0% found this document useful (0 votes)

1K views11 pagesAlignment and Symmetry Check - Piper Dakota

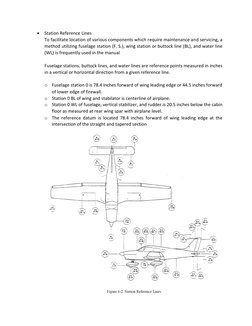

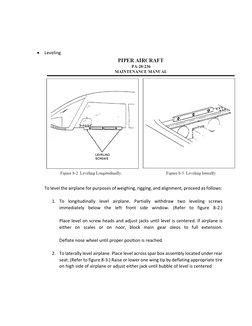

The document describes procedures for performing symmetry and alignment checks on a Piper Dakota aircraft as part of routine maintenance. This includes checking the wing dihedral angle, incidence angles, verticality of the fin, engine alignment, and performing a full symmetry check. The aircraft would be carefully leveled and measurements taken between reference points to identify any structural issues. Tolerance limits are specified and adjustments can be made by tightening or loosening bolts as needed.

Uploaded by

Ilham GumelarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views11 pagesAlignment and Symmetry Check - Piper Dakota

The document describes procedures for performing symmetry and alignment checks on a Piper Dakota aircraft as part of routine maintenance. This includes checking the wing dihedral angle, incidence angles, verticality of the fin, engine alignment, and performing a full symmetry check. The aircraft would be carefully leveled and measurements taken between reference points to identify any structural issues. Tolerance limits are specified and adjustments can be made by tightening or loosening bolts as needed.

Uploaded by

Ilham GumelarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd