Professional Documents

Culture Documents

TG - 13 - Operat'Nal Guide - Part 1

TG - 13 - Operat'Nal Guide - Part 1

Uploaded by

Abdul Hameed100%(1)100% found this document useful (1 vote)

931 views116 pagesOriginal Title

Tg_13- Operat'Nal Guide- Part 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

931 views116 pagesTG - 13 - Operat'Nal Guide - Part 1

TG - 13 - Operat'Nal Guide - Part 1

Uploaded by

Abdul HameedCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 116

Technicc idance TG20:13

Operational Guide

Fe ee ROR eet cc ae MS eed

Foreword

Falls from height remain the dominant cause of fatal and serious injures in the construction industry.

Property designed and constructed scaffolding has a key roe to play in reducing that tll of iniuries.

“The Work at Height Reguiations 2005 (WAHR) require that strength and stability calculations ere

carried out for al scaffold structures unless they conform to a recognised standard. The responsibility

for ensuring that this duty is met falls to both the scaffolding contractor and his client

HE is pleased to acknowledge that the NASC has wirtten T&20:13 to provide a standard for

traditional tube and fting scaffolds to helo industry manage safety risks effectively in the scaffolding

‘and wider construction sector, 5

HSE recognises that this guidance contains some advice that may go further than

the minimum needed to comply with health and safety law.

Heather Bryant, HM Chief Inspector of Construction,

Health and Satety Executive

|We applaud and support the work of the NASC which will no doubt result in safer scaffolding

structures being installed and thus reduce the frequency of scaffolding fallures, which at present

‘occur far too frequently across the industry.

‘The UKCG recommend the adoption and standardised use of TG.20:18 to the wider industries that

utilise scaffolding structures both within and outside the construction sector.

Stephen Ratcliffe,

Director, UK Contractors Group

Part-funded by

{This project has been delivered with support from the CITB Growth Fund, which aims

to-ensure thatthe construction industry has the right people, with the right skis, 9

the right place, atthe right time and is equipoed to meet the future skits demands of

the industry,

NOUNIGEINOD DNIGTOLIVOS ANY SSIIOV THNOLIVN

About TG 20:13

This edition of 720 is presented in two companion volumes with an interactive electronic guice.

1G20:13 Operational Guide

‘The TG20:13 Operational Guide provides comprehensive good

practice guidance for ll tose inwolved wth tube and ming

‘access scalding. Its intended for a wide audience end proviies

{guidance forthe erection and use of common steel access

Scaffolds for construction, maintenance, repa, demolition and

simiar works.

‘Tho 2uide provides clear defnitions for 20 compliant scafoling

‘common scaffolding structures that have been designed by

structural calculation to BS EN 12811, These defritions are

presented as 120 complance sheets, which are soafiolding

sign sheets that may be used to demonstrate that a scafold

does not require a bespoke design.

1G20:13 eGuide

‘The TG20:19 Operational Guide is supplemented by an electronic

{uide for the generation of TG20 comptance sheets,

The TG20:13 eGuide provides compliance sheets for the

‘complete range of TG20 compliant scaffolds, including TG20

‘compliant independent scaffolding, putiog scaffolding, loading >

ayo, owe, crime. sccas scflldng and ar ages,

bls aeperdent scalding variations nang bags oes,

Dron ano, carter lator and TC20 compan {

Priest stu tans ule

1G 20:13 User Guide

‘The TG20:18 User Guide Is a hand, easy-to-use pocket reference

{uide walten for scaffolding operatives, supervisors and cent

‘ite management that summarises the principal points from the

Operational Guide.

1G20:13 Design Guide

The TG20:13 Design Guide provides comprehensive technical

‘guidance forthe interpretation and application of BS EN 12811 and

‘he related structural design standards.

itis intended fo" use by scaffolding designers, temporary works

engines und all thase concemed with the design and manutacture

cf scaffolding structures and equipment.

Welcome

yo

Welcome to the TG 20:13 Operational Guide.

This cornorehensive guide to good practice is intended for ail trose

invoivad in the orocurement, supply and use of tuoe and fitting

soatoiding,

13 has een produced oy ie NASC, as the recognised UK

+rade dody, in resoonse to ine introduction of 8S EN12811. It provides

nerally recognised staicerc configurations of tuoe and fitting

scaffolding, as required oy 172. Work at Height Regulations, wi

have oger dasigned by structural Celculevon anc for which additiona!

oasooke dasiar is not required.

“Ine NASO, with sugport from the HSE, Ux Contractors Group and

OITS, aims to increase awareness of good practice in the wider

Industry and provide prac ‘c@l and technical advice io aid ai! scetoiding

iors in the implementation of BS EN 42811 anc the Work at

Regulations, maki good practices accessibie to ail.

National Access and Scaffolding Confederation

November 2013

NOLAND SNIGIOLVOS ANY SSE9D¥ TYNOLYN

Contents

1 _ Introducing 1620 07 06 Independent scaffolding 61

1.1 Which scatfolding requres design? 08 = 6.1 Scaffokling terminology 62

1.2 TG20 compliance sheets 09 6.2 Scaffold usage ard load class ot

1.3 _ Types of 7420 seatfocing 1063. Praform facing 5

14 T620 seatoldng feats 12 64 Pletiomn wine 6

8.5. Liftheights and headroom or

02 1620 eGuide 15 6.6 Standaras and lecgers 8

PHINES ances te 6:7 Joins in standards anc ledgers o

2.2 Using the TG20 eGuide Ww 68 Transoms 70

2.3 Selectng a TG20 compliance sheet 1g 69 Prefabricated transom units a

6.10 Foot its 72

03 _TG20 compliance sheets 23.811" Facade bracing *

6.12 Ledger bracing 76

3.1. Using the compliance sheots 26 ES onang ge tig ‘s

3.2 Understanding the itera 25 Een tring to

33 Theetfect ofthe site cation Eten, x

ote cating compres set 2 Gis totes

006 Poem comarcrmma Sy 847 es

CORREEE Secon Seat 248418. Inside boars and brackots as

009 Cantilever protection fan compliance sheets gg 810 Cantlevered platfoms Lod

010. Ladder-access tower compliance sheet 37 8.20 Internal edge protection =

DIT Loading bay compliance sheet 36 6:21 Double standards 90

012 Interior birdeage compliance shest 39 6.22 Ties to the building oO

013 Putlog scaffolding comptance sheet 4G 6.23 Rakers 92

14 Lit shat tower compliance sheet 41 624 Shooting and detris-neting 24

019. Froe-stancing tower corpiance shoots 42 6.25. Bick quarts 95

04 Scaffolding equipment 45 07 Ties to building fagades 97

41 Tubes 467.1 tnrocucing tes 8

42 Boaras 487.2 120tHe comptanc: 99

43° Cowes 5 7.3 _Tyingmetnode 100

4.4 Prefabricated beams St 7.4 Typical anchoring methods 01

4.8 Pretaricated transom units 62 7.5 Pues for spacing tes 102

48 Ladders 537.6 Type layouts 104

77 Ting etn 108

05 Foundations 55 78 Teeassembles 109

7.9 ing prnciles 110

5.1 Scalfokiing foundations 8 730 morning Wo lace ct ie

5.2 Scaffolding foundation loads 8 TN omm i

ee)

| 07. Ties tobuilding fagades .. 13. Interior birdeages 71

70 Upties 716 Tad TG20 complantinterorbrdeages 172

7.49 Through es > 416 19.2 Birdcage construction 174

7:14 Reveal tes 117 18. Bracing arangorents 176

7.45. Dail or east-n anchorages 118

7-18 Anchor Pes 120 14 Putlog scaffolding 179

7.47 Insaling anchors apa =

7.48. Praiminay anchor tosting 126 kee

19 Anchor i war

719 Retort ecg 15 Towers 183

08 Access and egress 129 SA 1

Fe ee 152. Stationary free-standing towers 485

alive Ho 15.2. Prefabricated mobile towers 186

8.2 Mechanical hoists ee ae ca

8:3 Stdrcase towers 192

8.4 Ladder access towers 196

85 Other methods of ladder access 4g 16 Chimney-stack scaffolding _189

88 Landing patios 198 Tel ypealarengemenis——SSCSC*~*~*~«

| 87 eval cates 137 162 Access scald 199

} 09 Openings and bridges 139 17 Plonning and preparation. 195

9.4 Bridge oveniow 140 17.1 Prepaing fora convact 196

: 9.2 Beam specication 142 17.2. The chontbiet 197

9.3 Fong the beams 143 17.9. Pre-oniract sto inspections 198

| 944 Lecng and bracing the bearss 144 17.4 Piskassessments 199

| | 9.5 Repeating the beam system 145 17.5 Method statements: 204

| 9.6 racing around the opening 146 17.68. Teining 205

| 10 Protection of the public 149 18 Work on site 207

| 0-7” Protection ofthe publ 160 “18.1 _Scafeng construction 208

| [102 Pavers 152 18.2 Handover certicates 210

10.3. Stabisng a pavement it 158 18. Seaton inspections 212

10.4 Pavement gantries: 155 18.4 _Dutles of persons using scaffolds 214

10.5 Protection fans 156 18,5 Protecting people and property 215

11 Raising & lowering materials 159 19 Appendix 217

+t Gnwhoos 760 “791_Defntons 218

11.2. Other iting methods 162102 Furthor reading 222

44.2. Liting regultions 462 19.8. Conformance with European Standards 224

41.3. Rubbish chutes 1631944 Acknowedgements 225

12 Loading bays 165

12.1 Loading plairms 766

122 Looding bay gates 167

123. Loading bay tower constuction 168

128 inspection and handover 169

NOUWTALINOD SNITTIOLIWOS ANY SS3DO¥ TYNOLTYN

Introducing TG20

Cnarion vs |

7620 has been developed by the NASG in response to the

introduction of BS EN 12611, the European Standard that

‘superseded the withdrawn 8S5973: code of practice for access

{and working scaffolds and special scafold structures in test

Unike 855973, BS EN 12811 Is a performance document for the

‘design of scaffolding by calculation and not a practical qude for

typical scatfolding structures.

In order to reinstate this practical guidance, the NASC italy

published T620 in 2006 as a guide to good practice for

Scaffolding with tubes and fitings to BS EN12811, T&20 was

revised in 2008 and, in ne with NASC poiicy, has ben updated

{or release in 2013 as TG20:18,

“The NASC has taken this oaportunity to significantly redevelop

“7620 into this new Operational Guide, which provides clear,

practical guidance for scafolding contractors and the wider

‘construction industry.

“Tagetiver with the TG20 Design Guide and the new TG20

‘eGuide, wich significantly reduces the requirement for bespoke

‘scaffolding design, TG20:13 aims to increase awareness of

{go0d practice and minimise the impact ofthe introduction of BS

{EN12811 on the scaffolding industry.

Information in this chapter

—

Which scaffolding requires design?

i)

_

7G20 compliance sheets

12

ee

Types of TG.20 scatiolding

13

ee

TG20 scaffolding features

1a

NOWNESGLINOD ONIGTOLIVOS ANY SSI9OV TWNOLYN

«: What scaffolding requires design?

The Work at Height Regulations state that

"Strength and stabifty calculations for satfolding

be carried out unless [i assembled in

‘conformity with a generally recognised stander

configuration.

Wor at Height Regulations 2 cule 3, Regulation 7,

Standard BS5973 provided such

«2 defnien fora standard configuration of independent

Scatfoidrg. Any independent scaffolding erected within the

—— _arameters ofthis defintion — with the prescribed it hights,

bay lena, pletform wats, bracing patterns, working loads

{and so on — did not require a special design,

‘The European Standard 8S EN 1281 1-1 does not contain

‘Such a standard configuration, impying that al scaffolding

structures require incvidual designs. Since ths is not workable

in Practice, the NASC has developed 720 to reintroduce the

‘Concent cf standard configurations of scaffolding,

‘hiss achieved by providing defintions for TG20 compat!

scaffolding. TG 20 complant scaffolds are standard

Configurations of scaffolding that have been designed by

structural calculation to BS EN 12811. Any soatfoling that

‘can be shown to be erected in accordance wth TG20 is,

therefore also in accordance withthe design requirements of

BS EN 12811 and exempt from further design,

Ais of the British and European design standarls to which

G20 scaffoing conforms is provided in the append of this

uid. This appendix also describes come departures from the

European Standard in the design of TG20 scattolding, which

have been enclorsed by the Health and Safety Executive,

\where the standard conficts with accepted best practice in

the Unitod Kingdom,

Compliance with 720 is demonstrated through the use of

TG20 compliance sheets, provided in chapter C3 of

{and the aecompanying eGuide. TG20 compliance sheets

provide a written record that scaffolgng is compkant and,

‘9xempt from the need! for adaitional design, as described in

the next section,

‘The withdrawn Bri

TG 20 compliant scaffolds are standard configurations

of scaffolding that have been designed by structural

calculation in accordance with BS EN 12811.

ATG 20 compliance sheet can be used to demonstrate

that a scaffold is TG20 compliant and therefore does not

need a special design

CHAPTER O1 | Introaucing 14.20

TG 20 compliance sheets

720 has been developed to include a range of standard

‘caolding configurations and variations that are described

throughout this chapter, AS a wide range of scaffolds aro

7620 compliant, tis important to provide clear and conse

eiitions for ther. These defintions can be used within a

‘Ste management process to ensure that tis clear to all partes

‘hich scaffolds are compliant and which require bespoke

design ace.

|ATG20 compliance sheet is a beet summary of the ote

that must be met in order for a ecaffold to be exemaot from

‘desig: Its provided as a checklist that can form part of the

process of planning, erecting and inspecting scaffolding,

Several standerd TG20 compbancs sheets are provided in

‘chapter 03 of this. guide, which are appropriate for commonly

Figure 1.1: the TG20 eGuide ancl a typical TG 20

sed scaffolds. The complete range of compliance sheets is

avaliable from the TG20 eGuide, including those for complex

‘satfolds that have traitionally required bespoke engineering

design.

TG20 compliant scaffoling structures include several

variations of independent scaffolding, loading bays, towers,

interior biroages and putiog scaffolding; with structural

features such as cantlevered protection fans, bridges

‘around! openings, and cantilevered platforms available for

independent scaftolding. A compiete lst cf compliant sceold

‘configurations is provided in sections 1.3 ~ 1.4 of this chapter.

Design advice, or specialist software, is requited for any

scaffolding for which a TG20 compliance sheet is unevaiable,

>

Stmdord unclad independent

k

i

j

a

3

'

i

j

a

i

i

i Types of TG 20 scaffolding

This guide provides good practice guidance and TG20 compliance sheets for several types of scaffolding structure that are

Apple iMac desktop and laptop computers

running MacOSX

Note that tabet computers running the Microsoft

Windows FT operating system are not supported by the

720 eGuide, but tablets running Windows 7 oF 8 are,

Installing the TG 20 eGuide

‘The TG20 eGuide must be installed onto @ computer before

use. The eGuides installed by inserting the CD into the CD

chive of the computer and wating for tne instalation process

to start automatically. The installation process can also be

started manualy by navigating to tie CD using Windowe

Explorer and double-clicking setup.exe (on the PO} or using

Finder to launch setup.2o0 (on the IMac).

‘Once the 7.20 eGuide has been installed i is started by

double-clicking the icon created on the Windows or MacOS

desktop.

Activating the TG 20 eGuide on first use

‘The 1620 eGuide must be activated before it can be used

Every copy ofthe TG.20 eGuide is provided with a unique

‘serial number. When prompted, the unique serial number

should be entered into the TG20 eGuide, as shown by figure

2A

(Once the serial number has been entered the eGuide must be

activated to ensure thal every serial number is only used on

‘one computor ormoblle device ata tm.

The computer or mobile device must be connected to the

Intornet to activate the TG20 eGuide,

\When promoted, the “Activate now option should be sele

toregister tne seal number on your computer or mobile

device over the Internet, If the seral rurnber is not already in

Use, the TG20 eGuide will become activate,

If. an internet connection is unavailable, the “Activate later’

‘option cen be selected, but the TG20 eGuide wil run in a

limited demonstretion moce unt itis subsequently activated.

While nthe demenstration mode it wil not be pessibe to view

or print 720 compliance sheets from the eGuide,

Transferring to another computer

The TG20 eGuide may be ransterred to another computor

or mobile davce by frst deactivating It, This is achoved by

selecting the information bution (he eter) from the men

bar of the Welcome soreon and choosing the ‘Deactuato"

option

A connection tothe ntamet is required vile deactivating

The serial number may then be used to activate the TG20

‘Guide on another computer.

Figure 2.2: activating the eGuide over the Internet

mBeuent

CHAPTER 02 | TG20 eGuide

Using the TG20 eGuide

‘The purpose ofthe TE.20 eGuide is to browse for 1020

compliance sheets. TG20 compliance sheets can be printed

from the eGuide on any compatible pritor or exported tothe

Adobe POF electror yrmat for distribution by email wakis

Putlog scaffolding

“The eGuide lows a wider varity of T620 compliance sheets ee

to bo provided than in chapter 02 of ths guide, Including

eccuratecalculabons forthe maximum safe height and =

required te duty of scaftokding,

Navigating the user-interface

Te TG20 eGuide has been designed for use on tradtonel

desktop or laptop computers controled with a mouse andl on

ces including compa taets end lepton

jhscreen csplay,

‘The TG20 eGuide prompts a series of options to select an

‘appropriate TG20 compliance shest, for exemple to select

the type of scatfold, the working load it wil support the site

in which it wi be located, and g0 an. The preferred option is

selected in each case by clicking it with the left mouse button

cor touching the soreen in the case of a touchscreen device,

Depending on the size ofthe alsplay screen and the number

cf options avalable at each stage, it may be necessary to

scrol the screen to see more options. This s indicated by the

presence of an artow at tne adge of the screen, as shown by

figure 2.4. These arrows can be clicked withthe mouse or

pressed with the finger to see more options

‘Aternatively, when these arrows aro present the screen can

bbe swiped with a finger to scroll the display, This can also be

‘achieved with a mouse by pressing and holing the lft mouse

button and moving the mouse in the indicated direction, 2.3: a TG20 compliance sheet in the eGuide,

fseoanson ting [unc baccope olalting

| =

Pressing ths araw

ed potog searing att owes scr the asplay

4: scroling the display to see acitional options,

NOMVerTASINOD SNIGTOAIVDS ANY SS1I9V THNOLYN

2.3

Selecting a compliance sheet

|ATG20 compliance sheet is selected by folowing the steps

prosented by the TG20 eGuide.

‘The steps for selecting a compliance sheet ae:

4. Select the type of scatold for which a

‘compliance sheet is required

2, Select options for the scaffold, for exarmpe Its

‘quired working load, width, height and other

‘dimensions;

‘Select which add-ons are required, such as a

bridge or cantlever fan, if they are permitted for

the chosen scaffold type:

4. Select the site locaton and wind exposure. if the

‘aod isto be stuated In luvation exposed to

the wind:

5, ‘Select the preferred TG20 compliance shect

if several are avellable that mest the specified

itera

These steps are described in tun

ras plus two inside boards

Selecting the scaffold type

“The fist step is 10 select the required scaffold type from the

avaiable options, as shown by figure 2.4,

Note that 1620 compliance sheets for ladder-access towers,

and loading bays, which are add-on scaffold towers, can

be obtained by ist selecting the ‘indepencient scaffolding’

option.

Selecting scatfold options

‘Once the scaffold type has been chosen a number of options

‘ar presented by the TG20 eGuide that depend on the

Scaffold type. Some typical options are iustrated in figures

255 to 27, which show how to select the scaffold width, tho

required ald-on features, and the required working toad,

“The working oad is selocted by clicking the required option

init the let mouse button or pressing the touchscreen, just as

‘whan selecting the soatfold type. Most of the options soreans

work in this way.

‘The required scatfold width, height and other dimensions

are selected using siders, as shown by fue 2.5. The sider

is eperated by pressing it with a finger and sliding it (fa

touchscreen display is used) or holding down the left mouse

‘button and moving the mouse

Figure 2.5: selecting the scaffold with wath

séiecting add-ons

Inckpendantecafoklng can reude aon, 3 dese

tec, 0 ofthis gue, incuding brages, pavement

in aor overed protton fare and carlovered patos

it, cant by aking tubes or rei boars brackels. Adg-ons

Seseectod as shown by figure 2.6.

iaseach add-ons elected, an acttional soroen may be

A ert oy tho ule oe tutor opts st 0

aac For oxampl, a tidge i eure inthe sass

tre ee seron is prod 1 soec the number oF sto

By eoppatod by, as shown by Howe 2.8.

possters

» maxirnum working

{tis also possible to speciy whetner an independent scat

will include an add-on scaffolding tower, which may be @

‘oading bay or ladder-aocess tower, in a similar way.

“The maximum safe height and required te duty rer

the TG20 compliance sheat forthe main access scat

vv include the effects of any add-ons, for example a

Ccantevered protection fan may decrease the maximum

helght ofthe scatfold or increase its required ts duty in

‘some crcumstances. A TG20 compliance sheet is also

provided for each add-on, speciving ts design and assembly

ted by

w

WW TYNOUWN

NOUNIESINOD ONIGTOALOS ANY S539"

2.3

# Select the site location

Selecting the site location

The site locaton must be spected ifthe scafld ist

be situated ine cation exposed fo the wind. Tne G20

Guide provides an intractve wind map, tustated by igure

2, which aviomaticaly calculates the wind exposure by

assessing ofc meteorological dala, the ste aitude and

toposraphy, the height ofthe scafod, and the extent to which

the wind exposure is reduced at rland sites,

“The interactive map is used by moving the site marker or by

entering the site address or postcode inthe ‘Search’ box.

Ifthe interactive map is used on a madie device with GPS

capability the ste automatically defaults to the current location

of the deviee.

“The intoractive map dlgplays three gauges at the right-hand

roan. The first displays the TG20 wind factor:

a calculated measure ofthe site wind exposure desorbed

20 Design Guide.

est ofa cif or escarpment have greater wind axpasure

than equivalent sites on fat teraln,

0 to cycle between,

ting

‘The third gauge can be clicked or pr

the seasons over which the scaffold wil be stancing,

in reduced wind exposure dunng the spring or summer.

‘The interactive wind map requires an Internat connection. i

‘@ connection is unavailable a simple wind map 's presented

28 shownin igure.2.10, which allows the ste wind exposure

{o\be selected as desorbed in soction 3.3 ofthis guide, tis

strongly recommended that the Interactive wind map is used,

‘where possible, to obtain the most ecient complant scatol.

Figure 2.8: the interactive wind map,

Figure 2.10: ihe smpie wind map,

selecting the preferred design

‘noe alo the required scafolang and site options rave been

ca coted a 720 compliance sheet is displayed that mest

seeped criteria Fane's aval f add-ons or acon

tre teing towers ae required 8 TG2O comolance chet vil

provided for each add-on in aden 10 the compliance

shoot forthe main scattotd

in some circumstances 2 720 complance sheet may not be

fund, for example if the required scatfoking height cannot

be achioved with the selected options. In these cases the

problem is reported, a8 shown by gure 2.11

internatively, several candidate designs may be avaliable. For

‘remple, I ay le necessary to reduce the bay ength of the

aretiiding or use en arTangerent oes with te postions at

Seehy at inorder to achove the recuied scaffolding height. 1

those cases the aterative designs are presented, as shown

ty fou 2.12, 0 the preferred TG20 complance sheet 27

be selected.

Printing or sending by email

‘noe a 76.20 compkance shoot has been selected. the

signature area inthe footer section can be completed by

typing in the allocated spaces, as shown by figure 2.13, and

adding a signature. The Information entered in the footer Is

remembered by the TG20 eGuide so it does not need to be

repeatedly entered foreach scaffold in a project

2.3

Once this has been completed the TG20 compliance sheot

‘Can be exported to the Adobe POF electronic format go that it

nay be printed, saved to the computer or sent by eral. This

is achieved by selecting the ‘Save as POF" option.

ferrame as doled i 1620.13 chant 03 er a

Sciam

coon

Este 0:0 const nani vn a

«emacs Nevertire: Gane

© en ee en soe

LMSnuentaootevecgneancrenm a” sat

cops ee

o reangsinmtnanioreinstans

sionatt

te sense ree

"Save as PDF || Start

NoLLWusaLINOD ONITTOIIVDS ANY SS399¥ THNOLLYN

Jue 2.13: saving the competed TG20 sheet to POF

— t

a * Standard unclad independent

StI § "seasons

eran Ese Coon

ba — ener

oni er sii cae ~ _

enn ien ve | see

TG 20 compliance sheets

seep upuneaneareses: #8

“Tis chapter contains compliance sheets for TG20 scatilcing

‘salt-contained definitions of scaffolds that have been designed by

Structural calculation and do not require addtional design.

“The TG20 compliance sheets specity the design criteria for

several common configurations of scatfolding, including the

heights to which they may be safely erected, the maximum

dimensions to Which they must conform end, where applicable,

the les required to stabiise ther.

“These complance sheets may be used during the planning and

execution ofa project, as described in chapters 17 and 18, to

‘domonstrate which scaffolding is T620 compliant and wich

scaffolding requires special guidance from a scatfokdng designer.

“The 720 complence sheets may be photocopied or preferabiy,

thay may be printed from the TG20 eGuide.

In addition to the ‘basic’ compance sheets provided in this

‘chapter, the eGuide provides compliance sheets for a wide range

Of variations, inctuding greater safe heights than pematted by

the basic compliance shoots and a variety of Day enaths, tie

arrangements and equipment options.

“The compliance sheets printed from the TG20 eGuide are also

taiored for local concitions by an accurate assessment of the site

wind exposure, allowing the TG20 compliance sheets printer

fom the eGuide to provide rrore efcient designs for lower

soatfolds and safe designs for tal scatfoiing,

However, the basic 1620 compliance sheets in this chapter

alow many typical scatoids to be erected and checked for 120

‘comaiance without the need to consult the eGuide,

‘Usage instructions for the TG 20 eGuide are provided in chapter

Information in this chapter

——

Using the compliance sheets

Bridge compliance sheets

asian 718

es

Cantiever protection fan compianca sheat

Dasign &

ee

Ladder-access tower compliancs sheat

Dasqn 12

Loading bay compliance shest

Design 14

ee

Intarior brccage compliance shest

Design 12

Ptlog scaffocing compliance shoet

Design 13

Design 14] 18,

NOUVEIALENOD SNITIOUIVDS ANY SSIDOV TWNOLLYN

~——— tis recommended that, as part ofthe planning phase, either

si Using the compliance sheets

‘The purpose of the TG20 compliance sheets isto clearly and a TG20 compliance sheet ora bespoke design is provided

concisely summarise the dlmensions and other itera to for each scatfold as part of the project method statement, as

\which a scaffold must conform in order to be TG20 compliant described in chagter 17,

land exempt from bespoke design,

‘The compliance sheets state the specific soatfolds to which

‘The compliance sheets should be used in conjunction withthe they apply, proving documentary evidence of the seats

tex ofthis guide, which specties detailed information about on the site that are TG20 compliant. This information

‘each design criterion, fentered in the footer area of the complane sheet, which also

Drovides @ space ‘or the signature of a responsible porson to

‘confirm thatthe scaffold has becn erected in accordance wth

the design.

‘A compliance sheet is required for each scaffold, or each

group of similar scaffolds, on a project to demonstrate that

they conform to a TG20 standerd configuation.

‘The ful range of compliance sheets, including those provided

in this chapter, is evalablo from the TG20 eGuide.

Is required for every

* Standard unclad independent scaffold, or group of

‘So wc io 0d tg depend sos 2m mann hg, scaffolds, that conform to

an the design

arn

aE = maeserneere

— ‘Ramemeteeaeuae | Every such scala must

cea Conform to the eritria

ee described on the sheet.

oe Atmbewon saat a The subsequent chapters

meena a ra of tis guide provide

detailed information for

‘each oriterion and shouk

‘Screpmerenremetn ae. anes be conte er futher

Soma easter Saets Ranke ees details,

‘bin oro 10 cn tbr et teen TO 9 at

‘osm a Pot hi ‘The footer area dofines

the ste and scaffolding

Signott that the compliance sheet

‘manvategtet Cleon Coane cesar ain

ua — I ‘Spaces are provided for

rte Senter: 1] aresponsibie, competent

te sown incividual to sign the

fads a ne sheet and confirm that the

seatlldng wi corepard

“Seiaecamieercrenmasimeae — | | winthereaemansct

the compan set

‘emperor ter ce vod

Figure 3.1: the features ofa 7620 complance sheet

CHAPTER 03 | IGzU compnance snevw

Understanding the criteria

In ord fora scaffold to be TG20 compliant it must maet the design cfteria defined in he compliance sheet:

Maximum height

“This is the maximum safe height to which a scaffold may

be erected, measured to the platform of the top lit. tis

necessary to erect a tall scatfold a diferent compliance

‘Sheet may be avallable, typically a sheet printed from the

7620 eGuide, or t may be necessary to sack design advice.

Ties

‘The compliance sheets specity when itis necessary to tie he

‘Sao to @ permanent structural feature and, so, how the

‘scaffold should be ted,

“The tie specication defines the strength of ies that are

required (he te duly, the number of ties required per square

‘metre of scaffolding the tie density) and the maximum

Cistance between lines of tie. In ganeral, scaffolds that are

sheeted of exposed to high winds reauire ties of greater duty

Or greeter density than unclad scatloiding in areas of low wind,

“The complanoe shoes also provide guiclance for the fxing

oftie tubes and state when the effects of the sito wind

necessitate additional stabilisation methods.

Further guidance fo ties is provided in chapter O7,

Mendmum loading

‘The TG20 compliance sheets speciy the maximum working

load thet the soatold is designed to support. Generel-purpose

independent scaffolding is designed to support 2.0KN/m?

{eppreximataly 200kg/m) at tho working it, but alternative

‘designs are avalable for greater loads, which ray require

adcitiona strengthering depending on the scald height,

‘Some scaffold types, such as birdcages, ae typically used for

lighter-duty work. Scaffold platform load classes and loading

fare described in sections 6.2 ~ 6.8.

“The compliance sheets also specify the maximum number

cot pletforms that may be loaded at any time, per elevation

Cf scaffolding, as itis normal practice for one platform to be

‘actively used, with another platform for the temporary light

‘storage of tools and materials, even if more scaffold its are

boarded,

Maximum dimensions

720 compliant scaffolding must conform to certain

maximum dimensions stated by the compliance sheets, These

are primarly the maximum bay length (the stance between

‘adiacent pairs of stander}, the ift height (the vertical

‘stance between platforms) and the maximum transom

‘spacing (the maximurn spacing between board-bearing

trancoms). In general, heavier-duty lads require reduced bay

lengths and transom spacing,

“These compliance citria are described in more detain the

subsequent chapters ofthis guide. It is important to be familar

‘wih them before using the TG.20 compliance sheets.

Add-ons and structural features

“The G20 compliance sheets for independent soatfoiding

state whether they are designed to include add-ons or otner

‘structural features such as a bridge, cantilever protection fan,

Ccantiever working platform or pavernent lit. TG'20 complance

Shoots should be provided for the main scatfoid and for each

Structural feature not Included in the basic specication.

In some cases a structural feature may change the design of

the main scaffold, for example the maximum sate height of a

scaffold may be reduced by providing a cantlever protection

fan. To accommodate this, the compliance shests for the

majority of special features are printed from the eGuide rather

‘than being provided in this chapter, 80 the safe height and tie

duty reperted on the compliance sheets can be customised

forthe selected structural features and ste location, as

eserbed in chapter 02

Erection toleramces

“The dimensions reported on the TG20 compliance sheets are

subject to the following erection tolerances:

Feature ction tolerance

Vertical to within « 20mm in 2m, to @

Standards ppayimum total deviation of SOmm.

Level to within + 20mm in 2m, to a maximum

Led9erS total deviation of 50mm.

‘Transoms + 100mm on the target spacing

Bay length + 200mm on the designated length.

Lift height + 100m on the designated height

‘Table 3.1; erection tolerances.

“Tolerances are intended to allow operatives to work to a

reasonable degree of accuracy and should not be used to

for example, repeatedly tect 2.1 m its when 2.0m lifts are

‘stated on a TG20 compliance sheet. Tis is similarly the case

for the bay length and transom spacing

Lift heights, bay lengths and transom spacings may be

reduced below the stated values to sut site conditions.

3.2

NOUWEIGLINOD ONITIOLVDS ANY SSI99¥ TYNOLYN

3.3

The effect of the site location

“The site wind exposure can affect the manierum

height ofa scaffold and the duty ofthe ties roquited to

stabilise it, especially vihen the scaffold is sheeted or

dobris-retted,

A simp wind exposure clasitication system is

lustrated hor, to be used with the basic TG20

compliance sheets within thi chapter. A more

‘accurate wind analysis, which can result in increased

safe haghts and reduced tie duties, is avalabie rom

the T20 eGuide and further achice for scaiflding

signers is provided in the T&20 Design Guide.

‘The wird exposure ray be classiied as moderate,

high or extreme using the wind map and detinions

provided in figura 3.2, togethor with 1

classifications in figure 3.3.

This wind exposure may then be reduced to a lower

classification, i appropriate, to consider seasonal

and wind shielding factors. This can regut in the

ind exposure being reduced to a spatial low

assiication, as expiainad in the examples on

the opposite page,

Moora vi 0 odorata wind exposure on nemioaly fat grunt

an ite of ‘oan alttude of 150m,

High wind exposure on a moderate o steep ito an High wie exposure on a moderate hilo an

atiuds of 150m, cr ft ground at #603601, alttude of 150m, or fet ground at 150 3601,

rome win exposure ona moderate ors Bareme wind expesure on asleep if, ona

hia alttudes exceecing 150m ane an fat grouns ‘modorata till anove 180m and on fat ground

Above 350m, sbove 360m. °

fwd exposure to an altitude of 150m on arene wird expoeuco tis recom

orn fat ground the 7820 eGuide ueed to

wind exposure assessment for

ended tat

rome wind exposure on all moderate oF stoep hits

0 08 love and on fat ground above 150)

nt independent scaffolds as defined in this chapter,

CHAPTER US | 1G2u culmpnunee suc

site topography

“Fe tes considered o be on a moderate il or stze9 hil, as specif in fqure 2 ths within the orange zones

Free carer Othowoe the sto cansicoed to Be on nominal fat ground forthe purpose ofthe wind assessment

25% ‘50% hill length 25% ‘Slope fength 190% slone iengen 3.3

ee —

i S086 ena

Moderate cliff or escarpment, average slope 1 : 200 1:5.

Slope length 150% slope length

<—_——

509% onath

> —

‘Steap hil, average slope above 1:5. ‘Steep af or escarpment, average slope above 1:5,

fgure 3.3: topogracical locations on which ast is consdared to be on a moderate or step hillor escarpment

{A site is considered to bein a city if tis in an area

in which at least 15% of the surtace is covered with

buildings and their average height exceeds 15m. The

site should be at least 2km from any surrounding large

‘open spaces, countryside or coastline. The scaffold

‘should be within approximately 30m of these buildings

in order to be effectively shielded.

“The wind exposure of a sit in a city can be reduced

by one classification. This reduction may be used in

‘addition to the soasonal reduction if a city scaffold

is standing over the spring or summer. The wind

classification may not be reduced below low.

NOMWirgaaINOD SNIGIOSAVIS ANY SSIDO¥ THNOLYN,

NASC

= Standard unclad independent

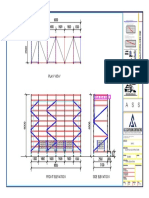

An uncad tube and ting ted independent scaffold with 2.0m maximum it heights

Design height

Mesienum height: 16m tothe top kt

Maximum loading

One it oad, plus one It 50% loaded, por fagade with

moading |

4 General purpose 2.0kN/m#

4 Hoavy duty 3.0%N/m?

Inside boards loaded to 0.7SkNven? atthe working it

Foundation design leg load {forthe client) 16.0kN

(18.65KN if a cantiever fan is included,

Ties

Y 1x 3.5kN flight duty) tle per 16.

Y Max 4.0m between te lines (ied at etornate lit):

Max 4.0m horizontal distance between vertical ti nes.

Location, Add-on features

Vali in the British Isles where the site wind exposure is not” This scaffold may optional include a TG20 compliant

‘extreme as defined in TG-20:13 chapter 03, bridge, pavement ft, cantiever fan, loading bay and

ladder tower with a 120 compliance sheat for aach

Criteria

To be erected as a TG.20 compliant ted independent scaffold as described in TG20:13 chepter 06:

8-5 main boards and up to 2 inside boards wide; Fagade braced in every elevation, one ect per six bays: }

Maximum it height: 2.0m: Ledger braced at alternate standards and at end frames:

Maximum bay ienath: 2.0m (oad class 8), 1.8m (cess 4); Double querd ras and toe boars at boarded lit (hiplo

Maximum transom spacing: 1.2m (load class 8), 0.9m Suara permited atthe top It required);

(load class 4) Y Single guard ras at unboarded lifts;

May not be clad with debris-netting or sheeting; Internal edge protection provided where required

Y Boerded at any number ofits; Tied in accordance with T@20:13 chapter 07.

Tied to an impermeable fagade (no significant openings}:

Sign-off

Mimi working leat: [J] 2.0xNre []2.0Kime

Company: 2 ‘Scatfold reference: a

NASC membership 90%: ..ee.--+ . Site reference: “

Name: oo Signature:

Position: sonst ceveeeseeee Date! a

7620 complanee sheets for scatlds of greater height and of other coniguratons are avaiable rom the TS 20 eGuide.

Uso of this NASC document doesnt infer NA

nembershp, Go to wwwn.nasc.org uk to contim membership.

Location.

Valid in the British isles where the site wind exposure is not

extreme as defned in TG.20:13 chapter 03.

Criteria

v3-

main boards end up to 2 inside boards wide;

Maverumn it height: 2.07;

Maximum bay length: 2.0m foad class

1.8m (lass 4

Masirnumn transom spacing: 1.2m (load ciass 3), 0.8m

(oad class 4);

‘Clad with high-permeabilty debris-netting; no sheeting:

oarded at any number of its

Tied to an impermeable fagade (no significant openings

Sign-off

Maxérrum working load

2oknim? []3.0KWim?

‘Company

NASC membership n0%:...

Name:

Postion:

7620.

iance sects for scaffoiss of greater height and of othe

ership, Go to ven.

enarion us

standard debris-netted independent

‘tube and tng ted independent satfokd with 2,0m maximum it eights, ay oF Para

1 with permeable debi noting,

Design height

J Maximum height: 16m othe top HR

Maximum loading

One ift loaded, phis one It 50% loaded, per fagace with:

3 General purpose

4 Heavy duty

Inside boards loaded to 0.75kN/m? at the working it

Foundation design log toad (forthe client): 16.1 kN.

(1 BkN ita cantilever fan is included)

Ties

VY. 4x8.5K0 (ight duty tie por 16m*(r

V1 6:1 KN (stendard duty) tie per 18m high wind sites)

Y- Mex 4.0m between to lines (tied at alternate Hs}

roderate wind sites

Max 4.0m horizontal distance between vertical te tines:

Tred at the top lit at ledger-breced standards

Add-on features

This scaffold may optionaly include a TG20 comptiant

bridge, pavernent lf, cantiever fan, loading bay and

ladder tower with aTG20 comptance sheet for each.

Tobe erected as aTG20 compliant ted independent scafod as described in TG20:19 chapter 08:

V Fagade braced in every elvation, ane sat par sik bays:

V Ledger braced at alternate standards and at end frames;

Double quard rails and toe boards at boarded its

‘Single guard rails at unboarded its:

/- Internal edge protection provided where required.

V- tructuraltransoms at ledger-braced frames when the

Scaffold height exogeds 4m and the site wind is high

hapter 7.

“Tied in accordance with 7620:

Wind exposure: [C7] Low or Moderete

Orn

Scaffold reference:

Site reference:

Signature:

Date: :

Lonfgurations ara avaiable from the 7620 eG.

2.orquk to confrm membership

NUNeEIaaINOD DNITTOIAVDS ANY SSIDOV TYNOLLVN

NASC

¥th spon irom

Standard sheeted independent |

‘A lube and fiting ted independent scaffold with 2.0m maxirnum lt heights,

Location

Vali in the British isles where the site wind exposure is not

‘extrame as defined in TG20:13 chapter 03,

Criteria

‘To be erected as a 7620 compliant tied independent scafold as

3-5 main boards and up to 2 inside boards wide;

Maximum itt height: 2.0m;

Maximum bay length: 2.0m (load class 3), 1.8m (lass 4);

Maximum transom spacing: 1.2m (load class 8), 0.8m

oad class 4)

Clad with impermeséle sheeting:

Board at any number of tts;

Tied to an impermoabio facade (no signiicant operingy)

Sign-off

Maximum working load

oven CJaomvme

Company: cose .

NASC membership no%

Name:

Postion:

720 compliance sheets for scatfols of greater height

2 of his NASC document doesnot nf NASC members. Goto wawnase.orguk to

Wyorparay cua vin inpemestiostectng, |

Design height

18m to te top it, 14m fr 2 side boards in nigh

Maximum loading

One it loaded, plus one it 60% loaded, er fagace with

wing

3

General purpose 2.0kN/m?

Heavy duty 8.0KN/mt

Inside boards loaded to 0.75kN/m? at the working it

Foundation design leg load (for the cent): 16.4kN.

(19.9kN if a cantiover fan is included,

Ties

"1X 6.1KN (Standard duty) ta per 16! (moderate wind);

1X6.1KN (standard duty) tie per 13mm? or 1 x 9.4 kN.

(class 6 standard duty) tie per 16? (high winds

Max 4.0m between to ines ted at alternate Hs);

‘Max 4.0m horizontal distance betwaon vertical te ines;

Tec atthe top it at ledger-braced standards,

Add-on features

This scaffold may optionally include a 720 compliant

bridge, pavement ift,cantlever fan loading bay and.

lacider tower with a TG.20 compliance sheet for each,

described in TG.20:13 chapter 06:

Fagacie braced in every elevation, one set per six bays;

Y Ledger braced at a

ie Standards and at end frames;

Double guardrails and toe boards at boartied its;

Single guard rails at unboardd tits

Internal edae protection provided where require

Y Tied in accorcance with TG20:18 chapter 07;

Structural butting transoms at every node point connected

to the inner and outer ledgers with right-angle couplers or

equivalent

Wind excosure: [Low oe Moderate

Cron

‘Scatfold reference:

Sito reference:

‘Signature:

Date:

20 of other configurations are avaiable from the TG20 eGuide

nfm membership,

Bp eeoeseaeseeueepeeasrn

NASC

CHAPTER 03 | TGZU compuance sneers

Unclad independent with transom units

‘An nclad tiod independent scald with 2.0m maximum it heights, assembled fom tubes, fitings and 20-13 compliant

Tofabreated structural transom units. Ledger bracing may be omitted,

Location

Vala inthe British sles where the site wind exposure is not

extreme as defined in TG20:13 chapter 03.

Criteria

“Tobe erected as a 7G20 compliant ted independent scaffold as

¥ 1620-18 compliant prefabricated structural ransom units

provided at evory standard-to-iedger intersection;

Ledger bracing may be omitted from this scefoid to the

‘maximum safe height specific:

35 main boards and up to 2 inside boards wide;

Maximum it height: 2.01

Maximum bay length: 2.0m foad class 3}, 1.8m (ease 4)

Maximum transom spacing: 1.2m (oad class 3), 0.8m

(load class 4);

Sign-off

Mavirum wesking oct [1] 2.0%N/n?

3.0kN/m*

Company:

NASC membership 10? ..

Name:

Position:

Design height

¥16mto the top it, 14m with two inide boar

‘Maximum loading

Ono it loaded, plus one it 50% loaded, per fagad wit

2.0KN/mt

3.,0kN/m?

3 General purpose

4 Heavy duty

Inside boards loaded to 0.75kNV/m? atthe working lit

Foundation design lag load (forthe client): 13.8kN,

Ties

YY 1x3.5KN (ight duty tie per 16m

Y Max 4.0m between tis ines (tied at alternate its

V-Max 4.0m horizontal istance between vertical tie Ines.

Add-on features

This seatfold may optionaly inctude a TG20 compliant

bridge, pavement kt, loading bay and ladder tower with a

G20 complance sheet for each (s9e the eGuide for fans)

deseribed in 7620:13 chapter 06:

May net be clad with debris-netting or sheeting:

Y Boarded at any numberof tits;

Tied to an impermeable facade (no sigaicant openings}

.gade braced in every elevation, one set per six bays:

Double guard rails and toe boards at boards its

Single guard rais at unboarded fits:

internal edge protection provided where require

V Tied in accordance with TG.20:1S chapter O7.

Scaffold reference:

Site reference: .

Signature

Date:

©7020 complance sheets or scafois of greoter height and fothar configurations are avaiable fram the TG20 etude

Use of thi NASC document does natn

JASC membership, Go fo wwrwnasc org.uk fo confi membership.

NOLVEIGRINOD SNIGTOLIVDS ANY SSEDO¥ THNOLWN

NASC

Debris-netted independent with transom units

A tied independent scaffold with 2.0m maximum lft heights, partial or fully clad with high-permeabilly debris-netting,

‘assembied from tubes, fitings and 7G 20:13 compliant prefabricated struct

Location

Vali in the British leo where the site wind expcaure ia not

extreme as defined in TG20:13 chapter 03,

Criteria

To be erectedas a TG20 compliant tied independent scatfold as described in 1620-13 chapter 06:

Y 1G20:13 complant prefabricated structural ransom units

proved a every stancard-to-ledger intersection;

Ledger brecing ray be omitted from this scaffold to the

maximum safe height spectiod;

36 mainboards and up to 2 Inside boards wide;

Maximum lift height: 2.0m;

¥ saxinum bay length 2.0m oad class 3, 1.8m (las

Maximum transom spacing: 1.2m feat lass 9), 0.9m

(load class 4);

Sign-off

Maxirun working oad: [C]204Nvm? []smNin?

‘Company:

NASC mambership no...

Name:

Postion: ee

With support fom:

‘ransom units. Ledger brachg may be omitted.

Design height

16 mte the top ltt wth upto one inside board; 14m (oad

c2ass § or 12m (oad class 4) with two inside boards

Maximum loading

One itloaded, plus one tt 909% loaded, per fapade wth

aA ERA ts |

General puposo— 2.0kN/m?

4 Heavy duty 3.0kN/m#

Y nsice boards loaded to 0.75kNin? atthe working it

Founclton design lag lac (or the chen): 13.

Ties

1 9.5KN\ ight day te par 18m moderate win sas);

1 x6.10\(tanaard aury ve per 15m fugh wind ste);

5).

V Max4.0m horizontal distance between vertical tia ines;

Y Max4.0m betwen to ines (tad at alternato i

Tiedt the top lit at alternate standards,

Add-on features

Tria scaffold may optonally inckide a 70.20 comaliant

bridge, pavement it, loading bay and ladder tower with a

20 compliance sheet for each (800 the eGuide for far).

Clad with high-permeabilty detxis-netting: no sheeting:

Y Boarded at any numberof its;

Ted oan inporeatetaade ro sgntcan| opening A

Facade braced in every elevation, one set par skxbays:

Double guard rails and toe boards at boarded its

Y Single quar rails at unboarded its

Internal edge protection provided where roqured:

Ted i accordance with T20:18 chapter 07.

Wind exposure: [T] Low or Moderate

Clo

‘Scaffold reference:

Site reference;

Signature on

Date:

CHAPTER 03 | TG20 compliance sheets

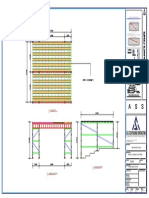

Pavement lift

‘Apavoment ft for TG.20 compliant ted independent scatolding as described in T620:13 chapter 10. The cross symbols

below indicate a ine of ties at alternate (oreferably ladger-braced) standards as dascribed in TG20:13 chapter 07

Plan bracing at

every bay of the

Methods of stably: tie markers indicate a fine of tes at alternate standards,

Re pavement ft must be erected and maintained in accordance wth the requirements ofthe local Highway Author undor an

appropriate street or pavement closure cence. Further information is provided in SG24: Guidance on protection of the put

Criteria.

Suitable for TG20 compliant tied independent scaffolang; Ledger bracing omitted below the fst it

‘Maximum 2.7 m pavement itt height First it to be close-boarded or double-boarded with an

Mrimum 2.44m clear headroom, mediate waterproof membrane;

Pavement it stabilsed with method (a, (0) or (e, as

Five boards wide plus up to two Inside boards; lustrated above and described in T&20:18 chapter 10,

Signott

[E71 @ Second it ted, plan beac

[JB Pavement tes at atrate () Second it tied no more than

every bay ofthe pavement

(ledger braced) standards 4.0m from the ground,

Company; sseonsssss = ise. Scaffold reference:

NASC membership no": caves Ste reference:

Name es Signature: a

Psion: 7 sas Date ita

“Bear NAS docunont coe nate NASC membership. Go fo was or. to confi meters 3

NOLWUIGLINOD SNIOTOLIVDS GNV SS290¥ TVNOLLYN

EES

compliant ted independent scaffold as deserved in 1520: 13 cha 09

Design height

Suitable for use vthin 8 TG20 con

scaffold of 16m maximum height"

Y The supporting standards should be douiied where the

foundation design tag load excexis 22,0HN

1pfant tid independent

‘suppattiog up to 8 its

4 6 8

199 22 245

= Two-bay bridge

Beam specification

‘Supported by a pair of 805mm (ri

beams or equivalent stoa! or aluminium ittice oF

sth the folowing minimum structural properties

‘Safe working moment resistance with 12.5KNm

top chord restraints at 1.2 m spacing

Safe working shear resistance skh Lach hoe seve Baten

Beam fixing and bracing

‘Boome atthe inner and outer faces, ted to ead!

the top and bottom chords with righ-an

‘Bears braced with tubes and right-angle or sw

to form "box girder

v

between bottom chords at 2.4m spacing:

Plan braced in the top thi of the beams at

‘Section bracing at 2.4m spacing.

sign-off

“The bridge wl bo within TG.20 compliant ted in

‘Company:

NASC membership 70%

Name:

Postion:

ot npn

inimum) deep steel ladder

le couplers.

Lacing tubes between top chords at 1.2m spacing and

186 apoument does ne

Bridge specification

Y- Maximum span of 4.0m (8.6m for load class 4 scaffolds

Y-Abteast one braced bay of suattoiing io roquiead both

Sides of the opening snd between openings;

The opening may extend vertically to form a partial

poring in the scafotd or extend the foundation:

The scaffold isto be tied at the supporting standards.

Pan baci Lacing te at ho top chants

unit bears

horde ae pune

{acing tbe bw te bt chads

hy standart athe aopotig senards

a eure, flowing guidance tom te beam manila

Wel coupias — Scaffold bracing

the bridge at the nner and

Fagade braced both sides of

pening, to the height of

‘within six bays of the oF

+.2mspacing:

Y- Supperting standards ledger braced both sides of the

‘pening to the height ofthe bridge.

dependent scaffolding of maximum working load:

2owvine []aokwine |

j

‘Scaffold reference:

Site reference:

Signature:

Date:

1 sheets for bigs within scafolas of oreater|

infer NASC membershi.

ott a0 aval rm the T6z0 0Gute.

Go towmw.nasc org.uk 0 confirm members.

NASC

CHAPTER 03 | TG20 compliance sheets

Three-bay bridge

‘A bidge supporting a tee-bay opening in a TG 20 compl ted independent scald as described in 720-19 chapter 09

£

Beam specification

‘Supported by a pair of 610mmn (minimum) deep stee! lattice or

Unit beams or equivalent aluminium beams withthe folowing

minimum structural properties

‘Safe worlang moment resistance with 27.0kNm

top chord restraints at 1.2 m spacing

Safe working shear resistance 15.6KN

Beam fixing and bracing

Beams atthe inner and outer faces, fixed to each standard at

the top and bottom chords with right-angle couplers

‘Beams braced with tubes and right-angle or swivel couplers

toform a ‘box gid’

acing tubes between top chords at 1,2m spacing and

‘betwoen bottom chords at 2.4m spacing,

Plan beaced inthe top thicd of tha beams at 1.2m spacing;

Section bracing at 2.4m spacing

Sign-off

Design height

Suitable for use within a T620 compliant tod independent

Scaffold of 16m maximum height”, supporting uo to 8 fit;

The supporting standards should be doubled where the

foundation design leg oad exceeds 22.0 KN:

a

(FOGRIORIBRAN) 17.0 225 240 257 292 207

Bridge specification

Maximum span of 6.0m (5.4m for load cass 4 scat

A least one braced bay of scaffolding is required both

‘ides of the opening and betwean openings;

The opening may extend vertically to form @ partial

‘pening in the scaffold or extend tothe foundation;

Y The scat

isto be tied at the supporting standards,

Pan bracing Lacig tube atthe tap chords

Lacing tube above the botom

chords athe purehaons

Lag ube below the batt chords

atthe supporing standars

tam hres wh £N74 Cass B couple, or chek couplers prvise,

ire bage supports 7 oF Bite atove with te hide Boards

Scaffold bracing

Facade braced both sides ofthe bridgo at the inner ancl

‘outer faces, within six bays of the opening, tothe height of

the bridge;

Supporting standards ledger braced both sides of the

‘pening to the height of the bridge,

‘The bridge willbe within TG 20 complient ted independent scaffolding of maximum working loact [[] 2.0Kw/me []3.0xn/m=

Company:

NASC membership no.

Name:

Paton:

1720 compliance sheat for gas wihin scat of rater height are evalabe rom the 1820.

Use of is NASC document does notin NASC membarshia, Goto wwrw.nase. org.uk

‘Soatfoid reference:

‘Ste reference:

Signature:

Date:

NOUWUICEINCD SNITIOAIVDS GNY SSI99¥ TYNOLYN

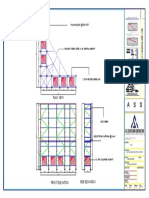

= Cantilever protection fan

9

1 by 276.20 compliant tod independant scald as described in TG2O:19 chapter 10

‘A cantilever protection fan support

Design height

Suitable for use wth 2 7620 conan tod indapandont

Sore tower aca wah maim 2.0m bays and a

rapenunn eight 1.0m to the top HA"

Fan specificettion

Maximum one fan per scaffolding etevation,

J Minmam clearance of 244m for pedestians and

sree: verdes, subject to lcal Highway Aunty

requirements

Y Maxirnum fan width: 6 boards

Ties

“The it supporting the fan must be tied at alternate (preteraby

ledger-braced) standards with:

3.5K) fight duty) tes if the sestold is unclad,

V6.1 KN (standard duty) tes if the scafold is debris-netted

Oris sheeted and in a site with moderate wind exoosure

V Q:1KN (class B standard duty) tis ifthe scatfold is shestedt

‘and in a ste with high wind exposure

Fan usage Fan construction.

Supported by propped cantilever priraial transoms

rratching the bay spacing of the main scatflc

Connected below the inner ladger and above the outer

jedger ofthe rain scaffold with right-angle couplers:

| Intended to catch small objects such as fitings fromm 8

‘maximum vertical distance of 6.0m;

Protection fans cannot be guaranteed to catch and retain

faling objects and must be used as part of @ safe syste

of work based on a risk assessrrent Preferably supported by raking props connected to the fit

| | The effectiveness of a fan less than six boards wide will be below, or by raking hangers to the lit above, at ‘the bay

reduced accoingy. Spacing ofthe man scafl:

Fan loadin: V Docked with 38mm thick timber sao boards, tose

Ys g ad of 0.75KN/ boarded and restrained from liting off,

.spports a maximum loa of 0.75kN/r

pet “ Decking supported by intermediate transorns with a

% Must nat be used forthe storage of matrals. Agaregate® ———mzximum spacing of 12m:

fx snow must be cleared prompt.

V Toe boards and quard ais must remain in pao atthe it

rapportng tha fn

sign-off j

‘Wind exposure: ‘Low or Moderate High 1

wo more than one su fan wi be ted per ovation of TG20 compl fed independent seaoksng. i

cos bs ated ioe

NASC membership 900% -eeeeeee-o—~ ‘Site reference: ?

Name : Signature

Poston: ee Date: -

7 sv@z0 camgtence sects or cntoer protection fars win safe of rater Deg we aveiae fom Pe 1220 ec |

vrven ot NAG document des na ne NASC member. Go To venues auto conker PamDaSAP

NASC

Standard ladder-access tower

CHAPTER 03 | 1620 compliance sheets

th ston om

‘A scafolding tower forthe provision of external ladder access toa ted independent scald

Location

Valin the British Isles except where the site wind speed is

extrame as defined in T320:13 chapter 03.

Criteria,

Design height

‘Suitable for use with a 720 complet tied independant

‘scaffold to 2 maximum height of 16.0m to the top it

Mexximum loading

Designed to support up to six its simultaneously loaded

with personnel fo a maximum load of 1.0 kN/m™,

Foundation design leg load or the client): 20.44;

| Must not be used for the storage of materials

Ties

Tied at the end standards at aternate its wit,

¥ 3.5KN (ight duty ties if unclad,

Y 6.1KN (standard duty) tes if debris-netted orf sheeted

and in alow wind site;

9.1K (class B standard duty) tes if sheoted and ina

moderate wind site,

12.2KN (heavy duty) tes if sheeted and in high wind, or

sStandrd duty tes atthe end standards at every lit

Add-on features

Design advice may be required it any add-on features not

Stated on this compliance sheet are attached to the tower.

Tobe erected 28a 7620 ladderaccess tower or a TG20 ted independent scaffold as described ih TG20:78 chapter 08;

Maximum it height: 2.0m,

Maximum length: 2.0m bays (2.1.8 for load class 4

scafiolds)

‘Maximum transom spacing: 1.2m;

3-5 boards wide:

Fazade braced at the outer face ofthe tower;

edger braced atthe end faces ofthe tower

May be clad with sheeting or debis-netting:

Sign-off

Wind exposure:

tow F}ocerate [ign

Company:

NASC membership no ®:

Name:

Postion:

7620 comptance sheets fr adc towers to access scafoling ofa greater hight are ava fom

~” Bouble guardrails and toe boards at boarded ite;

Single guard rais at unboerced itts;

Tie tubes connected tothe inner, middle and outer end

standards or ladgers with right-angie couplers,

©’ Wing braced back to the main scaffold at alternate tod)

lits and the top it. Plan bracing may be provided Instead

of wing bracing if preferred;

End transoms connected with right-angle coupirs at th

top wing-braced it itis not ted,

‘Scaffold reference:

Site reference:

Signature:

Date:

NOMWISCEINOD SNITTOLIVDS GNV SSEDOV-TVNOLLVN,

7620 eGuide

*Us9 0/188 NASC document does nt ine NASC membership. Go to vowwnasc of uk sont remberstip,

i

NASC

Stondard loading bay

‘rrenoroed seftkdng tower or the storage of palets of materia, whien may be carey fact by machen ical means.

Location

\Valid in the Bish isles where the site wind exposure is not

extreme as datined in TG20:1S chapter 03,

Criteria

Design height

¥- Suitable for use with a T62¢

Seaffold to a maximum height of 16m 0 t

Maximum loading

Y Loaded on one lift to @ maximum of 10.0 N/m

Foundation design lag load (fr the chen) 22.0.

plant ti indeperdont

top it

Ties

V Tied at the end standards at alternate its, to the duty

specified by the main scaffold compliance shoe

Permitted dimensions

Y Maximum length: 2x2,0m bays (2x 1.8m bays if the rain

scatfol is of load ciass 4);

Maximum if height: 2.0m;

Maximum width: 5 boards;

Y Maximum transom spacing: 0.45m.

Add-on features

Design advice may be required if any add-on features not

stated on this complancs sheet are attached to the tower.

Jo be erected as @ 1620 compliant loading bay as desorbed in T320:19 chapter {2

/ Fagad braced at the inner and outer faces of the tower:

Ledger braced at each pair of standards:

Principal transom connected with right-angle couplers 10

the outer, middle and inner ledgers at each nods point:

Wing beacad at alternate (ted) Its end the top I

Tne loaded tit to be supported by a palr of 205mm deep

steel ladder bears, or equivalent stest or aluminium atioe

or unit beams, as defined in T-20:18 chapter 04;

Beams fixed to each standard atthe top and bottom

chords with right-angle couplers;

May be loaded by mechanical means;

Sign-off

Company: a

NASC membership no'®:

Name:

Position:

Y ‘Asupplementary couplers required under both of the

ppottom beam chords at tne midale standard unless EN74

class 6 couplers are used:

/ Boome used instead ofthe ledgers at the to lit or Fixed

eow them. fixed below them, the ledger and beam

should be fixed with swivel couplers every 1.0m:

/’ Beems let in place at each lit or moved progressively:

Single querd ras required at unboarded tits:

Voces via @ gale oF removable double guard rails. Oouble

fond guard ral, toe boards and brick guards required

% May not be clad with sheating or debris-netting.

‘Soaftold reference:

Sie reference:

‘Signature:

nen

Date:

cvrezocemplance sess oroaing bays win scafing of arate hight ar aveaie tn he TS20 6A. |

ruse orbs NASC dooumant doesnot fr NASC members, Go fo wrwn.nasc og uk fo crf mamDaP.

NASC

CHAPTER 03 | 7G20 compliance sheets

Butted interior birdcage scaffold

‘A securely butted birdcage scaold for use in interior environments not exposed to the wind

Location

Vali only within an enclosed building shielded from the wir

‘A bespoke design is required if erected outdoors, within an

‘9p8n structure, or in any environment exposed 10 the wind.

Criteria

Design height

Maximum height: 10.5m to the top i

Maximum loading

°Y Top itt and up to one perimeter if loaded at any time to:

1 Very light duty (0.75kN/m2

2 Ugh duty 1.8kN/m?

3 General pupose —-2.0kN/m?

Foundation design log load (for the client): 14.3KN,

Permitted dimensions

1 21m 2.1m boards)

2 1.9m 1.9m (@ boards)

3 1.7m 1.7m (7 boards)

Add-on features

A gin whee! may be used to it a maximum of SOkg,

DDesign advice may be required if eny add-on features not

Stated on this compliance sheet ae attached to the scaffol,

‘To'be erected as a TG20 compliant interior tube-and-iting birdcage seafold as described in TG20:18 chapter 18

Securely butted at the top it at alternate bays against

the pamanent building structure i all directions,

© Maximum it eight: 2.0, or 2.51m atthe fst it;

Top Ht boarded. Optional boarded perimeter bays (5

boards wide) and ladder bays atthe its below:

~” One bay braced at every trame for every six bays along the

ength and six bays along the width

Souble guard rails and toe boards at boarded sections of

Sit except whore there is no risk of injury as defined by the

risk assessment,

Sign-oft

‘Company: soreness

NASC membership no®

Name:

Position:

7920 complarce sets or bccages tha are hee-standng, ted ero med support are avalible tom the 7620 ecuce

Single guard rails latin place at unboarded its;

Ledgers connected with right-angle couplers at al its;

Principal transoms connected to standards with right-

‘angle couplers. Band and plate couplers may be usod at

the top it

Board transoms connected with putiog couplers at 1.2m

Spacing (oad class 1} or 0.9m spacing load class 2 or 3}

Load ciass 2 oF 3: a supplementary coupler is required

below each connection between the ledgers and intornal

standards atthe top it unless EN 74 Glass B couplers are

sod,

‘Scattold reference:

Site reference:

Signature:

Date:

‘sea tis NASC document doesnot ner NASC members. Go to wwew.naSc019 uk fo ant membership,

a

NOWWICEINOD ONICIOAIVOS GN SS290¥ TYNOLLYN.

13

NASC

Putlog scaffolding

‘An unclad putiog scaffold with a maximum It height of 2.0m.

Design height

v

v

Location

\Val in the Brtsh Isles where the site wind exposure is not

‘extreme as defined in TG20:13 chapter 03,

Criteria

To be erectedas a ted TC

¥ 9-5 boards wide:

Y Maximurn it height: 2.0;

LUnclad or with brick guards. No sheeting or dobrie-netting:

Maximum 4,0m vertical interval between tie ines:

‘Maximum 4.0m horizontal interval between tie Ines;

‘A least one set of fazade bracing in each elevation oF

‘every six bays if longer

Y Ledger bracing at alternate bays, tothe fst it only:

SKN

Sign-off

‘Maximum workhng load

20x? [1] 3.0kN/m?

‘Company:

NASC membership no":

Name:

Position: .

Maximum loading

Ties

YY 1x3.5kN (ight duty) te per 16mm?

Permitted dimensions

‘Maximum bay length: 2.0m for generel purpose

Add-on features

Y- Agin wheat may be used to lit a maximum of SOks,

Design advice maybe required if any add-on features not

‘tated on tis compfance sheet are attached to the scatfolc

1620 compliant tube-and-fiting puitog scaffold as describe

longitudinal foot tle 150-200mm above the base

Maximum height: 6.07 to the top it

‘Ono it loaded, plus one lit $0% loaded, per facade with:

20KN/m?

3.0kN/m?

3 General purpose

4 Heavy duty

Foundation design lag load (for the chon: 10.7 KN.

seatfoding or 1.8m for heavy duty scafolding:

Maximurs putlog spacing: 1.2m for general purpose

‘soatidding or 0.9m for heavy duty scafoiing.

1 in TG20:13 chapter 14:

An underslung inner ledger at every It;

Double guard ras and toe boards at boarded its;

Y single quord ras at unhoarded its;

End quard rails must be connected to an inner standard

May be ted to a permeable facade with openings.

| Mortar joints should be alowed to sufficiently cure befors

Ihe prceworle io used a8 a support or te anchorage.

‘Scaffold reference:

‘ste reference: 2

Signature =

Date: .

ns ofthis NASC document dos not ier NASC members. Go fo war.nasc craukto confi maeR

40

CHAPTER 03 | TG20 compliance sheets

NASC

Lift shaft tower

A scafolding tower butted onal sides at every lft sutable for use in an enclosed lit shat

Design height

Maximum height 34.0m to the to

Maximum loading

Loaded on up to 2 working lifts with up to 0.75KN/m

Foundation design og load (fr the ln): 28.5KN

Permitted dimensions

Y Maximum length: 2.77:

Maximum with: 2.7m;

Maximum transom spacing: 1.2m,

Location Add-on features

wind. Ain wheel may be used to it a maximum of 60kg.

Vall onty within an enciosad it shaft shielded! from

Design advice may be required i any add-on features nat

Stated on this compliance sheet are attached to the scat.

Critena,

Tobe erected as 6 TS20 compliant it shaft tower scaffold as described in T&20:13 chapter 16:

Y Maximum lit height: 2.0mm; May be clad with sheeting or debris-netting

Any sumber of itis may be boarded; Double guard rails and toe boards at boerded ltt i

required by the risk assessment;

Single guard rails at unboerded lit if required by the risk

Mavirnum of tw lifts loaded with personnel and material;

Y Seourly butted in al four drections at every i pel na z

By» ecinsrstes nteasad do tothe eh 3

é

B &

8

| g

WE sonott é

Vy. i

FP company . cess Scaffold reference: . a é

2

I NASC membership no® . Site reference: cose 7

8

Name ccc eves Signature - ¢

VE rest a oat a:

g

| 7620 comptance shoots eit shaft owers of grater highs aro avaiable om the T620 eGuice 4

‘Use of ns ASC document coes not infer NASC memberstio. Golo warn nase org.uk ta

rm membersti,

NASC

= Interior free-standing tower

15

190 in an enclosed building shielded fromm the wind.

‘A tea-stancing stationary scaffolding tower suitable for us

Maximum loading

1 Very ight duty access O.7SKN/m®

2 Light duty work 1.SKN/

3 Heavy duty tower 20KNent

Foundation dasign leg load (forthe client): 16.5 KN.

Permitted dimensions

1 2.Imx21m 0.8m

2 2Amx 2.1m Bam

3 4.8m x 1.8m 7am

Y Minimum pase dimension: 1.2m along the length and

wath;

¥ Meximum height no greater than four tines the minimum

base cimension.

Location Add-on features

VA gin whee! may be used tit a maxsrum of Ok.

‘May not be used outdoors, in any open structure, orwitnn Design ackice ay oe required i any add-on features not

any environment exposed to the wind. ‘lated on this compliance sheet are attached to the scaffold.

Valid only within an enclosed building shieted from the wind,

Criteria

‘Tobe erected as a TG20 compliant interior stationar

& Maxienum it height: 2.0m:

1y toe-stancing tower scald as descrip in TG20:18 chapter 1

Standards should preferably be unjointed tubes. Any joints:

Y exmur ransom spacing: 1.2m: shoud be sleeve couplers above the frst two Hts,

Double guard rails and toe boards at boarded its

Y- Any number ofits may be boarded:

Single guard rails at unboarded tits;

VY Naximum of one it loaded wth personne end mates;

rome connected wth right-angle couples:

Y Braced on all sides at every lit; End wansoms co —

Y Ladéer openings protected wit rapdoars or sila

Y Pan braved at alternate its including the top

Y May be clad with sheating or debris-netting.

Sign-oft

Maximum wong oad: [Jo.zstevm? [[]1.50knm# [2.008

‘Seatfold reference:

Company:

NASC membership no 7 Site reteronce - 2

Name: Signatur:

Poston: 7 Date:

iyo of NAGE docurant does note NASC manbrsip, Goo ww nso. 19 cant mambo

42

CHAPTER 03 | TG20 compliance sheets

NASC

Exterior free-standing tower

A fge standing stationary scafccing tower suitable fr use in external envianments within a wind management systom

Maximum loading

U

1 Very ight duty access 0.75kN/m?

2 Light duty work 1.5kN/m#

3 Heavy duty tower 2.0kN/m?

Foundetion design leg load (forthe cant): 9.9kN,

Permitted dimensions

1 2.7mx 27m 80m

2 2Amx 24m 63m

3 1.8m x 1.8m sam

Minimum base dimension:

wiath;

‘Maximum height no greater than three times the micimum

base dimension

22m along the length and

Wind management Add-on features

‘The tower must be cismentied or termporary kentledge or