Professional Documents

Culture Documents

Aluminum 1100-H14: Metal Nonferrous Metal Aluminum Alloy 1000 Series Aluminum

Uploaded by

Jennifer KirklandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum 1100-H14: Metal Nonferrous Metal Aluminum Alloy 1000 Series Aluminum

Uploaded by

Jennifer KirklandCopyright:

Available Formats

3/10/2021 Aluminum 1100-H14

Aluminum 1100-H14

Categories: Metal; Nonferrous Metal; Aluminum Alloy; 1000 Series Aluminum

Material This is a common commercial grade sold when 'aluminum' is specified. As with other unalloyed aluminum

Notes: grades, it is used where the intrinsic formability and corrosion resistance of aluminum is needed while high

strength is not. Example applications include chemical and food handling, sheet metal, hollowware, heat

exchangers, and lighting.

Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR

DESIGN.

Composition Notes:

The aluminum content for unalloyed aluminum not made by a refining process is the difference between

100.00 percent and the sum of all other analyzed metallic elements present in amounts of 0.010 percent of

more each, expressed to the second decimal before determining the sum. For alloys and unalloyed

aluminum not made by a refining process, when the specified maximum limit is 0.XX, an observed value or

a calculated value greater than 0.005 but less than 0.010% is rounded off and shown as " less than 0.01%".

Composition information provided by the Aluminum Association and is not for design.

Key Words: Aluminium 1100-H14; UNS A91100; ISO Al99.0Cu; NF A45 (France); CSA 990C (Canada); AA1100-H14;

Al1100-H14

Vendors: Visit Metalmen Sales for your commercially pure Aluminum 1100 needs. Stocking bar and plate for

immediate delivery. Small quantities, cut to order. Contact us for sheet. coil and wire. Phone 1-800-767-

9494.

Click here to view all available suppliers for this material.

Please click here if you are a supplier and would like information on how to add your listing to this material.

Physical Properties Metric English Comments

Density 2.71 g/cc 0.0979 lb/in³ AA; Typical

Mechanical Metric English Comments

Properties

Hardness, Brinell 32 32 AA; Typical; 500 g load; 10 mm ball

Tensile Strength, 124 MPa 18000 psi AA; Typical

Ultimate

110 - 145 MPa 16000 - 21000 psi Wire and rod (rivet and cold heading grade)

110 - 145 MPa 16000 - 21000 psi Sheet and plate

14.0 MPa 2030 psi

@Temperature 371 °C @Temperature 700 °F

20.0 MPa 2900 psi

@Temperature 316 °C @Temperature 601 °F

28.0 MPa 4060 psi

@Temperature 260 °C @Temperature 500 °F

69.0 MPa 10000 psi

@Temperature 204 °C @Temperature 399 °F

97.0 MPa 14100 psi

@Temperature 149 °C @Temperature 300 °F

110 MPa 16000 psi

@Temperature 100 °C @Temperature 212 °F

125 MPa 18100 psi

@Temperature 24.0 °C @Temperature 75.2 °F

130 MPa 18900 psi

@Temperature -28.0 °C @Temperature -18.4 °F

140 MPa 20300 psi

@Temperature -80.0 °C @Temperature -112 °F

205 MPa 29700 psi

@Temperature -195 °C @Temperature -319 °F

>= 110 MPa >= 16000 psi Wire, rod, and bar (rolled or cold finished)

www.matweb.com/search/datasheet_print.aspx?matguid=c0652f2efeac49b89b50e7e4c6fba759 1/3

3/10/2021 Aluminum 1100-H14

@Thickness <=9.50 mm @Thickness <=0.374 in

>= 110 MPa >= 16000 psi Drawn tube

@Thickness 0.356 - 12.7 mm @Thickness 0.0140 - 0.500 in

Tensile Strength, Yield >= 95.0 MPa >= 13800 psi Sheet and plate

117 MPa 17000 psi AA; Typical

11.0 MPa 1600 psi

@Temperature 371 °C @Temperature 700 °F

14.0 MPa 2030 psi

@Temperature 316 °C @Temperature 601 °F

18.0 MPa 2610 psi

@Temperature 260 °C @Temperature 500 °F

52.0 MPa 7540 psi

@Temperature 204 °C @Temperature 399 °F

83.0 MPa 12000 psi

@Temperature 149 °C @Temperature 300 °F

105 MPa 15200 psi

@Temperature 100 °C @Temperature 212 °F

115 MPa 16700 psi

@Temperature -28.0 °C @Temperature -18.4 °F

115 MPa 16700 psi

@Temperature 24.0 °C @Temperature 75.2 °F

125 MPa 18100 psi

@Temperature -80.0 °C @Temperature -112 °F

140 MPa 20300 psi

@Temperature -195 °C @Temperature -319 °F

Elongation at Break 1.0 - 10 % 1.0 - 10 % Sheet and plate

20 % 20 %

@Temperature -28.0 °C @Temperature -18.4 °F

20 % 20 %

@Temperature 24.0 °C @Temperature 75.2 °F

20 % 20 %

@Temperature 100 °C @Temperature 212 °F

23 % 23 %

@Temperature 149 °C @Temperature 300 °F

24 % 24 %

@Temperature -80.0 °C @Temperature -112 °F

26 % 26 %

@Temperature 204 °C @Temperature 399 °F

45 % 45 %

@Temperature -195 °C @Temperature -319 °F

75 % 75 %

@Temperature 260 °C @Temperature 500 °F

80 % 80 %

@Temperature 316 °C @Temperature 601 °F

85 % 85 %

@Temperature 371 °C @Temperature 700 °F

9.0 % 9.0 % AA; Typical

@Thickness 1.59 mm @Thickness 0.0625 in

20 % 20 % AA; Typical

@Diameter 12.7 mm @Diameter 0.500 in

Modulus of Elasticity 68.9 GPa 10000 ksi AA; Typical; Average of tension and

compression. Compression modulus is about

2% greater than tensile modulus.

Notched Tensile 138 MPa 20000 psi 2.5 cm width x 0.16 cm thick side-notched

Strength specimen, Kt = 17.

Ultimate Bearing 200 MPa 29000 psi Edge distance/pin diameter = 2.0

Strength

Bearing Yield Strength 159 MPa 23100 psi Edge distance/pin diameter = 2.0

Poissons Ratio 0.33 0.33

Fatigue Strength 48.3 MPa 7000 psi completely reversed stress; RR Moore

@# of Cycles 5.00e+8 @# of Cycles 5.00e+8 machine/specimen

Machinability 30 % 30 % 0-100 Scale of Aluminum Alloys

Shear Modulus 26.0 GPa 3770 ksi

www.matweb.com/search/datasheet_print.aspx?matguid=c0652f2efeac49b89b50e7e4c6fba759 2/3

3/10/2021 Aluminum 1100-H14

Shear Strength 75.8 MPa 11000 psi AA; Typical

Electrical Properties Metric English Comments

Electrical Resistivity 0.00000300 ohm-cm 0.00000300 ohm-cm

Thermal Properties Metric English Comments

Heat of Fusion 390 J/g 168 BTU/lb

CTE, linear 21.8 µm/m-°C 12.1 µin/in-°F

@Temperature -50.0 - 20.0 °C @Temperature -58.0 - 68.0 °F

23.6 µm/m-°C 13.1 µin/in-°F AA; Typical; average over range

@Temperature 20.0 - 100 °C @Temperature 68.0 - 212 °F

24.5 µm/m-°C 13.6 µin/in-°F

@Temperature 20.0 - 200 °C @Temperature 68.0 - 392 °F

25.5 µm/m-°C 14.2 µin/in-°F

@Temperature 20.0 - 300 °C @Temperature 68.0 - 572 °F

Specific Heat 0.904 J/g-°C 0.216 BTU/lb-°F

Capacity

Thermal Conductivity 220 W/m-K 1530 BTU-in/hr-ft²-°F

Melting Point 643 - 657.2 °C 1190 - 1215 °F AA; Typical range based on typical composition

for wrought products >= 1/4 in. thickness

Solidus 643 °C 1190 °F AA; Typical

Liquidus 657.2 °C 1215 °F AA; Typical

Optical Properties Metric English Comments

Emissivity (0-1) 0.050 0.050 Bare Metal

Reflection Coefficient, 0.86 0.86 Tungsten Filament Source, Bare Metal

Visible (0-1)

Processing Metric English Comments

Properties

Annealing 343 °C 650 °F

Temperature

Component Metric English Comments

Elements Properties

Aluminum, Al >= 99.00 % >= 99.00 % Specified

Beryllium, Be <= 0.0008 % <= 0.0008 % welding electrode and filler wire only

Copper, Cu 0.05 - 0.20 % 0.05 - 0.20 %

Manganese, Mn <= 0.05 % <= 0.05 %

Other, each <= 0.05 % <= 0.05 %

Other, total <= 0.15 % <= 0.15 %

Si+Fe <= 0.95 % <= 0.95 %

Zinc, Zn <= 0.10 % <= 0.10 %

References for this datasheet.

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistent format.

Users requiring more precise data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to

equivalent units. We advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you

refer to MatWeb's terms of use regarding this information. Click here to view all the property values for this datasheet as they were originally entered into MatWeb.

www.matweb.com/search/datasheet_print.aspx?matguid=c0652f2efeac49b89b50e7e4c6fba759 3/3

You might also like

- AISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDocument2 pagesAISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDiegoAlvarezHuguezNo ratings yet

- Hydro Forming-Automotive ComponentsDocument6 pagesHydro Forming-Automotive ComponentsJennifer KirklandNo ratings yet

- 1 Strengthofmaterials Interview QuestionsDocument21 pages1 Strengthofmaterials Interview QuestionsChanduReddyNo ratings yet

- 1 Strengthofmaterials Interview QuestionsDocument21 pages1 Strengthofmaterials Interview QuestionsChanduReddyNo ratings yet

- Kitchen Details by 0631 - DAGANTA PDFDocument1 pageKitchen Details by 0631 - DAGANTA PDFJay Carlo Daganta100% (1)

- Modeling of The Evaporation and Condensation Phase Change Problems With FLUENTDocument17 pagesModeling of The Evaporation and Condensation Phase Change Problems With FLUENTRashed KaiserNo ratings yet

- Mechanical Vibration WorksheetDocument6 pagesMechanical Vibration Worksheetduraiprakash83No ratings yet

- Al 1100-H18 Material PropertiesDocument3 pagesAl 1100-H18 Material PropertiesCarlos Andres Garcia MuñozNo ratings yet

- SNI 4658-2008-Pelek Kategori LDocument4 pagesSNI 4658-2008-Pelek Kategori LDimazNugrahaNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument4 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyJhonny IDNo ratings yet

- Aluminum 3004-O: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyDocument3 pagesAluminum 3004-O: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyLuis BadoffNo ratings yet

- Aluminum 7075-T6 7075-T651Document5 pagesAluminum 7075-T6 7075-T651Paul SangopantaNo ratings yet

- Aluminum 2014-T6 2014-T651 (Extended Form Data) : Advertise With Matweb!Document9 pagesAluminum 2014-T6 2014-T651 (Extended Form Data) : Advertise With Matweb!vishwanadh kNo ratings yet

- Statement of The Problem ScrewDocument18 pagesStatement of The Problem ScrewRuby Jane LuchingNo ratings yet

- 405 Stainless Steel sheetDocument1 page405 Stainless Steel sheetLorena Grijalba LeónNo ratings yet

- Special Metals UDIMET® Alloy 520 SuperalloyDocument2 pagesSpecial Metals UDIMET® Alloy 520 Superalloyapurv bhartiNo ratings yet

- Tube Material DataDocument8 pagesTube Material DatasemetayNo ratings yet

- AISI 4340 Steel, Oil Quenched 845°C, 650°C (1200°F) TemperDocument2 pagesAISI 4340 Steel, Oil Quenched 845°C, 650°C (1200°F) TemperDiegoAlvarezHuguezNo ratings yet

- Anexo A - Magnesium Elektron Elektron® ZRE1 Magnesium Alloy, UNS M12330 - DatasheetDocument3 pagesAnexo A - Magnesium Elektron Elektron® ZRE1 Magnesium Alloy, UNS M12330 - DatasheetAmilton CardosoNo ratings yet

- ASM Material Data Sheet 316Document2 pagesASM Material Data Sheet 316.xNo ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- 304 Stainless Steel Tecnical DataDocument2 pages304 Stainless Steel Tecnical DataArmando MátalNo ratings yet

- Aluminum 1060-O alloy data sheetDocument2 pagesAluminum 1060-O alloy data sheetMaruda8382No ratings yet

- AISI 1035 SteelDocument2 pagesAISI 1035 SteelCarlos Andres Garcia MuñozNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080No ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- AISI 1020 Steel, Normalized at 870°C (1600°F)Document2 pagesAISI 1020 Steel, Normalized at 870°C (1600°F)Vitor GodoyNo ratings yet

- 316 Stainless Steel, Annealed SheetDocument2 pages316 Stainless Steel, Annealed SheetZASSNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- AISI 1020 Steel, As RolledDocument3 pagesAISI 1020 Steel, As Rollednum fistismNo ratings yet

- AISI 1020 Steel, As RolledDocument3 pagesAISI 1020 Steel, As RolledS.Mohana sundaramNo ratings yet

- Sandvik Cuprothal 10 Resistance Wire: Metal Nonferrous Metal Copper AlloyDocument1 pageSandvik Cuprothal 10 Resistance Wire: Metal Nonferrous Metal Copper AlloyLorena Grijalba LeónNo ratings yet

- Aluminum 380.0-F Die Casting AlloyDocument2 pagesAluminum 380.0-F Die Casting AlloyLuis BadoffNo ratings yet

- AISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundDocument2 pagesAISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundGiancarlo PassalacquaNo ratings yet

- AISI 1025 Steel, Cold Drawn, High Temperature, Stress Relieved, 32-50 MM (1.25-2 In) RoundDocument3 pagesAISI 1025 Steel, Cold Drawn, High Temperature, Stress Relieved, 32-50 MM (1.25-2 In) RoundAJESH KUMARNo ratings yet

- Special Metals INCONEL® Alloy 625: Categories: Material NotesDocument6 pagesSpecial Metals INCONEL® Alloy 625: Categories: Material Notesdheeraj616No ratings yet

- AISI 4340 Steel, Oil Quenched 800°C (1470°F), 540°C (1000°F) Temper, 50 MM (2 inDocument2 pagesAISI 4340 Steel, Oil Quenched 800°C (1470°F), 540°C (1000°F) Temper, 50 MM (2 indiego AlvarezNo ratings yet

- 303-Stainless Steel-Annealed BarDocument2 pages303-Stainless Steel-Annealed BarARUNKANNANNo ratings yet

- Hot Rolled AISI 1045 Steel Round BarDocument2 pagesHot Rolled AISI 1045 Steel Round Bardiego AlvarezNo ratings yet

- Master Bond EP17HT LODocument3 pagesMaster Bond EP17HT LORusty AllenNo ratings yet

- 316L-SS-annealed BarDocument2 pages316L-SS-annealed BarARUNKANNANNo ratings yet

- Aisi 5140Document2 pagesAisi 5140rumabiswas853No ratings yet

- SUS 316 Material Properties PDFDocument1 pageSUS 316 Material Properties PDFYudo ArdianNo ratings yet

- 304HDocument1 page304HsemetayNo ratings yet

- 304Document2 pages304julianmorantesNo ratings yet

- Properties s45cDocument3 pagesProperties s45ctomas duranNo ratings yet

- LDX 2101 OutokumpuDocument2 pagesLDX 2101 OutokumpuLahire Solér JuniorNo ratings yet

- Aisi e 52100 SteelDocument2 pagesAisi e 52100 SteelFelipeTadeuNo ratings yet

- Nickel Aluminum Bronze PropertiesDocument6 pagesNickel Aluminum Bronze Propertiesdheeraj616No ratings yet

- AISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument3 pagesAISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelAleesha RehanNo ratings yet

- Haynes Hastelloy C-276 Alloy Sheet 2MMDocument3 pagesHaynes Hastelloy C-276 Alloy Sheet 2MMJitendra AmbaselkarNo ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless Steeldaniel enrique romero robayoNo ratings yet

- Aluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument2 pagesAluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyLuis BadoffNo ratings yet

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismNo ratings yet

- Al7050 T7451Document16 pagesAl7050 T7451Fatih HocaogluNo ratings yet

- Physical Properties Metric English: @strain 2.00 % @strain 2.00 %Document1 pagePhysical Properties Metric English: @strain 2.00 % @strain 2.00 %Rahul SanjayanNo ratings yet

- AISI 1005 Steel: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument2 pagesAISI 1005 Steel: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelIsrael BenavidesNo ratings yet

- Aluminum 6351-T6, Aluminium DatasheetDocument2 pagesAluminum 6351-T6, Aluminium DatasheetvikrantNo ratings yet

- Aluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg AlloyDocument3 pagesAluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg Alloyvishwanadh kNo ratings yet

- Acero Inox 410 MaterialData - 12949Document2 pagesAcero Inox 410 MaterialData - 12949Arturo AguilarNo ratings yet

- 316 Stainless Steel, Anneal...Document3 pages316 Stainless Steel, Anneal...Moisés Vázquez ToledoNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloySaad SaudNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Hydro Forming-Automotive ComponentsDocument6 pagesHydro Forming-Automotive ComponentsJennifer KirklandNo ratings yet

- Fea1 QuestionsDocument1 pageFea1 QuestionsJennifer KirklandNo ratings yet

- Fea 3Document1 pageFea 3Jennifer KirklandNo ratings yet

- Fea 2Document1 pageFea 2Jennifer KirklandNo ratings yet

- Torsion of Circular ShaftsDocument11 pagesTorsion of Circular Shaftsmatteo_1234No ratings yet

- 10028351689201002Document1 page10028351689201002dr maha laxmiNo ratings yet

- Fea 1Document1 pageFea 1Jennifer KirklandNo ratings yet

- Masters Thesis Walters FINALDocument174 pagesMasters Thesis Walters FINALJennifer KirklandNo ratings yet

- Mechanical Behavior of MaterialsDocument3 pagesMechanical Behavior of MaterialsJennifer KirklandNo ratings yet

- Design of Vehicle Structures For Crash Energy ManagementDocument85 pagesDesign of Vehicle Structures For Crash Energy ManagementMelissa StoicNo ratings yet

- FAQs OF FEMDocument5 pagesFAQs OF FEMUmer FarooqNo ratings yet

- Mtech 1st Sem CAPPDocument4 pagesMtech 1st Sem CAPPJennifer KirklandNo ratings yet

- Rapid PrototypingDocument4 pagesRapid PrototypingJennifer KirklandNo ratings yet

- Computer Integrated Manufacturing S3 M.tech KTU 2017 JanDocument2 pagesComputer Integrated Manufacturing S3 M.tech KTU 2017 JanJennifer KirklandNo ratings yet

- Ccard Tutorial de Catia v5Document0 pagesCcard Tutorial de Catia v5sgtjcNo ratings yet

- With Valves Supplied by Siemens: Building TechnologiesDocument45 pagesWith Valves Supplied by Siemens: Building TechnologiesHamid AbdNo ratings yet

- Sizing a Flare Stack and Calculating Flame Distortion from Wind VelocityDocument49 pagesSizing a Flare Stack and Calculating Flame Distortion from Wind VelocityBayu AjipNo ratings yet

- Philippine Presidents' Transportation Projects ComparisonDocument12 pagesPhilippine Presidents' Transportation Projects ComparisonEmmerson NavarroNo ratings yet

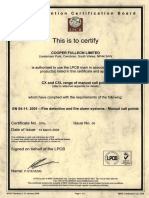

- LPCBDocument3 pagesLPCBhomaNo ratings yet

- CV Imen KrifaDocument1 pageCV Imen Krifaapi-732929360No ratings yet

- DryLin Drive Technology - Introduction ChapterDocument6 pagesDryLin Drive Technology - Introduction ChapterigusukNo ratings yet

- Theory of Anti Relativity" by E P DollardDocument16 pagesTheory of Anti Relativity" by E P DollardKWojtek100% (2)

- Ceo Proposed Os 2022 - Whole DeptDocument1 pageCeo Proposed Os 2022 - Whole Deptthethird20No ratings yet

- Chapter-XI-BOQ and Percentage Weightages-2279Document29 pagesChapter-XI-BOQ and Percentage Weightages-2279Prince AnejaNo ratings yet

- Kwa FORM RA2Document7 pagesKwa FORM RA2Anand Vamadevan0% (1)

- Adding New Fields To Condition Field CatalogDocument11 pagesAdding New Fields To Condition Field CatalogAnupa Wijesinghe86% (7)

- Apis PHP enDocument265 pagesApis PHP enAMORSIKO.EXENo ratings yet

- Marine & Offshore Safety ProductsDocument40 pagesMarine & Offshore Safety ProductsJose Manuel Jose ManuelNo ratings yet

- Descriptive Statistics Using SPSS: Ex No: DateDocument5 pagesDescriptive Statistics Using SPSS: Ex No: Datepecmba11No ratings yet

- Hydraulic Cartridge Logic Valves - Hydraulic ValveDocument2 pagesHydraulic Cartridge Logic Valves - Hydraulic Valveasif bashaNo ratings yet

- (BS 5955-8-2001) - Plastics Pipework (Thermoplastics Materials) - Specification For The Installation of Thermoplastic Pipes and Associated Fittings For Use in Domestic HoDocument14 pages(BS 5955-8-2001) - Plastics Pipework (Thermoplastics Materials) - Specification For The Installation of Thermoplastic Pipes and Associated Fittings For Use in Domestic HojohnNo ratings yet

- Mitsubishi Lifts BrochureDocument28 pagesMitsubishi Lifts Brochurenaveenarora298040No ratings yet

- Bohr Model PowerpointDocument21 pagesBohr Model Powerpointengchemistry18No ratings yet

- Proposal For A Cloud Computing Solution and Application in A Pedagogical Virtual OrganizationDocument10 pagesProposal For A Cloud Computing Solution and Application in A Pedagogical Virtual OrganizationloneislandNo ratings yet

- Work Experience: Kamble Arti Navnath MOB: (+91) 8830600972Document3 pagesWork Experience: Kamble Arti Navnath MOB: (+91) 8830600972KambleNo ratings yet

- Instruction Manual CZ 75 SP 01Document19 pagesInstruction Manual CZ 75 SP 01Rocco Volpe100% (2)

- A Comparative Study of The Provisions OF ACI: 318-08 AND IS: 456-2000 BUILDING Codes For Design of Flat SlabsDocument3 pagesA Comparative Study of The Provisions OF ACI: 318-08 AND IS: 456-2000 BUILDING Codes For Design of Flat Slabswafiullah sayedNo ratings yet

- Knauf OnBoards External CeilingsDocument2 pagesKnauf OnBoards External CeilingsScott FullerNo ratings yet

- BenQ G610HDA - V1Document47 pagesBenQ G610HDA - V1adriantxeNo ratings yet

- K1000 Agent Release NotesDocument6 pagesK1000 Agent Release NotesChail MiNo ratings yet

- Vol06 Tab02Document387 pagesVol06 Tab02D2FNo ratings yet

- Comparing Virtualization Platforms - PowerVM and VMWareDocument26 pagesComparing Virtualization Platforms - PowerVM and VMWareBart SimsonNo ratings yet