Professional Documents

Culture Documents

Discharge Coefficient Calculation Method of Landing Gear Shock Absorber and Its Influence On Drop Dynamics

Uploaded by

Raja Sekaran SajjaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Discharge Coefficient Calculation Method of Landing Gear Shock Absorber and Its Influence On Drop Dynamics

Uploaded by

Raja Sekaran SajjaCopyright:

Available Formats

2943.

Discharge coefficient calculation method of

landing gear shock absorber and its influence on drop

dynamics

Yong Wei Ding1, Xiao Hui Wei2, Hong Nie3, Yong Ping Li4

1, 2, 3, 4Key

Laboratory of Fundamental Science for National Defense-Advanced Design Technology of

Flight Vehicle, Nanjing University of Aeronautics and Astronautics, Nanjing, China

2, 3State Key Laboratory of Mechanics and Control of Mechanical Structures, Nanjing University of

Aeronautics and Astronautics, Nanjing, China

2Corresponding author

E-mail: 1wyljdyw@163.com, 2wei_xiaohui@nuaa.edu.cn, 3hnie@nuaa.deu.cn, 4864053407@qq.com

Received 4 September 2017; received in revised form 3 February 2018; accepted 13 March 2018

DOI https://doi.org/10.21595/jve.2018.19049

Copyright © 2018 Yong Wei Ding, et al. This is an open access article distributed under the Creative Commons Attribution License,

which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract. Oleo-damping performance is a key factor affecting the landing gear buffer

performance, while the flow discharge coefficient determines buffer damping force. For

improving the calculation precision of discharge coefficient estimation method in aircraft design

manual, a model for discharge coefficient is established based on pipeline fluid mechanics and

damping orifice structure, and a numerical calculation is performed. Computational fluid

dynamics (CFD) analysis is also conducted for damping orifice structure using the commercial

software FLUNET. The simulation result of damping orifice discharge coefficient correlates well

with the theoretical result. On this basis, landing gear drop dynamic response are calculated with

the numerical analysis method using obtained discharge coefficient and compared with

experimental results. Furthermore, the influences of current discharge coefficient estimation

method and simulation method are analyzed and compared on the hydraulic force and the ground

reaction force. The study demonstrates that the poor precision of discharge coefficient estimation

method in aircraft design manual leads to more than 30 % differences between the drop dynamic

estimation results and the experimental results. The method of CFD simulation or theoretical

analysis can improve the calculation precision of discharge coefficient by about 17 %.

Keywords: landing gear, shock absorber, drop dynamic, discharge coefficient, hydraulic force.

1. Introduction

The shock absorber is an essential component of modern landing gears, as it absorbs most of

the impact energy that aircraft suffered during takeoff and landing phase [1]. For the landing gear,

the buffer performance, an important performance index, can be effectively checked through drop

test. There are four fundamental force elements, (hydraulic force, air spring force, friction force

and structural limit force), in landing gear drop dynamic modeling usually [2]. Among them, the

hydraulic force accounts for a large proportion of the axial force. And the energy absorbed by the

shock absorber is mostly dependent on the hydraulic force generated by the oil flow through orifice

to dissipate [3]. For a given shock absorber, the magnitude of hydraulic force is determined by the

orifice discharge coefficient, oil properties and strut telescoping velocity.

In previous studies, the main focus on the drop dynamic response of landing gear is the

structural parameters, air spring force, friction force and structural force, rather than the discharge

coefficient [4-7]. It is common that the discharge coefficient is estimated empirically as a constant

in the landing gear dynamic analysis. However, Wahi M. K. elaborated the effects of Reynolds

number and metering pin shapes on the discharge coefficient and established the expression of the

discharge coefficient [8].

At present, estimation methods of the discharge coefficient are mostly based on the data and

experience, which are accumulated in the experimental studies of the existing orifices. Some

2550 JOURNAL OF VIBROENGINEERING. NOVEMBER 2018, VOLUME 20, ISSUE 7

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

estimation rules are summed up based on orifice area and inlet status, but other factors such as the

ratio of orifice length to orifice diameter (𝑙/𝑑), the ratio of orifice diameter to pipe diameter (𝑑/𝐷),

Reynolds number and back pressure are not taken into account [9]. It is the main reason that result

in the low accuracy of current estimation methods. To obtain a more accurate result of discharge

coefficient, the theoretical and CFD simulation methods are essential.

Theoretical studies of the orifice discharge coefficient are primarily based on the Bernoulli

equation and the experimental data to derive the empirical or semi empirical formulas. In previous

work, many researchers tested different structural orifices, and investigated the effects of orifice

structures on the discharge coefficient [10-15]. Unlike the single orifice, the performed orifice has

some unique properties. In Shanfang Huang’s [16] research, the effect of the performed orifice

structural parameters on the discharge coefficients was assessed in terms of pressure drop. Yu B.

[17] and Tharakan K. J. [18] observed the influence of back pressure on the discharge coefficient

and proposed a series of empirical formulas for predicting the discharge coefficient with wide

applications. Mazzei L. [19] collected a number of previous investigations of the discharge

coefficient and compared them with new experimental data.

In this paper, according to the shortcomings of the current discharge coefficient estimation

method, the theoretical calculation and CFD simulation methods are put forward. These methods

are adopted to calculate the orifice discharge coefficient, hydraulic force and drop dynamic

response of an unmanned aerial vehicle (UAV) nose landing gear respectively. To analyze the

influences of calculation methods, comparisons are conducted between obtained results and

experimental results.

2. Modeling of shock absorber

2.1. Shock absorber configuration

The UAV has a half-fork nose landing gear, mainly constituted of tire, fork, shock strut and

torque arm. Among them, the shock strut is with the most complex structure. Fig. 1 shows a

schematic sketch of the landing gear and its shock absorber.

a) Landing gear b) Shock absorber

Fig. 1. Landing gear configuration and shock absorber with section view

During the compression stroke, the oil flows from the lower chamber to the upper chamber

ISSN PRINT 1392-8716, ISSN ONLINE 2538-8460, KAUNAS, LITHUANIA 2551

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

through the main orifice and compresses the air in the air chamber. Synchronously, part of the oil

flows to the recoil chamber through the recoil orifice. When the shock absorber reaches the

maximum compression stroke, it enters the rebound process under the stored potential energy of

the air spring. While the floating ring moves upwards, the oil is forced from the recoil chamber to

the upper chamber through the orifices of the floating ring. The high pressure in the air chamber

drivers the oil return to the lower chamber through the main orifice. At this point, the shock

absorber hydraulic force is mainly generated by the main orifice and the orifices of the floating

ring. The recoil orifices as well as the main orifice are square-edged cylindrical orifices, and their

sizes are described in Table 1.

Table 1. Geometry of the orifices

Orifice diameter Orifice Pipe diameter 𝑙 𝑑

Orifice Number

𝑑 / mm length 𝑙 / mm 𝐷 / mm 𝑑 𝐷

Main orifice 1 4.8 7 41 1.4583 0.117

Recoil orifice

34 2 14 8.16 7 0.29

(compression)

Recoil orifice

3 1.3 2 25.82 1.538 0.05

(rebound)

2.2. Damping characteristic analysis

As shown in Fig. 2, after passing through the orifice inlet, the oil forms a vena contracta at

c-c section, where the paths of the particles are parallel. Bernoulli’s equation is applied to 1-1 and

2-2 sections:

𝑃 𝑣 𝑃 𝑣

+ +𝑍 = + 1+𝜉 +𝑍 , (1)

𝜌𝑔 2𝑔 𝜌𝑔 2𝑔

where 𝑃 and 𝑃 is the pressure in the 1-1 and 2-2 section respectively, 𝑔 donates the gravitational

constant, 𝑣 and 𝑣 is the mean velocity of the fluid in the 1-1 and 2-2 section respectively, 𝑍 and

𝑍 is the height of the 1-1 and 2-2 section respectively, 𝜉 is the resistance coefficient, 𝜌 is the

density of the fluid.

Fig. 2. Schematic diagram of orifice outflow

Therefore, the expression of the flow rate and the hydraulic force can be obtained:

2Δ𝑃 2Δ𝑃

𝑄=𝐶 𝐶 𝐴 =𝐶 𝐴 , (2)

𝜌 𝜌

𝜌𝐴 𝑄

𝐹 = Δ𝑃𝐴 = , (3)

2𝐶 𝐴

2552 JOURNAL OF VIBROENGINEERING. NOVEMBER 2018, VOLUME 20, ISSUE 7

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

where Δ𝑃 is the pressure difference, 𝐶 is the contraction coefficient, 𝐶 is the velocity coefficient,

𝐶 is the discharge coefficient, 𝑄 is the flow rate through orifice, 𝐴 is the sectional area of the

orifice inlet, 𝐴 is the sectional area of the 2-2 section, 𝐹 is the hydraulic force.

Form Eq. (2), the discharge coefficient is related to the flow rate, pressure difference and fluid

property, and its value cannot be obtained by purely theoretical calculations. Some estimation

methods of the discharge coefficient are provided in a few engineering manuals.

3. Discharge coefficient and hydraulic force calculation method

Fig. 3 shows the flow diagram of different calculation methods for the shock absorber

discharge coefficient. For the current discharge estimation method, drop test is indispensable to

obtain the accurate result of the discharge coefficient. The initial discharge coefficient estimation

result is substituted into the dynamic model to calculate the dynamic response, and it is adjusted

according to the comparison with the experimental result. After iterations and adjustments, the

calculation result of the dynamic response is basically consistent with the experimental result.

Thus, the accurate result of the discharge coefficient is obtained.

While the estimation method costs a lot of time and resources, the theoretical calculation and

CFD simulation methods can calculate the discharge coefficient quickly and accurately according

to the given shock absorber structures.

Fig. 3. Flow diagram of discharge coefficient calculation methods

3.1. Discharge coefficient estimation method

At present, the following equation in the aircraft design manual is used to calculate the

hydraulic force of the oleo-pneumatic shock absorber [9]:

𝜌 𝐴 +𝐴 𝐴 𝜌𝐴

𝐹 =𝜉 𝑆𝑆 ≈𝜉 𝑆𝑆. (4)

2𝐴 2𝐴

In which:

1

𝜉 = , (5)

𝐶

where 𝐴 is the hydraulic area, 𝜉 is the damping coefficient, 𝑠is the strut telescoping stroke.

The discharge coefficient estimation of square-edged cylindrical orifice is mainly based on the

area ratio of the orifice. The orifice with round inlet usually has a larger discharge coefficient

under the same condition. For this kind of orifice, it is necessary to estimate the discharge

coefficient according to the radius of the inlet round.

In the aircraft design manual, the recommended value for damping coefficient of sharp-edged

orifice and rounded orifice is 2.0-2.5 (𝐶 = 0.632-0.707) and 1.2 (𝐶 = 0.913) respectively [9].

Aircraft landing gear strength design guidelines suggests that the orifice discharge coefficient

should be 0.7-1.0 [21]. There is no specific method to estimate the discharge coefficient in other

ISSN PRINT 1392-8716, ISSN ONLINE 2538-8460, KAUNAS, LITHUANIA 2553

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

aircraft landing gear design manuals. Commonly, it is regarded as a known constant of the landing

gear.

All the orifices involved in this paper are square-edged cylindrical orifices. According to the

estimation method in the aircraft design manual, the result of main orifice discharge coefficient is

0.695. The discharge coefficient of the recoil orifice in compression stroke and rebound stroke is

0.652 and 0.694 respectively.

3.2. Discharge coefficient theoretical calculation

The calculation of orifice discharge coefficient involves many parameters, such as orifice

diameter, 𝑙 ⁄𝑑 ratio, 𝑑 ⁄𝐷 ratio, back pressure, Reynolds number, inlet status, et al. Among them,

𝑙 ⁄𝑑 ratio and Reynolds number are the main factors that affect the discharge coefficient, and

others are treated as correction factors to correct the expression of the discharge coefficient.

As can be seen from Table 1, the main orifice and the recoil orifice in rebound stroke have the

same geometric sizes. When the Reynolds number is less than 5000, the calculation equation

proposed by Yu B. [18] is applicable to these orifices:

/

𝑅

𝐶 = . (6)

17.11𝑙 .

+ 1.65𝑅

𝑑

When the Reynolds number is not less than 5000, the calculation equation proposed by Hall

GW is adopted [17]:

.

𝑙

1 − 𝐶 = 0.184 − 1 + 1.11𝑅 .

𝑅 .

. (7)

𝑑

Since the 𝑙 ⁄𝑑 ratio of the recoil orifice in compression stroke is greater than 2, the following

equation can be used over the entire Reynolds number range [20]:

1 1 20 𝑙

= + 1 + 2.25 . (8)

𝐶 𝑙 𝑅 𝑑

0.827 − 0.0085

𝑑

Using the above three equations, the discharge coefficients throughout the entire stroke are

obtained and shown in Fig. 4.

Fig. 4. Effects of Reynolds number on discharge coefficient

According to Fig. 4, the discharge coefficient increases rapidly with Reynolds number at first

and then gradually tends to a constant value. The discharge coefficient of the main orifice and the

2554 JOURNAL OF VIBROENGINEERING. NOVEMBER 2018, VOLUME 20, ISSUE 7

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

recoil orifice in rebound stroke is basically the same, and the final stable result is 0.79. Due to the

large 𝑙 ⁄𝑑 ratio, the discharge coefficient of recoil orifice in compression stroke is smaller than

that of main orifice, and its stable result is 0.76. Fig. 4 also shows the estimation results of orifices,

and it can be found that there are great differences between the estimation results and the

theoretical calculation results.

3.3. Modeling of shock absorber hydraulic force

The expression of the main orifice hydraulic force is described in Eq. (4). Unlike the main

orifice, there are several parallel orifices in the recoil chamber. According to the pipeline fluid

mechanics, each orifice has the same flow rate when the fluid passes through the parallel orifice.

So, each orifice produces same energy loss and hydraulic force, which can be calculated by the

same way in the main orifice. The recoil orifice hydraulic force can be expressed as:

𝑛𝐴

𝐹 =𝜌 𝑆𝑆, (9)

2𝐶 𝐴

where 𝑛 is the number of recoil orifices, 𝐶 is the discharge coefficient of the recoil orifice, 𝐴

is the sectional area of the recoil orifice, 𝐴 is the hydraulic area of the recoil orifice.

The hydraulic force of the shock absorber can be expressed as:

𝐴 𝑛𝐴

𝐹 =𝜌 + 𝑆𝑆. (10)

2𝐶 𝐴 2𝐶 𝐴

3.4. Hydraulic force CFD simulation

The current empirical formulas of the discharge coefficient are not widely applicable to various

types of orifices, resulting from their different requirements for the orifice geometry and the

Reynolds number. For some special orifice structure, the applicable empirical formula is still

lacking. Thus, a more widely applicable CFD simulation method is adopted to calculate the

discharge coefficient and the hydraulic force.

The three-dimensional models of shock absorber are generated by using the commercial

pre-processor ICEM, as showed in Fig. 6. Velocity inlet and pressure outflow boundary conditions

are specified at the inlet and outlet of the model respectively. Owing to the periodic property of

models, periodic boundary is assigned to the side surfaces, and the remainder is defined as wall

boundary condition. It minimizes the number of grids and significantly reduces the computing

time. To obtain a grid-independent solution, the grid of the finite volume model is refined until

the result no longer varies with the grid density. The hydraulic force is obtained by measuring the

pressure loss between the ends of the shock absorber.

The standard form of 𝑘 - 𝜀 turbulence model is used in the simulation. It introduces an

additional equation of turbulent dissipation rate𝜀on the basis of the equation for the turbulent

kinetic energy 𝑘. Its control equations are written as:

∂ 𝜌𝑘 ∂ 𝜌𝑘𝑢 ∂ 𝜇 ∂𝑘

+ = 𝜇+ + 𝐺 − 𝜌𝜀, (11)

∂𝑡 ∂𝑥 ∂𝑥 𝜎 ∂𝑥

∂ 𝜌𝜀 ∂ 𝜌𝜀𝑢 ∂ 𝜇 ∂𝜀 𝐶 𝜀 𝜀

+ = 𝜇+ + 𝐺 −𝐶 𝜌 , (12)

∂𝑡 ∂𝑥 ∂𝑥 𝜎 ∂𝑥 𝑘 𝑘

where 𝑘 is the turbulent kinetic energy, 𝜀 is the turbulent dissipation rate, 𝜇 is the molecular

viscosity, 𝜇 is coefficient of turbulence viscosity, 𝐺 is the generation item of turbulent kinetic

energy caused by velocity gradient, 𝐶 , 𝐶 is the empirical coefficient. The calculation results

ISSN PRINT 1392-8716, ISSN ONLINE 2538-8460, KAUNAS, LITHUANIA 2555

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

are shown as Fig. 6.

a) Compression

b) Rebound

Fig. 5. Finite volume models of shock absorber

a) Compression

b) Rebound

Fig. 6. Velocity distribution

The discharge coefficients calculated above are substituted into Eq. (10) to obtain the

relationship between the shock absorber hydraulic force and the strut telescoping velocity, as

shown in Fig. 7.

As can be seen from the Fig. 7, the simulation result is consist with the theoretical result with

a maximum error of 3 %. However, the estimation result is significantly greater than the CFD

result.

Fig. 7. Effects of calculation methods on discharge coefficient

4. Drop dynamic model

4.1. System motion equations

Fig. 8 shows the forces on the landing gear. The basic equations of motions are those used of

a two-degree-of freedom system as shown in Fig. 9. The landing gear mass is simplified into two

2556 JOURNAL OF VIBROENGINEERING. NOVEMBER 2018, VOLUME 20, ISSUE 7

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

parts: the sprung mass and the unsprung mass, and two independent coordinate systems are

established at the mass centroid of these two parts respectively.

Fig. 8. Forces on the landing gear Fig. 9. System with two degrees of freedom

In Fig. 8, 𝐹 is the air spring force, 𝐹 is the hydraulic force, 𝐹 is the friction force, 𝐹 and 𝐹

is the vertical and horizontal tire reaction force respectively, 𝑅 and 𝑅 is the upper and lower

bearing reaction force in 𝑂𝑥𝑧 plane respectively, 𝑅 and 𝑅 is the upper and lower bearing

reaction force in 𝑂𝑦𝑧 plane respectively, 𝛼 is the anteversion angle of shock strut.

Without considering the tire rotation and deformation in the horizontal direction, equations of

motion can be expressed as:

𝑚 𝑧 = 𝑚 𝑔 − 𝐹 + 𝐹 + 𝐹 cos𝛼, (13)

𝑚 𝑧 = 𝑚 𝑔 + 𝐹 + 𝐹 + 𝐹 cos𝛼 − 𝐹 , (14)

where 𝑧 and 𝑧 is the vertical displacement of the sprung mass and unsprung mass respectively.

4.2. Modeling of shock absorber forces

4.2.1. Air spring force

In the oleo-pneumatic shock absorber, air is mainly used to store part of the absorbed impact

energy. The air spring force is influenced by a lot of factors, and it can be expressed as [3]:

𝑉

𝐹 =𝐴 𝑃 −𝑃 , (15)

𝑉 −𝐴 𝑆

where 𝐴 is the pneumatic area, 𝑃 is the initial air pressure, 𝑉 is the initial air volume, 𝛾 is the

air polytropic exponent, 𝑃 is the atmosphere pressure.

4.2.2. Friction force

The friction force in the landing gear mainly comes from two sources, friction due to the

ISSN PRINT 1392-8716, ISSN ONLINE 2538-8460, KAUNAS, LITHUANIA 2557

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

tightness of the seal and the deformation of the shock strut, and it can be expressed by [4]:

𝐹 =𝐹 +𝐹 , (16)

where 𝐹 is the friction force due to the deformation of the shock strut, 𝐹 is the friction force

due to the tightness of the seal.

The friction due to the deformation of the strut is the result of the strut anteversion angle and

the forces on tire. It can be expressed by:

𝐹 =𝜇 𝑅 + 𝑅 + 𝑅 + 𝑅 , (17)

where 𝜇 is the friction coefficient.

The seal friction is assumed to be a function of air pressure and can be expressed as:

𝐹 =𝜇 𝐹, (18)

where 𝜇 is the friction coefficient of the seal cup.

4.2.3. Tire vertical reaction force

During landing gear landing progress, the vertical reaction force is result from the tire

compression, and it can be expressed as [2]:

𝐹 = 1+𝐶 𝛿 𝑓 𝛿 , (19)

where 𝐶 is the tire vertical damping coefficient, 𝛿 is the tire hub vertical displacement, 𝛿 is the

tire hub vertical speed, 𝑓 𝛿 is the tire static compression curve.

4.2.4. Hydraulic force

The equation of hydraulic force is shown in Eq. (10).

5. Drop dynamic analysis

5.1. Drop test system

As shown in Fig. 10, the drop test system is mainly composed of lifter, vertical slide rail,

impact platform and basket. The connect method of the landing gear and the basket is same as that

of the landing gear and the fuselage. Before the test, it is necessary to calculate the release height

and weight according to the aircraft parameters and the sinking speed. The additional weight is

added to the basket, and both the landing gear and the basket are lifted to the release height by the

lifter.

Once the basket is released, a variety of sensors are used to record the dynamic response of the

landing gear. Three displacement sensors are used to measure the shock absorber compression

stroke, the tire compression and the vertical displacement of the basket, respectively. An

acceleration sensor is placed at the basket to measure its vertical acceleration, and two acceleration

sensors are placed at the tire axle to measure its vertical and horizontal acceleration. Besides, there

are five force sensors at the bottom of the impact platform, one for horizontal force measurement

and the rest for vertical force measurement.

2558 JOURNAL OF VIBROENGINEERING. NOVEMBER 2018, VOLUME 20, ISSUE 7

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

Fig. 10. Drop test system

5.2. Numerical calculation and analysis

According to the drop dynamic model constructed above, a program was developed to

calculate the dynamical response of the landing gear during drop process. Parameters of the

landing gear used in the analysis are listed in Table 2. The results of dynamic response are

compared with experimental and estimation results, as shown in Figs. 11-13 and Table 3.

Table 2. Parameters of the landing gear

Anteversion Pneumatic Hydraulic Air Air Release Release

angle / ° area / cm2 area /cm2 pressure / MPa volume / ml weight / kg height / mm

8 18.1 13.2 0.64 268 315 269

Fig. 11. Results of shock strut axial force Fig. 12. Results of hydraulic force

Fig. 13. Landing gear energy absorption of drop test

ISSN PRINT 1392-8716, ISSN ONLINE 2538-8460, KAUNAS, LITHUANIA 2559

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

As can be seen from Fig. 11 and Fig. 13, the theoretical calculation and CFD simulation results

of axial force and energy absorption are both consistent with experimental results. Since the

discharge coefficient estimation value is smaller than the actual value, the estimation result of

hydraulic force is significantly greater than the actual hydraulic force. Because of the large

proportion (up to 60 %) of hydraulic force in the axial force, the axial force estimation result is

also greater than the experimental result.

Table 3. Comparison of numerical calculation and experimental results

𝐹 / kN 𝐹 / kN 𝐹 / kN 𝐹 / kN 𝐹 / kN

Experimental results 11.691 0.896 8.473 / /

CFD results 10.824 0.849 8.181 10.041 –0.649

Relative error –7.42 % –5.25 % –3.45 % / /

Theoretical results 10.786 0.852 8.133 9.832 –0.641

Relative error –7.74 % –4.91 % –4.01 % / /

Estimation results 16.092 0.502 10.775 15.901 –1.023

Relative error 37.64 % –43.97 % 29.71 % / /

In Table 3, 𝐹 is the total axial force of the shock strut, subscript max and min stands for the

maximum and minimum value, 𝐹 is the axial force at the second wave crest.

According to Fig. 13 and Table 3, the estimation results of hydraulic force are about 57 %

larger than the CFD simulation results. The CFD simulation results of axial force are around 5 %

smaller than the experimental results. And the maximum error occurs at the position of the

maximum axial force, where the CFD simulation result is 7.42 % smaller than the experimental

result. The axial force adds almost 30 % when using the estimation method to calculate the

discharge coefficient.

6. Conclusions

Based on the study of the discharge coefficient calculation methods and their influences on the

drop dynamic response of the landing gear, it comes to the conclusions as follows:

1) In this paper, the discharge coefficient theoretical and CFD simulation results are basically

identical, and they are in good agreement with the experimental data. There is 17 % error between

the discharge coefficient estimation results and the simulation results. It is a large error in view of

the fact that the variation range of the discharge coefficient is small.

2) Discharge coefficient has an enormous influence on the hydraulic force. While the discharge

coefficient varies 17 %, the hydraulic force varies 57 %.

3) The hydraulic force is an important part of the axial force, which can account for up to 60 %

of the total axial force. It results in the calculation accuracy of the landing gear dynamic response

being very sensitive to the discharge coefficient. The simulation results are in good agreement

with the experimental results, while there is 30 % error between the estimation results and the

experimental results.

Acknowledgements

This study was co-supported by the National Natural Science Foundation of China (Grant

No. 11372129) and the Priority Academic Program Development of Jiangsu Higher Education

Institutions.

References

[1] Choi Y. T., Wereley N. M. Vibration control of a landing gear system featuring electrorheological

/magnetorheological fluids. Journal of Aircraft, Vol. 40, Issue 3, 2003, p. 432-439.

2560 JOURNAL OF VIBROENGINEERING. NOVEMBER 2018, VOLUME 20, ISSUE 7

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

[2] Wen Z., Zhi Z., Zhu Q. Dynamic model of carrier-based aircraft landing gears landed on dynamic

deck. Chinese Journal of Aeronautics, Vol. 22, Issue 4, 2009, p. 371-379.

[3] Nie H. Dynamic Design and Analysis of Aircraft Landing Gear. Northwestern Polytechnical

University Press, Xi’an, 2013, (in Chinese).

[4] Wei X. H., Liu C. L., Nie H., Wang Y. L., et al. Study on drop dynamics and the influence of

structural parameters on half-axle landing gear. Journal of Vibration Engineering, Vol. 27, Issue 1,

2014, p. 40-45.

[5] Wei X. H., Nie H. Dynamic analysis of aircraft landing impact using landing-region-based model.

Journal of Aircraft, Vol. 42, Issue 6, 2005, p. 1631-1637.

[6] Fan R., Fang Y. Y., Han Y., et al. Landing gear dynamic simulation of aircraft landing gear with

multi-struts. Journal of Vibration Engineering, Vol. 16, Issue 5, 2014, p. 2494-2507.

[7] Paletta N., Dmytriv A., Belardo M., et al. Landing gear concept and dynamic landing loads of the

unmanned space re-entry vehicle USV3. Proceedings of the 1st International Conference on Structural

Integrity, Funchal, Portugal, 2015.

[8] Wahi M. K. Oleopneumatic shock strut dynamic analysis and its real-time simulation. Journal of

Aircraft, Vol. 13, Issue 4, 1971, p. 303-308.

[9] Gao Z. J. Aircraft Design Manual: Take-Off and Landing System Design. Aviation Industry, Beijing,

2002, (in Chinese).

[10] Canbazoğlu S., Canbulut F. A note on the flow coefficients of capillary tube and small orifice

restrictors exposed to very low Reynolds number flow. Industrial Lubrication and Tribology, Vol. 57,

Issue 3, 2005, p. 116-120.

[11] Belforte G., Raparelli T., Viktorov V., et al. Discharge coefficients of orifice-type restrictor for

aerostatic bearings. Tribology International, Vol. 40, Issue 3, 2007, p. 512-521.

[12] Idris A., Pullen K. R. Correlations for the discharge coefficient of rotating orifices based on the

incidence angle. Proceedings of the Institution of Mechanical Engineers Part A Journal of Power and

Energy, Vol. 219, Issue 219, 2005, p. 333-352.

[13] Payri R., Guardiola C., Salvador F. J., et al. Critical cavitation number determination in diesel

injection nozzles. Experimental Techniques, Vol. 28, Issue 3, 2006, p. 49-52.

[14] Payri F., Bermúdez V., Payri R., et al. The influence of cavitation on the internal flow and the spray

characteristics in diesel injection nozzles. Fuel, Vol. 83, Issue 4, 2004, p. 419-431.

[15] Huning M. Discharge coefficient measurements of round, inclined orifices with inlet cross-flow in

and against direction of inclination. Proceedings of Institution of Mechanical Engineers Part C Journal

of Mechanical Engineering Science, Vol. 227, Issue 227, 2013, p. 1266-1279.

[16] Huang S. F., Ma T. Y., Wang D., et al. Study on discharge coefficient of perforated orifices as a new

kind of flowmeter. Experimental Thermal and Fluid Science, Vol. 46, Issue 4, 2013, p. 74-83.

[17] Yu B., Fu P. F., Zhang T., et al. The influence of back pressure on the flow discharge coefficients of

plain orifice nozzle. International Journal of Heat and Fluid Flow, Vol. 44, Issue 4, 2013, p. 509-514.

[18] Tharakan T. J., Rafeeque T. A. The role of backpressure on discharge coefficient of sharp edged

injection orifices. Aerospace Science and Technology, Vol. 49, 2016, p. 269-275.

[19] Mazzei L., Winchler L., Andreini A. Development of a numerical correction for the discharge

coefficient of round inclined holes with low crossflow. Computers and Fluids, Vol. 152, 2017,

p. 182-192.

[20] Liu R. C. Aircraft Landing Gear Strength Design Guidelines. Science and Technology Press, Sichuan,

1989, (in Chinese).

Yong-Wei Ding received the B.S. degree in aircraft design from Nanjing University of

Aeronautics and Astronautics, Nanjing, China, in 2015. Now he is studying for a Master

degree with aircraft design, Nanjing University of Aeronautics and Astronautics, Nanjing,

China.

ISSN PRINT 1392-8716, ISSN ONLINE 2538-8460, KAUNAS, LITHUANIA 2561

2943. DISCHARGE COEFFICIENT CALCULATION METHOD OF LANDING GEAR SHOCK ABSORBER AND ITS INFLUENCE ON DROP DYNAMICS.

YONG WEI DING, XIAO HUI WEI, HONG NIE, YONG PING LI

Xiao-Hui Wei received Ph.D. degree in aircraft design from Nanjing University of

Aeronautics and Astronautics, Nanjing, China, in 2006. Now he is a Professor in State Key

Laboratory of Mechanics and Control of Mechanical Structures, Nanjing University of

Aeronautics and Astronautics, Nanjing, China.

Hong Nie received Ph.D. degree in aircraft design from Nanjing University of Aeronautics

and Astronautics, Nanjing, China, in 1990. Now he is a Professor in State Key Laboratory

of Mechanics and Control of Mechanical Structures, Nanjing University of Aeronautics

and Astronautics, Nanjing, China.

Yong-Ping Li received the B.S. degree in aircraft design from Nanchang Hangkong

University, Nanchang, China, in 2015. Now he is studying for a Master degree with aircraft

design, Nanjing University of Aeronautics and Astronautics, Nanjing, China.

2562 JOURNAL OF VIBROENGINEERING. NOVEMBER 2018, VOLUME 20, ISSUE 7

You might also like

- Numerical Analysisofa Small Pneumatic Hammer Performance Basedon Evaluation Methodof Friction ForceDocument11 pagesNumerical Analysisofa Small Pneumatic Hammer Performance Basedon Evaluation Methodof Friction ForceLeonardo G. DiasNo ratings yet

- lsa report final(1)Document18 pageslsa report final(1)SUMITH NAIKNo ratings yet

- Entropy Generation Analysis of Water Jet Pump Using Computational Fluid DynamicsDocument8 pagesEntropy Generation Analysis of Water Jet Pump Using Computational Fluid DynamicsEnrique FloresNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Aerodynamic Characteristics of Naca 0012 Airfoil by CFD AnalysisDocument8 pagesAerodynamic Characteristics of Naca 0012 Airfoil by CFD AnalysisNetherlands PressNo ratings yet

- Numerical Simulation of PCV ValveDocument5 pagesNumerical Simulation of PCV Valve11751175No ratings yet

- Effect of Blade Thickness On Hydraulic Performance of A Mixed-Flow Pump Impeller VFDocument13 pagesEffect of Blade Thickness On Hydraulic Performance of A Mixed-Flow Pump Impeller VFBoon ThiamNo ratings yet

- Ipr TPRDocument6 pagesIpr TPRsisiminkinNo ratings yet

- Aerodynamic Characteristics of Naca 0012 Airfoil by CFD AnalysisDocument8 pagesAerodynamic Characteristics of Naca 0012 Airfoil by CFD AnalysisŞevki SağlamNo ratings yet

- Compresor CentrifugoDocument16 pagesCompresor CentrifugoIgnacio SotoNo ratings yet

- 2012 MIT KFUPM McGovern Ejector Efficiency PDFDocument12 pages2012 MIT KFUPM McGovern Ejector Efficiency PDFeldwin_dj7216No ratings yet

- Accurate Modelling of An Injector For Common Rail SystemsDocument26 pagesAccurate Modelling of An Injector For Common Rail SystemsJimmyCenturionNo ratings yet

- Analysis of The Induction Effect On The Performance of Wind TurbineDocument16 pagesAnalysis of The Induction Effect On The Performance of Wind TurbineKhalil DeghoumNo ratings yet

- Yoon-Kyu Lee1 Shock ObserverDocument8 pagesYoon-Kyu Lee1 Shock ObserverMohammed ImranNo ratings yet

- Steady and Unsteady Flow Simulation of A Combined Jet Flap and Coanda Jet Effects On A 2D Airfoil Aerodynamic PerformanceDocument6 pagesSteady and Unsteady Flow Simulation of A Combined Jet Flap and Coanda Jet Effects On A 2D Airfoil Aerodynamic PerformancefasterNo ratings yet

- Journal Pre-Proofs: Engineering Failure AnalysisDocument20 pagesJournal Pre-Proofs: Engineering Failure AnalysisSanti Osorio DiezNo ratings yet

- Control of Boundary Layer Build-Up in An Impeller: C. Nithiyapathi & B. AkilanDocument6 pagesControl of Boundary Layer Build-Up in An Impeller: C. Nithiyapathi & B. AkilanTJPRC PublicationsNo ratings yet

- Performancemeasurementofrevolvingvanecompressor. International Compressor Engineering ConferenceDocument11 pagesPerformancemeasurementofrevolvingvanecompressor. International Compressor Engineering ConferenceAlbert CalderonNo ratings yet

- Research ArticleDocument11 pagesResearch ArticleMühtür HerhaldeNo ratings yet

- AOT303 - Ktu Qbank PDFDocument8 pagesAOT303 - Ktu Qbank PDFUmarul MushtaqNo ratings yet

- TTL Extension of Landing GearDocument12 pagesTTL Extension of Landing GearDeepak SarhochNo ratings yet

- Performance Analysis of The Effect On Insertion Guide Vanes For Rectangular Elbow 90 Cross SectionDocument13 pagesPerformance Analysis of The Effect On Insertion Guide Vanes For Rectangular Elbow 90 Cross SectionFitria IdrusNo ratings yet

- L Cai (2011)Document10 pagesL Cai (2011)Virendra KumarNo ratings yet

- Compressor Design Method in The Supercritical CO2 ApplicationsDocument13 pagesCompressor Design Method in The Supercritical CO2 ApplicationsShantanu ThadaNo ratings yet

- Numerical Computation of Supersonic-Subsonic Ramjet Inlets A Design ProcedureDocument6 pagesNumerical Computation of Supersonic-Subsonic Ramjet Inlets A Design Procedureindra44No ratings yet

- Supercritical Airfoils With FluentDocument10 pagesSupercritical Airfoils With FluentErnesto Padilla MarquezNo ratings yet

- Lienhard - One DimensionalDocument13 pagesLienhard - One DimensionalDhaval PatelNo ratings yet

- Articulo Rompedor de VorticeDocument10 pagesArticulo Rompedor de VorticeLuis Camilo Gomez TrujilloNo ratings yet

- Ye Et Al 2017 An Improved Model For Tip Clearance Loss in Transonic Axial CompressorsDocument20 pagesYe Et Al 2017 An Improved Model For Tip Clearance Loss in Transonic Axial CompressorsUmair MunirNo ratings yet

- Tip Leakage FlowDocument15 pagesTip Leakage FlowMuhammad Zubair SheikhNo ratings yet

- Centrifugal Pump Performance AnalysisDocument8 pagesCentrifugal Pump Performance AnalysisFaiz AkbarsyahNo ratings yet

- Aerodynamic HeatingDocument12 pagesAerodynamic HeatingAswith R ShenoyNo ratings yet

- Hydrogen Fuelled Scramjet Combustor - The Impact of Fuel InjectionDocument17 pagesHydrogen Fuelled Scramjet Combustor - The Impact of Fuel InjectionArnalt StalinNo ratings yet

- CFD Analysis of Flow through Compressor CascadeDocument10 pagesCFD Analysis of Flow through Compressor CascadeKhalid KhalilNo ratings yet

- Determination of Shock Losses and Pressure Losses in UG Mine OpeningsDocument74 pagesDetermination of Shock Losses and Pressure Losses in UG Mine OpeningsSantanu kumar AichNo ratings yet

- Paper PDFDocument7 pagesPaper PDFTinku BhargavNo ratings yet

- Effect of Geometric Configuration on Performance of Uniflow CycloneDocument7 pagesEffect of Geometric Configuration on Performance of Uniflow Cyclonesauerbach1No ratings yet

- Fluid Dynamics of A Gas Turbine Wheel-Space With Ingestion: Carl M Sangan, Yogesh Lalwani, J Michael Owen and Gary D LockDocument17 pagesFluid Dynamics of A Gas Turbine Wheel-Space With Ingestion: Carl M Sangan, Yogesh Lalwani, J Michael Owen and Gary D Lockamir moniriNo ratings yet

- Inlet Diameter and Flow Volume Effects On Separation and Energy Efficiency of HydrocyclonesDocument11 pagesInlet Diameter and Flow Volume Effects On Separation and Energy Efficiency of HydrocyclonesAdrian SetyadharmaNo ratings yet

- Theoretical model predicts cavitation inception in centrifugal pumpsDocument13 pagesTheoretical model predicts cavitation inception in centrifugal pumpsdodo1986No ratings yet

- 1 s2.0 S0140700720302772 MainDocument12 pages1 s2.0 S0140700720302772 MainAnıl TAŞKINNo ratings yet

- Effects of Co-And Counter-Swirl On The Droplet Characteristics in A Spray FlameDocument9 pagesEffects of Co-And Counter-Swirl On The Droplet Characteristics in A Spray Flamedr_s_m_afzali8662No ratings yet

- Chapter 2: Exhaust Nozzle and CharachteristicsDocument12 pagesChapter 2: Exhaust Nozzle and CharachteristicsaunbhuttaNo ratings yet

- The Flow Patterns in Two Immiscible Stratified Liquids Induced by Bubble PlumeDocument19 pagesThe Flow Patterns in Two Immiscible Stratified Liquids Induced by Bubble PlumeDennisQuNo ratings yet

- Energies: Corner Separation Control by Boundary Layer Suction Applied To A Highly Loaded Axial Compressor CascadeDocument14 pagesEnergies: Corner Separation Control by Boundary Layer Suction Applied To A Highly Loaded Axial Compressor Cascadeinam vfNo ratings yet

- 1.1 Gas Turbine EngineDocument21 pages1.1 Gas Turbine EngineaarthiNo ratings yet

- Design and Experimental Investigations of Pressure Swirl Atomizer of Annular Type Combustion Chamber For 20 KW Gas Turbine EngineDocument11 pagesDesign and Experimental Investigations of Pressure Swirl Atomizer of Annular Type Combustion Chamber For 20 KW Gas Turbine EngineIAEME PublicationNo ratings yet

- Report NewDocument24 pagesReport NewSana KodakeriNo ratings yet

- Efficiency Analysis of An Aerospike Nozzle: Dipak J. Choudhari, Uday V. AsolekarDocument5 pagesEfficiency Analysis of An Aerospike Nozzle: Dipak J. Choudhari, Uday V. AsolekarAswith R ShenoyNo ratings yet

- مقاله کمکی 3Document5 pagesمقاله کمکی 3korope8705No ratings yet

- Ejector Air-AirDocument9 pagesEjector Air-AirMatteo RicciNo ratings yet

- Flow Analysis of Intake Manifold Using Computational Fluid DynamicsDocument5 pagesFlow Analysis of Intake Manifold Using Computational Fluid DynamicserpublicationNo ratings yet

- Measurements of Ingress in Upstream and Downstream Turbine Wheel-SpacesDocument12 pagesMeasurements of Ingress in Upstream and Downstream Turbine Wheel-SpacesAgung SulistyonoNo ratings yet

- Machines: Calculation of The Incompressible Viscous Fluid Flow in Piston Seals of Piston Hybrid Power MachinesDocument28 pagesMachines: Calculation of The Incompressible Viscous Fluid Flow in Piston Seals of Piston Hybrid Power MachinesBig FloresNo ratings yet

- Optimal Supersonic Intake Design For AirDocument17 pagesOptimal Supersonic Intake Design For AirMihai ClaudiuNo ratings yet

- Evaluation of Steam Jet EjectorsDocument11 pagesEvaluation of Steam Jet EjectorsRajeh Somrani100% (3)

- Vortex PDFDocument6 pagesVortex PDFSourabh JainNo ratings yet

- 3D Asphalt Construction of Special ProfilesDocument30 pages3D Asphalt Construction of Special ProfilesRaja Sekaran SajjaNo ratings yet

- Parkin 2007Document138 pagesParkin 2007Raja Sekaran SajjaNo ratings yet

- Achievements - RambalDocument2 pagesAchievements - RambalRaja Sekaran SajjaNo ratings yet

- MET2016 Snyder AlexDocument31 pagesMET2016 Snyder AlexRaja Sekaran SajjaNo ratings yet

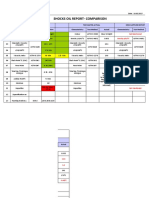

- Shocks Oil - Comparison ReportDocument2 pagesShocks Oil - Comparison ReportRaja Sekaran SajjaNo ratings yet

- Paving Streets-Part 1Document15 pagesPaving Streets-Part 1Raja Sekaran SajjaNo ratings yet

- Spring Tech 101Document8 pagesSpring Tech 101Raja Sekaran SajjaNo ratings yet

- ATRO Field Manual 061214Document68 pagesATRO Field Manual 061214Raja Sekaran Sajja100% (1)

- Gabriel Annual Report 2015-16Document151 pagesGabriel Annual Report 2015-16Raja Sekaran SajjaNo ratings yet

- LENOVO K3 NOTE K50-T3S Specifications, Price Compare, Features, ReviewDocument11 pagesLENOVO K3 NOTE K50-T3S Specifications, Price Compare, Features, ReviewRaja Sekaran SajjaNo ratings yet

- Test Yourself - Sample QuestionsDocument2 pagesTest Yourself - Sample QuestionsRaja Sekaran SajjaNo ratings yet

- Road SignsDocument24 pagesRoad SignsRaja Sekaran SajjaNo ratings yet

- Pedestrian SignalsDocument2 pagesPedestrian SignalsRaja Sekaran SajjaNo ratings yet

- Pavement Markings Guide Traffic Flow & SafetyDocument4 pagesPavement Markings Guide Traffic Flow & SafetyRaja Sekaran SajjaNo ratings yet

- IPHONE - How To Free Up SpaceDocument34 pagesIPHONE - How To Free Up SpaceRaja Sekaran SajjaNo ratings yet

- Ms. Sandhiya SalemDocument1 pageMs. Sandhiya SalemRaja Sekaran SajjaNo ratings yet

- Shock Absorber Assembly Mounts Fluid ComponentsDocument8 pagesShock Absorber Assembly Mounts Fluid ComponentsRaja Sekaran SajjaNo ratings yet

- Real Time Vibration Control of Active Suspension System With Active Force Control Using Iterative Learning AlgorithmDocument6 pagesReal Time Vibration Control of Active Suspension System With Active Force Control Using Iterative Learning AlgorithmRaja Sekaran SajjaNo ratings yet

- How To Photograph The Milky Way - A Detailed Guide For BeginnersDocument44 pagesHow To Photograph The Milky Way - A Detailed Guide For BeginnersRaja Sekaran SajjaNo ratings yet

- 13 Effective Natural Remedies To Keep Bees AwayDocument14 pages13 Effective Natural Remedies To Keep Bees AwayRaja Sekaran SajjaNo ratings yet

- Everything You Need To Know About Macro Lenses - Food Photography AcademyDocument30 pagesEverything You Need To Know About Macro Lenses - Food Photography AcademyRaja Sekaran SajjaNo ratings yet

- Landscape PhotographyDocument9 pagesLandscape PhotographyRaja Sekaran SajjaNo ratings yet

- ViewNX 2 - NikonDocument3 pagesViewNX 2 - NikonRaja Sekaran SajjaNo ratings yet

- Lens Filters ExplainedDocument19 pagesLens Filters ExplainedRaja Sekaran SajjaNo ratings yet

- Dynamic Behaviour of An Air Spring ElementDocument4 pagesDynamic Behaviour of An Air Spring ElementRaja Sekaran SajjaNo ratings yet

- Experimental Investigation On Road Vehicle Active SuspensionDocument6 pagesExperimental Investigation On Road Vehicle Active SuspensionRaja Sekaran SajjaNo ratings yet

- Nikon - Download Center - NX StudioDocument4 pagesNikon - Download Center - NX StudioRaja Sekaran SajjaNo ratings yet

- Stabilizer bar calculations exampleDocument9 pagesStabilizer bar calculations exampleRaja Sekaran SajjaNo ratings yet

- ITI - Sim: Simulation ApplicationDocument2 pagesITI - Sim: Simulation ApplicationRaja Sekaran SajjaNo ratings yet

- 2010t5z4 16Document9 pages2010t5z4 16Samik MukherjeeNo ratings yet

- BOYSEN® Marmorino™ Italian Marble Finish: Liters UseDocument1 pageBOYSEN® Marmorino™ Italian Marble Finish: Liters UseJohn Ray Esmama CalasicasNo ratings yet

- Filipinism 3Document3 pagesFilipinism 3Shahani Cel MananayNo ratings yet

- Manual HandlingDocument14 pagesManual Handlingkacang mete100% (1)

- Technical Report Writing For Ca2 ExaminationDocument6 pagesTechnical Report Writing For Ca2 ExaminationAishee DuttaNo ratings yet

- Travel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteDocument1 pageTravel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteMark Levin Munar100% (1)

- Yuken Series PVL Vane Pumps Catalogue en PDFDocument69 pagesYuken Series PVL Vane Pumps Catalogue en PDFAgilRinaldiNo ratings yet

- MDP Module 2Document84 pagesMDP Module 2ADITYA RAJ CHOUDHARYNo ratings yet

- Advances in Cultivation of Commercial Seaweed SpeciesDocument21 pagesAdvances in Cultivation of Commercial Seaweed SpeciesDHEERAJ KUMARNo ratings yet

- Abdul Jabbar (Mechanical Engineer) AGROFEED KSADocument4 pagesAbdul Jabbar (Mechanical Engineer) AGROFEED KSAftimum1No ratings yet

- TMF1014 System Analysis & Design Semester 1, 2020/2021 APPENDIX C: Group Assignment Assessment RubricDocument4 pagesTMF1014 System Analysis & Design Semester 1, 2020/2021 APPENDIX C: Group Assignment Assessment RubricWe XaNo ratings yet

- RADEMAKER) Sophrosyne and The Rhetoric of Self-RestraintDocument392 pagesRADEMAKER) Sophrosyne and The Rhetoric of Self-RestraintLafayers100% (2)

- Panasonic Sx-kc211 User ManualDocument36 pagesPanasonic Sx-kc211 User ManualJoshua Chong100% (1)

- (Architecture Ebook) Building Design and Construction HandbookDocument5 pages(Architecture Ebook) Building Design and Construction HandbookJESÚS GARCÍA PÉREZNo ratings yet

- Logix5000 Control Systems: Connect Kinetix 350 Drives Over An Ethernet/Ip NetworkDocument50 pagesLogix5000 Control Systems: Connect Kinetix 350 Drives Over An Ethernet/Ip NetworkAlan Ruiz CortezNo ratings yet

- Tema Line Solutions BrochureDocument8 pagesTema Line Solutions BrochureUmair Mushtaq SyedNo ratings yet

- Cylinder Head Cover, 6T-830 and 6ta-830 Emissions Certified EngineDocument3 pagesCylinder Head Cover, 6T-830 and 6ta-830 Emissions Certified EngineJose A PerezNo ratings yet

- TOS - MathDocument4 pagesTOS - MathGeorge Ezar N. QuiriadoNo ratings yet

- Ac and DC MeasurementsDocument29 pagesAc and DC MeasurementsRudra ChauhanNo ratings yet

- Resume summary of monthly sparepart costs and production in 2021Document590 pagesResume summary of monthly sparepart costs and production in 2021winda listya ningrumNo ratings yet

- Find Out Real Root of Equation 3x-Cosx-1 0 by Newton's Raphson Method. 2. Solve Upto Four Decimal Places by Newton Raphson. 3Document3 pagesFind Out Real Root of Equation 3x-Cosx-1 0 by Newton's Raphson Method. 2. Solve Upto Four Decimal Places by Newton Raphson. 3Gopal AggarwalNo ratings yet

- BrochureDocument2 pagesBrochureNarayanaNo ratings yet

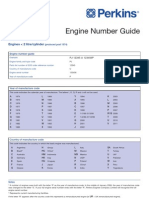

- Perkins Engine Number Guide PP827Document6 pagesPerkins Engine Number Guide PP827Muthu Manikandan100% (1)

- Review of Guyana's Social Education ProgramDocument6 pagesReview of Guyana's Social Education ProgramTineka Jagan CharlesNo ratings yet

- Group Case Study: Premier Automotive Services LimitedDocument2 pagesGroup Case Study: Premier Automotive Services LimitedKryzel Jean Tumbaga ValdezNo ratings yet

- CSR of DABUR Company..Document7 pagesCSR of DABUR Company..Rupesh kumar mishraNo ratings yet

- I/O Buffer Megafunction (ALTIOBUF) User GuideDocument54 pagesI/O Buffer Megafunction (ALTIOBUF) User GuideSergeyNo ratings yet

- Circuit Breaker GTSDocument31 pagesCircuit Breaker GTScpandey01_688066930No ratings yet

- Solve Equations and InequalitiesDocument13 pagesSolve Equations and InequalitiesFons Roxas-ChuaNo ratings yet

- Cooler Catalogue PDFDocument12 pagesCooler Catalogue PDFCărunta-Crista CristinaNo ratings yet

- June 28th Altran Capital Market Day Presentation DeckDocument52 pagesJune 28th Altran Capital Market Day Presentation Deckvenkata.krishnan100% (1)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansFrom EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerRating: 4 out of 5 stars4/5 (1)