Professional Documents

Culture Documents

Boq Hvac

Boq Hvac

Uploaded by

rajendra timalsinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boq Hvac

Boq Hvac

Uploaded by

rajendra timalsinaCopyright:

Available Formats

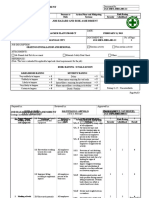

BOQ

Item Description Unit Qty Rate Amount

1 AIRCOOLED PACKAED UNITS

Supplying, installing and commissioning of Air cooled type Packaged

air-conditioning units complete with Hermetically sealed MULTI

SCROLL compressors fitted inside the indoor unit & first charge of

refrigerant & oil ,air cooled condensor, fan section with

statically/dynamically balanced centrifugal blower driven by a TEFC

squirrel cage three speed motor, Multi rows cooling coil of copper with

aluminium fins etc. The enclosures shall be fabricated of M.S. The

Package unit shall be equipped with synthetic fibre filter, insulated drain

pan, controls all encased in a unit. The casing shall be factory powder

coated. Electrical panel board for Package units shall comprise of SFU’s,

Fuses, Voltage scanner, complete with overload, low voltage, high

voltage & phase imbalance protection. Along with VI Pads complete with

all ancillary including MS painted stand for Outdoor units of suitable size,

foundation ( RCC cubes with double vibration pad and GI strip) and allied

minor civil works as per instructions of engineer in charge of following

ratings including GI supply air damper of suitable size, outdoor control

cabling, 63 Amp Isolator fitting in electric control panel & fitting as per

1.1 16.5 TR nominal capacity suitable for atleast 6400 cfm air capacity. (with Nos 3

specifications.

3 compressors)

1.2 11.5 TR nominal capacity suitable for atleast 4400 cfm air capacity. (with Nos 2

2 compressors)

2 REFRIGERANT PIPING

Supplying, Installation, Testing and Commissioning of Refrigerant copper

piping complete with all fittings such as bends, tees, elbows etc. as per

specifications. The quoted rates shall include rates for chiseling, making

good of wall and clamps etc.

2.1 Refrigerant piping for 16.5/17 TR units (for 3 circuits – 3 suction and 3 Rmt 42

discharge lines)

2.2 Refrigerant piping for 11/11.5 TR units (for 2 circuits - 2 Suction and 2 Rmt 30

discharge lines)

3 Supply, Installation, testing and commissioning of PPRC piping complete

with fittings, supports as per specifications (condensate water drain line)

3.1 25 mm Dia Rmt 150

4 Supply, installation, balancing and commissioning of fabricated at site

GSS sheet metal rectangular/round ducting complete with neoprene

rubber gaskets, elbows, splitter dampers, vanes, hangers, supports etc. as

per approved drawings and specifications of following sheet thickness

complete as required as per specifications.

4.1 Thickness 0.63 mm sheet Sqm. 60

5 Supply and installation of External Thermal insulation on ducts with

cross linked nitrile rubber class O as per the approved specifications.

Quoted price shall be inclusive of adhesive, 3” black tapes as per

5.1 Inside the building

5.2 13 mm thick insulation for air ducts. Sqm 65

6 Supply and fixing of UL approved Underdeck thermal insulation for the sqm 300

roofs with 25 mm thick closed cell nitrile rubber insulation of class 'O'

Fire rating confirming to BS 476 part 6 including providing adhesive,

adhesive tapes, etc all complete

7 Supply, installation, testing and commissioning of 32 kg/m3 density

fiberglass insulation in the form of 25 mm Thick Fiber Glass boards, 2

Layers of Tissue paper finished with 28 gauge perforated Aluminum sheet

with nuts, bolts complete as per specifications.

7.1 25 mm thickness acoustic lining inside the duct and 0.6 aluminium Sqm. 65

perforated sheet

8 Supply, installation, testing and balancing of powder coated extruded Sqm 10

return air aluminum grills without aluminum volume control dampers as

per approved drawings and specifications.

9 Power Cabling:

Supply, laying testing and commissioning of 1100 volt grade armored

XLPE. insulated and sheathed aluminium/copper conductor cables of

sizes as below, on cable trays with suitable clamps, saddles, hooks, bolts

etc. complete as per specifications and as required. The quoted rate shall

include the cost of proper dressing of cables and also providing

9.1 4 C x 6 sqmm copper cable Rm 150

9.2 4 C x 10 sqmm copper cable RM 100

1 Fire Damper with Control Mechanism sqm 7

Ref no Supplying, Fixing,testing and commissioning of fire dampers in supply air

16.20.1 duct/main branch and return air path as and where required of required

sizes i/c control wiring,the damper shall be motorized and spring return so

as to close the damper in the event of power failure automatically and

open the same in case of power being restored. The spring return action

shall be inbuilt mechanism and not externally mounted. The damper shall

also be closed in the event of fire signal complete as required and as per

Electric Actuator

Ref no Electric actuator with necessary linkage to actuate fire dampers complete Nos. 10

16.20.2 with required wiring and associated accessories.

Note: Fire dampers shall be supplied with sensors/actuators/control etc

duly factory fitted and tested at manufacturers works and certificate to this

effect produced along with delivery of fire damper.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Material Safety Data Sheet: 1-IdentificationDocument3 pagesMaterial Safety Data Sheet: 1-IdentificationKhaled Anwar100% (1)

- Gsis Loan of Deped EmployeesDocument11 pagesGsis Loan of Deped EmployeesJoy Manaog100% (1)

- JGS SHES JHRA 001 13 Grating Installation and RemovalDocument2 pagesJGS SHES JHRA 001 13 Grating Installation and Removalarnel sungkip100% (2)

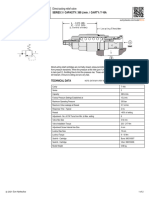

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- RBFA Full en Metric LetterDocument2 pagesRBFA Full en Metric LetteressamNo ratings yet

- Downloads - Paro SoftwareDocument4 pagesDownloads - Paro SoftwareessamNo ratings yet

- Adobe Acrobat Reader - Free PDF ViewerDocument2 pagesAdobe Acrobat Reader - Free PDF VieweressamNo ratings yet

- FLeX Series 2-Stage, Solenoid-Operated Adjustable Relief Valve, Normally VentedDocument8 pagesFLeX Series 2-Stage, Solenoid-Operated Adjustable Relief Valve, Normally VentedessamNo ratings yet

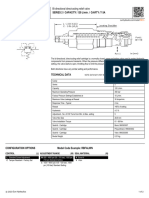

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- Re92076 - 2022 02 16Document76 pagesRe92076 - 2022 02 16essamNo ratings yet

- Control Devices HM, HS5 and EO Series 1X: AmericasDocument76 pagesControl Devices HM, HS5 and EO Series 1X: AmericasessamNo ratings yet

- User'S Manual: Ipower SeriesDocument20 pagesUser'S Manual: Ipower SeriesSilvio SantosNo ratings yet

- Compressed Air Filters PDFDocument70 pagesCompressed Air Filters PDFdj22500No ratings yet

- 6V Battery Charger Circuit For Lead Acid Battery - Simple ElectronicsDocument4 pages6V Battery Charger Circuit For Lead Acid Battery - Simple Electronicsmuralidharan23100% (1)

- Eapp Q1 W3Document14 pagesEapp Q1 W3Raiza Mai MendozaNo ratings yet

- Strategies For Managing Disciplinary Problems Among Secondary Schools in Izzi Local Government AreaDocument100 pagesStrategies For Managing Disciplinary Problems Among Secondary Schools in Izzi Local Government AreaOpia Anthony100% (1)

- Code - 2216 - Congenital EventrationDocument5 pagesCode - 2216 - Congenital EventrationHumaida Hasan SamiraNo ratings yet

- Ticks in MichiganDocument1 pageTicks in MichiganJessica StrachanNo ratings yet

- Be Well HospitalDocument2 pagesBe Well Hospitalabhishek viswamNo ratings yet

- TemperamentDocument2 pagesTemperamentBatka BekNo ratings yet

- Alchemists ConcordanceDocument108 pagesAlchemists Concordanceroger santosNo ratings yet

- Maintanance Bohai #27 NewDocument30 pagesMaintanance Bohai #27 NewB LloydNo ratings yet

- Road SafetyDocument48 pagesRoad SafetyAlie Bhin Abhu DhabiNo ratings yet

- Clement ReasonDocument3 pagesClement ReasonTnem NatNo ratings yet

- RapeDocument34 pagesRapeGurpreet Singh Mandair100% (1)

- Ao Alliance Handbook Nonoperative Fracture Treatment Complete PDFDocument164 pagesAo Alliance Handbook Nonoperative Fracture Treatment Complete PDFvicageoNo ratings yet

- ICSB Mexico MSMEs Outlook Ricardo D. Alvarez v.2.Document4 pagesICSB Mexico MSMEs Outlook Ricardo D. Alvarez v.2.Ricardo ALvarezNo ratings yet

- ABC Tracker: Routines AnalysisDocument3 pagesABC Tracker: Routines Analysisapi-455438287No ratings yet

- Use of Remote Sensing Data in A GIS Environment For Water Resources ManagementDocument13 pagesUse of Remote Sensing Data in A GIS Environment For Water Resources ManagementchuniNo ratings yet

- Verification & Approval of Cad ProjectDocument17 pagesVerification & Approval of Cad ProjectCommunication GuyNo ratings yet

- Eugene Rawls - Handbook of Yoga For Modern LivingDocument177 pagesEugene Rawls - Handbook of Yoga For Modern LivingSandorhazi Robertino MihaiNo ratings yet

- Answer To Exam 3A-2020Document7 pagesAnswer To Exam 3A-2020Phạm Thái HàNo ratings yet

- Lampa Cu Senzor de Miscare 19138 ManualDocument2 pagesLampa Cu Senzor de Miscare 19138 Manualcostin5No ratings yet

- Erp SSTDocument32 pagesErp SSTAzmi Nurse OfficialNo ratings yet

- Muscle Structure and Functions of The Muscular SystemDocument4 pagesMuscle Structure and Functions of The Muscular SystemscadmoreNo ratings yet

- 2022-01-06 St. Mary's County TimesDocument32 pages2022-01-06 St. Mary's County TimesSouthern Maryland OnlineNo ratings yet

- Managing Diversity in Jamaican ClassroomDocument2 pagesManaging Diversity in Jamaican ClassroomManushka Thomas100% (1)

- Saudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechAnonymous S9qBDVky0% (1)