Professional Documents

Culture Documents

Ialt00228 MDW Catalog

Uploaded by

Franklin RochaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ialt00228 MDW Catalog

Uploaded by

Franklin RochaCopyright:

Available Formats

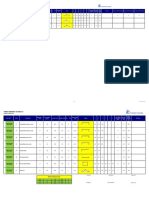

IWAKI MDW

Dimensions

series

g h A

H

Magnetic Drive Pump

f

b

c d a i

e W

Motor output Mass

Model (kW) W H L* a b c d e f g h i A B (kg)

22 (1397) 420

(540) (485) 500 (255) 840 205 1250 260 (380) 4xø23

30 (1435) 430

37 530

2P (505) (1495) 280 125 (400) 50A 80A

45 (610) 550 (280) 940 230 1400 545

4xø27

55 (525) (1508) 300 (425) 580

75 (660) --- (1645) 600 (320) 1060 270 1600 330 --- 735

MDW50

11 320

(1350) (259)

15 335

(485)

18.5 (540) 500 (255) 840 205 1250 260 4xø23 395

4P (1397) 125 (380) 50A 80A

22 405 The MDW Series are the largest fluoroplastic magnetic drive pumps in the world, offering high efficiency and

30 (1435) (380) 435 durability for chemical process applications.

37 (610) (505) (1525) 550 (280) 940 230 1400 280 (400) 4xø27 540

• High discharge capacity, High head and high efficiency - The heavy-duty MDW is capable of a

37 515

(1535) (400) maximum discharge capacity of 5,000 L/min and max. discharge head of 98m, enabling applications

45 (610) 550 (265) 940 230 1400 300 530

2P (580) 125 4xø27 80A 125A in previously unexplored areas with a wide range of liquid specific gravities.

55 (1548) (425) 570

75 (660) (1685) 600 (305) 1060 270 1600 330 --- 790

• Highly chemically resistant - Fluoroplastic and fine ceramic wetted parts offer high

11 335

MDW80 (1390) (259) resistance to virtually every industrial chemical, irrespective of concentration.

15 350

(540) 500 (240) 840 205 1250 4xø23

18.5 415

4P (580) (1437) 300 125 80A 125A • Robust structure - Use of the high strength ductile cast iron external armour is

22 (380) 425

mandatory for heavy duty chemical process applications. High casing pressure resistance is achieved

30 (1475) 465

(610) 550 (265) 940 230 1400 4xø27 with a unique rear casing design preventing stress concentration and incorporating a triple-layer

37 (1565) (400) 520 structure (PAT). A special metal shaft is used on the MDW to withstand high radial forces and allow

37 510

(560) (1535) 280 (400) continuous extended operation even under harsh service conditions.

45 (610) 550 (265) 940 230 1400 530

2P 125 4xø27 100A 125A

55 (580) (1548) 300 (425) 620

• Back pullout system - The back pullout system allows easy maintenance and inspection without

75 (660) --- (1685) 600 (305) 1060 270 1600 330 --- 760

removing pipework. Integrated components and a sealed rear casing support structure enable motor

11 340

MDW100 (1390) (259) removal safely without chemical leakage.

15 355

(540) (560) 500 (240) 840 205 1250 4xø23

18.5 420

4P (1437) 280 125 100A 125A • ISO compliant - The MDW is dimensionally compliant with the international standard (ISO2858,

22 (380) 430

3661) and is interchangeable with conventional sealed centrifugal pumps.

30 (1475) 470

(610) (560) 550 (265) 940 230 1400 4xø27

37 (1565) (400) 515

* Based on motor manufacturer

IALT00228.B August 2015

www.IwakiAmerica.com www.IwakiCustomPumps.com

Five Boynton Road • Holliston, MA • 01746 USA • Tel: 508-429-1440 • Fax: 508-429-1386 info@iwakiamerica.com

MDW Wet-end materials 1 Front casing 2 Impeller

8 Gasket

(m)

50Hz MDW

100

series 7 Sleeve 3 Rear casing

series

90

8 Gasket

Part Name MDW50 MDW80,100

(Air vent port)

80

1 Front casing PFA ETFE

2 Impeller PFA CFRETFE MDW50 (2P)

70

3 Rear casing PFA

4 Split plate PFA

60

Magnet cap-

5 PFA

HEAD

sule MDW80 (2P)

6 Bearing SiC 50

7 Sleeve SiC MDW100 (2P)

8 Gasket PTFE 40

9 O-Ring Kalrez®

30

8 Gasket 5 Magnet capsule

(Drain port) 4 Split plate

20

Model Identification 9 O ring 6 Bearing

10

MDW50 (4P) MDW80 (4P) MDW100 (4P)

MDW 100 - 200 E K Z C 750 J - D 2

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 (L/min)

30 60 90 120 150 180 210 240 270 300 (m3/hr)

CAPACITY

Pump size Nominal impeller size Wet-end main material Motor poles

50: 80mm x 50mm 170 to 260 E: ETFE, CFRETFE, PFA 2: 2P

(m)

80: 125mm x 80mm P: PFA 4: 4P

100: 125mm x 100mm 60Hz

100

Material of Bearing/Sleeve Material of O-ring Type of motor 90

K: SiC Z: Kalrez® C: Foot mounted type motor

80

MDW50 (2P)

70

Motor output Pump standard Special version

110 to 750: 11kW to 75kW J: JIS flange A: Without drain + With base, coupling, coupling cover

A: ANSI flange S: Without drain + With base, coupling, coupling cover + Special version

60

D: With drain + With base, coupling, coupling cover

HEAD

X: With drain + With base, coupling, coupling cover + Special version

B: Without drain + Without base, coupling, coupling cover

Y: Without drain + Without base, coupling, coupling cover + Special version 50

E: With drain + Without base, coupling, coupling cover MDW80 (2P)

Z: With drain + Without base, coupling, coupling cover + Special version

40

Specifications 50/60 Hz MDW100 (2P)

30

Capacity

Pump Size (mm)

Nominal Head Motor

Model Suction Discharge Impeller Size L/min m3/hr (m) (kw) 20

250/220 833/1000 50/60 83/93 2P 22, 30, 37, 45, 55, 75

MDW-50 80 50

250/260 417/500 25/30 21.5/31 4P 11, 15, 18.5, 22, 30, 37

10

MDW50 (4P) MDW80 (4P) MDW100 (4P)

250/220 2667/2000 160/120 90/99 2P 37, 45, 55, 75

MDW-80 125 80

255/255 1333/2000 80/120 23/30 4P 11, 15, 18.5, 22, 30, 37

0

200/200 3333/2000 200/120 62/97 2P 37, 45, 55, 75 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 (L/min)

MDW-100 125 100 30 60 90 120 150 180 210 240 270 300 (m3/hr)

235/235 1667/2000 100/120 21.5/30 4P 11, 15, 18.5, 22, 30, 37

CAPACITY

MDW Wet-end materials 1 Front casing 2 Impeller

8 Gasket

(m)

50Hz MDW

100

series 7 Sleeve 3 Rear casing

series

90

8 Gasket

Part Name MDW50 MDW80,100

(Air vent port)

80

1 Front casing PFA ETFE

2 Impeller PFA CFRETFE MDW50 (2P)

70

3 Rear casing PFA

4 Split plate PFA

60

Magnet cap-

5 PFA

HEAD

sule MDW80 (2P)

6 Bearing SiC 50

7 Sleeve SiC MDW100 (2P)

8 Gasket PTFE 40

9 O-Ring Kalrez®

30

8 Gasket 5 Magnet capsule

(Drain port) 4 Split plate

20

Model Identification 9 O ring 6 Bearing

10

MDW50 (4P) MDW80 (4P) MDW100 (4P)

MDW 100 - 200 E K Z C 750 J - D 2

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 (L/min)

30 60 90 120 150 180 210 240 270 300 (m3/hr)

CAPACITY

Pump size Nominal impeller size Wet-end main material Motor poles

50: 80mm x 50mm 170 to 260 E: ETFE, CFRETFE, PFA 2: 2P

(m)

80: 125mm x 80mm P: PFA 4: 4P

100: 125mm x 100mm 60Hz

100

Material of Bearing/Sleeve Material of O-ring Type of motor 90

K: SiC Z: Kalrez® C: Foot mounted type motor

80

MDW50 (2P)

70

Motor output Pump standard Special version

110 to 750: 11kW to 75kW J: JIS flange A: Without drain + With base, coupling, coupling cover

A: ANSI flange S: Without drain + With base, coupling, coupling cover + Special version

60

D: With drain + With base, coupling, coupling cover

HEAD

X: With drain + With base, coupling, coupling cover + Special version

B: Without drain + Without base, coupling, coupling cover

Y: Without drain + Without base, coupling, coupling cover + Special version 50

E: With drain + Without base, coupling, coupling cover MDW80 (2P)

Z: With drain + Without base, coupling, coupling cover + Special version

40

Specifications 50/60 Hz MDW100 (2P)

30

Capacity

Pump Size (mm)

Nominal Head Motor

Model Suction Discharge Impeller Size L/min m3/hr (m) (kw) 20

250/220 833/1000 50/60 83/93 2P 22, 30, 37, 45, 55, 75

MDW-50 80 50

250/260 417/500 25/30 21.5/31 4P 11, 15, 18.5, 22, 30, 37

10

MDW50 (4P) MDW80 (4P) MDW100 (4P)

250/220 2667/2000 160/120 90/99 2P 37, 45, 55, 75

MDW-80 125 80

255/255 1333/2000 80/120 23/30 4P 11, 15, 18.5, 22, 30, 37

0

200/200 3333/2000 200/120 62/97 2P 37, 45, 55, 75 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 (L/min)

MDW-100 125 100 30 60 90 120 150 180 210 240 270 300 (m3/hr)

235/235 1667/2000 100/120 21.5/30 4P 11, 15, 18.5, 22, 30, 37

CAPACITY

IWAKI MDW

Dimensions

series

g h A

H

Magnetic Drive Pump

f

b

c d a i

e W

Motor output Mass

Model (kW) W H L* a b c d e f g h i A B (kg)

22 (1397) 420

(540) (485) 500 (255) 840 205 1250 260 (380) 4xø23

30 (1435) 430

37 530

2P (505) (1495) 280 125 (400) 50A 80A

45 (610) 550 (280) 940 230 1400 545

4xø27

55 (525) (1508) 300 (425) 580

75 (660) --- (1645) 600 (320) 1060 270 1600 330 --- 735

MDW50

11 320

(1350) (259)

15 335

(485)

18.5 (540) 500 (255) 840 205 1250 260 4xø23 395

4P (1397) 125 (380) 50A 80A

22 405 The MDW Series are the largest fluoroplastic magnetic drive pumps in the world, offering high efficiency and

30 (1435) (380) 435 durability for chemical process applications.

37 (610) (505) (1525) 550 (280) 940 230 1400 280 (400) 4xø27 540

• High discharge capacity, High head and high efficiency - The heavy-duty MDW is capable of a

37 515

(1535) (400) maximum discharge capacity of 5,000 L/min and max. discharge head of 98m, enabling applications

45 (610) 550 (265) 940 230 1400 300 530

2P (580) 125 4xø27 80A 125A in previously unexplored areas with a wide range of liquid specific gravities.

55 (1548) (425) 570

75 (660) (1685) 600 (305) 1060 270 1600 330 --- 790

• Highly chemically resistant - Fluoroplastic and fine ceramic wetted parts offer high

11 335

MDW80 (1390) (259) resistance to virtually every industrial chemical, irrespective of concentration.

15 350

(540) 500 (240) 840 205 1250 4xø23

18.5 415

4P (580) (1437) 300 125 80A 125A • Robust structure - Use of the high strength ductile cast iron external armour is

22 (380) 425

mandatory for heavy duty chemical process applications. High casing pressure resistance is achieved

30 (1475) 465

(610) 550 (265) 940 230 1400 4xø27 with a unique rear casing design preventing stress concentration and incorporating a triple-layer

37 (1565) (400) 520 structure (PAT). A special metal shaft is used on the MDW to withstand high radial forces and allow

37 510

(560) (1535) 280 (400) continuous extended operation even under harsh service conditions.

45 (610) 550 (265) 940 230 1400 530

2P 125 4xø27 100A 125A

55 (580) (1548) 300 (425) 620

• Back pullout system - The back pullout system allows easy maintenance and inspection without

75 (660) --- (1685) 600 (305) 1060 270 1600 330 --- 760

removing pipework. Integrated components and a sealed rear casing support structure enable motor

11 340

MDW100 (1390) (259) removal safely without chemical leakage.

15 355

(540) (560) 500 (240) 840 205 1250 4xø23

18.5 420

4P (1437) 280 125 100A 125A • ISO compliant - The MDW is dimensionally compliant with the international standard (ISO2858,

22 (380) 430

3661) and is interchangeable with conventional sealed centrifugal pumps.

30 (1475) 470

(610) (560) 550 (265) 940 230 1400 4xø27

37 (1565) (400) 515

* Based on motor manufacturer

IALT00228.B August 2015

www.IwakiAmerica.com www.IwakiCustomPumps.com

Five Boynton Road • Holliston, MA • 01746 USA • Tel: 508-429-1440 • Fax: 508-429-1386 info@iwakiamerica.com

You might also like

- Four Seasons Hotels and Resorts Luxury Hotels Four Seasons Lung King Heen 自選菜單Document1 pageFour Seasons Hotels and Resorts Luxury Hotels Four Seasons Lung King Heen 自選菜單Terrence KuNo ratings yet

- Presion Neumaticos 931Document1 pagePresion Neumaticos 931kathy fernandezNo ratings yet

- Volvo Penta 300 340 380Document2 pagesVolvo Penta 300 340 380Phong Trương100% (1)

- Volvo Penta Inboard Diesel: 5.5 Liter, In-Line 6 CylinderDocument2 pagesVolvo Penta Inboard Diesel: 5.5 Liter, In-Line 6 Cylinderabduallah muhammadNo ratings yet

- D6-300/340/380 DPI: Volvo Penta Aquamatic DuopropDocument2 pagesD6-300/340/380 DPI: Volvo Penta Aquamatic DuopropPlingu RazvanNo ratings yet

- R4A51 / V4A51 / R5A51 / V5A51: RWD 4 & 5 SpeedDocument8 pagesR4A51 / V4A51 / R5A51 / V5A51: RWD 4 & 5 Speedmarran almarranyNo ratings yet

- Katalog MesinDocument23 pagesKatalog MesinNitia FailarizkaNo ratings yet

- D6-300/340/380/400 DPH: Volvo Penta Aquamatic DuopropDocument2 pagesD6-300/340/380/400 DPH: Volvo Penta Aquamatic DuopropDinamikaMarineNo ratings yet

- SK73 - IEC160: Date Name Drawn SystemDocument1 pageSK73 - IEC160: Date Name Drawn SystemHugo AcevedoNo ratings yet

- کاتالوگ ولوو پنتاDocument2 pagesکاتالوگ ولوو پنتامحمد محمدNo ratings yet

- JCB 8025-8035Document8 pagesJCB 8025-8035SC Colosseum Print SRL100% (1)

- Kruger - CSD Cabinet FanDocument4 pagesKruger - CSD Cabinet FanBismech EngineeringNo ratings yet

- Arburg Allrounder 570s Multi-Component TD 680169 en GBDocument16 pagesArburg Allrounder 570s Multi-Component TD 680169 en GBEko Prastyo100% (1)

- scx800hd-2 PRDocument6 pagesscx800hd-2 PRДмитрий БакайNo ratings yet

- Bar Bending Batching PlantDocument3 pagesBar Bending Batching PlantAnonymous 5OUozYNo ratings yet

- A4rab4rab46abdrabmxam4ras4raslxa20420speed PDFDocument2 pagesA4rab4rab46abdrabmxam4ras4raslxa20420speed PDFedger100% (1)

- FR24 - P4 Fabricate Hooper TankDocument5 pagesFR24 - P4 Fabricate Hooper TankSyaiful DarmawanNo ratings yet

- Volvo Penta Inboard Diesel: Technical DataDocument2 pagesVolvo Penta Inboard Diesel: Technical Datahusan shahNo ratings yet

- Nictoro Brochure Cabinet FanDocument12 pagesNictoro Brochure Cabinet FanFaquruddinNo ratings yet

- Kruger CSD FansDocument4 pagesKruger CSD FansoTexasRangerNo ratings yet

- Modeling and Simulation of Friction Stir Welding of Dissimilar Alloys and MaterialsDocument7 pagesModeling and Simulation of Friction Stir Welding of Dissimilar Alloys and MaterialsEdilberto Murrieta LunaNo ratings yet

- RUPETDocument1 pageRUPETMaksim DubovikNo ratings yet

- Inspection Astronic Cf75cf85xf95 12toDocument1 pageInspection Astronic Cf75cf85xf95 12toDaniel PricopNo ratings yet

- Brabus D6 (Ii) : BasisDocument1 pageBrabus D6 (Ii) : BasisP ANo ratings yet

- Canopy PlanDocument1 pageCanopy Plansasi00027No ratings yet

- 44 SF TR - enDocument1 page44 SF TR - entarek.amirecheNo ratings yet

- FWD 3 Speed: 000 Paper & Rubber Kit 002 Overhaul KitDocument4 pagesFWD 3 Speed: 000 Paper & Rubber Kit 002 Overhaul KitKelvin Samuel Chirinos ChirinosNo ratings yet

- Single Beam Trolley Z420 - Brano PDFDocument4 pagesSingle Beam Trolley Z420 - Brano PDFНиколаЖижовићNo ratings yet

- IEC 60071-1 Page 22Document1 pageIEC 60071-1 Page 22omid fathiNo ratings yet

- NISSINDocument97 pagesNISSINTeepoonsab somsaiNo ratings yet

- Fahu 01Document9 pagesFahu 01Aiman AliNo ratings yet

- Inspection Astronic cf75cf85xf95 16tdDocument1 pageInspection Astronic cf75cf85xf95 16tdInjeletro DieselNo ratings yet

- Solidwork HomeworkDocument3 pagesSolidwork Homeworkchroeun sokayNo ratings yet

- RAV Mercedes RAV8055.2.54MB 01Document2 pagesRAV Mercedes RAV8055.2.54MB 01Gabriel LaureanoNo ratings yet

- RAV Mercedes RAV8055.2.54MB 01 PDFDocument2 pagesRAV Mercedes RAV8055.2.54MB 01 PDFGabriel LaureanoNo ratings yet

- D6-44o/480 WJ: Volvo Penta Inboard DieselDocument2 pagesD6-44o/480 WJ: Volvo Penta Inboard Dieselabduallah muhammadNo ratings yet

- Volvo Penta Inboard Diesel: 3.7 Liter, In-Line 4 CylinderDocument2 pagesVolvo Penta Inboard Diesel: 3.7 Liter, In-Line 4 CylinderSutiknoNo ratings yet

- Generator Base DrawingDocument1 pageGenerator Base Drawingpasan rajasingheNo ratings yet

- Water Jet TrusmasterDocument5 pagesWater Jet TrusmasterSagita WidyatamaNo ratings yet

- Projeto Guarda Corpo Da EscadaDocument1 pageProjeto Guarda Corpo Da EscadaJardielson JoseNo ratings yet

- Heat Exchanger - Sheet1Document1 pageHeat Exchanger - Sheet1meteNo ratings yet

- Technical Spec-Denyo DCA-New StagingDocument2 pagesTechnical Spec-Denyo DCA-New StagingisnanhidayNo ratings yet

- Cat K Series Tooth System Model Guide: Conversion ChartDocument4 pagesCat K Series Tooth System Model Guide: Conversion ChartJOSE FRANCO CRUZNo ratings yet

- Pump Reference PDFDocument2 pagesPump Reference PDFRolando RodriguezNo ratings yet

- 45 Pump Industry: RPM Trimming (R) : Curve No: 50 HZ SUC: 65 Disch: 50Document1 page45 Pump Industry: RPM Trimming (R) : Curve No: 50 HZ SUC: 65 Disch: 50Yiannis KontominasNo ratings yet

- Choose Your Power Right: Highlander SeriesDocument1 pageChoose Your Power Right: Highlander SeriesFian -No ratings yet

- Filter DuplexDocument1 pageFilter DuplexM Talib HRNo ratings yet

- Hang Rào 3Document1 pageHang Rào 3Tre VanNo ratings yet

- 3a TDA (Smokespill) - KVM - LEA026.ED2Document2 pages3a TDA (Smokespill) - KVM - LEA026.ED2Helda MhptNo ratings yet

- E-Brochure CKE Warehouse-Factory BuildingDocument8 pagesE-Brochure CKE Warehouse-Factory BuildingAchmadAscarNo ratings yet

- NewsReleaseEDocument2 pagesNewsReleaseEcahaya subuhNo ratings yet

- 138 O Legato Interlock Block 1600 X 800 X 800Document1 page138 O Legato Interlock Block 1600 X 800 X 800BogdanBNo ratings yet

- Escalator Industry - E Series: Bush TypeDocument2 pagesEscalator Industry - E Series: Bush Typeapuhapuh_153349No ratings yet

- Projeto de Plataforma Com SegurançaDocument1 pageProjeto de Plataforma Com SegurançaJardielson JoseNo ratings yet

- Vinodrai Engineers PVT LTD: Date Appd - by Name Y.B.Shaikh Customer Name:-Description: - 28-03-2023 28-03-2023 28-03-2023Document1 pageVinodrai Engineers PVT LTD: Date Appd - by Name Y.B.Shaikh Customer Name:-Description: - 28-03-2023 28-03-2023 28-03-2023Shaikh YusufNo ratings yet

- 50-40 - 50-42leDocument4 pages50-40 - 50-42leHendro NuryahyaNo ratings yet

- Lay Out Taso Gudang PLB 15-03-2024Document2 pagesLay Out Taso Gudang PLB 15-03-2024ferikomangNo ratings yet

- An805 8Document3 pagesAn805 8jcNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Iwaki: Magnetic Drive PumpDocument4 pagesIwaki: Magnetic Drive PumpFranklin RochaNo ratings yet

- Iwaki: Magnetic Drive PumpDocument4 pagesIwaki: Magnetic Drive PumpFranklin RochaNo ratings yet

- Ialt00273 NRD BrochureDocument4 pagesIalt00273 NRD BrochureFranklin RochaNo ratings yet

- Iwaki: Self-Priming Magnetic Drive PumpDocument4 pagesIwaki: Self-Priming Magnetic Drive PumpFranklin RochaNo ratings yet

- Iwaki: Magnetic Drive PumpDocument4 pagesIwaki: Magnetic Drive PumpFranklin RochaNo ratings yet

- IALT00035 MX BrochureDocument4 pagesIALT00035 MX BrochureFranklin RochaNo ratings yet

- Iwaki: Direct Drive Seal-Less PumpDocument4 pagesIwaki: Direct Drive Seal-Less PumpFranklin RochaNo ratings yet

- IALT00040 Bellows BrochureDocument2 pagesIALT00040 Bellows BrochureFranklin RochaNo ratings yet

- Solar Pumping Design Manual Eng 1Document70 pagesSolar Pumping Design Manual Eng 1Franklin Rocha100% (2)

- Performance Measurement. The ENAPS ApproachDocument33 pagesPerformance Measurement. The ENAPS ApproachPavel Yandyganov100% (1)

- Portugal Espacial PT Space Catalog 2011 Screen VersionDocument86 pagesPortugal Espacial PT Space Catalog 2011 Screen Versionpmjafonso100% (1)

- Company Work Execution Plan For A Long Form ContractDocument4 pagesCompany Work Execution Plan For A Long Form Contractshojaee1063No ratings yet

- IP10G-CLI User Guide Version 6.7 March2011Document124 pagesIP10G-CLI User Guide Version 6.7 March2011JorgIVariuS100% (1)

- Urethyn HG 0 - Pi - (Gb-En)Document2 pagesUrethyn HG 0 - Pi - (Gb-En)CriVe OffeNo ratings yet

- Generator Hydrogen Cooling InfoDocument21 pagesGenerator Hydrogen Cooling InfovarsbsNo ratings yet

- Ddal Players Guide v5Document12 pagesDdal Players Guide v5Jakob Cherpovsky100% (1)

- Intel® Desktop Board DP35DPDocument84 pagesIntel® Desktop Board DP35DPAnticristo69No ratings yet

- 5 Arduino IDE GyroDocument12 pages5 Arduino IDE Gyrowaleed_buttzNo ratings yet

- BRO MAHA Alle Fahrwerkstechnik ENDocument8 pagesBRO MAHA Alle Fahrwerkstechnik ENFranco DiacNo ratings yet

- Savitha S. Panikar, PH.DDocument4 pagesSavitha S. Panikar, PH.Diboorose7No ratings yet

- Adarsh J - Resume (Curriculum Vitae)Document2 pagesAdarsh J - Resume (Curriculum Vitae)Adarsh J100% (1)

- CP R77.20 EndpointSecurity AdminGuideDocument168 pagesCP R77.20 EndpointSecurity AdminGuideMSNo ratings yet

- Topray Tpsm5u 185w-200wDocument2 pagesTopray Tpsm5u 185w-200wThanh Thai LeNo ratings yet

- ANSI-IEEE, NEMA and UL Requirements For SwitchgearDocument4 pagesANSI-IEEE, NEMA and UL Requirements For Switchgearefmartin21No ratings yet

- IA-NT-PWR-2.4-Reference GuideDocument110 pagesIA-NT-PWR-2.4-Reference GuideSamuel LeiteNo ratings yet

- GPRS Session 4 Power Control Twn01Q4Document18 pagesGPRS Session 4 Power Control Twn01Q4Nguyen LeNo ratings yet

- J030 J032 Eu Aa V1.00Document41 pagesJ030 J032 Eu Aa V1.00gkalman_2No ratings yet

- Well Control Manual - DRILL0108W01 - 24-3-08Document93 pagesWell Control Manual - DRILL0108W01 - 24-3-08hosam aliNo ratings yet

- Pressostato SUCO - 0159Document3 pagesPressostato SUCO - 0159Hugo Lemos ArthusoNo ratings yet

- Accreditation ScopeDocument19 pagesAccreditation ScopeTrainer 01No ratings yet

- Requirements For Transferees FinalDocument29 pagesRequirements For Transferees FinalKaren GedalangaNo ratings yet

- 2001 - Chetty - CFD Modelling of A RapidorrDocument5 pages2001 - Chetty - CFD Modelling of A Rapidorrarcher178No ratings yet

- DER11001 Reference DrawingsDocument2 pagesDER11001 Reference DrawingsPrime Energy Warehouse-YemenNo ratings yet

- Drainage Service GuidelinesDocument15 pagesDrainage Service GuidelinesMarllon LobatoNo ratings yet

- Lecture 1 - Course IntroductionDocument46 pagesLecture 1 - Course IntroductionRifaqat ZaheerNo ratings yet

- RFQ - Printer Cartridge HP - A0066Document1 pageRFQ - Printer Cartridge HP - A0066منتظر عليNo ratings yet

- SAP OKES - Splitting StructureDocument9 pagesSAP OKES - Splitting StructureneoclessNo ratings yet

- Curriculum Review - PrinciplesDocument8 pagesCurriculum Review - Principlesa_magomnangNo ratings yet