Professional Documents

Culture Documents

Fabrication Materials PT Description N.S QTY Client Code: Yna-AC

Uploaded by

Marcellino YohanesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication Materials PT Description N.S QTY Client Code: Yna-AC

Uploaded by

Marcellino YohanesCopyright:

Available Formats

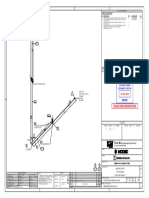

BILL OF MATERIALS

N FABRICATION MATERIALS

14 PT DESCRIPTION N.S CLIENT CODE QTY

2 1 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, PE, CS01, XS 1 PAC11APEG0DXS 2.7 M

2 ELBOW 90, ASTM A105N, ASME B16.11, SW, CL 3000, CS01 1 E9C31HSW3TG0D 5

3 ELBOW 45, ASTM A105N, ASME B16.11, SW, CL 3000, CS01 1 E4C31HSW3TG0D 1

4 FLANGE SW, ASTM A105N, ASME B16.5, RF, CL 150, CS01 1 FSC31ARFAAG0F 3

<7 14 2

> 8 EL +36385

15 1

<8> 1

124

1"NS

13

12

CONT. ON 16 <6> 1

02-CM-A2-140649-01

E 162067

771

S9

N 9071

UB1B-1in

EL +36261

2P-PWT-SPS-117

11

139

ERECTION MATERIALS

3 PT DESCRIPTION N.S CLIENT CODE QTY

<5 98

> 5 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER (E.G. 1 GAS71PAA0D 3

2 1 GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK (3.175 MM THK

10 SOLID RINGS), FLEXITALLIC TYPE "CGI", CL 150

6 65 MM Zn-Ni Plated + Whitford Xylan 1014 COATING / ASTM A320 GR 1/2 BSL61BB0E065 12

L7 / ASTM A194 GR 7 WITH 2 HVY HEX NUTS, Deep Med Blue

7 FLANGE BLIND WITH 1/2" FNPT, ASTM A105N, ASME B16.5, RF, CL 150, 1 FCC31ARFAAG0D0B 1

9 153 CS01

<4> 8 VALVE BALL LONG PATTERN FULL BORE ANSI B16.10 #150.RF.LOP 1 A2-2RBC 1

2 8 1 9 GUIDE U-BOLT UB1B, SEE STD DWG. 0568-MI20-92S1-1503-001 1 2

EL +35615

108

3

45°

6 EL +35507

8

10

<3> 1

950

5-1

SPL-2

E 162175 5 F4 G5 B6

N 8710 127

F1 EL +34240 8

7 F3 01-A2-2RBC-1406-143 CUT PIECE

F4 G5 B6 F2

1"N 01-A2-2RBC-1406-143 PIECE NO LENGTH N.S REMARK PIECE NO LENGTH N.S REMARK

CONN FROM SPT-141004 S SPL-1 4 VALVE LEVER/HW ORIENTATION D

BY TUBING F4 G5 B6 VALVE SPINDLE ORIENTATION S

1 150 1"

2 150 1"

<2> 1

1 82 3 928 1"

1-1 4 114 1"

181

5 350 1"

S9 6 723 1"

UB1B-1in <1

> 7 100 1"

2P-PWT-SPS-103 1 8 100 1"

3

18

1 D YNA- M AC Engineering Services Pte Ltd.

45 GUL ROAD, SINGAPORE 629350

2 CLIENT:

OWNER:

F1 F3

PROJECT TITLE :

1 16

DRAWING TITLE :

MODULE 2P-PWT Client

SPL-1 SPL-2

Rev

PWT PACKAGE

DESIGN CONDITION NOTES: LEGEND 1

DE. PRES. (BARG) : 16 STRESS CRITICAL : NDT (NOTE 5) 1. ALL DIMENSIONS ARE IN MILLIMETER (mm) 01-CM-A2-141024-01

OP. PRES. (BARG) : STRESS No. : RT (%) : 10% (Note 1) 2. ALL DIMENSIONS TO BE VERIFIED ON SITE SPOOL No. : THREAD No. :

DE. TEMP. (°C) : 93.3 PIPE SPEC : A2 LPT (%) : 3. DATA BASED ON LINE LIST REV. 5 DME Drawing Number : Sheet No Rev Size Scale

OP. TEMP. (°C) : 60 INSUL. (TYP.) : MPIT (%) : 4. DESIGN CONDITION TO BE CONFIRMED SHOP WELD No. : MTR No. :

TEST PRESS. (BARG) : 24 TRACING : UT (%) : WITH LATEST LINE LIST. 0 DME 29-OCT-20 ISSUED FOR CONSTRUCTION RJP NAA MW P102105-02P-PIP-WMD-CS-10157 1 / 1 0 A1 NTS

FIELD WELD No. : PIPE SUPPORT Drawn Chk'd Engrg

TEST MEDIUM : Note 4 PCKLG&PSVTN : PAUT (%) : 5. THERMAL INSULATION SPECIFICATION

Status/

Origi- by by Mgr Rev

Rev.

REFER 0568-MI20-00S1-0010. Date Description of revision MODEC Document Number :

CHEM. CLEANING : N PMI : P.W.H.T. (%) : No WELD No. : nator

Checked Approved

COATING SYS : B1 P&ID No. : VI (%) : FLG. REF. No. :

0568-DME20-92DJ-2001-002 0

COPYRIGHT OF DYNA-MAC ENGINEERING SERVICES PTE. LTD. WHOSE PROPERTY THIS DOCUMENT REMAINS. NO PART THEREOF MAY BE DISCLOSED, COPIED,

COLOR : 1410 2020 C DUPLICATED OR IN ANY OTHER WAY MADE USE OF, EXCEPT WITH APPROVAL OF: DYNA-MAC ENGINEERING SERVICES PTE LTD, 45 GUL RD, SINGAPORE 629350.

You might also like

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- TR-DM-MI-0218: Issued For ConstructionDocument2 pagesTR-DM-MI-0218: Issued For ConstructionMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- 7ansmittal Transmittal: To: Anecan (Batam) AttentionDocument2 pages7ansmittal Transmittal: To: Anecan (Batam) AttentionMarcellino YohanesNo ratings yet

- FALL 1:100: Fabrication Materials PT Description N.S QTY Client CodeDocument2 pagesFALL 1:100: Fabrication Materials PT Description N.S QTY Client CodeMarcellino YohanesNo ratings yet

- 7ansmittal Transmittal: To: Anecan (Batam) AttentionDocument2 pages7ansmittal Transmittal: To: Anecan (Batam) AttentionMarcellino YohanesNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mech 3-Module 1Document41 pagesMech 3-Module 1melkisidick angloanNo ratings yet

- Quality ControlDocument10 pagesQuality ControlSabbir AhmedNo ratings yet

- 2019 All PDFDocument27 pages2019 All PDFvishesh bhatiaNo ratings yet

- Standardization of Naoh 1Document3 pagesStandardization of Naoh 1api-309208977No ratings yet

- FL-02-01 PM SheetDocument12 pagesFL-02-01 PM SheetBikas SahaNo ratings yet

- Alien Vault Lab2Document28 pagesAlien Vault Lab2DukeNo ratings yet

- ZF CAT EBook Oil-Filters-Construction-Agricultural-Machinery-Transmissions 50114 201806 V02 IN PDFDocument142 pagesZF CAT EBook Oil-Filters-Construction-Agricultural-Machinery-Transmissions 50114 201806 V02 IN PDFdeisy ortegaNo ratings yet

- zx350lc 3 InglesDocument6 pageszx350lc 3 InglesLuis Nahuelhuaique LemusNo ratings yet

- Idlers - Medium To Heavy Duty PDFDocument28 pagesIdlers - Medium To Heavy Duty PDFEd Ace100% (1)

- BurnerDocument4 pagesBurnerAhmed Mohamed KhalilNo ratings yet

- Advanced Cooling System - EMD00253ENDocument4 pagesAdvanced Cooling System - EMD00253ENnarayanan_anoob0% (1)

- EN 1991-1-4 NA enDocument4 pagesEN 1991-1-4 NA enanuj3936100% (1)

- Psychrometric Chart - Us and Si UnitsDocument1 pagePsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914No ratings yet

- Optimizing Technique-Grenade Explosion MethodDocument18 pagesOptimizing Technique-Grenade Explosion MethodUday Wankar100% (1)

- Kathir CollegeDocument3 pagesKathir Collegeshanjuneo17No ratings yet

- RT L2 General Examination PaperDocument4 pagesRT L2 General Examination PaperdaddadNo ratings yet

- Dynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass DcpsDocument2 pagesDynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass Dcpsd'Hell CaesarNo ratings yet

- D 2510 - 94 R98Document3 pagesD 2510 - 94 R98David Cazorla100% (1)

- How Is Electrical Energy MeasuredDocument4 pagesHow Is Electrical Energy MeasuredSonya ReddyNo ratings yet

- Hot Air Oven Or Dry Oven: نﺎﺸﻄﻋ ﻦﻴﺴﺣ ﻲﻠﻋ G @a - nv19Document2 pagesHot Air Oven Or Dry Oven: نﺎﺸﻄﻋ ﻦﻴﺴﺣ ﻲﻠﻋ G @a - nv19حسين محمد مطرود كاظمNo ratings yet

- Astm D3359Document9 pagesAstm D3359Angel GuachaminNo ratings yet

- VB Script ReferenceDocument27 pagesVB Script ReferenceRajkumarNo ratings yet

- ISO 9001:2015 Questions Answered: Suppliers CertificationDocument3 pagesISO 9001:2015 Questions Answered: Suppliers CertificationCentauri Business Group Inc.100% (1)

- Portland CementDocument46 pagesPortland Cementni putu diah untariningsihNo ratings yet

- Method StatementDocument4 pagesMethod StatementtayitbatovNo ratings yet

- Sewer Connection Application Guidance PDFDocument7 pagesSewer Connection Application Guidance PDFSamuel FuentesNo ratings yet

- Phase DiagramDocument36 pagesPhase Diagramzainal arifinNo ratings yet

- NBN Co: Financial Management SolutionDocument2 pagesNBN Co: Financial Management SolutionAccentureAustraliaNo ratings yet

- Lecure Two. ReactorsDocument56 pagesLecure Two. ReactorsSophia WambuiNo ratings yet

- Mauser 98K - Model 48 Rifle ManualDocument20 pagesMauser 98K - Model 48 Rifle ManualMeor Amri96% (28)