Professional Documents

Culture Documents

Fabrication Materials PT Description N.S QTY Client Code: Yna-AC

Uploaded by

Marcellino YohanesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication Materials PT Description N.S QTY Client Code: Yna-AC

Uploaded by

Marcellino YohanesCopyright:

Available Formats

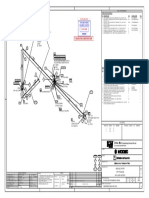

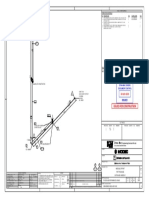

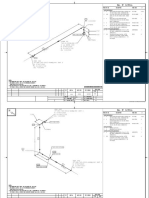

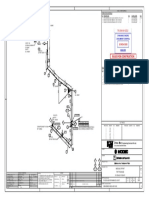

BILL OF MATERIALS

N CONT. ON FABRICATION MATERIALS

02-PG-A5DN-140725-P-01 PT DESCRIPTION N.S CLIENT CODE QTY

E 165952 1 PIPE, SEAMLESS ASTM A106 GR B, ASME B36.10, BE, CS01N NACE, STD 4 PAC11ABEN04ST 0.8 M

N 8588 2 REDUCER ECC, SEAMLESS ASTM A234 GR WPB-S, ASME B16.9, BW, CS01N 4X2 REC41DBWN04ST02X 1

EL +47739 NACE, STD x XS

3 FLANGOLET, ASTM A105N, MSS SP-97, ASME B16.5, RF, CL 300, CS01N 4X3/4 OFC31BRFBBN04ST0 1

14 NACE, STD x S160

1-1 4 ELBOW 90, SEAMLESS ASTM A234 GR WPB-S, ASME B16.9, R=1.5D, BW, 4 E9C41EBWN04ST 2

0.75-B2N-2RBC-1407-050 CS01N NACE, STD

5 FLANGE WN, ASTM A105N, ASME B16.5, RF, CL 150, CS01N NACE, STD 4 FWC31ARFAAN04ST 2

0.75-B2N-2RBC-1407-050 6 FLANGE WN, ASTM A105N, ASME B16.5, RF, CL 150, CS01N NACE, XS 2 FWC31ARFAAN02XS 1

SPL-1 VALVE LEVER/HW ORIENTATION S 7 STANDARD WELDED SHOE - S3, SEE STD DWG. 0568-MI20-92S1-1503-001 4 1

VALVE SPINDLE ORIENTATION W 8 REINFORCEMENT PAD - RP1, SEE STD DWG. 0568-MI20-92S1-1503-001 4 1

F6

166 4"N E 165952

S N 8166

2

2 EL +48080

4X2"NS

27MM OFFSET F2

FLAT SIDE UP 1

25 G10 B11

6 F1

152 15

S20

GT4E-4in-0.75in-MPM S16

PS-1 BP-4in

S19 G10 B11

207 3

GT1-0.75in-MPM

4X3/4"NS

OLET DIR U

9

S7

ERECTION MATERIALS

S3-4in-375-MPM

S18 PT DESCRIPTION N.S CLIENT CODE QTY

2P-PWT-PS-489

G2-4in 9 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER (E.G. 4 GAS71PAA04 2

GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK (3.175 MM THK

SOLID RINGS), FLEXITALLIC TYPE "CGI", CL 150

EL +47712 10 GASKET, 316L SS (ALL RINGS) WITH NON-ASBESTOS FILLER (E.G. 3/4 GAS71PBB0C 2

40

S8 9 <1 GRAPHITE), SPIRAL WOUND ASME B16.20, 4.5 MM THK (3.175 MM THK

> SOLID RINGS), FLEXITALLIC TYPE "CGI", CL 300

RP1-415-MPM-MPWT 1 11 80 MM Zn-Ni Plated + Whitford Xylan 1014 COATING / ASTM A320 GR 5/8 BSL62BB0F080 8

4 L7M / ASTM A194 GR 7M HVY HEX NUTS Black

S17 3 12 95 MM Zn-Ni Plated + Whitford Xylan 1014 COATING / ASTM A320 GR 5/8 BSL62BB0F095 16

L7M / ASTM A194 GR 7M HVY HEX NUTS Black

LS2A-4in 13 VALVE BALL LONG PATTERN FULL BORE ANSI B16.10 #150.RF.LOP 4 A2N-2RBC 1

14 VALVE BALL LONG PATTERN FULL BORE ANSI B16.10 #300.RF.LOP 3/4 B2N-2RBC 1

15 FLANGE BLIND, ASTM A105N, ASME B16.5, RF, CL 300, CS01N NACE 3/4 FBC31ARFBBN0C 1

16 PTFE BEARING PAD - BP, SEE STD DWG. 0568-MI20-92S1-1503-001 4 1

17 LINE STOP ON PIPE SHOE - LS2, SEE STD DWG. 4 1

0568-MI20-92S1-1503-001

4 18 GUIDE FOR PIPE ON SHOE-G2, SEE STD DWG. 0568-MI20-92S1-1503-001 4 1

19 GUSSET SUPPORTS FOR BRANCH - GT1, SEE STD DWG. 3/4 1

0568-MI20-92S1-1503-001

20 GUSSET SUPPORTS FOR VENT, DRAIN, & INSTRUMENT VALVE - GT4, SEE 3/4 1

STD DWG. 0568-MI20-92S1-1503-001

330

<2> 1

CONT. ON

04-FL-A2N-140704-01

E 166207

8 N 7758

F5 G9 B12 EL +46915

13

5 229

04-A2N-2RBC-1407-051 1

> CUT PIECE

04-A2N-2RBC-1407-051 F3 F4 <3

S

VALVE LEVER/HW ORIENTATION D 4"N PIECE NO LENGTH N.S REMARK PIECE NO LENGTH N.S REMARK

VALVE SPINDLE ORIENTATION W SPP-140709

5 SPL-2 1 513 4"

25

229

6 2 101 4"

3 103 4"

F5 G9 B12

7

6-1

4

EL +46915 D YNA- M AC Engineering Services Pte Ltd.

45 GUL ROAD, SINGAPORE 629350

CLIENT:

OWNER:

PS-1 PS-1

F1 F4

PROJECT TITLE :

1 9

DRAWING TITLE :

MODULE 2P-PWT Client

SPL-1 SPL-2

Rev

PWT PACKAGE

DESIGN CONDITION NOTES: LEGEND 2

DE. PRES. (BARG) : 17.5 STRESS CRITICAL : Y NDT (NOTE 5) 1. ALL DIMENSIONS ARE IN MILLIMETER (mm) 04-FL-A2N-140726-01

OP. PRES. (BARG) : 8.5 STRESS No. : RT (%) : 10% (Note 1) 2. ALL DIMENSIONS TO BE VERIFIED ON SITE SPOOL No. : THREAD No. :

DE. TEMP. (°C) : 105 PIPE SPEC : A2N LPT (%) : 3. DATA BASED ON LINE LIST REV. 5 DME Drawing Number : Sheet No Rev Size Scale

OP. TEMP. (°C) : 52 - 75 INSUL. (TYP.) : MPIT (%) : 4. DESIGN CONDITION TO BE CONFIRMED SHOP WELD No. : MTR No. :

TEST PRESS. (BARG) : 26.25 TRACING : UT (%) : WITH LATEST LINE LIST. 0 DME 23-OCT-20 ISSUED FOR CONSTRUCTION RAJ NAA MW P102105-02P-PIP-WMD-CS-10007 1 / 1 0 A1 NTS

FIELD WELD No. : PIPE SUPPORT Drawn Chk'd Engrg

TEST MEDIUM : Note 4 PCKLG&PSVTN : PAUT (%) : 5. THERMAL INSULATION SPECIFICATION

Status/

Origi- by by Mgr Rev

Rev.

REFER 0568-MI20-00S1-0010. Date Description of revision MODEC Document Number :

CHEM. CLEANING : N PMI : P.W.H.T. (%) : No WELD No. : nator

Checked Approved

COATING SYS : B1 P&ID No. : VI (%) : FLG. REF. No. :

0568-DME20-92DJ-2001-002 0

COPYRIGHT OF DYNA-MAC ENGINEERING SERVICES PTE. LTD. WHOSE PROPERTY THIS DOCUMENT REMAINS. NO PART THEREOF MAY BE DISCLOSED, COPIED,

COLOR : 1407 2020 C DUPLICATED OR IN ANY OTHER WAY MADE USE OF, EXCEPT WITH APPROVAL OF: DYNA-MAC ENGINEERING SERVICES PTE LTD, 45 GUL RD, SINGAPORE 629350.

You might also like

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- FALL 1:100: Fabrication Materials PT Description N.S QTY Client CodeDocument2 pagesFALL 1:100: Fabrication Materials PT Description N.S QTY Client CodeMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- TR-DM-MI-0218: Issued For ConstructionDocument2 pagesTR-DM-MI-0218: Issued For ConstructionMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Bill of Materials: 331U15-OWS-002-02-1Document1 pageBill of Materials: 331U15-OWS-002-02-1PT Bumi Liputan PusakaNo ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Diesel Pipeline: S7 S6B TYBE-2Document1 pageDiesel Pipeline: S7 S6B TYBE-2jibran42No ratings yet

- Material List - Fabrication: PT. Size Description QTYDocument4 pagesMaterial List - Fabrication: PT. Size Description QTYmixmixmixNo ratings yet

- 0468 Asom20 00TQ 0001 001 BDocument14 pages0468 Asom20 00TQ 0001 001 BDenny AgusNo ratings yet

- General Arrangement Drawing For Slug Catcher Rev.c IfaDocument1 pageGeneral Arrangement Drawing For Slug Catcher Rev.c IfaMe RahmanNo ratings yet

- Chwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)Document1 pageChwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)vishwas salunkheNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- HS372221 26 Pip Iso 0168 0000 1 - Rm01aDocument1 pageHS372221 26 Pip Iso 0168 0000 1 - Rm01aibrahim qasimovNo ratings yet

- Chwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)Document1 pageChwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)vishwas salunkheNo ratings yet

- Pdf24 Merged (1)Document11 pagesPdf24 Merged (1)jep jepriNo ratings yet

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocument1 page01 E02STB007-W146693-03-0 - BC - Stress Update86tejasNo ratings yet

- Material List for Piping ComponentsDocument1 pageMaterial List for Piping Componentsvishwas salunkheNo ratings yet

- Lista de Materiales: Item Diam Cant DescripcionDocument1 pageLista de Materiales: Item Diam Cant DescripcionMarcia IturraNo ratings yet

- Piping Isometric - 3Document1 pagePiping Isometric - 3CosminMarianNo ratings yet

- 150 10xaa1 H50 21RDCH 1004 1Document1 page150 10xaa1 H50 21RDCH 1004 1uma raneNo ratings yet

- 4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Document1 page4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- JI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1Document1 pageJI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1weerachai phosoongNo ratings yet

- So6625 61DD3 61DD3L So6625-Eh0d-Iso-61dd3l-015 03 Er-000 03Document2 pagesSo6625 61DD3 61DD3L So6625-Eh0d-Iso-61dd3l-015 03 Er-000 03Erick's Cer'LpzNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- 4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Document2 pages4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- FABRICATION MATERIALS AND COMPONENT LISTDocument7 pagesFABRICATION MATERIALS AND COMPONENT LISTCLS AKNo ratings yet

- Pipe Support: 1. Paddle Flange Detail 8. 1 EA: Bill of MaterialsDocument1 pagePipe Support: 1. Paddle Flange Detail 8. 1 EA: Bill of MaterialscostonzNo ratings yet

- D A42 1362 0001J 17 Isometric ExtractedDocument3 pagesD A42 1362 0001J 17 Isometric ExtractedAnhNtCaoNo ratings yet

- J3BGDF02BR005 01 01Document1 pageJ3BGDF02BR005 01 01saleem naheedNo ratings yet

- EL +101840 4"NPD 3: Bill of MaterialDocument5 pagesEL +101840 4"NPD 3: Bill of MaterialDANLIN ENGINEERSNo ratings yet

- Fabrication Materials ListDocument1 pageFabrication Materials ListSaptarshi MandalNo ratings yet

- Tal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Piping Isometric - 7Document1 pagePiping Isometric - 7CosminMarianNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Tupi BV: Cosco (Dalian)Document1 pageTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Corrosion Inspection of Piping CircuitDocument14 pagesCorrosion Inspection of Piping CircuitPrasad ChakkrapaniNo ratings yet

- 4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Document11 pages4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- 335A01-PN-118-02-SP - 1: Bill of MaterialsDocument1 page335A01-PN-118-02-SP - 1: Bill of MaterialsDavid LekaNo ratings yet

- NDT SpecsDocument3 pagesNDT SpecsRam Shankar SahuNo ratings yet

- Issued For Construction Modular Isometrics: Piping Isometric DrawingDocument1 pageIssued For Construction Modular Isometrics: Piping Isometric Drawing86tejasNo ratings yet

- A303hal Aish L Mto 2001 A3Document7 pagesA303hal Aish L Mto 2001 A3THOMASNo ratings yet

- 3D PV 2017 BrochureDocument6 pages3D PV 2017 BrochurehabilNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- P4059zor 62 22 1 T1001 018 002 - ADocument1 pageP4059zor 62 22 1 T1001 018 002 - Ashravan.office11No ratings yet

- SL 6900K01C50 10164 01 - 00Document2 pagesSL 6900K01C50 10164 01 - 00effiezool mohdNo ratings yet

- BILL OF MATERIALSDocument1 pageBILL OF MATERIALSABAID ULLAHNo ratings yet

- 4103 TOYO20 92DJ 1300 040 - Rev 1 - Sht001Document6 pages4103 TOYO20 92DJ 1300 040 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Client Tie-in Schedule and System Design DataDocument2 pagesClient Tie-in Schedule and System Design DataManuel SerranoNo ratings yet

- Tal Wsa PNG Iso 1SF058302 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1SF058302 - 01 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- IsoDocument20 pagesIsoGökhanNo ratings yet

- All Piping Drawings Spec SheetsDocument18 pagesAll Piping Drawings Spec Sheetsc.reidNo ratings yet

- Design, Manufacturing, Supply, Installation, Construction & Commissioning of BQPS RLNG Spur Pipeline Project Line ListDocument3 pagesDesign, Manufacturing, Supply, Installation, Construction & Commissioning of BQPS RLNG Spur Pipeline Project Line ListUmair A. KhanNo ratings yet

- Profile RT 21-060-004Document4 pagesProfile RT 21-060-004Marcus AntoniusNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- TR-DM-MI-0218: Issued For ConstructionDocument2 pagesTR-DM-MI-0218: Issued For ConstructionMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- 7ansmittal Transmittal: To: Anecan (Batam) AttentionDocument2 pages7ansmittal Transmittal: To: Anecan (Batam) AttentionMarcellino YohanesNo ratings yet

- DYNA-MAC Engineering Services Pte Ltd TransmittalDocument2 pagesDYNA-MAC Engineering Services Pte Ltd TransmittalMarcellino YohanesNo ratings yet

- TR P102105 000 DM SC 0150 - ANECAN - ListDocument1 pageTR P102105 000 DM SC 0150 - ANECAN - ListMarcellino YohanesNo ratings yet

- Form 7Document2 pagesForm 7Wing TabarNo ratings yet

- Design Report For Proposed 3storied ResidentialbuildingDocument35 pagesDesign Report For Proposed 3storied ResidentialbuildingMohamed RinosNo ratings yet

- Quickguide Students For CopyrightsDocument2 pagesQuickguide Students For Copyrightslordvorldomort100% (1)

- Gray Iron Castings: Standard Specification ForDocument6 pagesGray Iron Castings: Standard Specification Forsafak kahramanNo ratings yet

- Document Revision TableDocument11 pagesDocument Revision Tableseva1969No ratings yet

- Pharmacy Perspective on Improving Patient SafetyDocument44 pagesPharmacy Perspective on Improving Patient SafetydicodrNo ratings yet

- Fundamentals Deep Learning Activation Functions When To Use ThemDocument15 pagesFundamentals Deep Learning Activation Functions When To Use ThemfaisalNo ratings yet

- HackSpace - June 2021Document116 pagesHackSpace - June 2021Somnath100% (1)

- Australian Institute For Teaching and School Leadership - AITSLDocument5 pagesAustralian Institute For Teaching and School Leadership - AITSLYu LiNo ratings yet

- 4 Operation of Design Review in Small Irrigation Projects inDocument20 pages4 Operation of Design Review in Small Irrigation Projects inJoseph Rana SangpangNo ratings yet

- Som-Ii Uqb 2019-20Document23 pagesSom-Ii Uqb 2019-20VENKATESH METHRINo ratings yet

- Chemists 12-2023Document7 pagesChemists 12-2023PRC BaguioNo ratings yet

- Glossary of Permafrost and Ground-Ice IPA 2005Document159 pagesGlossary of Permafrost and Ground-Ice IPA 2005NatitaGonzàlezDíazNo ratings yet

- Audit Chapter 7Document5 pagesAudit Chapter 7Addi Såïñt George100% (2)

- Water TreatmentDocument6 pagesWater TreatmentSantiago LarrazNo ratings yet

- RD218 Gardan 3110 Ob2226657 NDocument1 pageRD218 Gardan 3110 Ob2226657 Nopen hartigNo ratings yet

- Smart Panels - Digitized Switchboards - Blokset Desing and Assembly GuideDocument94 pagesSmart Panels - Digitized Switchboards - Blokset Desing and Assembly Guidelorentz franklinNo ratings yet

- 3M SS Filters Data SheetDocument4 pages3M SS Filters Data SheetbinnisfquoteNo ratings yet

- Sample Resume For HRDocument2 pagesSample Resume For HRnapinnvoNo ratings yet

- Texto en inglesDocument5 pagesTexto en inglesJesus Andres Lopez YañezNo ratings yet

- Hatsun Supplier Registration RequestDocument4 pagesHatsun Supplier Registration Requestsan dipNo ratings yet

- READING U8Document4 pagesREADING U8Như TrầnNo ratings yet

- MathWorks Interview ProcessDocument2 pagesMathWorks Interview ProcessPawan Singh100% (1)

- Dear Boy (Acordes para Cancion)Document4 pagesDear Boy (Acordes para Cancion)Rodolfo GuglielmoNo ratings yet

- Crash of Air France ConcordeDocument11 pagesCrash of Air France ConcordeAhmad Aimi SafuanNo ratings yet

- Proposal On Online Examination For BE EntranceDocument21 pagesProposal On Online Examination For BE Entrancesubhash22110360% (5)

- Akuntansi Keuangan Lanjutan - Akuntansi Penggabungan UsahaDocument67 pagesAkuntansi Keuangan Lanjutan - Akuntansi Penggabungan UsahachendyNo ratings yet

- Improve Product Packaging at Annual Board MeetingDocument9 pagesImprove Product Packaging at Annual Board Meetingizzat89% (9)

- SRT95 Off-Highway Truck Rear Axle Assembly: Structure and Installation Part 2 Parts Presentation Part 3 MaintenanceDocument29 pagesSRT95 Off-Highway Truck Rear Axle Assembly: Structure and Installation Part 2 Parts Presentation Part 3 MaintenanceoktopusNo ratings yet

- Professional Education ReviewerDocument22 pagesProfessional Education ReviewerJustine WicoNo ratings yet