Professional Documents

Culture Documents

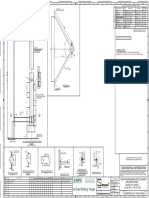

General Arrangement Drawing For Slug Catcher Rev.c Ifa

Uploaded by

Me RahmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Arrangement Drawing For Slug Catcher Rev.c Ifa

Uploaded by

Me RahmanCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12

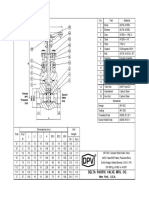

ITEM QTY DESCRIPTION

BILL OF MATERIAL

MATERIAL DIMENSION REMARKS

DESIGN DATA

C 1 2 ELLIPSOIDAL HEAD (2:1) SA 516 GR.70 PL, THK 34 x 1600.ID TAG NO. : TGCL-MBA-220

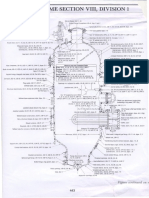

2 1 SHELL SA 516 GR.70 PL, THK 30 x 3923 x 5212 CODE : ASME SECTION VIII DIV. 1, 2019 EDITION

N2 SV SO N4 N3 3 1 FLANGE WN RF SA 105 NPS 18", #300 ASME B16.5 : YES

LS.02 AT 45° 4 1 FLANGE WN RF SA 105 NPS 12", #300 ASME B16.5

MIGAS CERTIFICATE

4 10 20 12" 2" 12" 2" 2"

45° 5 9 FLANGE WN RF SA 105 NPS 2", #300 ASME B16.5

SERVICE : SLUG CATCHER

A N2 6 1 FLANGE WN RF SA 105 NPS 24", #300 ASME B16.5 DESIGN PRESSURE (MIN/MAX) Psig 625 AA

12" 7 2 BLIND FLANGE RF SA 105 NPS 2", #300 ASME B16.5 DESIGN TEMPERATURE (MIN/MAX) °F 150

0° 8 1 BLIND FLANGE RF SA 105 NPS 24", #300 ASME B16.5 OPERATING PRESSURE (MIN/MAX) Psig 252.8

9 1 NECK NOZZLE 18 IN SA 106 GR.B NPS 18" x THK 25mm x 359 L

OPERATING TEMPERATURE (MIN/MAX) °F 105

0

10 1 NECK NOZZLE 12 IN SA 106 GR.B NPS 12" x SCH80 x 280 L

18

29 28 27 N9 11 7 NECK NOZZLE 2 IN SA 106 GR.B NPS 2" x SCH160 x 155 L SPECIFIC GRAVITY 0.64

2"

55 12 1 NECK NOZZLE 24 IN SA 516 GR.70 NPS 24" xTHK 30mm x 223 L VISCOCITY cP 0.0115

C

315°

1 13 1 NECK NOZZLE 2 IN SA 106 GR.B NPS 2" x SCH160 x 575 L

COMPRESSIBILITY FACTOR Z 0.95

14 2 NECK NOZZLE 2 IN SA 106 GR.B NPS 2" x SCH160 x 845 L

800

LS.03 AT 292.5° 15 2 NOZZLE PIPE SLEEVE SA 106 GR.B NPS 2" x SCHSTD x 60 L

HYDROSTATIC TEST PRESSURE Psig 884.72

508

16 1 NOZZLE SKIRT OPENING SA 106 GR.B NPS 12" SCHSTD x 60 L M.D.M.T °F -20

17 2 NECK SS SA 106 GR.B NPS 2" x SCHSTD x 60 L MAX. ALLOW. WORKING PRESSURE Psig 627.21

100

SS

54 LH.01

50

18 1 PAD MANHOLE SA 516 GR.70 PL, THK 30 x

4" POST WELD HEAT TREATMENT AS PERCODE

19 1 PAD NOZZLE INLET SA 516 GR.70 PL, THK 3O x

N5 20 1 PAD NOZZLE OUTLET SA 516 GR.70 PL, THK 20 x STRESS RELIEVING OF HEAD AFTER COLD FORMING AS PERCODE

B CW.01 21 2 GASKET 2" SPW #300 SPW RING SS 316L THK 4.5, NPS 2", #300 RADIOGRAPHY 100 % B

2"

22 1 GASKET 24" SPW #300 SPW RING SS 316L THK 4.5, NPS 24", #300 JOINT EFFICIENCY 1

N8 270° 90° MH 23 24 STUD BOL 5/8" UNC SA 193 GR. B7 5/8" UNC x 100 L

2" 24" PAINTING NOTE 8

24 48 HEX NUT 5/8" UNC SA 192 GR.2H 5/8" UNC

LS.01

25 16 STUD BOLT 1 1/2" UNC SA 194 GR.B7 1 1/2" UNC x 230 L

PROCESS CONDITIONS

45°

571 N4 26 32 HEX NUT 1 1/2" UNC SA 192 GR.2H 1 1/2" UNC

3510

2"

5 27 2 PAD LIFTING LUG SA 516 GR.70 PL, THK 30 x 610 x 360

CW.02 OPERATING PRESSURE (MIN/MAX) Psig 252.8

11 28 2 LIFTING LUG SA 36 PL, THK 30 x 260 x 1054

LS.02

OPERATING TEMPERATURE °F 105

LS.01-03 AT 24.5° 29 2 SUPPORT LIFTING LUG SA 36 PL, THK 19

GAS FLOW RATE MMSCFD 80

30 2 HAND HOLE SA 36 RB, OD 16 x 350 L

46 31 1 PIPE DAVIT ARM SA 106 GR.B NPS, 2" x SCHXXS x 1275 L FLOW RATE BLPD -

11 32 1 END PLATE DAVIT ARM SA 36 PL, THK T x 96 x 96 OPERATING Lbs 20,825.5

5

N9 225° 1 WEIGHT

2800 Ø1600(ID.SHELL) 33 BRACKET DAVIT ARM SA 36 PL, THK 20 x 63 x 200

EMPTY Lbs 20,091.5

°

11 2" N7B N7A 34 1 SLEEVE DAVIT ARM SA 106 GR.B NPS 2" x SCHSTD x 220 L

136

FULL OF WATER Lbs 41,618.5

C N8 2" 2" 35 1 U-BAR SA 36 RB, OD3/4" x 150 L

C

5 2"

2800 50 36 1 EYE BOLT RB, 3/4" x 415 L

NOTE:

37 1 COLLAR DAVIT ARM SA 36 PL, THK 19 x 96 x96 1. ALL DIMENSIONS ARE MM UNLESS OTHERWISE NOTED.

1524

19 38 2 HEX NUT 3/4" UNC SA 194 GR.2H 3/4"UNC 2. ALL BOLT SHALL STRADDLE THE CENTERLINE FOR SHELL NOZZLES.

39 1 SA 36 3. SERVICE GASKET SHALL BE USED FOR ALL NOZZLES IN HYDRO TESTING.

2 9 135° WASHER 3/4" 3/4"

4. GASKET SPEC. SPRIRAL WOUND FLEXIBLE GRAPHITE, THIKNESS 4.5 MM. C

40 1 RIB DAVIT ARM SA 36 PL, THK 6 x 155 x 495

N1 N6A SS N6B 5. ALL FABRICATED NOZZLE NECK WELDS SHALL BE 100% RADIOGRAPHED.

2400

18"

3 41 1 BASE RING SA 36 PL, THK 32 x1960 x1960 6. ALL REINFORCING PAD WELDS FOR NOZZLE AND ANY OTHER TYPE OF ATTACHMENT

30 2" 4" 2" 42 1 SUPPORT SKIRT SA 36 PL, THK 12 x 1851 x 1660 SHALL BE CHECKED FOR LEAKS WITH MINIMUM AIR PRESSURE OF 50 Psig PRIOR TO

26 40 R1784 43 1 TOP BASE RING SA 36 PL, THK 20 x1960x1960 THE PRESSURE TEST. ALL REINFORCEMENT PAD TELL TALE HOLES SHALL BE WITH SILICONE SEALANT.

2205 48 44 16 STIFFENER PLATE SA 36 PL, THK 14 x200 x 150

TELLTALE HOLES SHALL BE AT 90 DEGREE TO VESSEL AXIS.

7. EXTERNAL BOLT/NUTS SHALL BE FLUOROCARBON COATED. D

25 39

T/T.4023

49 45 2 EARTING LUG SA 240 GR.316L PL, THK 3 x 50 x 33 8. EXRENAL PAINTING AS PER DOC CKL-EPC-00-PIP-SPC-004 SPECIFICATION FOR PAINTING.

46 11 INTERNAL LADDER SA 36 RB, OD20 x 620 L 9. PLATFORM-LADDER SEE DOC. AJM24-113-004-PDD-010.

21 38 180° 47 1 VORTEX PLATE SA 516 GR.70 PL. THK 10 x 60 x 120

CW.03

11 38 SV N1 48 1 BRACKET NAME PLATE SA 516 GR.70 PL, THK 6 x 150 x 275

N6A 49 1 NAME PLATE SA 240 GR.316L PL, THK 3 x140 x155

7 2" 18"

D ±HLL 1727

2"

37 50 1 HALF PIPE SA 516 GR.70 PL, THK 25 x 718 x 815

N7A 24

APPROX.6753

51 1 TAILING LUG SA 36 PL, THK 30 x 345 x 200

5 1600 36

51

2" 1676 23

52 1 ELBOW LR 90 BW SA 234 WPB NPS 2", SCH160

35

22 TOPP VIEW ( 1 : 32 ) 53

54

1

1

EQUAL TEE BW

MIST ELIMINATOR

SA 234 WPB

SA 240 GR.316L

NPS 2", SCH160

OD1660 x 150

LS.03

32 55 1 PLATFORM-LADDER SS-400 NOTE 9

NOZZLE SCHEDULE

18 56 8 ANCHOR BOLT SA 307 M25 x 560 L C GALVANIZED

31 RATING PROJECTION

18 0° 22.5° MARK QTY SIZE SCH/

FROM OD

SERVICE/REMARKS

30 (TH'K) RATING FACING TYPE

12 E

1828

N1 1 18" 25mm 300# RF WN 10" GAS INLET

RF GAS OUTLET

8 N2 1 12" 80 300# WN 16"

N7B MH N3 1 2" 160 300# RF WN 6" DRAIN

6

45

750 750

1800.BCD

°

2" 24" N4 1 2" 160 300# RF WN 6" VENT

N3 N5 1 2" 160 300# RF WN 6" LIQUID OUTLET

E

11 5 2"

700 37 34 30x8 HOLES N6A/B 1 2" 160 300# RF WN 6" LEVEL GAUGE

±LLL FOR B/N/W M25 x 560 L N7A/B 2 2" 160 300# RF WN 6" SPARE+BLIND

N8 2 2" 160 300# RF WN 6" PI

TYP

300

REF. LINE 356 N9 1 2" 160 300# RF WN 6" TI

50

20

CW.04 MH 1 24" 30mm 300# RF WN 12" MANHOLE

1960

14

SO 1 12" STD - - - 1.18" SKIRT OPENING

100

- - -

270° 90° SS 2 4" STD 1.18" PIPE SLEEPE

F

LH.02 SV 2 2" STD - - - 1.18" SKIRT VENT

47

550

14

SV

F 17

160

2" 56

13

This drawing is the exclusive property of ARMINDO and it contains

450

5 14 16 53 informations regarded as confidential by ARMINDO. This drawing

12 41 shall not be traced, copied or reproduced in any manner, nor used for

1930

42 N6B SS SO any purpose whatsoever except written permission of ARMINDO.

2" 4" 12"

N5 SS

44 OWNER :

2" 4" 180°

50 Ø1660(OD) 345 5 15

14

45 43 CONTRACTOR :

52 SECTION M- M ( 1 : 32 )

20

M M

G G

415

200

FABRICATOR :

AT 0°

32

Ø1420

Ø1960

51 PERSPECTIVE ( 1 : 70 )

PROJECT :

ELEVATION VIEW ( 1 : 32 ) DESIGN NOZZLE LOAD (DOC NO:CKL-EPC-00-MEC-SPC-001-REV 0) JASA PERANCANGAN, PENGADAAN DAN KONSTRUKSI (EPC)PEMBANGUNAN

SIZE RATING FX FY FZ MX MY MZ PIPA GAS CIKARANG LISTRINDO JABABEKA

H H

NPS /CLASS (lbf) (lbf) (lbf) (ft.lbf) (ft.lbf) (ft.lbf) C 13/05/2020 RE-ISSUED FOR APPROVAL HL YD DN TITLE : GENERAL ARRANGEMENT DRAWING

B YD

2" 300 630 471.8 630 268.8 207.2 310.8

20/04/2020 ISSUED FOR APPROVAL HL DN SLUG CATCHER

A 06/04/2020 ISSUED FOR REVIEW HL YD DN (TGCL-MBA-220)

12" 300 3780 2830.8 3780 9676.8 7459.2 11188.8 PRE'P CHKD APP'D CHECK APP'D

SHEET SCALE DRAWING NO. REV.

18" 300 5670 4246.2 5670 21772.8 16783.2 25174.8 REV DATE DESCRIPTION

PT.ARMINDO JAYA MANDIRI PT. ELNUSA TBK 1 OF 1 NTS AJM-24-114-005-GAD-005 C

1 2 3 4 5 6 7 8 9 10 11 12

You might also like

- Risk Assessment For Temporary ServicesDocument15 pagesRisk Assessment For Temporary Servicesfaizan khan100% (2)

- SEVPL BrochureDocument20 pagesSEVPL BrochureNaveen AnandNo ratings yet

- Asme Guide For Sec Viii Div 1Document1 pageAsme Guide For Sec Viii Div 1siddharth pawarNo ratings yet

- Brosur Reckat 2019Document16 pagesBrosur Reckat 2019wika mepNo ratings yet

- EXP 2 Compressible Gas Flow 08-15 PDFDocument16 pagesEXP 2 Compressible Gas Flow 08-15 PDFKamran MostajiriNo ratings yet

- Brosur Reckat 2017 PDFDocument12 pagesBrosur Reckat 2017 PDFRidwanda HimawanNo ratings yet

- 20ft Skid ISO FrameDocument1 page20ft Skid ISO FrameThanhdong DoNo ratings yet

- Aerial Work Platforms Diesel Articulated Jib: Technical SheetDocument5 pagesAerial Work Platforms Diesel Articulated Jib: Technical Sheet2a nauraNo ratings yet

- JMS Operating Manual Niftylift HR 21Document46 pagesJMS Operating Manual Niftylift HR 21Ивайло ДимитровNo ratings yet

- Valve World - India: 3 - 4 October 2019Document11 pagesValve World - India: 3 - 4 October 2019aharnishaNo ratings yet

- SET P&ID - Filter Cellar - Tibasosa PDFDocument9 pagesSET P&ID - Filter Cellar - Tibasosa PDFJairo Hernando Rojas PulidoNo ratings yet

- Final Reports 2019 - 2 PDFDocument178 pagesFinal Reports 2019 - 2 PDFRounak SriwastawaNo ratings yet

- BY: R Reason For Change Date: Chk'D. R Drawing No.: 0Document1 pageBY: R Reason For Change Date: Chk'D. R Drawing No.: 0josebaldesNo ratings yet

- GondolaDocument1 pageGondolascax25No ratings yet

- 70t MOD 70 Spreader Beam SpecsDocument2 pages70t MOD 70 Spreader Beam SpecsWes NowakNo ratings yet

- Sample Seal Pot DWGDocument1 pageSample Seal Pot DWGsandesh sadvilkarNo ratings yet

- Pressure Drop Caln - 1Document390 pagesPressure Drop Caln - 1Prashant SinghNo ratings yet

- Pricelist JindalDocument12 pagesPricelist JindalAr Nitin Aggarwal0% (1)

- Building Plumbing Systems Design - (Lecture 01-Introduction)Document30 pagesBuilding Plumbing Systems Design - (Lecture 01-Introduction)محمد إسلام عبابنه100% (3)

- 050 0160 A (Main Frame Assembly)Document3 pages050 0160 A (Main Frame Assembly)Miltongrimi GrimilNo ratings yet

- Plumbing - Specification 2011.Document8 pagesPlumbing - Specification 2011.Ponz MadianoNo ratings yet

- LMB2-E-FC-PIP-OCS-MS1-0015 Stress & Flexibility Analysis Report For Steam Separator LMB-ADocument30 pagesLMB2-E-FC-PIP-OCS-MS1-0015 Stress & Flexibility Analysis Report For Steam Separator LMB-AAzhar BudimanNo ratings yet

- Design For External Pressure-13022018Document14 pagesDesign For External Pressure-13022018ToniNo ratings yet

- Standard Size Trap - Taylor ForgeDocument1 pageStandard Size Trap - Taylor ForgeAlessio BarboneNo ratings yet

- Advanced High Pressure Engine Study For Mixed Mode Vehicle ApplicationsDocument318 pagesAdvanced High Pressure Engine Study For Mixed Mode Vehicle Applicationsdjeffal mohammed amineNo ratings yet

- Proposed Azon Rice Mill: Engr. Ramil S. CatamoraDocument3 pagesProposed Azon Rice Mill: Engr. Ramil S. CatamoraKristoperOrtizNo ratings yet

- Skimmer Pipe Example DrawingDocument1 pageSkimmer Pipe Example Drawingjagannadha varma100% (1)

- 26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002Document33 pages26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002ogyriskyNo ratings yet

- $huldo :run 3odwirupv 'Lhvho $uwlfxodwhg With - Le: 7hfkqlfdo VKHHWDocument2 pages$huldo :run 3odwirupv 'Lhvho $uwlfxodwhg With - Le: 7hfkqlfdo VKHHWManitouNo ratings yet

- MM-ZTK-1B-WP6-STR-MTO-2001 Rev.B1 PDFDocument105 pagesMM-ZTK-1B-WP6-STR-MTO-2001 Rev.B1 PDFvu tuanNo ratings yet

- Specialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Document1 pageSpecialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Naresh KumarNo ratings yet

- Gruvlok CatalogDocument276 pagesGruvlok CatalogFerdie WakeUp FromAdversityNo ratings yet

- Piping CalculationsDocument5 pagesPiping CalculationsreenaNo ratings yet

- ISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108Document1 pageISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108TomasPavlovicNo ratings yet

- 4 tOPIC 2 TAKING OFF COLD WATER PIPEDocument23 pages4 tOPIC 2 TAKING OFF COLD WATER PIPEaremyul100% (1)

- Legend Sheet P&ID For As-Built - Drafting On 20210722-4Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-4Ludi D. LunarNo ratings yet

- Price EstimationDocument6 pagesPrice EstimationJosua Ferry ManurungNo ratings yet

- Uk Mod 24 Ui - Jul 15Document2 pagesUk Mod 24 Ui - Jul 15yogihardNo ratings yet

- Flanges - Standard Dim For Flanges Used in InvestaDocument2 pagesFlanges - Standard Dim For Flanges Used in InvestaBharat TailorNo ratings yet

- Valve Seat Material GuideDocument1 pageValve Seat Material GuidewawanNo ratings yet

- Skid 1 - Foundation Load Table: Dead Weight (LB) Wind Load (120 MPH) Load (LBF) Load (LBF) S 0.825gDocument3 pagesSkid 1 - Foundation Load Table: Dead Weight (LB) Wind Load (120 MPH) Load (LBF) Load (LBF) S 0.825gomarNo ratings yet

- ZA14J/ZA18J: Articulating Boom LiftsDocument2 pagesZA14J/ZA18J: Articulating Boom Liftskarthik bhatNo ratings yet

- Customer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaDocument2 pagesCustomer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaomarNo ratings yet

- UntitledDocument108 pagesUntitledM-NCPPCNo ratings yet

- Bronze Ball Valves Flammable Fluid Fuel Gas Applications - TBDocument4 pagesBronze Ball Valves Flammable Fluid Fuel Gas Applications - TBGreg FarzettaNo ratings yet

- Output File S3 R5 Z4Document72 pagesOutput File S3 R5 Z4Ankush JainNo ratings yet

- Option-2-Piping Support Structural BOQDocument12 pagesOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenNo ratings yet

- 1714010223-Vent Ext Fima - RDocument1 page1714010223-Vent Ext Fima - RMilton IngaNo ratings yet

- TII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptDocument18 pagesTII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptBorn ToSinNo ratings yet

- 12 Inches Pig Receiver Supports Design PDFDocument13 pages12 Inches Pig Receiver Supports Design PDFolomuNo ratings yet

- 7.5 Tons Overhead CraneDocument1 page7.5 Tons Overhead CraneGnabBangNo ratings yet

- Non Critical Lines SupportingDocument8 pagesNon Critical Lines SupportingKKNo ratings yet

- Din 6914-10.9Document2 pagesDin 6914-10.9vpjagannaathNo ratings yet

- PDILDocument13 pagesPDILSergio SmithNo ratings yet

- Custody Transfer Metering Skid - Sea TransportationDocument518 pagesCustody Transfer Metering Skid - Sea Transportationswathi.nayudu2k3No ratings yet

- 2.ANNEXUREDocument89 pages2.ANNEXUREAnonymous fLgaidVBhzNo ratings yet

- Att 15 - Equipment Nozzle LoadsDocument11 pagesAtt 15 - Equipment Nozzle LoadsahmedalishNo ratings yet

- Delta Pacific Valve Mfg. Co.: New York, U.S.ADocument1 pageDelta Pacific Valve Mfg. Co.: New York, U.S.ALê Tuấn AnhNo ratings yet

- Material Take Off Bulk MTODocument6 pagesMaterial Take Off Bulk MTOJordan MosesNo ratings yet

- L&T Aquaseal Butterfly Check Valves PDFDocument28 pagesL&T Aquaseal Butterfly Check Valves PDFSanjay SahulNo ratings yet

- Fixotec Technical CatalogueDocument71 pagesFixotec Technical CatalogueSaqib AliNo ratings yet

- r1Document3 pagesr1naseema1No ratings yet

- GA Drawing SLOP TankDocument2 pagesGA Drawing SLOP TankMathivanan AnbazhaganNo ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Bill of Materials: 331U15-OWS-002-02-1Document1 pageBill of Materials: 331U15-OWS-002-02-1PT Bumi Liputan PusakaNo ratings yet

- P4059zor 62 22 1 T1001 018 002 - ADocument1 pageP4059zor 62 22 1 T1001 018 002 - Ashravan.office11No ratings yet

- SL 6900K01C50 10164 01 - 00Document2 pagesSL 6900K01C50 10164 01 - 00effiezool mohdNo ratings yet

- Vendor Mto 12 10 22Document23 pagesVendor Mto 12 10 22Me RahmanNo ratings yet

- AVEVA LFM Datasheet 2018 PDFDocument5 pagesAVEVA LFM Datasheet 2018 PDFCecep RoniNo ratings yet

- Pengadaan Instrument Air Compressor Package & Instrument Air Receiver For Area Semberah Pertamina Ep Asset 5 Field SangattaDocument6 pagesPengadaan Instrument Air Compressor Package & Instrument Air Receiver For Area Semberah Pertamina Ep Asset 5 Field SangattaMe RahmanNo ratings yet

- Legend & Symbol GeneralDocument2 pagesLegend & Symbol GeneralMe RahmanNo ratings yet

- 12 PG CL A0 - SHT - 1Document1 page12 PG CL A0 - SHT - 1Me RahmanNo ratings yet

- P-Plp-001-Pipde Piping Tega of 5 Rev 1Document1 pageP-Plp-001-Pipde Piping Tega of 5 Rev 1Me RahmanNo ratings yet

- DCI Double Flanged Pipe, L 6m, DN 110 MM DCI Double Flanged Pipe With Puddle Flange PN 16, L 0.6m, DN 100 MMDocument19 pagesDCI Double Flanged Pipe, L 6m, DN 110 MM DCI Double Flanged Pipe With Puddle Flange PN 16, L 0.6m, DN 100 MMMiko AbiNo ratings yet

- SERIES 5 QuestionsDocument6 pagesSERIES 5 QuestionsTon Ton BondaNo ratings yet

- LAM 0208 HDA GuidelinesDocument13 pagesLAM 0208 HDA GuidelinesNorizam AyobNo ratings yet

- IBR FormsDocument32 pagesIBR FormsPradeep Kumar BendalaNo ratings yet

- Drawings All PUBLIC 7-14-20 - HuntingDocument33 pagesDrawings All PUBLIC 7-14-20 - HuntingjaymuscatNo ratings yet

- ECM442 Lecture 2 SMM CESMMDocument13 pagesECM442 Lecture 2 SMM CESMMDijah SafingiNo ratings yet

- What Is Pipe Schedule Explanation and Pipe Schedule ChartsDocument4 pagesWhat Is Pipe Schedule Explanation and Pipe Schedule ChartsiaftNo ratings yet

- Slurry Crutcher P&idDocument1 pageSlurry Crutcher P&idfadi713No ratings yet

- Mitsubishi Electric PUHY-P YJM-A PUHY-EP YJM-A Installation Manual EngDocument24 pagesMitsubishi Electric PUHY-P YJM-A PUHY-EP YJM-A Installation Manual Engasas0% (1)

- Lab 2 ReportDocument16 pagesLab 2 ReportLiyanna Blanda100% (2)

- Parker (NS) Volume Control Valves PDFDocument5 pagesParker (NS) Volume Control Valves PDFKamal NarangNo ratings yet

- Roke Needle Valves NewDocument8 pagesRoke Needle Valves NewBay SetyaNo ratings yet

- Iti VGBF GB Regulador QseDocument18 pagesIti VGBF GB Regulador QsedieguineoNo ratings yet

- PED 2014-68-EU Guidelines EN v2Document225 pagesPED 2014-68-EU Guidelines EN v2Stefano FavaroNo ratings yet

- 2017 03438 01 003 - Bom 490Document3 pages2017 03438 01 003 - Bom 490sundyaNo ratings yet

- Plumbing EstimateDocument3 pagesPlumbing Estimatedanny hugNo ratings yet

- Duyar VanaDocument83 pagesDuyar VanaÖzgür BiliciNo ratings yet

- Getting Your Threads RightDocument4 pagesGetting Your Threads Rightsatheez3251No ratings yet

- VDP Series: Dynamic Differential Pressure Control Valves (DPCV)Document3 pagesVDP Series: Dynamic Differential Pressure Control Valves (DPCV)Muhammad MuslimNo ratings yet

- 2006 National Standard Plumbing Code ILLUSTRATED 256 To 258Document3 pages2006 National Standard Plumbing Code ILLUSTRATED 256 To 258Ahmed Mohamed GadoNo ratings yet

- AV6+ BypassGeneralDescriptionDocument14 pagesAV6+ BypassGeneralDescriptionGaurav ChauhanNo ratings yet

- PIPE FLOW 3-Equivalent LengthDocument4 pagesPIPE FLOW 3-Equivalent LengthBasil DubeNo ratings yet