Professional Documents

Culture Documents

Wind Load On Facade Scaffolding

Wind Load On Facade Scaffolding

Uploaded by

Abdul Hameed0 ratings0% found this document useful (0 votes)

68 views13 pagesOriginal Title

wind load on facade scaffolding

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

68 views13 pagesWind Load On Facade Scaffolding

Wind Load On Facade Scaffolding

Uploaded by

Abdul HameedCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

Journal o Bullding Engineering £2 (2021) 102816

‘Contents lists available at ScenceDine=t

peers

Breast

Journal of Building Engineering

ereevien reeee enenene ee eeere ee

Wind load on facade scaffolding without protective cover - Eurocode and Si!

in-situ measurement approaches

‘Tomasz Lipecki , Paulina Jamiriska-Gadomska, Ewa Blazik-Borowa

aro of Socal Macha Labi testy of Tee, Lb Paand

ARTICLE INFO ApsTRACT

Kowrie ‘This paper presens an analysis of seafodng response co ste wind action, bared on diferent approsches. The

Sealing stale wind load was adopted according to Eurocode standard that required separate calculation forthe load

Wind acto ‘ting perpendicular lod ease B) and parallel (load ease C) tothe fagade ofthe bulding on which the sea

tees remem folding was altached, Inthe second approach, the wind load was calculated onthe bass ofits measurements

performed on safodngstractres ston constriction sites (oa cge A), The research was carried ot on 61

fogade seaflding structures without protective covers. Models of every scafolding were created inthe Fini

Element aye, based on their ral geometry taken from geodete measurements, Statlestrength analysis

Allowed comparison ofthe satfolding response determined by node displacements, normal ses and ail free

resulted inthe greatest axa force or normal ses in elements In a few eases, the load Based on in-situ tests

caused greaer response ofthe structures and the permisble suess and axl force value in te elemens were

taceeded. These seafolding srctures were ually deiached from the wall and twisted out of plane. Analyses

pointed out that the sefflding during is operational se eould experience a load other than perpendicular oF

Paralle to its fagadeas is given in Eurocoe

1, Introduction

The main loads acting on scaffolding are: deadweight, service load

‘and wind action, According tothe FN 1211-1 standard {1], two varl=

ants should be analyzed when designing fagade scaffolding. The first

‘variant applies when itis in use. Work on scaffolding can be maintained

‘only for the wind velocities below 10 m/s [7]. This variant takes into

‘account the service load and the wind action with constant value over

‘the entire height of the sucure, corresponding tothe mean wind ve-

locity of 10 mys. The second variant describes the situation when the

permissible velocity of 10 m/sis exceeded and employees are prohibited

from working on scaffolding. This case assumes thatthe wind acts with

maximum velocity, and takes into aecount the vertial profile of wind

velocity and turbulence.

The EN 18211-1 [i] recommends to take into account in

static strength analyzes the wind action inthe direction parallel to the

fagade at which the scaffolding stands and in the direction perpendicular

to the facade separately. The standard als indicates how to consider the

‘impact of the building at which the scaffolding stands on the wind action

~ Comrsponding author

mal addres: ipccki@pollb pipe

hutps//doi ong/20.1016/ joe. 2021102516

by introducing site coefficient. The research described in this work

shows thatthe system of forces resulting ftom the wind action can be

‘more complex than assured in standards, Therefore, the question arises

‘whether the standard recommendations guarantee that the design is

always on the safe side from the point of view ofthe falure-fee oper

ational use of the construction

Scaffolding in iterature is described relatively often especially inthe

‘eld of laboratory tests and FE (Finite Element) calculations focused on

‘the strength of individual elements and connections as well as entice

scaffolding, eg: [3-8]. Several important works referring to some

extent to the topics discussed in this paper are described below. The

‘paper [I presents the results of research onthe reliability of saffolding

A series of numerical analyzes were carried out in wich the material

‘properties ofthe scaffolding components and the loads were random

variables with @ normal distribution, The conclusions mainly concern

the reliability index. It was found thatthe statistics describing the load

capacity of the scaffolding depend on the jack extension and do not

depend on the external dimensions ofthe entice seaffolding. The rel

ability index decreases with the increase ofthe live-to-dead load ratio.

{@polu pl C- Lipecki,pjaminskapolub p (P. Jambska-Gadomska,« leike@polub pl (F Blank Borowa),

Received 11. August 2020; Received in revised form 23 Febuary 2021; Accepted 8 April 202

‘Avalble online 20 Apel 2021,

2352-7102/ 2021 sever Lid, Alright reserved,

“The analyzes were continued in Ref. (8 where it was noted that the

recommendations of design standards should take into account that

‘material properties and loads are random process, and thus partial

safety factors should take into account the results of advanced relisbilty

analyzes,

The influence of geometric imperfections, defined as the offsets of

frame standards connections relative to their ideal geometry, on internal

forces in the seaffolding were investigated in Re. [9]. It was found that

normal forces in bracings were primarily sensitive to imperfections

along the scaffolding, regardless of the type of external oad. On the

‘other hand, che internal forces in the standards were seasitive to im

perfections regardless oftheir direction in relation to the scaffolding

Plane. The imperfection increase caused primarily the inetease of

bending moments in standards

The paper [10] and dissertation [11] describe the influence of the

frame arched deformation and the pipe dent on the stress state in the

frame and inthe entire scaffolding. It was found that the deflection of

‘the standard less than 6 mm and the dents les than 10% of the pipe

diameter have a negligible effect on the load capacity ofthe frame. The

{impact ofthis typeof damage is evident with normal forces greater than.

80 KN, whieh do not appear in real scaffolding. In the second study,

static analyzes ofthe ful frame scaffolding were performed, taking into

‘account geometric nonlinearities, introducing element damages and

‘controlling the influence of material nonlinearities. I was shown that

the mechanical damage tothe seafTolding element does not necessarily

require its disassembly, but due to the possible propagation of micro-

‘damages, this clement should not be used in subsequent seafflding, ia

which its effort could be considerably higher,

The behavior ofthe frame scaffolding under the influence of eccen-

twically applied loads, with diferent boundary conditions describing the

scaffolding foundation, and with diferent bracing systems was investi=

‘gated in Ref, [5]. The authors formulated conclusions important for

‘engineering practice, namely thatthe load capacity ofthe scaffolding

‘was adversely affected by the lack of bracings atthe lowest level, the

lack of anchoring of the highest standards, and hinged foundation on the

‘ground. In the next work (12) various frame scaffolding systems were

tested, in which components of different heights were used to build one

plane. The authors showed that in this way the load capacity of the

scaffolding ean be increased, The second conelusion is important for this

article, whieh states that stresses in scaffolding elements are primarily

‘determined bythe location and direction ofthe load. The importance of

the load shape is also indicated in the work [15] but in relation to

‘cubature seaffolding, most often serving as the supporting structure for

the seafoldingitsel

Inthe article, the main emphasis was placed on the analysis of wind

{impact on scaffolding structures. However, there is not much literature

data inthis regard. The research within this scope can be divided into

three groups: model test in wind tunnels, insita tests and computer

simulations of the flow around stafolding elements. Model tests are

performed mainly for the scaffolding with a protective mesh or clad

represented by plates standing next tothe building wall. Model tests on

‘covered saffolding standing at walls with diferent levels of filling and

in various configurations around the building, taking into account the

interference caused by dhe neighboring building, were presented in

papers (1,15). Another model studies combined with CFD (Compata-

tional Fluid Dynamics) simulations regarding scaffolding with various

types of protective covers were presented in paper [1c]. Wind action on

the integral-lift scaffolding mounted a large heights, also covered with

protective clemeats was reported in papers [17,18]. Wind pressuce

distribution on the plastic cover of scaffolding was described in work

19]. Proper modelling ofthe scaffolding structure (without protective

cover) and building requires elements with very small cross-sections

representing scaffolding tubular elements. Taking into account scaling

used in wind tunnels and dimensions of buildings and tubular sca

folding elements this is mostly impossible. The full-scale tests on seaf-

folding focused on wind action are also very rare. Measurements of wind

renal f Bang Eneicg 42 (2021) 102516

pressure inside and outside the scaffolding net were described in

Ref. (20], and based on that work some proposal for how to prevent

eladded scaffolding from being detached from the building wall were

given in Ref. [21]. Another work based on in-situ measurements was

focused on scaffolding structures without nets and clads [22]. It also

contained multiple two dimensional CED analyses of the flow around

building with scaffolding. As tis shown in is. 1 [22), the flow around

building-scaffolding system can be complex, resulting in various wind

vector directions at scaffolding stands. In this figure, two rows of stands

are placed at the longer windward wal ofthe solid building. Asitean be

seen the outer stands may be more heavily loaded than athersat oblige

angles of wind attack.

This paper i base on in-situ measurements that were carried out on

61 facade saffoldng structures without protetive cover. al structures

‘wore measured at various construction site. The FE models dseribing

real scaffolding geometry were created on the base of geodetic mea.

surements, Wind load was assumed according to wind velocity mea

surements performed for each scaffolding and according to Eurocode (1

recommendations covering two variants of load: perpendicular and

‘parallel to the facade. The FE stati analyzes were performed fr all eases

of loads. The response of the structures given in displacements, stress

and axial force in structural elements were calculated and compared to

tach other, The results verified the correciness of standard recommen:

dations regarding wind loa.

2, Methods of research

2.1, Tested scafoldng sructures

The In-situ measurements were carted out within the research

project "Modelling of Risk Assessment of Construction Disasters, Aci

dents and Dangerous Incidents at Workplaces Using Scaffoldings” con

ducted from Apel 2016 to July 2018. The total number of 120

scaffolding structures standing atthe outer walls of buildings and made

in freme technology vas teste. The scaffolding structures were located

in he following provinces of Poland (24 in each): Lower Silesia (denoted

later as DO1-D24), Lédé (EO1-F24), Lublin (LO1-L24) and Masovie

(QWO1-W24), The cemaining 24 structures were located in various parts

of Poland (PO1-P24). The dimensions and areas of measured structures

fare shown in Pig. 2 and Vig. 3, respectively, where: L— length Im), H

height (mi, L/L ~ aspect rato,

“More than a half of 120 structures ~ 61 (50.8%) were not covered by

any protective elements, the rest were covered with various types of nets

and clads, Further analysis is limited only to the 61 structures without

protective cover. Their structural data in statistical terms are shoven in

Fig, 4 using histograms of individual feacuzes. In particular, it is showe

how many structures had the given area, the number of modules in the

horizontal direction and the nurmber of platforms in the verial dire

tion, Scaffolding structures had different dimensions, the length (L)

‘ange was from 4 m (single frame module) to 75 m, the height (5) was

from 4 m (2 levels of decks) to 58 m, and H/L was from 0.2 0 4.5. The

area of outer fagade varied from 54 m to 1500 m?. Structures with the

area less than S00 m? were classified as small, with the area between

500m and 1000 mas medium and withthe area over 1500 mas large.

means that 59.0% (36 structures) were small, 29.54 (18) were me:

dium and 11.5% (7) were large. The highest numbers of modiules and

Platforms in the single seaffolding were 25 and 28, respectively

The data necessary to determine the wind load are: wind zone,

topography and solidity of a building fast. Considered scaffolding

structures were set at buildings located mostly in city centers (terrain

category IV ~42), but also in less developed suburbs (terrain category Il

= 13), and in less urbanized areas (Cerrain category Il - 6). Most were

located in the wind zone 1 covering the majority of Polané's territory

(69 which is 96.73), and only 1 in the area by the sea (zone 2) and lin

the highlands area (zone 3). In most cases, the building fagade was fully

filled ~50 buildings (82%), which meant that the solidity ratio was equal

eel of Bing Egesing 422021) 102516

© with ciisheet

© no cladisheet

SPE%50,, 8°

HIL (mi)

1500,

1280

E 150

soo

Fig. 4 Histograms of tractral features of scaffolding strctares withost protective cover,

to 1.0. The solidity ratio of building walls in remalning cases was less

than 0.1 (2), 0.2-0.3 (1), 03-04 (1), 04-0. (1), 05-06 (D), 06-07

(1), 0.8-0.9 (1), 0.9-1 (4). The variety of tested scafolding structures is

presented in P'.5

2.2, In-situ measurements

ach scaffolding was tested through one working week that was,

usually 5, sometimes 6 days. The following measurements and analyzes

were cartied out during one week of tests: scaffolding elements in

‘ventory, damage inventory, operational load inventory, fee vibrations

pec ea

renal f Bang Eneicg 42 (2021) 102516

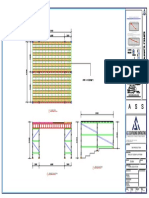

Fig. 5. Examples of faced scaffolding structure, top - compact, middle - wide, bottom — high

measurements, vibration measurements under the excitations from the

‘construction machinery, forces in base jack, bearing capacity of the

‘groune, load capacity of anchors, wind velocity and direction, atmo-

spheric pressure, air temperature and humidity, sound intensity level,

illumination. Moreover, surveys were done about: general information

‘on seafolding an its users, following the health and safety regulations,

construction site organization, energy effort of employees and changes

in their other physiological parameters during the work. Particular re

sults and practical impact of environment on workers and structures

‘were described eg in Ref. [22-25]

In thie research results regarding wind velocity are used. The detailed

description of measurements is given in paper [25] and heze it i only

summarized. The measurements were performed with use of KIMO

mulkfunetion instrument AMI 310 and a telescopic vane probe SHT100.

“The main advantage of KIMO was its portability enabling quick and easy

‘measurements in multiple points during a day, what was very important

taking into account the number of points tested on each structure and

‘number of repeats. The wind velocity and other environmental param

‘ters were usually measured on the frst, middle and top deck levels of

the seafolding twas limited 102 or even level incase oflow and very

low structures. The measurements took place in 2-4 locations at each

level in dependence on the horizontal dimension. In total, 4 to 12 1o-

cations were used in the single course of measurements. The time

‘duration of the single course was usually 1-2.5 h, The measurements

‘were repeated 3-4 times a day and lasted for $-6 working days. The

wind measurements in every location consisted of two 605 time series

that referred to two components of the horizontal wind velocity. The

‘component perpendicular to the building fagade was measuted as the

first and parallel component asthe second. All dats were recorded on

the memory card, Some data were lost due to weather conditions,

memory card error or error of the person operating the equipment. In.

{formation on available data is presented in iy. 6. The aumber of sea:

folding structures in dependence on the number of measuring locations

‘onthe single structure, numberof all courses during the testing week,

‘resulting number of all measurements (ocation times repeat), and the

percentage loss of the records are shown, The most important infor

mation Is that in case of 34 structures (55.7% of all structures without

protective cover) only less than 3% of environmental data were lost.

‘The approximation of possible static load acting on the entire scaf-

folding was established on the base of wind velocity measurements

In order to compare the results with the design loads based on Eurocode

(1,271 it was necessary to recalculate the measured T-min mean wind

velocities to 10-min values. For this purpose, meteorological data ob

‘tained from the nearest meteorological station were used. The wind

‘velocity atthe station was established as the reference value in reel

‘ulation tothe design wind velocity given inthe Eurocode [7]. Detailed

‘description ofthe whole procedure is provided in paper (20. The static

Toad determined on the base of e-stu measurements using KIMO de

vices gave the approximation ofthe wind action but also indicated that

‘the perpentleular and parallel loads recommenced by standarts could

not cover the most unfavorable situations

23, FE modeling

ach scaffolding was modeled in the PE system. For this purpose, the

results from inventory control based on the geodetic measurements [28]

renal f Bang Eneicg 42 (2021) 102516

é

amber of

ig. 6, Jnformation on performed measurements on saffoling structures without potecive coves

‘and damage inventory [11,28] were used, The position of two points on

the stand perimeter was measured using total station, andthe location of

‘the centr ofthe stand was determined on this bass. Such measurements

were made in one or two locations on each stand. As the result, cloud of

points was obtained, which allowed forthe ereation of real scaffolding

[geometry in the FE system, The geometry ofthe frames was checked and

it was found that the deviations of diagonals atthe level of 0-5 mm

‘constituted about 90% of all deviations, ikewise angle deviations within

the range of 0-0.5" [28]. The inventory control of damage consisted of a

Visual asessment of all scaffolding components. Arched deformation of

‘elements, camage causing a change inthe cross-section shape, cracks,

corrosion, damage to the attachment points of the handrails ete. were

listed during inventory. In case of safflding frames, mainly damage to

the lower crossbars blocking the platforms was found, Less frequently,

the elements had damage in the form ofthe point dent, with a size not

‘exceeding 10% of the transverse dimension of the standard pipe. For

‘example, only 9 out of 120 measured structures had more than 10 cases

‘of such damage inal frame elements. As it was shown in Ref. (11], this

kind of damage does not signifcanty affect stresses in the entire

Tolding, therefore they were omitted in geometry shaping of numerical

‘models,

It means that static-stength analyses were performed on scaffolding,

structures in their actual geometty as erected on the construction site

‘and took into account the inaccuracy oftheir assembly. The FE models

were supplemented with boundary conditions, material data and

_geometrical characteristics ofthe elements. Furthermore, the obtained

models were calibrated by comparison between computed natural

vibrations and free vibrations measured in-situ, Possible modifiations

in the wall anchoring and in ground supports, as well as in connections

with neighboring sc folding were introduced if necessary. In practice,

respective degrees of fcedom were released or blocked of elastie sup

ports were used. The description of used FE elements and applied con

nections between them are described in paper [10]. The examples of FE

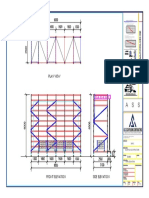

‘models ae shown in Fg. 7.

24, FE statie-strength analysis

‘Wind foad was determined for each scaffolding according to three

variants:

- load approximated by in-situ measurements, referred as load case A,

~ load perpendicular tothe building facade according to Refs. (1,271,

referzed as load case 8,

ng fagade according to Refs. (1,271,

The characteristic wind veloity in accordance with the given wind

zone was ured. In load case A, the measured values ofthe wind velocity

‘wore recalculated tothe design values using the velocity atthe meteo:

rological station as the reference.

The load was determined according tothe standard formula (e. (2),

«cases B and ©) [1] and according tothe formula deseribing the actual

Toad (eq, (2), case A:

Fig. 7. HE modes of satfolding structures, fom the lft: POL, 19, WOS, WI.

peta

Foe Stheun) o

Pers @

‘where: A - the reference area, D ~ the reference dimension of the

element, e/~the aerodynamic eoeMeient,¢,—the site coefMcient, q— the

‘characteristic wind velocity pressure, { ~ the ith element of the

structure.

In Joad eases B and © (eq, (1)) the characteristic wind velocity, and

‘thus the pressure were modified in accordance with the low direction

‘and vertical wind speed profile forthe given terrain category in whieh

the structure was located [27]. The height of te construction sie above

the sea level vas also taken into account. The site coefficient was

‘determined on the basis of seatfoding code [1]. In eg) the reference

area was replaced by the dimension D ofthe -th scaffolding element to

1get the load in kN/m. Such assumption significantly simplified load

{implementation in FE system, there was no need to collect loads to the

particular nodes of the structure. Aerodynamic cooficients of individual

scaffolding elements were adopted in accordance with the wind code

en,

Inload ease A (eq (2), the value of pressure q was determined on the

basis of measured wind velocity. Other parameters (ey and D) were the

same like in eg. (2). The load was applied in FE system in kN/m. No

‘corrections caused by the diection of the wind action (direction coef

‘cient in Eurocode) or the building presence (site coefticient in seaf=

folding code) were applied. The measured wind velocities were assumed

8 producing real loads acting on the structure.

All loads were implemented in the FE system as uniformly disteib-

‘uted in the given area or at the given height constant loads (kN/m)

‘acting on structural elements, Vertical changes in load values resulted

from the vertical wind velocity profile in cases B and C, and from the

measurements made insit—in case A. Moreover, in case A the load alsa

varied in the horizontal direction.

eel of Bing Enesricg 42 2021) 102516

3 Results and at

ly

3.1, Isis measurements

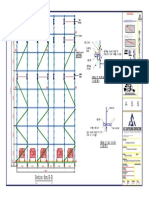

ig. 8 presents the characteristies of the recorded wind velocity,

values in relation to the components parallel and perpendicular to the

scaffolding, vy and vg respectively. There ae ranges of all instantaneous

1. velocity values measured during one working week. Maximum ang

‘minimum I-min mean velocities and the maximum standard deviation

‘of velocity are also showin in is. &. Mean values were calculated fo

Tocations on the scaffolding, forall repetitions during the single day and

for all days.

3.2. FE sti strength analysis

Calewlations were made foreach seaffoldng in theee load cases— A 8

‘and C, as mentioned above, The deadweight and other loads were not

‘considered. The following results were analyzed: maximum magnitude

of displacements in stands, maximum normal stress in stands and base

jacks, maximum axial foree in bracings and anchors. Only absolute

‘maximum values were considered in case of normal stress and axial

force. Normal stest includes the influence of bending moments in two

‘perpendicular directions and the influence of axial force causing tension

‘or compression of the element, The considered elements are structural

‘and have the major impact on stability, rigiity and response to static

Toads. The examples of analyzed element in eal structures are shown in

Fig. 0

‘ig. 10 shoves the maximum magnitude of displacements in stands

“The average values forall scaffolding structures, fo each oad case, A—

6.5mm, B-4.7 mm, C-5.8 mm, were comparable and at relatively low

level. Maximum values foreach load case were: A ~ 34.1 mm, B= 27.5

‘mm, C- 25.1 mm. In design pracle, there are no specific guidelines

regarding the permiscible deflections of scaffolding stands, The value of

‘H/250 is often taken as the serviceability condition, where H is the

scaffolding height In none ofthe analyzed structures and load eases the

limit value 1/250 was exceeded. It's worth to mention that the obtained

‘splacements came only from the wind action and that all structures

were modeled in their actual geometry found on construction sites, i.

Velocity component [m5]

bbbenene

‘Velocity component ms}

na

Seafoing

ESE,

ig. 8. Characteristics of wind veloly daca from insiu measurements on scaffolding structures without protective coves

pec ea

eel of Bing Egesring 422021) 102516

BE

S2RRG S50 WHS 48859858555)

Bo ae

du Uke

bo ze x TT

be $5098 “3889800 83% See nog" ageb3 9% fSoes%ags $

a

SESS SEER REESLESELESRRASSES LSE LSELS

Seaffolding without nevelad

Fig. 10, Displacement of scatfolding structores without protective cover.

‘withthe initial deformation. Taking this into account, and additionally

‘considering the deadweight ofthe structure, che displacements in many

‘cases could approach or even exceed the permissible limit. The highest

‘maximum displacements were obtained in 17 structures a load case A,

1GatBand 31 atC In load case A, the significant displacement occurred

‘mostly locally and was caused by increased loadin the given area ofthe

scaffolding, and often appeared in theless anchored area

ig. 17 shows values of maximum normal stress in stands and base

gs

3

‘Stress in stands [MPa]

a 8

Jacks. The average values forall scaffolding structures, fr each load case

were: A 60.9 MPa; B= 35.9 MPa, C - 62.9 MPs, while the maximum

values were: A 372.1 MPa; B 247.0 MPa, C = 244.6 MPa. The

‘permissible stes for steel scafolding is usually between 260 and 320

(MPa, Al structures were made from steel components. When the upper

value of 320 MPa was adopted as the limiting value, the load capacity

‘was exceeded in two structures (LO3, P18) in load case A, and in none in

uroeode load cases B and C, If we assumed the lower limit of 260 MPa,

GHGSS8 85585595555:

AAEREEESELE LES LESL ASS BSSSESE SS

‘Scaffolding without neiclad

Stress in base jacks [MPa]

SSSd5z2 282

Scaffolding without nevclad

Fig. 11, Maximum norma stress in stands and bese jacks of scaffolding structures without protective cover

it was exceeded in one more scaffolding in load case A (W14), and in

none in load cases B and C. Fvery scaffolding is assembled many times

‘on construction sites and often, individual elements, especially stands,

‘may have various minor defects unnoticed when admitted to use, but

‘which can signifcanty affect their load capacity. Assuming the decresse

in strength to e.g. 80% ofthe lowest value of 260 MPa, i. to 208 MPs

the load capacity inthe stands was exceeded in the next five eases —

(A), 2 (B) and 2 (©). In only one scaffolding (W13) this ime was

‘exceeded forall lad variants, in other cases the limit was exceeded at

various loads. The relationships between values of maximum normal

‘ress in stands, ealealated for diferent loads, aze shown ia Vig. 12. The

highest maximum normal stress was obtained in 16 structures at load

‘ase A, in 8 at Bane in 37 at C.

The values of normal stress in base jacks, average forall structures,

for each load case were: A~ 54.3 MPa, 8- 12.7 MPa, C~64.0 MPa, and

the maximum values were: A ~ 530.7 MPa, B ~ 159.2 MPa, © = 171.1

MPa, The stress limit value adopted at the level of 320 MPa was

‘exceeded in 2 structures in load case A (03, P18) and in none in load

‘eases Band C. I the limit value was rediced to 260 MPa, no adlitionsl

structure exceeded i. Assuming the decrease inthe load capacity 10208

(MPa, the value above this range additionally appeared in only 1 seaf=

folding forthe load ease A (B09). The highest normal stress inthe base

Jacks were obtained in 15 structures at load case A, in at Band in 41 at

ig, 19 shoves maximum values of axial force calculated in bracings

and anchors. The values of maximum axial force in bracings, average for

all structures, foreach load ease, were equal to: A~1.66 KN, B-0.34 KN,

1.69 kN, whereas maximum values were: A= 15.35 KN, 85.60 kN,

5.23 kN. There are no specific guidelines on permissible axial force in

these elements, Individual manufacturers" catalogs give the maximus

recommended force depending on the height of the scaffolding frame

‘and the distance between the two frames. Ata distance of approximately

‘3m between the frames, ic the maximum distance that occurred in the

‘analyzed structures, the force is determined inthe range of 6.6-7.5 KN.

‘These values are for elements under compression and are higher when

tension appears. Assuming 6.6 KN asthe limit value, it was exceeded in 3

structures in load case A (P18, LO3, E09), and in none in eases B and C.

‘The load case C caused the greatest axial force in the largest number of

structures ~42.1n 18 the highest values were obtained atload case A and

‘only in 1 at B, The dependence of the maximum axial force onthe load

variant is shown ing. 14,

When analyzing the axial force inthe anchors, limit force of 2.5 KN

was assumed (2), with the standard fastening ofthe anchor in the wall

“There were standard fastenings in 60 structures, and 1 scaffolding was

not anchored at all (115). This structure was low, 6 m of height.

‘Moreover, in several structures, besides anchoring in the wall the

‘outside supports and hooking tothe surrounding elements were used

cna f Bang Eneicg 42 (2021) 302516

2.SkN was exceeded inall load cases A, Band Cin 1 saffolding (P12). in

load eases A and C, the exceedance did not accur in other structures,

hile in load ease B, st occurred in 1 more seafolding 15 shows the

dependencies of the maximum axial force in the anchors on the load

‘variant. In 46 structures, the greatest forces were obtained atthe oad

perpendicular tothe fagade~ B, in 9 atthe load assumed on the bass of

‘measurements ~ A, and only in 3 atthe load paallel tothe fagade -

‘An additional comparison of the results is shown on histograms

presenting the differences in the obtained values of normal stest

(ig. 16) ane axial force (Vig. 17) calculated in three variants of loads

Relative and absolute differences were determined i the relation to load

case C, which for most structures caused the greatest response. In all

fraphs, positive values on the horizontal axis mean that the greater

stressor axial force was obtained at load case C. The number of seat

folding structures in te given range of differences ison the vertical axis

of particular plots.

For most structures, load case C caused higher maximum stress, by

(0-60 MPa in the stands and by 0-80 MPa inthe base jacks. This corte

sponded to up to 100% greater stress than in other load variants, Oly in

the individual scaffolding structures mentioned above, greater stress

occurred at load case A. In these structures, the diferences in values

were very large, even exceeded 400%. In the case of axial fore in

bracings, the relationship was similar ~ the values at load case C were

higher than the force in variants A and B in the range up to 3 KN. It

corresponded to the increase of force up to 100%, Single structures

deviated from that relationship for which significantly higher force was

determined at load ease A. A different situation was observed for aa

chors for which the highest force was obtained at load case B, whereas

‘variant © gave the lowest axial force in the majority of structures,

Summarizing, for the most seaffolding structures, the highest load

acting onthe elements isthe load parallel to the facade (C) calculated

according to Eurocode, This applies to stands, base Jacks and bracings.

On the other hand, the load perpendicular to the fagade (B), also

calculated in accordance to Furocode, resulted in the greatest axial force

ln the anchors, The load capacity of 320 MPa was not exceeded in any of|

the elements under load cases (8 and C) recommended by Eurocode. The

Toad capacity reduced to 208 MPA, vias exceeded in te stands of only 2

scaffolding structures, Doth at the load cases B and C. For Eurocode load

cases the assumed limit valve of axial force in the bracings was not

exceeded in any scafolding but was exceeded in structures (B)andin 1

structure (C) in the anchors. The results obtained at the load case A

indicated scaffolding structures in which stressor axial force inthe el-

ements were higher than ones ealcuated in aecordance with the Euro

code and exceeded the limit values. The highest values were obtained in

‘the seafflding LO3 and P18 (stand, base jacks, bracing), W14 (stands),

09 (bracings). Another situation occurred for the anchors, for which

the greatest force were determined in scaffolding P12 (A, Band C) and

The average for all structures, and maximum values of axial force inthe 12 (B)

anchors, foreach load case, were respectively: A~0.41 kN and 452 KN,

B=O.73KNand4.261N and C-0.21 kN and 3.95 KN. The limit value of

400 400 400

2.300 300. 2,300

e : S

Z 200 200 200

3 100 ZI 5 G00

a a gett of G

o of °

© 100 200 300 400 © 100-200 300 400-0100 200 300 400

stress in stands, A [MPa]

Fig. 12. Maximum normal sues in stands of scaffolding sutures without protective cover,

stress in stands, A [MPa]

stress in stands, B [MPa!

‘elationshipsbecween load cases A, 3 and.

pec ea cna f Bang Eneicg 42 (2021) 302516

{Force in bracings [KN]

Axi

RSSSSSS ASSARESERE TEE ESSE

Scaffolding without net/lad

Axial foree in anchors [KN]

SESSS290885

Scaffolding without nevclad

ig. 19, Aaa fore in bracngs and anchors of sealfldig structures without protective cover.

z gi gis

= | 5

ie an fo

Es Es Es

Ba Ba bate %

° “ ° 3 o

Dt ho we Oo 4 8 Ow Oe

hit froin big ABN] dua focein acing ARN] xia foe in racing B RN

ig. 14. Al fore in bracngs of sealfolding structures without protective cover, relationships between loud cases A,B and C

force in anchors, B [kN]

axial force in anchors, C [kN]

axial force in anchors, C [kN]

80f > tT 1

o 12 3 4 5 o 123 4 5 0 123 45

axial force in anchors, A KN] axial foree in anchors, A [RN] axial force in anchors, B [kN]

Fig. 15. Asa force in anchors of seaoling stuctures without protective cover, relationships between loud eases A,B and

33. Analysis of individual cases were examined in more detail. Their shape is presented in is. 18.

‘The 103 scaffolding stood next tothe building withthe full facade,

In order Co identify the possible causes of the occurrence of high and was clasiied as smal structure with dimensions 18.43 mand H

stress and axial force at load case A, the above mentioned structures — 8m, During the inventory, normal wear of the components was found.

renal f Bang Eneig 42 (2021 302516

‘Number of structure

: AA

Number of structures

gagegacssa

Shean bests CB

Be

difference (C-A)/C and (C

Ve 8

goes gaRgRszR° RS

C

agggege

Sess inasejashs(C-ANC[P] Suess in bse jacks (-BYC

rams of dilferences between maximum normal stein stands and base jacks rom the lef: absolute diference CA and C-B (MP3), and eelatve

2)

Aus tnbogs

: 4° i :

Achtfoet Banton CAN] Alfonso 0] Aaa ce te CONC

Fig. 17, Hiswgrams ofeitferences between maximum aval force in bracings and anchors; fom the left absolute diference C-A and C-B [MPa], and rlative

ference (C-A)/C and (C-8)/€ (9.

1 the seafolding was not new, and was used many times on construction

sites, but the number of damages in elements was at acceptable level —

normal wear was assumed, The stands at one side of the scaffolding

(ight side in ig. +8) protruded beyond the borizontal outline of the

building In this area ofthe scaffolding the highest wind velocity was

measured and tus the highest load was determined. ln the upper part of

the seaffelding this load acted slightly from behind the building. Such

‘wind action detached the scaffolding from the wall In the rex of the

scaffolding area, the wind was pressing dovn the seafflding othe wall

In result the whole structure was twisted. [twas probable reason that

stress and axial force were greater than those determined according to

the standard approach.

‘The P18 scaffolding was also small, with dimensions L=9 m and H.

15.6 m and stood next to the building withthe Full fagade, Duting the

inventory, normal wear of stands, railings, bracings and very high wear

‘of platforms and toe-boards was found. The part of the wall of the

building with seaffolding protruded about 1 m infront of the adjacent

parts. n the part ofthe building adjacent the analyzed area on the lft

were baleony niches ofthe approximately 1.5 m depth. The niches were

also a the corer ofthe entre building and had no walls inthe direction

perpendicular tothe analyzed fagade, The measured wind load acted on

the significant part of the scaffolding slighty from the behind of the

building, from the side of open balcony niches. It seems thatthe main

cause of high stess and axil force in the elements was similar to that

found forthe saffolding 103, ie. the twisting of the structure.

The W14 scaffolding was large and high, with dimensions — 17 m

and 143.11 m,Ie-was seta the central part of the fall fade of the

long building. The wear of the scaffolding elements was determined as

normal. Other tall buildings were located in front of the analyzed

structure, which means that the seaffolding stood in Uhe area with a

significant contraction of the flow, like in the street canyon. In the

‘prevalent atea ofthe scaffolding, the load acted along the eanyon and

building wall, causing forces to deflect approximately 20° from the

facade and pressing down the scaffolding tothe building, However, asin

the previous cases, de wind load acting on the part of the saffoding

caused deachment from the building facade and consequently its

pec ea

renal f Bang Eneig 42 (2021 302516

ig. 18, Seafolding structures with exceadance of iit valve of ses r axial free

twisting. Such an unnatural wind ditection was probably caused by

‘many balconies protruding from the facade of the building on the

‘windward side (let side in F's. 15), which introduced significant dis-

turbances to the Now.

Maximum axial force in the anchors was obtained in the P12 sca

folding at all lod cases, P12 scaffolding was the lage structure with

Tength L = 35 m and maximum height 4 = 36.68 m. It was the only

scaffolding among all analyzed structures that did not stand next to the

building. I was located under massive element coming out ofthe power

plant block. Various supported elements were placed under the over-

head seruture. The solidity ratio was determined as equal to 0.1. The

total number of 57 anchors were installed and fixed to the structure

supporting the overhead element. The measured wind load acted mainly

perpendicularly tothe scaffolding, and was similar to the load ease B.

‘Moreover, low value of solidity ratio caused loads B and C as well as

results of statiestrength analyzes similar to each other.

‘The L12 scaffolding was also a large structure with length L = 45 m

and maximum height 32 m. The total number of 36 anchors was used.

“The seaffolding was attached tothe building for whieh the solidity ratio

‘of the fagade was determined as 0.95, due to the lower roof on one part

of the building (ight side in Fig. 18). The extreme stands protruded

significantly beyond the building area (also right side in Fs. 18). The

Toad acting from behind the building was measured in these zones. At

‘the rest ofthe scaffolding area the load was most parale othe facade,

mostly pressing down the scaffolding tothe bullding. As in previously

‘analyzed cases, such load distribution caused twisting ofthe structure.

34, Influence of design parameters on scaffolding sa strength response

“The dependencies of the calculated results on structural parameters

of the saffolding: length (2), height 1D, aspect rato (L/D, sealfolding

area (A), number of anchors, ratio ofthe scaffolding area to number of

anchors; and on parameters influencing the wind load: solidity ratio of

the facade, wind zone, terrain roughness were also investigated. Some

‘examples of such dependencies are given below. In Fis. 19 maximum

normal stress in stands is show. In general, no clear trends were found

in any case. The increase in scaffolding area resulted in the greater

scatter of values of maximum normal stess in stands. Similar relation

was found for the increase of the seaffolding height (not showed in

figure). When considering aspect ratio H/L the scatter of results is larger

for relatively small aspect ratios (1-3.5), For larger H/l, whieh means

‘more slender scaffolding, usvally with small number of modules, the

‘values are similar and at rather low level. It is possible that high struc

tures are better anchored tothe wall. Moreover, all three diagrams show

that the highest stress can occur in small scaffolding. The same

‘description can be referred to values of maximum normal sess in base

Jacks. Very similar remarks ean be formulated in relation to axial foree i

bracings and anchors, which are shown in

4. Conclusions

Insitw measurements carried out on scaffolding structures used on

‘construction sites allowed to create FE models and calewate the wind

load. The computer models of structures reflected their actusl geometry

‘obtained aftr thelr erection. The correctness of FE models were veritied

by insitu dynamic tests and measurements of forces in stands. The FE

Sati.strength analysis was carried out for 3 wind load variants, namely

developed on the basis of measurements (load case A, adopted in

accordance with the Eurocode standard (load case B and C). signi

‘cant number ofseaffoldng structures ~ 61, made it possibe to carry out

the statistical analysis of static-strength response. Structural elements of

the scaffolding were analyzed in terms of exceeding the permissible

values of nocmal stress and axial force as well as in terms of differences

between the load variants

pec ea

ges

eel of Bing Enesing 422021) 102516

‘Nonna send

=

z ‘elise

a x wa on ec

dn i i

bo» t I

Yee eg ee ee gree eae) ara eee a

m0 Peano pact ent

19, Nora sve nds nd be jas in dependence on Had ere me of ors

ia icin being 8}

Asi ein ngs EN]

Arc unb f eni[

A fot in sets UN]

ig. 20, Axial force in bracings and anchors in dependence on H/, A and ratio of area to number of anchor.

Im most cases, the load parallel to the fagade (C) caused the greatest,

stress in stands and base Jacks and the greatest axial force in bracngs.

‘The perpendicular load (B) caused the greatest axial foree in the an-

cchors, in most considered structures. In the prevailing majority of

structures, these two load variants ensured the determination of

‘maximum values of stress and axial force.

However, the conducted analyzes indicated, that it was possible that

the wind load othe than that presribed by the Eurocode could appear,

and caused greater values of stress and axial force locally in structural

‘elements, The load determined on the base of in situ measurements (A),

With the direction changing over the entie surface of the scaffolding,

indicated that the stractre can e detached from the wall and twisted

‘Such situation occurred especially when the corner areas ofthe seaf-

folding were exposed to loads acting away from the wall of the building,

‘while in other areas the wind load was pressing down the scaffolding t0

the building In such cases the highest values of stress and axial force in

the elements were obtained, It seems that ifthe part ofthe scaffolding

‘extended beyond the building outline (comer, roo, such situation was

more likely o occu. Ofcourse, when preparing the design of thespecific

scaffolding that wil be erected onthe construction sie, iis impossible

to predict all situations, but i is worth to consider such potential lad.

‘The easiest way to counteract it may be using additional comer

anchoring

also should be noted that there was no clear correlation between,

2

the height or surface area ofthe scaffolding and the exceedance ofthe

permissible stress or axial force in elements. Tests and calculations

shoved thatthe limited stres can also be exceeded in low scaffolding.

Practice shows that large or tall scaffolding structures are usually well

anchored to the walls of bulldings, while low or small structures are

‘often erected intuitively without the required design.

In the presented statie-strength analyzes, only the wind load at the

velocity resulting ftom the Eurocode recommendations was assumed.

‘The deadweight and other loads, e.g. operational were disregarded. In

several analyzed cases, values of stess and axial force exceeded

‘permissible ones. If additional loads were considered in FE analyzes the

‘number of scaffolding structures where the permissible values were

‘exceeded would significantly increase. It is also worth noting that all

structures were modeled with the goomeay taking into account the

‘actual imperfections introduced on the construction site, which usually

increased the displacement ofthe scaffolding nodes, and consequent,

the values of interal force and stress in the elements, n some cases, the

"upper parts of the structures were deviated from the ideal (designed)

‘geometry even by several centimeters. It also should be remembered

‘that the scaffolding, as the structure repeatedly erected on various

‘construction sites is subjected to wear and its elements are subjected to

‘damage. During the inventory, most of the seafflding structures were

‘assessed a5 working in the normal technical condition, but there were

also structures with very poor condition of individual elements, This fact,

pec a

also should be taken into account during design by redueing the

Permissible load capacity ofthe elements.

‘Author statement

‘Tomasz Lipecki: Conceptualizaton, Methodology, Formal analysis,

Software, Writing - original draft, Writing ~ review & editing, Visuali-

zation, Peulina Jamitsks-Gadomske: Conceptualizaion, Methodology,

Formal analysis, Software, Writing ~ review & editing, Ewa Biazi

‘Borovra: Conceptualization, Methodology, Writing - review & editing,

Funding eequiston

Declaration of competing interest

‘The authors declare hat they have no known competing fnanclal

{interests or personal relationships that could have appeared to influence

‘the work reported in this paper.

References

(01 #528113, teporery Works Eapnent = Fat: Sails Perormance

lemenc and Genta! Design (lsh Version PRC ENI2N = 2007),

(esapatonl Hest ed Sey Suing Corson Weck 203, 9 4 pon 40

thas, a

Si Pag, KA Che, St han, Wt, Cen xpecinetal and analy states on

Stel scfols unde eeu las, Cs Stel Res. 88 2009) 422-485,

1 Zhang. T.Chandrngu,X. Rasmus, Probable dy of the seen of

‘eel ef per, Sct S32 (2010) 295401, pe Hy

1M. Pletke, ath-Rorowy, Nuneel eal fod bealg capciy of

‘otal sealing ede ag Sr 8 (2013) 19, hips 10018)

RE. Bel, Sead research reve, Contr Stal ex 9 2014) 188-200,

Iapan langt0soveeeranna Or 6

1. iH Zing KER ssn. Ya, yeas lk sate design

‘te for 3 eames user wid lod, J Coste, Sel Rs. 157 (2019)

(6 Wang. Zhang, XL. Rasmussen, Reynolds. Yan, Sytem relisbiy-hased

Tit mae den por sain ems, ng Sere. 216 (2020) 10677,

peor 10867 eerie 089 11007

bua torona, Coma, The uence of te dnasion aa contgraon of

geomet inpertacona on he sae rng ipl ade sealing. Ach

{Gi ech Hg 16 206) 268, poor 10.00 sae 20150100,

‘obs Baars, J.B, sence of expltaton damage one

‘ape of wafldng ne sande, A Cnt Poe (018) 192, =o

a

a

“i

sl

a

a

“1

o

ot

n

eel of Bing Egesring 422021) 102516

[11] A. Roba, Anal of he nfence of Opecting Damages of enfin Sroctare

ements onthe oad Crying Copesty a Pols), Lain Unversity of

‘Peg Pl Wan Sha, PX pring yo ing

(20) s00-404, hep /ca ony 1007 nsec ON

1b Peng SL chan, G1. Wie of yet shape and neementl os

‘on scfm. Const Ste Re 3 (2007) MBAS, his

To,ote/jar2006 07008,

comets and bung pening ratios, Wind ng In. ete, 120 (2013)

F Wang. Tamra, A, Yothid,tnerferene ees of neigh bling on

wind leeds on efiiing Wied Eng fe Aero 1252014) 125 om

p10 T046/} wea 20981, 005

He trazs, R..Beale, MLE. Gale, wind! investigation mt he pesire

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- TG - 13 - Operat'Nal Guide - Part 1Document116 pagesTG - 13 - Operat'Nal Guide - Part 1Abdul Hameed100% (1)

- Aramco ScaffoldingDocument158 pagesAramco ScaffoldingAbdul Hameed100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TAPROOT COMPLETE MAT LIST (Grand Stand)Document1 pageTAPROOT COMPLETE MAT LIST (Grand Stand)Abdul HameedNo ratings yet

- Terrace AccessDocument1 pageTerrace AccessAbdul HameedNo ratings yet

- End Plate Moment ConnectionDocument16 pagesEnd Plate Moment ConnectionAbdul HameedNo ratings yet

- 20x10M PREFAB OFFICE - 07-04-2023Document2 pages20x10M PREFAB OFFICE - 07-04-2023Abdul HameedNo ratings yet

- Grand StandDocument1 pageGrand StandAbdul HameedNo ratings yet

- Exhibition CatalogDocument1 pageExhibition CatalogAbdul HameedNo ratings yet

- Castor Wheel - Revvo - Tech DataDocument4 pagesCastor Wheel - Revvo - Tech DataAbdul HameedNo ratings yet

- System Reliability-Based Limit State Design of Support Scaffolding SystemsDocument12 pagesSystem Reliability-Based Limit State Design of Support Scaffolding SystemsAbdul HameedNo ratings yet

- Haris 2Document1 pageHaris 2Abdul HameedNo ratings yet

- Reaction Forces - Load ReportDocument68 pagesReaction Forces - Load ReportAbdul HameedNo ratings yet

- HARIS Led HOLDING STRUCTURE-ModelDocument1 pageHARIS Led HOLDING STRUCTURE-ModelAbdul HameedNo ratings yet

- AttentionDocument1 pageAttentionAbdul HameedNo ratings yet

- Design of Ledger TubeDocument17 pagesDesign of Ledger TubeAbdul HameedNo ratings yet

- Design Calculation For Raising PlateformDocument15 pagesDesign Calculation For Raising PlateformAbdul Hameed100% (1)

- User Guide Safety Harness With CuplokDocument6 pagesUser Guide Safety Harness With CuplokAbdul HameedNo ratings yet

- Ringlock Doka Scaffold Brochure 201119Document32 pagesRinglock Doka Scaffold Brochure 201119Abdul HameedNo ratings yet

- Ez Professional Courses-2023Document19 pagesEz Professional Courses-2023Abdul HameedNo ratings yet

- 2 ARENA ANALYST SITTING STAND-ModelDocument1 page2 ARENA ANALYST SITTING STAND-ModelAbdul HameedNo ratings yet

- 1.method Statement and Risk Assesment - SM ProductionDocument11 pages1.method Statement and Risk Assesment - SM ProductionAbdul HameedNo ratings yet

- 1-L Shaped LED SCAFFOLD - Copy-ModelDocument1 page1-L Shaped LED SCAFFOLD - Copy-ModelAbdul HameedNo ratings yet

- Ez FeesDocument7 pagesEz FeesAbdul HameedNo ratings yet

- Scale NtsDocument1 pageScale NtsAbdul HameedNo ratings yet

- Design Calc@Main StageDocument5 pagesDesign Calc@Main StageAbdul Hameed100% (1)

- 1 ARENA ANALYST PLTFORM-ModelDocument1 page1 ARENA ANALYST PLTFORM-ModelAbdul HameedNo ratings yet

- Design Calc@Main StageDocument5 pagesDesign Calc@Main StageAbdul Hameed100% (1)

- Wind Analysis On Partially Opened Scaffold StructureDocument2 pagesWind Analysis On Partially Opened Scaffold StructureAbdul HameedNo ratings yet