the best judgement of the designer.

Department of Applied Mechanics, VNIT NAGPUR 26

Point 7

In accordance with previous some increase in permissible

compressive stress is allowed for concentrated loads which

are concentric.

For Checking bearing stress under such a load, however, some

authorities on masonry recommend a conservative approach-

that is, either to take advantage of Note 3 of Table given

above or

To take advantage of provisions of previous point but do not

apply both the provisions of the code at the same time.

Department of Applied Mechanics, VNIT NAGPUR 27

Point 8

Advantage of Note 3 under Table above is taken when

considering bearing stress under a concentrated load from a

beam.

Bearing stress is worked out immediately below the beam and

this should not exceed the Basic compressive stress of

masonry (see Table below).

Also stress in masonry is worked out at a depth of H/8 from

the bottom of the beam.

This should not exceed the permissible compressive stress in

masonry.

If actual stress exceeds allowable stress in either case, a

concrete bed block is provided below the beam

Department of Applied Mechanics, VNIT NAGPUR 28

Department of Applied Mechanics, VNIT NAGPUR 29

Thank You

Visvesvaraya National Institute of Technology, Nagpur

Department of Applied Mechanics, VNIT NAGPUR

Contact

Dr. Ratnesh Kumar

Department of Applied Mechanics

Visvesvaraya National Institute of Technology, Nagpur

South Ambazari Nagpur

Maharashtra – 440010

Email: ratnesh.eq@gmail.com

Tele. +91 712 280 1582

Department of Applied Mechanics, VNIT NAGPUR

You might also like

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- Highrise DesignDocument5 pagesHighrise Designsuman33No ratings yet

- Proposed Standard for Seismic Design of Confined Masonry BuildingsDocument7 pagesProposed Standard for Seismic Design of Confined Masonry Buildingsdfv91No ratings yet

- Design of Masonry Structures GuideDocument31 pagesDesign of Masonry Structures GuideArunsai GillaNo ratings yet

- Minimum Thickness For Ductile RC Structural Walls: Y.H. Chai, S.K. KunnathDocument12 pagesMinimum Thickness For Ductile RC Structural Walls: Y.H. Chai, S.K. KunnathDavid FloresNo ratings yet

- 1 s2.0 S2949741823000195 MainDocument22 pages1 s2.0 S2949741823000195 Mainel mehdiaNo ratings yet

- 002-Retaining Wall DesignDocument3 pages002-Retaining Wall DesignBijay Krishna DasNo ratings yet

- High-Rise Shear Wall Strength and DuctilityDocument6 pagesHigh-Rise Shear Wall Strength and Ductilitymr.xinbombayNo ratings yet

- 02 WholeDocument386 pages02 WholeLenin Valerio MenaNo ratings yet

- Large Diameter Diaphragm Wall ShaftsDocument7 pagesLarge Diameter Diaphragm Wall ShaftsmeñoxNo ratings yet

- Design of High-Rise Core-Wall Buildings PerspectiveDocument8 pagesDesign of High-Rise Core-Wall Buildings Perspectivefoush bashaNo ratings yet

- Shear Design of WallsDocument8 pagesShear Design of WallsJohn Van RooyenNo ratings yet

- Diseño de Muros EspecialesDocument11 pagesDiseño de Muros EspecialesRonald Omar García RojasNo ratings yet

- Study On Effective Bracing Systems For High Rise Steel StructuresDocument7 pagesStudy On Effective Bracing Systems For High Rise Steel StructuresSaurabh PednekarNo ratings yet

- PBD 2Document7 pagesPBD 2Patel TosifNo ratings yet

- Dynamic Shear Force Ampli Fication in Regular Frame-Wall SystemsDocument24 pagesDynamic Shear Force Ampli Fication in Regular Frame-Wall SystemsMohamed Amine LemdaniNo ratings yet

- Shear Wall and Frame Interaction TerminologyDocument5 pagesShear Wall and Frame Interaction TerminologyGRD Journals100% (1)

- Displacement-Based Design of Concrete Wall Buildings in 2005 NBCCDocument14 pagesDisplacement-Based Design of Concrete Wall Buildings in 2005 NBCComaichuoiNo ratings yet

- Ce 479 Reinforced Masonry Fall 2004Document9 pagesCe 479 Reinforced Masonry Fall 2004Reinaldo Andrei SalazarNo ratings yet

- Chapter 2 Literature Review & ObjectiveDocument14 pagesChapter 2 Literature Review & ObjectivevanshajNo ratings yet

- RC WALL REINFORCEMENT LAYOUTSDocument12 pagesRC WALL REINFORCEMENT LAYOUTSSakisNo ratings yet

- The Use of Steel Damper For Enhancing The Seismic Performance of R/C Frame With Soft First StoryDocument12 pagesThe Use of Steel Damper For Enhancing The Seismic Performance of R/C Frame With Soft First StorySaurabh PednekarNo ratings yet

- IJETR2258Document4 pagesIJETR2258anil kasotNo ratings yet

- Reinforced Concrete Diaphragm DesignDocument6 pagesReinforced Concrete Diaphragm DesignkamakshiNo ratings yet

- Concrete Design Guide No. 3: Lateral Loads and Other FactorsDocument6 pagesConcrete Design Guide No. 3: Lateral Loads and Other Factorsspid003No ratings yet

- Shear WallDocument21 pagesShear WallMarwan AlferjaniNo ratings yet

- Ilovepdf MergedDocument39 pagesIlovepdf MergedAizon SusulanNo ratings yet

- UBC Earthquake Forces On WallDocument8 pagesUBC Earthquake Forces On WallAJBAJBNo ratings yet

- Performance Based Seismic Evaluation of G+9 RC Buildings With Openings in Infill WallsDocument10 pagesPerformance Based Seismic Evaluation of G+9 RC Buildings With Openings in Infill WallsLoren McmahonNo ratings yet

- T03 10 Serdar - Pejovic - GNP2020Document8 pagesT03 10 Serdar - Pejovic - GNP2020Kenan KajosevicNo ratings yet

- 17 MST0024 PublicationDocument7 pages17 MST0024 Publicationkguse2bNo ratings yet

- IJCRT2210458Document24 pagesIJCRT2210458omar heshamNo ratings yet

- Shear Wall NotesDocument7 pagesShear Wall NotesArfath Khan MohammedNo ratings yet

- The Control of Building Motion by Friction Dampers: Cedric MARSHDocument6 pagesThe Control of Building Motion by Friction Dampers: Cedric MARSHAlam Mohammad Parvez SaifiNo ratings yet

- Exploration Study On Energy Dissipation in Beam and Column Joint With Semi Rigid ConnectionDocument12 pagesExploration Study On Energy Dissipation in Beam and Column Joint With Semi Rigid ConnectionIJRASETPublicationsNo ratings yet

- Sp36-07 Cardenas Magura AciDocument32 pagesSp36-07 Cardenas Magura Acihcastelblancor100% (1)

- The Analysis of Earth Pressure On Retaining Wall Based On ABAQUSDocument4 pagesThe Analysis of Earth Pressure On Retaining Wall Based On ABAQUSroloheNo ratings yet

- Designed As Per Indian Standards and Also To Determine The Effect of Providing Shear Wall To Building FrameDocument7 pagesDesigned As Per Indian Standards and Also To Determine The Effect of Providing Shear Wall To Building FrameNitin shepurNo ratings yet

- Cyclic Behaviour of A Full Scale RC Structural WallDocument11 pagesCyclic Behaviour of A Full Scale RC Structural WallAzhar PLNo ratings yet

- Study The Reinforced Concrete Frame With Brick Masonry Infill Due To Lateral LoadsDocument6 pagesStudy The Reinforced Concrete Frame With Brick Masonry Infill Due To Lateral LoadsChidanand BhimannavarNo ratings yet

- Fragility Analysis of Open Ground Storey PDFDocument7 pagesFragility Analysis of Open Ground Storey PDFAce NovoNo ratings yet

- In-Plane Cyclic Performance of Confined Partially Grouted Masonry Walls With Joint and Vertical ReinforcementDocument12 pagesIn-Plane Cyclic Performance of Confined Partially Grouted Masonry Walls With Joint and Vertical ReinforcementPanayioti ZoupantisNo ratings yet

- Shear Behavior of Squat Heavyweight Concrete Shear Walls With Construction JointsDocument12 pagesShear Behavior of Squat Heavyweight Concrete Shear Walls With Construction Jointsabhishek kumarNo ratings yet

- Finite Element Modeling of Shear Strength of Infilled Frames With OpeningsDocument10 pagesFinite Element Modeling of Shear Strength of Infilled Frames With OpeningsGalal El-DarratNo ratings yet

- International Journal of Chemtech Research: Dharanya A, Gayathri S, Deepika MDocument8 pagesInternational Journal of Chemtech Research: Dharanya A, Gayathri S, Deepika MTeja Roop ReddyNo ratings yet

- Shear Wall Design Per ACI-318 05Document10 pagesShear Wall Design Per ACI-318 05nsrivasan100% (5)

- Jose SWDocument11 pagesJose SWTheyCalledMe ZafNo ratings yet

- Adebar and IbrahimDocument20 pagesAdebar and IbrahimMichael Murfinator MurphyNo ratings yet

- Seismic Performance of Precast Polystyrene RC Walls: Ari WibowoDocument8 pagesSeismic Performance of Precast Polystyrene RC Walls: Ari Wibowoc4ppuc1n0No ratings yet

- Ductility Detailing of StructuresDocument8 pagesDuctility Detailing of StructuresRabindraSubediNo ratings yet

- Tobctj 8 104Document18 pagesTobctj 8 104Ing Fredy William Campos FloresNo ratings yet

- Optimum Design of Post-Tensioned Concrete Waffle SlabsDocument19 pagesOptimum Design of Post-Tensioned Concrete Waffle SlabsVAIDEHI BEAUTY CARE by DEEPA BHAVSARNo ratings yet

- 10PCEE Paper 256 Sadeghian Koboevic ProceedingsDocument9 pages10PCEE Paper 256 Sadeghian Koboevic ProceedingshjmaranhaoNo ratings yet

- Ductility Design of Reinforced Concrete Shear WallsDocument12 pagesDuctility Design of Reinforced Concrete Shear WallsMohamad Reza100% (1)

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Tariff ParcelsDocument2 pagesTariff ParcelssatyanrayanaNo ratings yet

- Potential Water Sources For Coal-Fired Power Plants - ccc266 - 1Document97 pagesPotential Water Sources For Coal-Fired Power Plants - ccc266 - 1Arunsai GillaNo ratings yet

- SLSMDocument11 pagesSLSMMoh BayoNo ratings yet

- Tele VNITDocument100 pagesTele VNITdebjit123No ratings yet

- GE Power Bags Contract From NTPC Limited For Installation of Flue Gas Desulphurization (002) V2Document2 pagesGE Power Bags Contract From NTPC Limited For Installation of Flue Gas Desulphurization (002) V2Arunsai GillaNo ratings yet

- Thyroid Profile: Laboratory Test ReportDocument1 pageThyroid Profile: Laboratory Test ReportArunsai Gilla100% (1)

- Acknowledgement Slip PDFDocument1 pageAcknowledgement Slip PDFmadhu gundaNo ratings yet

- Listening Module KeyDocument4 pagesListening Module KeyArunsai GillaNo ratings yet

- Ietls Listening: An OverviewDocument8 pagesIetls Listening: An OverviewArunsai GillaNo ratings yet

- Isostasy: Note Prepared by Dr. Y.B. Katpatal For Internal Circulation of StudentsDocument19 pagesIsostasy: Note Prepared by Dr. Y.B. Katpatal For Internal Circulation of StudentsArunsai GillaNo ratings yet

- Is 4031 6 1988Document11 pagesIs 4031 6 1988HiteshAgarwalNo ratings yet

- Telangana COVID Test Report Shows Negative ResultDocument1 pageTelangana COVID Test Report Shows Negative ResultArunsai GillaNo ratings yet

- Design of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorDocument33 pagesDesign of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorArunsai GillaNo ratings yet

- Design of Masonry Structures: Masonry Units and Material PropertiesDocument30 pagesDesign of Masonry Structures: Masonry Units and Material PropertiesArunsai GillaNo ratings yet

- Design of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorDocument30 pagesDesign of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorArunsai GillaNo ratings yet

- Design of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorDocument32 pagesDesign of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorArunsai GillaNo ratings yet

- Crepido: About AXISDocument3 pagesCrepido: About AXISArunsai GillaNo ratings yet

- Petrology 1Document24 pagesPetrology 1Rahul SharmaNo ratings yet

- Earthquake Prediction & MeasurementsDocument28 pagesEarthquake Prediction & MeasurementsArunsai GillaNo ratings yet

- Folds & Faults PDFDocument34 pagesFolds & Faults PDFRamchandra Subbareddy GundareddyNo ratings yet

- Mineralogy PDFDocument14 pagesMineralogy PDFPranay NagpureNo ratings yet

- CCl.a2-5 Monnelat (E7¢fvo2t) Financial AnalysisDocument7 pagesCCl.a2-5 Monnelat (E7¢fvo2t) Financial AnalysisArunsai GillaNo ratings yet

- CD and Plate Tectonics - EncDocument98 pagesCD and Plate Tectonics - EncArunsai GillaNo ratings yet

- Design of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorDocument32 pagesDesign of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorArunsai GillaNo ratings yet

- Envo Final AssignmentDocument14 pagesEnvo Final AssignmentArunsai GillaNo ratings yet

- Financial Statement Analysis in 40 CharactersDocument14 pagesFinancial Statement Analysis in 40 CharactersEdilmar LulabNo ratings yet

- RCC Design by Shah and Kale Free Downloadzip PDFDocument4 pagesRCC Design by Shah and Kale Free Downloadzip PDFArunsai Gilla100% (1)

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- Structural Design Lecture NotesDocument119 pagesStructural Design Lecture NotesKannan KandappanNo ratings yet

- Corporate Level Strategies ExplainedDocument30 pagesCorporate Level Strategies ExplainedNazir AnsariNo ratings yet

- Remove Head IsmDocument67 pagesRemove Head IsmjeremyNo ratings yet

- Margie's Group Travel Presents The Sparks Rebellion 1855-1857Document12 pagesMargie's Group Travel Presents The Sparks Rebellion 1855-1857fcmitcNo ratings yet

- 12th English Elec Lyp 2013 DelhiDocument10 pages12th English Elec Lyp 2013 DelhiKanishkha SivasankarNo ratings yet

- SHORLUBE Self Lubricating Bearings PDFDocument20 pagesSHORLUBE Self Lubricating Bearings PDFNickNo ratings yet

- Seniors Playing Record Nov 20 To Dec 2021 New SystemDocument6 pagesSeniors Playing Record Nov 20 To Dec 2021 New Systemapi-313355217No ratings yet

- Alora Sealord History, How and Why They Were FormedDocument1 pageAlora Sealord History, How and Why They Were Formedgoddessjanefire003No ratings yet

- Download 3000+ Books by Acharya Pt. Shriram SharmaDocument89 pagesDownload 3000+ Books by Acharya Pt. Shriram SharmaAllWorld GaayatreeParivaar SaharunpurNo ratings yet

- Pricelist PT SCB Maret 2023Document11 pagesPricelist PT SCB Maret 2023PT RUKUN CAHAYA ABADINo ratings yet

- GJ ScriptDocument83 pagesGJ ScriptKim LawrenceNo ratings yet

- Parallel Computing: # Registering Cores For Parallel ProcessDocument4 pagesParallel Computing: # Registering Cores For Parallel ProcessJohn SinghNo ratings yet

- Natural Resources Management IntroDocument14 pagesNatural Resources Management IntroJoaquin David Magana100% (2)

- IMU 25,26 Oct 2014 (Other) ResultDocument2,582 pagesIMU 25,26 Oct 2014 (Other) ResultMuhammadFarhanShakee100% (1)

- Society of Radiographers - PDFDocument9 pagesSociety of Radiographers - PDFOsama AhmedNo ratings yet

- ED Review Test 4Document2 pagesED Review Test 4Huyen KimNo ratings yet

- En Subject C08Document13 pagesEn Subject C08jmolfigueiraNo ratings yet

- Anglo Agriparts Trade CatalogueDocument609 pagesAnglo Agriparts Trade CatalogueJoanne Champion100% (1)

- L-1 Preparation of Gases MCQDocument31 pagesL-1 Preparation of Gases MCQapi-233604231No ratings yet

- Quotes by Swami VivekanandaDocument6 pagesQuotes by Swami Vivekanandasundaram108No ratings yet

- Step 5 - PragmaticsDocument7 pagesStep 5 - PragmaticsRomario García UrbinaNo ratings yet

- Clarifying Oracle EPM Versioning - PatchesDocument3 pagesClarifying Oracle EPM Versioning - PatchesSathish BalaNo ratings yet

- FVNL"'" - TT - ..: MycotaDocument8 pagesFVNL"'" - TT - ..: MycotaAmbesh JhaNo ratings yet

- Handout-Wisdom QuestionsDocument1 pageHandout-Wisdom Questionsapi-369459770No ratings yet

- Lesson 10 - Classfying Food and Drink OperationsDocument25 pagesLesson 10 - Classfying Food and Drink OperationsRyl SorianoNo ratings yet

- Shahrzadgh InquiryassignmentDocument5 pagesShahrzadgh Inquiryassignmentapi-274076411No ratings yet

- Bitonio V CoaDocument24 pagesBitonio V Coamarjorie requirmeNo ratings yet

- BR COREnew Rulebook v1.5 ENG-nobackground-lowDocument40 pagesBR COREnew Rulebook v1.5 ENG-nobackground-lowDavid Miller0% (1)

- MSDS TriacetinDocument4 pagesMSDS TriacetinshishirchemNo ratings yet

- DocxDocument5 pagesDocxFelicya Angel Ivy LynnNo ratings yet

- Hatch-Slack PathwayDocument10 pagesHatch-Slack Pathwaychurail khanNo ratings yet