Professional Documents

Culture Documents

Ps AppendixE A11y

Uploaded by

Jesus HilarioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ps AppendixE A11y

Uploaded by

Jesus HilarioCopyright:

Available Formats

APPENDIX E FEBRUARY 2014

APPENDIX E – EXAMPLE CALCULATIONS

Example 1 – Continuous Two Span CIP Box-Girder Stressed from One End:

Information given on contract plans:

• 270 ksi low relaxation prestressing strand.

• E = 28,000 ksi.

• Pjack = 202.5 ksi.

CL CL CL

Abut 1 Bent 2 Abut 3

160′-0″ 140′-0″

Pjack Inflection

Point (typ)

6′-4″

4′-4″

5′-0″

12″

3′-6″

3′-6″

12″

64′ 80′ 16′ 14′ 70′ 56′

A B C D E F G

Figure 1 - Prestressing Cable Path.

The equation for stress in the prestressing steel at a distance x from the jacking end of the frame

is:

Tx = Toe−( μα +KL) (Equation 1)

Where: μ = 0.15 for frame lengths < 600 feet.

K = 0.0002.

μ = Cumulative angle change at point of interest x from jacking end.

L = Distance to point of interest x from jacking end.

CALTRANS ● PRESTRESS MANUAL E- 1

APPENDIX E FEBRUARY 2014

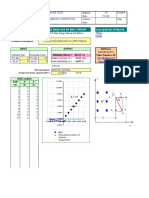

Find the measurable elongation for the prestressing path in Figure 1:

0.66

αcd αde

αbc αef

αfg

3.33

αab

2.50

2.50

64′ 80′ 16′ 14′ 70′ 56′

A B C D E F G

Figure 2 – Vertical Angle Change.

Step 1: Tendon elongations during the stressing operation are a function of both the average

stress in the strands, and the length of the tendon. The stress in the strands vary along the tendon

path due to angular friction between the tendon and the inside surface of the duct. Since there is

no horizontal curvature given in this exercise, the angle changes are based on the vertical tendon

profile only.

Vertical Angle Change Calculations

Segment y L α = 2(y/L)

(feet) (feet) (radians)

AB 2.500 64 0.0781

BC 3.333 80 0.0833

CD 0.666 16 0.0833

DE 0.666 14 0.0952

EF 3.333 70 0.0952

FG 2.500 56 0.0893

CALTRANS ● PRESTRESS MANUAL E- 2

APPENDIX E FEBRUARY 2014

Step 2: Now that the vertical angle change within each parabolic segment has been calculated, it

is time to compute the initial friction coefficients. These coefficients represent a decimal

percentage of the jacking stress at the end of each parabolic segment. Based on the results in the

following table, there is slightly more than 87 percent of Pjack in the strands at the dead end.

Initial Friction Coefficient Calculations

Friction α = 2(y/L) Σα Wobble L ΣL

Segment μ (radians) (radians) K (feet) (feet) (μΣα+KΣL) e-(μΣα+KΣL)

AB 0.15 0.0781 0.0781 0.0002 64 64 0.0245 0.976

BC 0.15 0.0833 0.1614 0.0002 80 144 0.0530 0.948

CD 0.15 0.0833 0.2447 0.0002 16 160 0.0687 0.934

DE 0.15 0.0952 0.3399 0.0002 14 174 0.0858 0.918

EF 0.15 0.0952 0.4351 0.0002 70 244 0.1141 0.892

FG 0.15 0.0893 0.5244 0.0002 56 300 0.1387 0.870

Step 3: With the initial friction coefficients in hand, it is now possible to compute the average

stress in the strands in each segment. Knowing the stress distribution along the entire length of

the frame, and assuming a Young’s modulus for prestressing steel of E = 28,000 ksi, the tendon

elongation can be calculated using the following equation:

Tavg L

Δ=

E

Elongation Calculations

Segment −(μα+KL)

To Tx=Toe-(μα+KL) Tavg L L Δx=TavgL/E

e (ksi) (ksi) (ksi) (feet) (in) (in)

AB 0.976 202.5 197.6 200.1 64 768 5.49

BC 0.948 202.5 192.0 194.8 80 960 6.68

CD 0.934 202.5 189.1 190.6 16 192 1.31

DE 0.918 202.5 185.9 187.5 14 168 1.13

EF 0.892 202.5 180.6 183.3 70 840 5.50

FG 0.870 202.5 176.2 178.4 56 672 4.28

Total Elongation 24.39

CALTRANS ● PRESTRESS MANUAL E- 3

APPENDIX E FEBRUARY 2014

Note that the length of the strand in the jack was not considered in the calculations. The total

elongation calculated above must be reduced by 20 percent to account for take-up and

reorienting of prestressing strand at the beginning of the stressing operation. The measurable

elongation, Δ80%, for this example problem is shown below:

Δ80% = 0.80Δ100% = 0.80 x 24.39 = 19.51 Δ80% = 19.51 in.

CALTRANS ● PRESTRESS MANUAL E- 4

APPENDIX E FEBRUARY 2014

Example 2 – Anchor Set Calculation:

The contract plans usually identify an anchor set length of 3/8 inch (10 mm). This length

represents the distance the strand slips back into the anchor head during the seating process.

Using the results from Example 1, what is the change in stress at the jacking end of the frame,

and how far into the frame does anchor set loss affect the stress in the tendon?

Given:

• E = 28,000 ksi

• ΔL = 3/8 in.

• Friction loss in length L = 202.5 ksi – 192.0 ksi = 10.5 ksi = d

CL CL

Abut 1 Bent 2

0.75fs′ = 202.5ksi

d = 10.5

Δf

≤ 0.70fs′

x

L = 144 ft.

A B C D E

Figure 3 – Anchor Set Loss Diagram

E(ΔL)L (28,000ksi)(0.375in)(144 ft)

x= = = 109.5 ft

d (10.5ksi)(12in / ft)

2dx (2)(10.5ksi)(109.5 ft)

Δf = = =15.97ksi

L 144 ft

The stress at the anchorage after seating must be less than 0.70f’s:

{202.5 ksi – 15.97 ksi = 186.53 ksi} < {0.70f’s = 0.70 (270 ksi) = 189 ksi} ∴ OK

CALTRANS ● PRESTRESS MANUAL E- 5

APPENDIX E FEBRUARY 2014

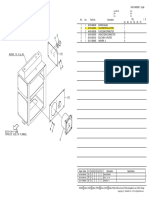

Example 3 – Simple Span Box Girder Stressed from One End:

Given:

• 140 ft long simply supported CIP P/S Box Girder = L.

• 270 ksi low relaxation strand.

• Pjack = 12,600 kips.

• Area of 0.5 inch diameter strand = 0.153 in2.

• Anchor set length = 0.375 in = ΔL

• One end stressing.

• μ = 0.15, K = 0.0002

CL CL CL

Abut 1 Span Abut 2

Pjack

6′- 3″

2′- 6″

70′-0″ 70′-0″

A B C

Center of Gravity of Prestressing Path

Find:

1. How many 0.5 inch diameter strands are required?

2. Find the initial and final stress distribution in the prestressing steel.

3. Find the final working force at the centerline of the span.

4. Find the theoretical and measurable elongation.

Part 1:Number of strands required:

0.75 f’s = The jacking stress on the contract plans = 0.75 (270 ksi) = 202.5 ksi

Ap/s = Pjack / fjack = 12,600 kips / 202.5 ksi = 62.22 in2

np/s = number of strands = Ap/s / Astrand = 62.22 in2 / 0.153 in2 = 407 strands

CALTRANS ● PRESTRESS MANUAL E- 6

APPENDIX E FEBRUARY 2014

Part 2: Initial and Final Stresses in Prestressing Steel:

CL CL CL

Abut 1 Span Abut 2

αab αbc

2′- 6″

70′-0″ 70′-0″

A B C

Stress at dead end:

αab = αbc = 2y/L = 2 (2.5) / 70 = 0.0714

At dead end, αac = 2 (0.0714) = 0.1428

Tx = Toe-(μα+KL)

At dead end, Tc = 202.5 e-[(0.15)(0.1428)+(0.0002)(140)] = 202.5 e-0.0494 = 192.73 ksi

Effect of anchor set:

E(ΔL)L (28,000ksi)(0.375in)(140 ft)

x= = = 112 ft

d (9.77ksi)(12in / ft)

2dx (2)(9.77ksi)(112 ft)

Δf = = =15.63ksi

L 140 ft

CALTRANS ● PRESTRESS MANUAL E- 7

APPENDIX E FEBRUARY 2014

Stress at jacking end:

Ta = fjack - Δf = 202.5 ksi – 15.63 ksi = 186.87 ksi

{Ta = 186.87 ksi} ≤ {0.70 f’s = 0.70 (270 ksi) = 189 ksi) ∴ OK

Assume long term losses = 20 ksi

CL CL CL

equal but opposite

Abut 1 Span slope Abut 2

≤ 0.75 fs′ =202.5ksi

Initial Stress

Δf = 15.63

0.70 fs′ = 189.00

194.68 ksi 192.73 ksi

186.87 ksi 0.70 fs′ = 189.00

20 ksi

x=112′

172.73 ksi

166.87 ksi

174.68 ksi Final Stress

70′ 70′

A B C

Initial and Final Stress Distribution in Prestressing Steel.

Part 3: Final working force at the centerline of span.

f b −166.87 174.68 −166.87

=

70 112

70(7.81)

f b −166.87 =

112

fb = 4.88+166.87 =171.75 ksi

Part 4: Theoretical and measurable elongation.

Δ100% =

[(202.5 +192.73)ksi / 2] (140 ft)(12in / ft)

= 11.86 in.

28,000ksi

Δ80% = 0.80 (11.86in) = 9.49 in.

CALTRANS ● PRESTRESS MANUAL E- 8

APPENDIX E FEBRUARY 2014

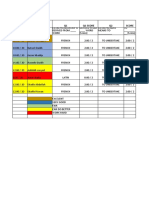

Example 4 – Continuous Four Span CIP Box-Girder Stressed from Both Ends

Given:

• 818 ft long continuous 4 span CIP P/S box girder frame.

• Two end stressing, with first stage jacked from left end.

• 270 ksi Low Relaxation strand.

• Jacking stress = 202.5 ksi.

• Area of 0.5 inch diameter strand = 0.153 in2.

• The initial force coefficient (FCi) at the point of no movement = 0.802.

• μ = 0.20, K = 0.0002 (informational only).

416′ 402′

186′ 230′ 230′ 168′

Abut 1 Abut 5

Point of no movement

For 2 end stressing

Bent 2 Bent 3 Bent 4

Frame Description

1.0

Actual FCi

distribution

0.9

Initial Friction Coefficient

0.8 C

FCi = 0.802

A

0.7 Simplified FCi

distribution

B

0.6

Length Along Frame

Initial Force Coefficient Diagram.

CALTRANS ● PRESTRESS MANUAL E- 9

APPENDIX E FEBRUARY 2014

Find: What is the total theoretical (expected) 1st stage elongation?

1. What is the measurable 1st stage elongation?

2. What is the theoretical (expected) 2nd stage elongation?

Part 1: Total Theoretical (expected) 1st Stage Elongation:

When calculating the first stage elongation, it is common practice to break the force coefficient

diagram into two parts, identified as areas A and B in the above diagram. The equation for

calculating tendon elongations is shown as follows:

PL

Δ=

AE

When jacking to 202.5 ksi, and using a strand nominal area of 0.153 in2 the jacking force per

strand is calculated below:

( )

Pstrand = 202.5 ksi (0.153) = 30.98 kips/ strand

When calculating ΔA, it is important to include the length of tendon within the jack. The strand

movement will be measured relative to the end of the ram, which generally results in 2½ to 3 feet

of extra of strand within the length of the jack.

ΔA =

(30.98 kips)(1+ 0.802) x (416 ft + 3 ft )(12) = (27.91)(1.153) = 32.2 inches

2 (0.153 in )(28,500 ksi)

2

In order to find the first stage elongation for area B, it is necessary to extrapolate the FCi out to

the dead end of the first stage post tensioning:

FCidead =1− [(2)(1 − 0.802)] = 0.604

(30.98 kips)(0.802 + 0.604) x (402 ft )(12)

ΔB =

2 (0.153 in )(28,500 ksi) = (21.78)(1.106) = 24.1 inches

2

Δ A+B = Δ1st stage = 32.2 + 24.1= 56.3 inches

theo

Part 2: Measurable 1st Stage Elongation:

The total theoretical elongation does not have direct practical application because it does not take

into account slack or strand reorientation in the tendon. The measurable elongation is determined

to be 80% of the theoretical, as strands are marked with paint after being stressed to 20% of Pjack.

In this case, after stressing the tendon to 20% of Pjack, the remaining 80% stressing should yield

an elongation of:

CALTRANS ● PRESTRESS MANUAL E- 10

APPENDIX E FEBRUARY 2014

Δ1st stage

meas

= (0.80)Δ1st stage

theo

( )

= (0.80) 56.3 inches = 45.0 inches

Part 3: Theoretical (expected) 2nd Stage Elongation:

Once the first stage stressing operation is complete, and the Engineer is satisfied with the

physical measurements obtained, the second stage stressing operation can begin. Theoretical 2nd

stage elongations must be calculated before stressing, to serve as a tool to guarantee that the

proper amount of P/S force is being delivered to the structure. The second stage elongation

equates to Area C in the force coefficient diagram. Again, the length of the tendon within the

jack must be included in the calculation.

ΔC = Δ 2nd stage =

(30.98 kips)(1− 0.604) x (402 ft + 3 ft )(12) = (6.13)(1.115) = 6.8 inches

theo 2 (0.153 in )(28,500 ksi)

2

CALTRANS ● PRESTRESS MANUAL E- 11

You might also like

- A-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportDocument4 pagesA-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportHari KarthickNo ratings yet

- ACI Section Crack Width ControlDocument6 pagesACI Section Crack Width ControlImaduddin KhajaNo ratings yet

- Base Plate MCCDocument7 pagesBase Plate MCCabbasamuNo ratings yet

- Shear Design SpreadsheetDocument15 pagesShear Design SpreadsheetCivilax.com0% (1)

- Conflict Resolution and Management Module 3 AssignmentDocument7 pagesConflict Resolution and Management Module 3 AssignmentZrii NaturalGreenWellnessNo ratings yet

- Workout Example Design of Short Column (Circular) : SolutionDocument4 pagesWorkout Example Design of Short Column (Circular) : SolutionMrAlittle FingerNo ratings yet

- Smart GoalsDocument3 pagesSmart Goalsapi-527878842No ratings yet

- ADAPT-ABI Examples Manual PDFDocument297 pagesADAPT-ABI Examples Manual PDFJesus HilarioNo ratings yet

- Calculation of Individual Pile SettlementDocument4 pagesCalculation of Individual Pile SettlementSivaathmiga RangeswaranNo ratings yet

- DIA - Calcul Grinzi Din Beton ArmatDocument12 pagesDIA - Calcul Grinzi Din Beton ArmatCristina DumitriuNo ratings yet

- Cara Penggunaan 1 Masukan Data Data Yang Tertera Pada File Mody 2 Data Data TSB Diambil Dari Bagian Bawah File ModyDocument5 pagesCara Penggunaan 1 Masukan Data Data Yang Tertera Pada File Mody 2 Data Data TSB Diambil Dari Bagian Bawah File ModyRahmat FadhilaNo ratings yet

- 3.4 Double-Tee Load Tables (Cont.) : Preliminary Design of Precast / Prestressed Concrete StructuresDocument1 page3.4 Double-Tee Load Tables (Cont.) : Preliminary Design of Precast / Prestressed Concrete Structuresسجى وليدNo ratings yet

- Industrial Hygiene: Duct DesignDocument36 pagesIndustrial Hygiene: Duct DesignMuhammad HanifNo ratings yet

- Span Length Glass Block: 22.50 MM 45.00 MMDocument16 pagesSpan Length Glass Block: 22.50 MM 45.00 MMTalha UmarNo ratings yet

- Fto G:1to 2: Spreadsheetsto BS8110&EC2Document1 pageFto G:1to 2: Spreadsheetsto BS8110&EC2Lavanyan SatchithananthanNo ratings yet

- Design of Short ColumnsDocument39 pagesDesign of Short Columnsjoni0% (1)

- Computation of Vu, VC, VS, S: Problem 1Document1 pageComputation of Vu, VC, VS, S: Problem 1ERICA ZOE CAYTONNo ratings yet

- Nozzle Reaction ForceDocument17 pagesNozzle Reaction ForceRIPUDAMAN SINGHNo ratings yet

- Qbase Isolation DesignDocument27 pagesQbase Isolation Designprraaddeej chatelNo ratings yet

- XxxCable Limiters Sell SheetDocument2 pagesXxxCable Limiters Sell SheetSabri GunaydinNo ratings yet

- Design For ShearDocument2 pagesDesign For ShearThomas John Doblas AgrabioNo ratings yet

- Example Problem 3.1 Given: Results SummaryDocument25 pagesExample Problem 3.1 Given: Results SummarygertjaniNo ratings yet

- Nwis Inplace Analysis ReportDocument5 pagesNwis Inplace Analysis ReportPrashanth Talkad RajagopalNo ratings yet

- 3.4 Double-Tee Load Tables (Cont.) : Preliminary Design of Precast / Prestressed Concrete ComponentsDocument1 page3.4 Double-Tee Load Tables (Cont.) : Preliminary Design of Precast / Prestressed Concrete ComponentsAkhtar KhanNo ratings yet

- Regional Conference and Exhibition On Electricity DistributionDocument8 pagesRegional Conference and Exhibition On Electricity DistributionramsesiNo ratings yet

- METODA HARDY-CROSS (Head Balance Loop Method)Document10 pagesMETODA HARDY-CROSS (Head Balance Loop Method)Tineu AprilliaNo ratings yet

- Testing Spreadsheet Vs LRFD Tables: Truss Tr23 YP 15-Apr Sample ConnectionDocument4 pagesTesting Spreadsheet Vs LRFD Tables: Truss Tr23 YP 15-Apr Sample Connectionhema kumarNo ratings yet

- 085psig NewDocument1 page085psig NewAnonymous aoNBPi2f1vNo ratings yet

- Z Modifier (Poulos)Document5 pagesZ Modifier (Poulos)Prashanth Talkad RajagopalNo ratings yet

- 4F Design-2Document12 pages4F Design-2Jake CortezNo ratings yet

- Aiwa Excelia Xc007Document25 pagesAiwa Excelia Xc007Ольга МартьяноваNo ratings yet

- Vigas Ipe: Hierrobeco, C.ADocument2 pagesVigas Ipe: Hierrobeco, C.Aandres castroNo ratings yet

- UntitledDocument10 pagesUntitledMoe Oo HtunNo ratings yet

- Hoja de Cálculo Excel - PilotesDocument6 pagesHoja de Cálculo Excel - PilotesDarwin Cano ValverdeNo ratings yet

- Short Pitch Precision Roller Chains (B Series)Document2 pagesShort Pitch Precision Roller Chains (B Series)venda conectNo ratings yet

- Standard Double Angle TableDocument12 pagesStandard Double Angle Tablesteve aronNo ratings yet

- Roomside Calculation SheetDocument7 pagesRoomside Calculation Sheetsunii19847908No ratings yet

- Standard Belt Cross SectionsDocument26 pagesStandard Belt Cross Sectionsagung badoNo ratings yet

- Canal Elements: (M /S) (M/S) (M) (M) (M) (M)Document40 pagesCanal Elements: (M /S) (M/S) (M) (M) (M) (M)NIA INIMONo ratings yet

- Mathcad - Bab 16 Perencanaan Pondasi MinipileDocument5 pagesMathcad - Bab 16 Perencanaan Pondasi MinipileAnanta Eka YudistiraNo ratings yet

- Journal o F Sound and VibrationDocument3 pagesJournal o F Sound and VibrationameypnNo ratings yet

- T60diffsimulatorDocument8 pagesT60diffsimulatorAns MehmoodNo ratings yet

- Calculo Base V1.0Document68 pagesCalculo Base V1.0andres osorioNo ratings yet

- BUS KV 3LG 2LG 1LG Ohmic Values BUS KV 3LG 2LG MVA A MVA A MVA A R1 X1 R2 X2 R0 X0 MVA A MVADocument7 pagesBUS KV 3LG 2LG 1LG Ohmic Values BUS KV 3LG 2LG MVA A MVA A MVA A R1 X1 R2 X2 R0 X0 MVA A MVAmesias johnNo ratings yet

- Design of Water Distribution Systems-Hardy Cross Method and Equivalent Pipe MethodDocument23 pagesDesign of Water Distribution Systems-Hardy Cross Method and Equivalent Pipe MethodMohamed Wageeh DiabNo ratings yet

- Fig.4. Cylinder Head & Bonnet: (E) (D) (C) (B) (A) 4TNE106T-TBLDocument1 pageFig.4. Cylinder Head & Bonnet: (E) (D) (C) (B) (A) 4TNE106T-TBLComercial AlfaOmega LimitadaNo ratings yet

- DIA Calcul Grinzi Din Beton ArmatDocument8 pagesDIA Calcul Grinzi Din Beton ArmatMadalin Popa0% (1)

- Objective: M U DX EIDocument10 pagesObjective: M U DX EIAsh DenemNo ratings yet

- Etabs 2016 16.2Document6 pagesEtabs 2016 16.2kervinarmasNo ratings yet

- TachometerDocument1 pageTachometerxtenis87No ratings yet

- MEMBER NAME: S1-One Way: MIDAS Information Technology Co., LTDDocument3 pagesMEMBER NAME: S1-One Way: MIDAS Information Technology Co., LTDAlisa Jane TuboroNo ratings yet

- 20b L2 SSD Interaction Diagram and Shear Design of Rectangular RC Shear WallDocument6 pages20b L2 SSD Interaction Diagram and Shear Design of Rectangular RC Shear WallKim Eng ChoueryNo ratings yet

- Solution To Assignment-2-S1-2018Document11 pagesSolution To Assignment-2-S1-2018Adrian VuNo ratings yet

- Soplador K04-MS-3-3Document2 pagesSoplador K04-MS-3-3Héctor RomeroNo ratings yet

- Amec ChainsDocument48 pagesAmec ChainsDavid Emanuel Girón ChávezNo ratings yet

- Length of Pipeline Pipe Diameter Assumed Potential Shift at Power Source Coating Quality: 1-Superb, 2-Excellent, 3-Very Good, 4, Good, - 5-PoorDocument5 pagesLength of Pipeline Pipe Diameter Assumed Potential Shift at Power Source Coating Quality: 1-Superb, 2-Excellent, 3-Very Good, 4, Good, - 5-PoorOussama BenzohraNo ratings yet

- Untitled 1Document1 pageUntitled 1Truong Phuoc TriNo ratings yet

- 05drain UndrainDocument88 pages05drain UndrainGanjarAsandiPutraPratamaNo ratings yet

- A. Design Case: Analysis For Design-1 B. Member InformationDocument4 pagesA. Design Case: Analysis For Design-1 B. Member InformationSopanat BoonkhanNo ratings yet

- Determination of Orifice Coefficients Year and Section: Date Started: Group Number: Date Finished: Group Members: Date SubmittedDocument5 pagesDetermination of Orifice Coefficients Year and Section: Date Started: Group Number: Date Finished: Group Members: Date SubmittedSpencer QuiachonNo ratings yet

- To Determine The Shear Center Location of An Open Section - ChannelDocument7 pagesTo Determine The Shear Center Location of An Open Section - ChanneljohnNo ratings yet

- Experiment 7Document9 pagesExperiment 7MahmoudSehweilNo ratings yet

- ch15 Torsion-2Document2 pagesch15 Torsion-2Pepito GrilloNo ratings yet

- Mathcad - Calzadura IBDocument6 pagesMathcad - Calzadura IBJesus HilarioNo ratings yet

- Debuggins FunctionsDocument14 pagesDebuggins FunctionsJesus HilarioNo ratings yet

- LibrosDocument1 pageLibrosJesus HilarioNo ratings yet

- Topic, Purpose, and Research QuestionsDocument16 pagesTopic, Purpose, and Research QuestionsVellardo AlbayNo ratings yet

- Impromptu Quote PromptsDocument2 pagesImpromptu Quote PromptsWei Ning100% (1)

- Biovia Materials Studio Dmol: DatasheetDocument3 pagesBiovia Materials Studio Dmol: DatasheettonymailinatorNo ratings yet

- Malik Badri - The Islamization of PsychologyDocument16 pagesMalik Badri - The Islamization of PsychologyCh NomanNo ratings yet

- Entrepreneurship Development Test 2 Assessment SheetDocument7 pagesEntrepreneurship Development Test 2 Assessment SheetHaseeb ShaikhNo ratings yet

- Benson Itec 7460 Evaluation InstrumentDocument7 pagesBenson Itec 7460 Evaluation Instrumentapi-674645435No ratings yet

- Astrovision May 2020Document81 pagesAstrovision May 2020Poornima100% (1)

- Sma 2201Document35 pagesSma 2201Andrew MutungaNo ratings yet

- Daily Lesson PlanDocument15 pagesDaily Lesson PlanNur MaizanNo ratings yet

- Lexicology Unit 8Document24 pagesLexicology Unit 8Business EnglishNo ratings yet

- Compabloc 207-235Document248 pagesCompabloc 207-235Anie EkpenyongNo ratings yet

- Focus4 2E Vocabulary Quiz Unit5 GroupBDocument1 pageFocus4 2E Vocabulary Quiz Unit5 GroupBТарас ОлейніковNo ratings yet

- Detailed Lesson Plan Physical Education: Labo Science and Technology High SchoolDocument4 pagesDetailed Lesson Plan Physical Education: Labo Science and Technology High SchoolDeogracia Rieza Borres50% (2)

- TB ch2Document58 pagesTB ch2Wasiu BabsNo ratings yet

- Dionex ICS-5000 HPIC SystemDocument19 pagesDionex ICS-5000 HPIC Systembizniz biznizNo ratings yet

- GAIL (India) Limited Recruitment of Executive Trainee (By Using GATE-2022 Marks) Frequently Asked Questions Sl. No. Query ReplyDocument7 pagesGAIL (India) Limited Recruitment of Executive Trainee (By Using GATE-2022 Marks) Frequently Asked Questions Sl. No. Query ReplyKaushik PatelNo ratings yet

- Optical Fibre Cables SILECDocument12 pagesOptical Fibre Cables SILECTalha LiaqatNo ratings yet

- Economic DevelopmentDocument3 pagesEconomic DevelopmentJiggy SyNo ratings yet

- Teaching StandardsDocument21 pagesTeaching Standardsapi-557400513No ratings yet

- A Semantic Analysis of The Verbs Conceal and Hide ArchiveDocument109 pagesA Semantic Analysis of The Verbs Conceal and Hide ArchivealaaNo ratings yet

- Wu XueyinDocument137 pagesWu XueyinSayed AhmedNo ratings yet

- Translating Isaac Bashevis SingerDocument4 pagesTranslating Isaac Bashevis SingerDavid StrombergNo ratings yet

- Shormista AssignmentDocument31 pagesShormista AssignmentSwakshar DebNo ratings yet

- Finals Module3Document29 pagesFinals Module3John RivasNo ratings yet

- Experiment No. 1 - AnthropometryDocument8 pagesExperiment No. 1 - AnthropometryBai MustaphaNo ratings yet

- MATH 223 Spring 20 Course OutlineDocument6 pagesMATH 223 Spring 20 Course OutlineJames JonesNo ratings yet

- Balance Chemical Equation - Online BalancerDocument2 pagesBalance Chemical Equation - Online BalancershoyebNo ratings yet