Professional Documents

Culture Documents

OS Whistler Corp

Uploaded by

Pradeep K0 ratings0% found this document useful (0 votes)

155 views14 pagesWhistler Corp case study

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWhistler Corp case study

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

155 views14 pagesOS Whistler Corp

Uploaded by

Pradeep KWhistler Corp case study

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 14

Whistler Corporation

Amit Bhalotia (2008007)

Mayank Mathur (2007096)

Naufal Kukkadi (2008039)

Pradeep K Panicker (2008093)

Vandana Rajendran (2007116)

Varun Basu (2008062)

Swapnish Khanolkar (2007112)

Synopsis

Whistler Corporation: Incorporated in 1970

Had been a market leader in the radar

detector industry since 1978.

Once profitable company has seen its

market share and sales decrease

dramatically.

Forced to examine its current manufacturing

strategies

Make possible recommendations for future

implementation.

Company Background

Whistler Corporation held a dominant position in the market

for civilian vehicle detection devices of police radar.

Between 1983 and 1987 the sales of radar detectors

increased by 450%.

The first radar detectors were introduced to market in 1972.

Multiple firms emerged and by 1987 there were nearly 20

companies vying for market share.

Due to intense competition and access to low cost

producers, the average price of radar detectors declined

steadily.

Radar detectors were a maturing product within the U.S. as

sales in the next few years were expected to level off.

Further, the entire radar detection market faced serious

curtailment through local and state legislation prohibiting such

devices.

Situational analysis

Functionally divided between two plants

in Westford and Fitchburg.

Financial performance had been rapidly

deteriorating

Company loosing market share.

In 1980, the market size was 473000

units.

Whistler’s manufacturing strategy : largely

tailored towards low volume, low variety

and stable demand conditions.

Problems

Quality Issues – First pass yields dropped

to critical levels and rework effort accounted

for nearly 30% of the WIP inventories.

Inefficient process workflows – As final

assembly was being done in Fitchburg,

components had to be shipped back and

forth between the plants.

Inefficient space utilization – 30% of

Westford plants floor space was taken up by

WIP which accounted for approximately

$600,000 of WIP inventories. This WIP was

susceptible to damage.

Problems

Inventory management - In-process inventory

levels soared across all points in the assembly line.

Material handling issues -

Defective boards hindering smooth material flow

High rate of defective subassemblies created problems

in matching subassemblies to final assembly kits since

parts from other batches were used as replacements

Sub-optimal process time - A unit spent an

average of 23 days in process whereby actual

production time was simply eight hours.

Other issues

There exists an additional threat to the

company in the form of increasingly

restrictive regulations with regard to the

use of the radar detector product.

The company is faced with the very real

possibility that the entire market could

literally vanish overnight due to a adverse

regulation coming into effect.

Alternatives

Multiple alternatives that can be adopted :

Whistler Corporation can outsource

manufacturing to suppliers in Korea

Whistler can implement RACE-ME for all

product lines

Outsourcing

Advantages of outsourcing:

There is a clear cost saving of 33% over its current costs

This will enable Whistler to concentrate on what it does best –

product design and marketing. This becomes particularly

important in the light of regulatory changes that might take place.

This allows Whistler to quickly dump the product line in case of

adverse regulations coming into force.

Disadvantages of outsourcing:

Whistler can no longer control product quality and hence may

not be able to command the same price premium

Since the suppliers are located in East Asia, they will be unable to

respond quickly to surges in demand due to shipping delays

Existing plants will need to be closed and the subsequent job

losses may lead to adverse reaction.

Proprietary designs of Whistler may not be adequately protected.

RACE-ME

Advantages of RACE-ME

There is a clear cost and productivity improvement

It enables the firm to obtain almost similar cost

advantage with outsourcing : added benefits of local ,

creating a clear competitive advantage.

Disadvantages of RACE-ME

Pull systems require high supplier co-ordination so

that low levels of input inventory can be maintained.

It appears that whistler’s distribution channels (mostly

retail) will not completely align with a made –to-

order strategy.

Implementing a pull strategy across the entire system

would require significant investment and commitment.

Recommendations

Outsource selected product lines

Implementation of RACE-ME

Closure of Fitchburg plant

Diversification into new product markets

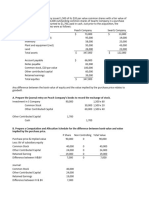

Estimated cost details

Cost head Estimated cost saving Estimated cost

Material 0 31.90

Scrap 17% 0.65

114% for 40% labour rework + 237% for 60%

Direct labor direct labour 5.44

Variable Overhead 68% 4.28

Shipping 0 0.00

Duty 0 0.00

U.S coordination 0 0.00

Fixed overhead

HQ 0 3.38

Westford 146% 6.36

0 0.00

Total 52.01

Conclusion

A successful scale up of RACE-ME will

cost $52, almost comparable to the

production cost ($47) at an outsourced

location

Manufacture high end products locally

leveraging RACE-ME to control quality

and response times

Outsource low end products to low cost

destinations.

You might also like

- Bergerac Systems: The Challenge of Backward Integration: Group 02, Section - CDocument5 pagesBergerac Systems: The Challenge of Backward Integration: Group 02, Section - CSaumya GautamNo ratings yet

- Group 7 Assignment 2 Wilkins - A Zurn CompanyDocument15 pagesGroup 7 Assignment 2 Wilkins - A Zurn CompanyVanshika Chhabra 27No ratings yet

- Group1 - Madras Refineries LimitedDocument5 pagesGroup1 - Madras Refineries LimitedDHRUV SONAGARANo ratings yet

- Barilla Spa (Hbs 9-694-046) - Case Study Submission: Executive SummaryDocument3 pagesBarilla Spa (Hbs 9-694-046) - Case Study Submission: Executive SummaryRichaNo ratings yet

- Sunbeam FS EvaluationDocument5 pagesSunbeam FS EvaluationSaurav GhoshNo ratings yet

- IM Group 3 Tyler AbrasivesDocument7 pagesIM Group 3 Tyler AbrasivesTejas ShahNo ratings yet

- Case Analysis Landmark FacilityDocument25 pagesCase Analysis Landmark Facilitystark100% (1)

- Session 4 - Mohali Gifts ShopDocument12 pagesSession 4 - Mohali Gifts ShopArpita DalviNo ratings yet

- Case Study 27 V2Document10 pagesCase Study 27 V2mrchardNo ratings yet

- Introduction To MacroeconomicsDocument102 pagesIntroduction To MacroeconomicsJessica TangNo ratings yet

- OSTR Assignment 3 Manzana InsuranceDocument4 pagesOSTR Assignment 3 Manzana InsuranceSrishtiNo ratings yet

- Nypro IncDocument13 pagesNypro IncRendy Fadhlan PutraNo ratings yet

- Bharat Forge Limited - Global Leadership - Submission by Group 3Document1 pageBharat Forge Limited - Global Leadership - Submission by Group 3Murali Dharan100% (1)

- Virgin Mobile USA: Pricing For The First Time: Case Group AssignmentDocument5 pagesVirgin Mobile USA: Pricing For The First Time: Case Group Assignmentbonfument100% (1)

- Group Project - OB - A8Document3 pagesGroup Project - OB - A8Khushboo LakhwaniNo ratings yet

- BarillaDocument3 pagesBarillaMohit Pandey0% (1)

- Sumeru Case SolutionDocument2 pagesSumeru Case SolutionAshwin KumarNo ratings yet

- When Workers Rate The BossDocument3 pagesWhen Workers Rate The BossSHIVANGI MAHAJAN PGP 2021-23 BatchNo ratings yet

- Balance Sheet Detective Additional AnalysisDocument2 pagesBalance Sheet Detective Additional AnalysisAlina ZubairNo ratings yet

- FM Section A - Group 9 Pre Read Assignment - Dell's Working CapitalDocument9 pagesFM Section A - Group 9 Pre Read Assignment - Dell's Working CapitalTalluri HarikaNo ratings yet

- Supporting Sheet - UV21001Document15 pagesSupporting Sheet - UV21001BikramdevPadhiNo ratings yet

- Impairing The Microsoft - Nokia PairingDocument54 pagesImpairing The Microsoft - Nokia Pairingjk kumarNo ratings yet

- Newell's Corporate StrategyDocument1 pageNewell's Corporate StrategyAmogh Suman0% (1)

- Cottle Taylor Case AnalysisDocument22 pagesCottle Taylor Case AnalysisRALLAPALLI VISHAL VIJAYNo ratings yet

- 09727980810949151Document13 pages09727980810949151Syed Ahmed AliNo ratings yet

- BOP ExpandingOpportunity+ (Fullreport) PDFDocument324 pagesBOP ExpandingOpportunity+ (Fullreport) PDFSher Singh YadavNo ratings yet

- B&D Case Write-UpDocument3 pagesB&D Case Write-UpCindy Arzola100% (1)

- DMUU Assignment2 - GroupCDocument4 pagesDMUU Assignment2 - GroupCJoyal ThomasNo ratings yet

- Midterm Exam AnswersDocument8 pagesMidterm Exam AnswersJ100% (1)

- Managing A Global TeamDocument17 pagesManaging A Global TeamAdil Huseyin HeymunNo ratings yet

- PGP MAJVCG 2019-20 S3 Unrelated Diversification PDFDocument22 pagesPGP MAJVCG 2019-20 S3 Unrelated Diversification PDFBschool caseNo ratings yet

- Porter's 5-Force Analysis of ToyotaDocument9 pagesPorter's 5-Force Analysis of ToyotaBiju MathewsNo ratings yet

- This Study Resource Was: Global Strategy at LenovoDocument3 pagesThis Study Resource Was: Global Strategy at LenovoAnukriti ShakyawarNo ratings yet

- Case Two - GE Healthcare in IndiaDocument3 pagesCase Two - GE Healthcare in IndiaAaina Jaiswal100% (1)

- Wilkins, A Zurn Company: Aggregate Production Planning: Group 4Document7 pagesWilkins, A Zurn Company: Aggregate Production Planning: Group 4Ayushi GuptaNo ratings yet

- Destin Brass ProductDocument5 pagesDestin Brass ProductRamalu Dinesh ReddyNo ratings yet

- Savemart Case StudyDocument11 pagesSavemart Case StudySanchit GuptaNo ratings yet

- Anne Mulcahy - Leading Xerox Through The Perfect StormDocument18 pagesAnne Mulcahy - Leading Xerox Through The Perfect Stormabhi.slch6853No ratings yet

- Iron Gate - InputDocument1 pageIron Gate - InputShshank0% (1)

- Savemart Wareshousing: Group 10Document3 pagesSavemart Wareshousing: Group 10arjavsNo ratings yet

- Case2: Liulishuo: AI English TeacherDocument3 pagesCase2: Liulishuo: AI English TeacherSoubhagya DashNo ratings yet

- This Study Resource Was: EndecaDocument6 pagesThis Study Resource Was: EndecaElad BreitnerNo ratings yet

- S0.0 MAACS Course Outline Mar Apr 2019Document9 pagesS0.0 MAACS Course Outline Mar Apr 2019Hongwei ZhangNo ratings yet

- Suzlon EnergyDocument32 pagesSuzlon EnergymysterydevilNo ratings yet

- Black & Decker ADocument17 pagesBlack & Decker ATanya KaurNo ratings yet

- Panera - A Fail Case Study of Pay What You Want StrategyDocument1 pagePanera - A Fail Case Study of Pay What You Want StrategyTuan AnhNo ratings yet

- Scotts Miracle GroDocument10 pagesScotts Miracle GromsarojiniNo ratings yet

- GE AnswerDocument2 pagesGE AnswerThanshali NarzaryNo ratings yet

- Genzyme CaseDocument2 pagesGenzyme CaseUday Shukla50% (2)

- Natureview Case StudyDocument3 pagesNatureview Case StudySheetal RaniNo ratings yet

- Innovation Simulation: Breaking News: HBP Product No. 8678Document9 pagesInnovation Simulation: Breaking News: HBP Product No. 8678Karan ShahNo ratings yet

- J&G DistributorsDocument6 pagesJ&G DistributorsAniket YevalkarNo ratings yet

- Garry Halper Menswear Limited A Loan Request For An Export OrderDocument17 pagesGarry Halper Menswear Limited A Loan Request For An Export OrderRahul KashyapNo ratings yet

- BarillaDocument7 pagesBarillasahil.ssc838No ratings yet

- Biocon LimitedDocument4 pagesBiocon LimitedMukesh SahuNo ratings yet

- Disposable Diaper Industry - Group 9Document8 pagesDisposable Diaper Industry - Group 9Kartik NarayanaNo ratings yet

- MARGINAL COSTING Short Run Decision AnalysisDocument61 pagesMARGINAL COSTING Short Run Decision AnalysisAshutosh DayalNo ratings yet

- Heranba Industries IPO Note ICICI DirectDocument12 pagesHeranba Industries IPO Note ICICI DirectVasim MerchantNo ratings yet

- Destin Brass AnalysisDocument2 pagesDestin Brass AnalysisGlenn HengNo ratings yet

- Flexcon Decision - Rondeeda MagbyDocument3 pagesFlexcon Decision - Rondeeda Magbyapi-376434895No ratings yet

- Department of Management Studies: CurriculumDocument2 pagesDepartment of Management Studies: CurriculumDawn CaldeiraNo ratings yet

- STATICVendor Document Submission Checklist 12 Feb 2015Document9 pagesSTATICVendor Document Submission Checklist 12 Feb 2015zhangjieNo ratings yet

- 大萧条:历史与经验Document54 pages大萧条:历史与经验吴宙航No ratings yet

- Consolidated Financial Statement Excercise 3-4Document2 pagesConsolidated Financial Statement Excercise 3-4Winnie TanNo ratings yet

- Actividad 19 Evidencia 7 Taller "Talking About Logistics, Workshop"Document5 pagesActividad 19 Evidencia 7 Taller "Talking About Logistics, Workshop"claudia gomezNo ratings yet

- Services Flyer en DEC 2022 FinalDocument35 pagesServices Flyer en DEC 2022 FinalPabloBecerraNo ratings yet

- AIS Review QuestionnairesDocument4 pagesAIS Review QuestionnairesKesiah FortunaNo ratings yet

- Project Cycle Management Report (AEPAM Pub.288)Document64 pagesProject Cycle Management Report (AEPAM Pub.288)Waqar AhmadNo ratings yet

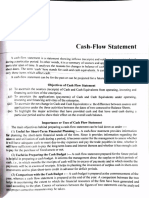

- Cash Flow Statements TheoryDocument16 pagesCash Flow Statements Theorysk9693092588No ratings yet

- Amarylis Putri - KERTAS KERJA JURNAL - Sent2Document6 pagesAmarylis Putri - KERTAS KERJA JURNAL - Sent2SatriaArdya10No ratings yet

- Pro Forma Balance Sheet and Income StatementDocument2 pagesPro Forma Balance Sheet and Income StatementMelinda AndrianiNo ratings yet

- frdA190220A1421665 PDFDocument2 pagesfrdA190220A1421665 PDFVeritaserumNo ratings yet

- PKGS Shipping BillDocument2 pagesPKGS Shipping BillAjay DarlingNo ratings yet

- Artikel MMT Lisa Nilhuda 17002060Document7 pagesArtikel MMT Lisa Nilhuda 17002060Erlianaeka SaputriNo ratings yet

- Management Accountants. Classify Each of The End-Of-Year Games (A-G) As (I) AcceptableDocument3 pagesManagement Accountants. Classify Each of The End-Of-Year Games (A-G) As (I) AcceptableRhea OraaNo ratings yet

- Tax Invoice: Invoice Issued For FlightDocument2 pagesTax Invoice: Invoice Issued For FlightManab HalderNo ratings yet

- Chapter 6 PRACTICING AS AN ETHICAL ADMINISTRATIONDocument8 pagesChapter 6 PRACTICING AS AN ETHICAL ADMINISTRATIONJR Rolf NeuqeletNo ratings yet

- COB 1 History of ManagementDocument18 pagesCOB 1 History of ManagementWhat le fuckNo ratings yet

- TATA 1MG Healthcare Solutions Private Limited: Wadi On Jalamb Road Khamgaon,, Buldhana, 444303, IndiaDocument1 pageTATA 1MG Healthcare Solutions Private Limited: Wadi On Jalamb Road Khamgaon,, Buldhana, 444303, IndiaTejas Talole0% (1)

- City Economic Enterprises DepartmentDocument3 pagesCity Economic Enterprises DepartmentRandell ManjarresNo ratings yet

- The Research On Impact of International Trade On China's EconomicDocument2 pagesThe Research On Impact of International Trade On China's EconomicLukman MasaNo ratings yet

- What Is Enterprise Agility and Why Is It ImportantDocument4 pagesWhat Is Enterprise Agility and Why Is It ImportantJaveed A. KhanNo ratings yet

- Performance Guarantees: A. Guarantees Subject To Liquidated DamagesDocument3 pagesPerformance Guarantees: A. Guarantees Subject To Liquidated Damagesdeepdaman18891No ratings yet

- MCom - Accounts ch-13 Topic3Document19 pagesMCom - Accounts ch-13 Topic3Sameer GoyalNo ratings yet

- Assessment Task 1-2 Workbook-Bsbcrt512-Bsb50420-Cycle A-Edu Nomad-V1.0 2023Document17 pagesAssessment Task 1-2 Workbook-Bsbcrt512-Bsb50420-Cycle A-Edu Nomad-V1.0 2023Sujal KutalNo ratings yet

- Consumer Behaviour Swiggy ZomatoDocument11 pagesConsumer Behaviour Swiggy ZomatowhoreNo ratings yet

- 43-Assignment-Business Studies Class Xii WorksheetsDocument81 pages43-Assignment-Business Studies Class Xii WorksheetsvinayakkanchalNo ratings yet

- Fighting Food Waste Using The Circular Economy ReportDocument40 pagesFighting Food Waste Using The Circular Economy ReportCaroline Velenthio AmansyahNo ratings yet

- Employee Performance Management Literature ReviewDocument6 pagesEmployee Performance Management Literature Reviewea8d1b6nNo ratings yet

- Strother v. 3464920 Canada Inc.Document2 pagesStrother v. 3464920 Canada Inc.Alice JiangNo ratings yet