RCC A3 Size Chart

Uploaded by

Ram TqrRCC A3 Size Chart

Uploaded by

Ram Tqr- Protective Coatings: Lists the types of protective coatings and chemicals used in civil engineering for corrosion resistance and longer lifespan of structures.

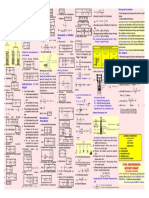

- Concrete Mix Design: Outlines guidelines and parameters for designing concrete mixes from M10 to M80, ensuring correct proportions and strength.

- Structural Chart: Contains essential structural charts indicating sections for reinforced concrete constructions and slab thicknesses.

- Material Properties: Provides a quick reference table for material properties like concrete grade, strength, and corresponding applications in construction.

- Design Formulas: Presents critical design formulas for reinforced cement concrete structures, covering main calculations and equations required in civil engineering.

Design of S.R Rectangular Section Short Column: Short if salenderness.

ratio of both axes are

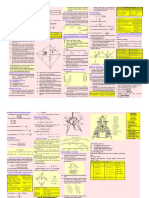

System Type of Range Arrangement Type of

Sec Modulus less than 12. (Country) tendon of of tendons in Anchorage

f M yf M Lateral ties: Diameter of lateral ties is given by criteria of force duct

d As

2

Ec 5700 f ck N / mm . , Min. grade = M15 (IS 456:1978) R ub 0.87f y jd stiffness not by strength. Hence, it is independent of grade of Freyssinet Wires Medium Annular, spaced Concrete

steel. (France) & Large by helical wire wedge

Analysis of Doubly Reinforced Section stands core.

E c 5000 f ck N / mm 2 . , Min. grade = M20 (IS 456:2000) longitudinal, max D Lee-mc-call Bar Small Single bars High

C1 C 2 T 0.36f ck x u b A sc (Fsc 0.45f ck. ) (Great threaded medium strength nut

Tie diameter t 4 , St 16 longitudinal, min Britain) at ends large

S. Discription Collapse Servicability 6 mm 300 mm

No. 0.87f y A st A sc (f sc 0.45f ck ) Gifford-Udall Wires Small & Evenly spaced Split Conical

1. D.L + L.L 1.5 1 T 0.87 f y Ast , x u Minimum Eccentricity (Great medium by perforated wedge

2. D.L + (W.L) or (E.L)

0.36f ck b. Britain) spacers

combination ley D y

(i) for normal case Nominal Shear Stress e y,min max 500 30 For non rectangular / circular section Magnel-

Blaton

wires Small

medium

Horizontal rows

of 4 wires

Flat steel

wedge in

20 mm (Belgium) large spaced by metal sandwich

D.L + W.L (or E.L) 1.5 1 le

D.L + W.L (or E.L) V Ast lex D x e min max 300

griller plates

v , c max 0.631 f ck . , %pt 100.

(ii) for checking

b.d bd e x,min max 500 30 20 mm

stability against over

turning/stress reversal 20 mm Stress Grade of Concrete

Effective span ( l eff )

D.L + W.L (or E.L) 0.9 1

Slenderness Limits to Ensure Lateral Stability M20 M25 M30 M35

Simply supported Continuous Cantilever Slenderness limits to ensure lateral stability

3. D.L + (L.L) + W.L 1.2 1 beam or slab beam or slab

(or E.L) combination d Direct Tension 1.2 1.3 1.5 1.6

d

D.L 1.2 0.8 l0

l0 l0 l0

Simply supported beam

Bending Tension 1.7 1.8 2.0 2.2

w < 12 w

12 d Cantilever beam

W.L (or E.L) 1.2 0.8 w w leff =l 0 +

same as 2 or

l0 + d simply

supported

d

d continuous beam Total of Loss Pretensioned Post tensioned

2p min.of or

w w case l0

25b 60 b

280 f cr 0.7 f ck , f ct 0.66f cr l0 +

2

+

2

l0 l0 l0 w

w (1) Elastic shorting 3% 1%

m DL d

l eff = l0 + 2 2 2 of concrete

3 cbc f cr (flexure Splitting Direct Tensile strength) Minimum of

l0 +

2

or w

Clear span < min. 100b Clear span < min. 250 b (2) Creep in concrete 6% 5%

l0 + 2 d d (3) Shrinkage of concrete 7% 6%

Calculation of effective

span Inclined Bars Control of Deflection: (4) Relaxation of steel 2% 3%

Cantilever beam 7 18% 15%

Calculation of total d

load w Vs VV cbd 0.87f y ASV (sin cos ) Simply supported beam 20

sv Continuous beam 26 S.No Type of Construction Min. Grade

0.148 fck Fe 250

1 Type of slab Mild steel Type of reinforcement

0.138 fck Fe 415 LSM Calculation of design

coefficient (Q)

WSM

Q CJK Sv 0.87f y As v d(cos sin ) , 1. Lean Concrete bases M5, M 7.5

2

0.133 fck Fe 500 Fe 415

2. Plain Concrete Cement M 15

0.87f y As v d Simply supported 35 28

Calculation of effective depth 3. RCC (general construction) M 20

A st

M WSM M Sv Vc c bd. Co n ti n u o u s 40 32

st . j.d

d

Qb v vc 4. Water tanks, dome M 30

Concentrically Loaded Column (e=0) 5. In sea water M30(RCC)

Check Maximm Spacing: 0.75d or 450mm

for

shear 0.5 f ck 4.6M u P 0.45f ck A y 0.75f y A st M20 (PCC)

v

v

C A st 1 1 bd st

bd f y f ck bd 2

Development Length: L d 4 6. Post-tensioned PSC M 30

bd Axially Loaded Column. (e < 0.05h) 7. Pre - tensioned PSC M40

For Singly Reinforced Rectangular beam Longitudinal Reinforcement: Pw 0.9P 0.4f ck A c 0.67f y A st

Unbalanced Section Balanced Section Tu l d / b Ast 0.85 Pr e tensioning Post tensioning

1 mf c m cbc M1 M1 M 2 M k ,

bd fy Prestressed Concrete: Anchoring of tendons, placing

Casting of concrete, placing

k kc (if m is given) 1.7 tendons, placement of anchorage

st st mf c st m cbc jacks, applying tension,

1 Slabs Loss due to length effect = Pok.x Stages

casting concrete & finally cutting

block & jack, applying

mf c tension to tendons & finally seating

ly ly Loss due to curvature effect = Po.. of tendons.

wedges

1 k 1 k

R f c k 1 Rc cbc kc 1 c 2, two way slab , 2 one way slab Loss of pre-stress at the Prestressing bed, Jack, Anchoring device,

Casting bed, Ducts, mould/Shuttering,

2 3 2 3 lx lx Devices End Abutments, Shuttering/mould,

Anchoring devices, Jacks.

L Harping device

n n Anchoring stage = Es

M Rbd 2 Ast f st d M c Rcbd 2 Ast st d c Member Max. reinfocement Min. reinforcement L Heavy casting place members

3 3 can be easily post-tensioned

Co l umn 6% of gross cross 0.8% of gross cross ES = Young’s Modulus for tension Advantages

Suitable for Large scale production

Transfer of prestress is independent

k k Do not required Large anchorage device

Ast f st d 1 Ast st d 1 c sectional area sectional area wires, L = length of tendon of length

3 3

Less waiting period in casting bed

Slab 0.15% for mild steel Loss of stress due to shrinkage of concrete = eshx Es

Good bond is neccessary between

A 50kf c A 50kc cbc & 0.125 for HYSD bars Loss of stress due to creep of concrete = .m.fc. Disadvan Requirement of anchorage

P st 100 Pc st 100 tages

transmission length.

device & grouting equipment.

bd f st bd st Beam 4% of gross sectional Losss of stress = strain lost in steel x ES Pre-stressing bed required

area for each compr- A st min 0.85

Doubly Reinforce Rectangular Setction fc P N

ession and tension bd fy

Es 0 CIVIL ENGINEERING

bx 2

'

Ec A Z ROCKET CHART

Hanger bars 0.2% of gross cross –

(m1 1)Ast x d ' m As d x Types of prestressing on various basis- FOR QUICK REVISION

2 in beams sectional area of beam

BY

Side face – 0.1% of the web area Source of force - Hydraulic, electrical, mechanical, chemical.

FLexure (LSM)- Balanced Section reinforcement Time of force application - pretensioning & post-tensioning. S.SOROUT: 9255624029

in beam

x 700 Sh ea r

Place of force application - External like as in bridges, internal DISTRIBUTOR

d

like as in sleepers.

d max 0.87f y 1100 reincorcement – 0.87f yAS v s 0.4bd GOLDEN BOOK DEPOT

v

DELHI (9811421791)

You might also like

- Design of Steel Structure and RCC Numrical ExampleNo ratings yetDesign of Steel Structure and RCC Numrical Example31 pages

- On Reinforcement Cover, Lapping and Development LengthNo ratings yetOn Reinforcement Cover, Lapping and Development Length13 pages

- Properties of Materials in Solid MechanicsNo ratings yetProperties of Materials in Solid Mechanics22 pages

- Navi Mumbai Environmental Status ReportNo ratings yetNavi Mumbai Environmental Status Report26 pages

- Understanding Prestressed Concrete BasicsNo ratings yetUnderstanding Prestressed Concrete Basics123 pages

- Karnataka PWD - Compulsory - Kannada - QCANo ratings yetKarnataka PWD - Compulsory - Kannada - QCA36 pages

- Building Construction and Maintenance EngineeringNo ratings yetBuilding Construction and Maintenance Engineering51 pages

- ESE2024 CivilEngineeringESETopic WiseConventionalSolvedpaper 1 1741780731069No ratings yetESE2024 CivilEngineeringESETopic WiseConventionalSolvedpaper 1 17417807310698 pages

- Bar Bending Schedule (The Ultimate Learning Series) - Detailing & Applications For Students & Working Professionals. by Srikanth NedhunuriNo ratings yetBar Bending Schedule (The Ultimate Learning Series) - Detailing & Applications For Students & Working Professionals. by Srikanth Nedhunuri67 pages

- Ready Recknoer For CPWD Field EngineersNo ratings yetReady Recknoer For CPWD Field Engineers58 pages

- Civil Engineering Mcqs by DR Munendra KumarNo ratings yetCivil Engineering Mcqs by DR Munendra Kumar120 pages

- DRCS Oral Exam Questions for Structural EngineeringNo ratings yetDRCS Oral Exam Questions for Structural Engineering3 pages

- 3 - Chapter 2 - Methods of Building EstimatesNo ratings yet3 - Chapter 2 - Methods of Building Estimates7 pages

- IS456-2000 Structural Design GuidelinesNo ratings yetIS456-2000 Structural Design Guidelines14 pages

- Concrete Structure Cross-Section DimensionsNo ratings yetConcrete Structure Cross-Section Dimensions7 pages

- Notes For STCOND1 (Principles of Reinforced Concrete 1)No ratings yetNotes For STCOND1 (Principles of Reinforced Concrete 1)38 pages

- Design of RC Structures To EC2 - v.2.1 Priyan DiasNo ratings yetDesign of RC Structures To EC2 - v.2.1 Priyan Dias78 pages

- CCIP - Design of Hybrid Concrete BuildingsNo ratings yetCCIP - Design of Hybrid Concrete Buildings107 pages

- Structural Load and Material Weights GuideNo ratings yetStructural Load and Material Weights Guide20 pages

- RCC-II Notes - Unit 1 - Portal Frame Design by Rajneesh SirNo ratings yetRCC-II Notes - Unit 1 - Portal Frame Design by Rajneesh Sir12 pages

- IS 456 vs ACI 318: Structural GuidelinesNo ratings yetIS 456 vs ACI 318: Structural Guidelines15 pages

- Structural Detailing PPT Training CentreNo ratings yetStructural Detailing PPT Training Centre68 pages

- Diamond Interchange: Important Year's of Highway DevelopmentNo ratings yetDiamond Interchange: Important Year's of Highway Development2 pages

- Photoelectric Effect & Photon CalculationsNo ratings yetPhotoelectric Effect & Photon Calculations15 pages

- ATOPCV1 2 6 Partial Molar Quantities Free Energy Volume Heat ConceptNo ratings yetATOPCV1 2 6 Partial Molar Quantities Free Energy Volume Heat Concept12 pages

- National Cement Emali - Reclaimer Bridge Ut Inspection ReportNo ratings yetNational Cement Emali - Reclaimer Bridge Ut Inspection Report4 pages

- TDS-103 Dispersion Techniques Carbopol PolymersNo ratings yetTDS-103 Dispersion Techniques Carbopol Polymers5 pages