Professional Documents

Culture Documents

USP General Chapter 1251

Uploaded by

Vania CanaparOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

USP General Chapter 1251

Uploaded by

Vania CanaparCopyright:

Available Formats

Accessed from 10.6.1.

10 by ProIndi7 on Thu Jan 15 07:23:50 EST 2015

USP 37 General Information / á1251ñ Weighing on an Analytical Balance 1253

AW = P/P0

á1251ñ WEIGHING ON AN

ERH(%) = AW × 100

ANALYTICAL BALANCE

Method INTRODUCTION

The water activity is determined by placing the sample in Weighing is a frequent step in analytical procedures, and

a small airtight cup inside which the equilibrium between the balance is an essential piece of laboratory equipment.

the water in the solid and the headspace can be established. The general information described here applies directly to

The volume of the headspace must be small in relation to electronic balances used in analytical procedures. Although

the sample volume in order not to change the sorption state many portions of the chapter are applicable to all balances,

of the sample during the test. The equilibration as a thermo- some are applicable only to analytical balances. This chapter

dynamic process takes time but may be accelerated by should not be considered all-inclusive, and other sources of

forced circulation within the cell. The acquired water activity information (e.g., the US National Institute for Science and

value is only valid for the simultaneously determined tem- Technology and balance manufacturers) may be useful and

perature. This requires a precise temperature-measuring de- applicable when analysts perform a weighing operation or

vice as part of the equipment. Furthermore, the probe must implement a weighing procedure.1,2 The information given

be thermally insulated to guarantee a constant temperature in this chapter is applicable not only to balances used for

during the test. The sensor measuring the humidity of the materials that must be accurately weighed (see Balances

General Chapters

headspace air above the sample is a key component. Theo- á41ñ) but also to balances used in all analytical procedures.

retically, all types of hygrometers can be used, but for ana-

lytical purposes miniaturization and robustness are a pre- QUALIFICATION

condition. The AW measurement may be conducted using

the dew point/chilled mirror method.1 A polished, chilled Users should consult Analytical Instrument Qualification

mirror is used as a condensing surface. The cooling system is á1058ñ, standard operating procedures, and recommenda-

electronically linked to a photoelectric cell into which light is tions from manufacturers when they devise qualification

reflected from the condensing mirror. An air stream, in equi- plans.

librium with the test sample, is directed at the mirror which

cools until condensation occurs on the mirror. The tempera- Installation

ture at which this condensation begins is the dew point

from which the ERH is determined. Commercially available The balance's performance depends on the conditions of

instruments using the dew point/chilled mirror method or the facility where it is installed. Analysts should consult infor-

other technologies need to be evaluated for suitability, vali- mation provided by the manufacturer before they install a

dated, and calibrated when used to make water activity de- balance.

terminations. Support surface: The balance should be installed on a

These instruments are typically calibrated over an ade- solid, level, nonmagnetic surface that minimizes the trans-

quate range, for example, using some saturated salt solu- mission of vibration (e.g., a floor-mounted, granite weigh

tions at 25° such as those listed in Table 1. bench). If a metallic support surface is used, the surface

Table 1. Standard Saturated Salt Solutions should be grounded in order to prevent the buildup of static

Saturated Salt ERH electricity.

Solutions at 25° (%) AW Location: If possible, the balance should be located in a

Potassium sulfate (K2SO4) 97.3 0.973 room that is temperature and humidity controlled. The loca-

Barium chloride (BaCl2) 90.2 0.902

tion should have a clean, consistent electrical power supply.

The location should be free of drafts and should not be near

Sodium chloride (NaCl) 75.3 0.753

ovens, furnaces, air conditioner ducts, or cooling fans from

Magnesium nitrate (Mg(NO3)2) 52.9 0.529 equipment or computers. The balance should be positioned

Magnesium chloride (MgCl2) 32.8 0.328 away from outside windows so that direct sunlight does not

Lithium chloride (LiCl2) 11.2 0.112 strike the balance. The balance should not be installed near

sources of electromagnetic radiation such as radio-frequency

generators, electric motors, or hand-held communication

devices (including cordless telephones, cellular telephones,

and walkie-talkies). The balance should not be located near

1 National Physical Laboratory. Good practice guide No. 70, weighing in the

pharmaceutical industry. 2004. http://resource.npl.co.uk/docs/science_tech-

nology/mass_force_pressure/clubs_groups/instmc_weighing_panel/pharma-

weigh.pdf. Accessed 21 March 2012. [NOTE—Nomenclature in this chapter

tends to follow this document, except where it conflicts with USP terms.]

2 American Society for Testing and Materials. E898 Standard test method of

testing top-loading, direct-reading laboratory scales and balances. 2005.

1 AOAC International Official Method 978.18. http://www.astm.org/Standards/E898.htm. Accessed 21 March 2012.

Official from December 1, 2014

Copyright (c) 2015 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.10 by ProIndi7 on Thu Jan 15 07:23:50 EST 2015

1254 á1251ñ Weighing on an Analytical Balance / General Information USP 37

magnetic fields induced by laboratory instrumentation or Performance Qualification

other equipment.

The performance of the balance should be assessed fol- Table 1 provides a list of the most important balance

lowing installation and before use in order to demonstrate properties that should be assessed during performance qual-

adequate performance. In some situations, it may not be ification. Depending on the risk of the application and the

possible to position the balance in an optimum environ- required weighing process tolerance, some of these tests

ment. Examples of potential facility issues include the fol- may be omitted. Tests also can be omitted if there is evi-

lowing: dence that the property in question has only minimal effect

1. Air currents sometimes are present in the laboratory. on the weighing performance. Any procedures used should

2. Temperatures in the laboratory vary excessively (check be consistent with in-house standard operating procedures,

the manufacturer's literature about temperature sensi- applicable for the specific balance, and adequately justified.

tivity). Performance qualification should be performed periodically

3. Humidity is either very low or very high. Either condi- as described in standard operating procedures, and the fre-

tion may increase the rate at which the sample weight quency of each of the individual tests can vary depending

varies because of pickup or loss of water. Low humidity on the criticality of the property.

increases the buildup of static electricity. The weights that are used to perform the tests should be

4. Adjacent operations are causing vibration. stored and handled in a manner that minimizes contamina-

5. Corrosive materials are used nearby or are routinely tion. Before executing the tests, the analyst should place the

weighed. weights in the vicinity of the balance for an appropriate

6. The balance is located within a fume hood because it is time to reach sufficient thermal equilibrium. If possible, all

General Chapters

used to weigh corrosive or hazardous materials. tests should be carried out with a single test weight in order

7. The balance is adjacent to equipment that produces a to minimize handling errors, but multiple test weights are

magnetic field (e.g., a magnetic stirrer). permitted.

8. Direct sunlight strikes the balance. The tests should be recorded in such a manner that the

In situations when the balance is located near equipment data can be used to easily track balance performance and to

or systems that induce vibration, drafts, electromagnetic ra- assist in laboratory investigations as needed. Meaningful ac-

diation, magnetic fields, or changes in temperature or hu- ceptance criteria can be set depending on the required

midity, the assessment should be conducted with those sys- weighing tolerance, i.e., the maximum allowed deviation

tems operating in order to duplicate a worst-case scenario. permitted by specifications, regulations, etc., of a quantity

to be weighed from its target value. Procedures should be in

Operational Qualification place to address test results that are outside acceptable

ranges and to provide assurance that balance cleanliness

An operational qualification should be performed either and environment have not affected the result. Also, a proce-

by the user or by a qualified third-party vendor after the dure should be in place for removing a balance from opera-

equipment has been installed. tion when observed results fall outside acceptable ranges.

As a minimum, the power should be turned on and the Sensitivity, linearity, and eccentricity all account for sys-

balance should be allowed to equilibrate according to the tematic deviations; i.e., they limit the accuracy of the bal-

manufacturer's instructions (1–24 h, depending on the type ance (based on the definition of accuracy in Validation of

of balance) before use. Depending on the balance, analysts Compendial Procedures á1225ñ and ICH Q2). In the Interna-

should include the following procedures in the operational tional Vocabulary of Metrology (VIM) and documents of the

qualification: International Organization for Standardization, this concept

1. Mechanical mobility of all moveable parts is referred to as trueness. Because deviations are largely in-

2. Control of stable indication dependent from each other, it is not likely that all deviations

3. Manually triggered or automatic adjustment by means occur simultaneously and have the same algebraic sign.

of built-in weights Therefore the arithmetic addition of all individual deviations

4. Operation of ancillary equipment to assess the balance accuracy would constitute a rather

5. Tare function conservative approach. A quadratic addition of the individu-

6. Initial calibration al deviations is a more realistic approach. By allocating 50%

Several types of electronic analytical balances use built-in of the weighing tolerance budget to the acceptance criteria

weights for manually triggered or automatic adjustment. of the individual properties, e.g., sensitivity, linearity, and

This adjustment usually is applied to reduce the drift of the eccentricity, analysts ensure adherence to the required

balance over time and to compensate for drifts caused by weighing tolerance. Therefore, the acceptance criteria for

variations in the ambient temperature. the individual properties that account for the systematic de-

Calibration normally is performed as part of the opera- viations are set to weighing tolerance divided by 2. These

tional qualification, but it also can be performed periodically properties—or a subset of them—also can be taken to fulfill

thereafter. Calibration should be performed at the location the accuracy requirement described in á41ñ. In this case the

where the balance is used in normal operation. acceptance criteria thus allow a maximum deviation of

0.05% for sensitivity, linearity, and eccentricity. Repeatabili-

ty preferably is tested with a test weight of a few percent of

the balance capacity. At the lower end of its measurement

range, the performance of laboratory balances is limited by

Official from December 1, 2014

Copyright (c) 2015 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.10 by ProIndi7 on Thu Jan 15 07:23:50 EST 2015

USP 37 General Information / á1251ñ Weighing on an Analytical Balance 1255

Table 1. Suggested Performance Tests and Acceptance Criteria

Property Definition Examples Acceptance Criteria

Change in weighing value divided by the

change in load, usually measured be- NMT 0.05% deviation where á41ñ is appli-

tween zero and the capacity of the bal- The test load at or sufficiently close to the cable. For other uses, respective toler-

Sensitivity ance. capacity of the balance. ance requirement divided by 2.

Ability of a balance to follow the linear re-

lationship between a load and the indi-

cated weighing value. Nonlinearity usu-

ally is expressed as the largest magni- NMT 0.05% deviation where á41ñ is appli-

tude of any linearity deviation within the From 3 to 6 points over the range of the cable. For other uses, respective toler-

Linearity test interval. balance. ance requirement divided by 2.

Deviation in the measurement value

caused by eccentric loading—in other Performed in the center of gravity and the

words, the asymmetrical placement of four quadrants (for rectangular platter

the center of gravity of the load relative shapes) or at analogous locations for

to the load receiver. Eccentricity usually other platter shapes. Test load usually

is expressed as the largest magnitude of should be 30% of the capacity of the

any of the deviations between an off- balance or higher (refer to the manufac- NMT 0.05% deviation where á41ñ is appli-

center reading and the center reading turer's manual for any possible upper cable. For other uses, respective toler-

Eccentricity for a given test load. limit). ance requirement divided by 2.

Ability of a weighing instrument to dis-

play identical measurement values for re-

General Chapters

peated weighings of the same objects

under the same conditions, e.g., the

same measurement procedure, same op-

erator, same measuring system, same

operating conditions, and same location

over a short period of time. Repeatability 10 replicate weighings (using a test Requirement from á41ñ where applicable.

usually is expressed as the standard devi- weight that is a few percent of the nomi- For other uses, user specified require-

Repeatability ation of multiple weighings. nal capacity of the balance). ments will apply.

the finite repeatability, and limitations induced by systemat- Balance Checks

ic deviations normally can be neglected. Therefore, the

whole weighing tolerance budget can be allocated to the A balance check using an external weight helps ensure

acceptance criterion of the repeatability test. that the balance meets weighing tolerance requirements.

For the sensitivity and linearity tests as described above, The balance check is performed at appropriate intervals

the analyst should use certified weights with an appropriate based on applicable standard operating procedures. The fre-

weight class (e.g., according to International Organization quency of the balance check depends on the risk of the ap-

of Legal Metrology R111 or American Society for Testing plication and the required weighing tolerance. Checks with

and Materials E617, available from www.oiml.org and external weights can be replaced partially using automatic

www.astm.org, respectively). [NOTE—If a differential meth- or manually triggered adjustment by means of built-in

od is used for the linearity test, certified weights may not be weights. When analysts perform the balance check with an

required.] external weight, the same acceptance criteria may apply as

Depending on the acceptance criterion, it may be suffi- described in the sensitivity test above.

cient to consider only the nominal weight value of the test

weights. If the nominal value of the test weight is consid- Minimum Weight

ered, analysts should ensure that the maximum permissible

error does not exceed one-third of the acceptance criterion. The minimum net sample weight, mmin, of a balance can

Alternatively, if the certified value of the test weight is con- be expressed by the equation:

sidered, its calibration uncertainty should not exceed one-

third of the acceptance criterion. If more than one weight is mmin = k × s/required weighing tolerance

used to perform the test, the calibration uncertainties of the

where k is the coverage factor (usually 2 or larger) and s is

weights must be summed and the sum should not exceed

the standard deviation (in a mass unit, e.g., in mg) of not

one-third of the acceptance criterion. For tests such as ec-

fewer than 10 replicate measurements of a test weight. The

centricity or repeatability, the use of certified weights is op-

minimum weight describes the lower limit of the balance

tional, but analysts must ensure that the mass of the weight

below which the required weighing tolerance is not adhered

does not change during the test.

to. The equation above takes into account that the perform-

The tests described above also can be included in formal

ance of laboratory balances at the lower end of the meas-

periodic calibration in order to fulfill applicable cGMP re-

urement range is limited by the finite repeatability.

quirements.

For materials that must be accurately weighed, á41ñ stipu-

lates that repeatability is satisfactory if two times the stand-

ard deviation of the weighed value, divided by the nominal

value of the weight used, does not exceed 0.10%. For this

criterion the equation above simplifies to:

Official from December 1, 2014

Copyright (c) 2015 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.10 by ProIndi7 on Thu Jan 15 07:23:50 EST 2015

1256 á1251ñ Weighing on an Analytical Balance / General Information USP 37

mmin = 2000 × s mass and small surface should be used (especially in cases

when specimens of low weight are being measured) or the

If not subject to the requirements of á41ñ, the minimum repeatability test should be performed with the receiver

weight value may vary depending on the required weighing placed on the weighing pan as a preload. Receivers should

tolerance and the specific use of the balance. be constructed from nonmagnetic materials in order to pre-

To facilitate handling, the test weight that is used for the vent magnetic interference with electronic balance compo-

repeatability test does not need to be at the minimum nents. Receivers should be used at ambient temperature in

weight value but can be larger because the standard devia- order to prevent the formation of air currents within the

tion of repeatability is only a weak function of the test weighing chamber.

weight value. Solid samples: Receivers for weighing solid materials

In order to satisfy the required weighing tolerance, when include weighing paper, weighing dishes, weighing funnels,

samples are weighed the amount of sample mass (i.e., the or enclosed vessels, including bottles, vials, and flasks. Hy-

net weight) must be equal to or larger than the minimum groscopic papers are not recommended for weighing be-

weight. The minimum weight applies to the sample weight, cause they may have a detrimental effect on the observed

not to the tare or gross weight. results.

Factors that can influence repeatability while the balance Weighing dishes typically are constructed from a polymer

is in use include: or from aluminum. Antistatic weighing dishes are available

1. The performance of the balance and thus the minimum for measuring materials that retain static electricity. Weigh-

weight can vary over time because of changing envi- ing funnels typically are constructed from glass or from a

ronmental conditions. polymer. The design of this type of receiver combines attrib-

2. Different operators may weigh differently on the bal-

General Chapters

utes of a weighing dish and a transfer funnel, which can

ance—i.e., the minimum weight determined by differ- simplify the analytical transfer of a weighed powder to a

ent operators may be different. narrow-necked vessel such as a volumetric flask. For solid

3. The standard deviation of a finite number of replicate samples that are volatile or deliquescent, analysts must

weighings is only an estimation of the true standard weigh the material into an enclosed vessel. Where practical,

deviation, which is unknown. analysts should use an enclosed vessel with a small opening

4. The determination of the minimum weight with a test in order to reduce sample weight loss from volatilization or

weight may not be completely representative for the weight gain from the adsorption and absorption of atmos-

weighing application. pheric water.

5. The tare vessel also may influence minimum weight be- Liquid samples: Receivers for liquid samples typically

cause of the interaction of the environment with the are inert, enclosed vessels. For liquid samples that are vola-

surface of the tare vessel. tile or deliquescent, analysts should use an enclosed vessel

For these reasons, when possible, weighings should be with a small opening, and the enclosure should be replaced

made at larger values than the minimum weight. rapidly following material transfer. Special precautions

should be taken to be certain that the receiver and the en-

OPERATION OF THE ANALYTICAL BALANCE closure are constructed from a material that is compatible

with the liquid sample. The receiver and enclosure must

Select the appropriate balance for the quantity and per- have a seal that is sufficient to prevent leaks from a liquid

formance needed. General chapter á41ñ provides require- that is of low viscosity or has low surface tension or a low

ments for balances used for materials that must be accurate- boiling point.

ly weighed.The balance user should check the balance envi-

ronment (vibration, air currents, and cleanliness) and status Types of Weighing

of calibration before use.

Weighing for quantitative analysis: The initial step for

Receivers many quantitative analyses is to accurately weigh a specified

amount of a sample. Section 6.50.20 in the General Notices

To ensure suitable performance in measuring the weight stipulates that solutions for quantitative measures must be

of a specimen, analysts should consider selection of a proper prepared using accurately weighed analytes: i.e., analysts

receiver for the material. must use a balance that meets the criteria in á41ñ. Errors in-

General characteristics: All receivers must be clean, troduced during the weighing of a sample can affect the ac-

dry, and inert. The total weight of the receiver plus the curacy of all subsequent analytical measurements.

specimen must not exceed the maximum capacity of the Addition weighing: Addition weighings typically are

balance. With a properly maintained and adjusted laborato- used for solid samples or liquid samples for which volatility

ry balance, weighing uncertainty for small samples, i.e., net is not an issue. The receiver is placed on the balance. After

weights with a mass not exceeding typically a few percent the balance display stabilizes, the analyst should tare the

of the capacity of the balance, essentially is determined by balance; add the desired amount of material to the receiver;

the repeatability. However, repeatability depends on the size allow the balance display to stabilize; record the weight;

and surface area of the weighed object. For this reason large and quantitatively transfer the material to an appropriate

or heavy receivers introduce a deviation from the conditions vessel or, if it cannot be guaranteed that the entire amount

under which the repeatability was determined without con- has been transferred, weigh the receiver again and note the

sidering the receivers. Therefore, either receivers of a low weight difference.

Official from December 1, 2014

Copyright (c) 2015 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.10 by ProIndi7 on Thu Jan 15 07:23:50 EST 2015

USP 37 General Information / á1265ñ Written Prescription Drug Information 1257

Dispense weighing: Dispense weighing typically is along the flask and reduces the apparent weight of the con-

used for weighing emulsions or viscous liquids such as oint- tents by viscous friction.

ments. In these situations it is not practical to weigh the ma- Hygroscopic samples: Hygroscopic materials readily

terial into a typical receiver. Accordingly, the analyst should absorb moisture from the atmosphere and steadily gain

tare the balance; place the sample on the balance in a suita- weight if left exposed. Therefore, hygroscopic samples must

ble container (e.g., a bottle, tube, transfer pipet, or syringe) be either weighed promptly or placed in a vessel with a gas-

that has been wiped clean on the outside; record the weight tight enclosure. For a gas-tight vessel, analysts should tare

after the balance display stabilizes; transfer the desired the vessel and enclosure, add the desired amount of sample,

amount of sample to an appropriate receiving vessel, such and replace the enclosure. After the balance display stabil-

as a volumetric flask; and place the pipet or syringe back on- izes, the analyst can record the specimen weight.

to the balance. The difference in the two weighings is equal Aseptic or biohazardous samples: The weighing of

to the weight of the transferred specimen. sterile or biohazardous samples should take place within the

Gravimetric dosing: Gravimetric dosing typically is confines of a clean bench, biosafety cabinet, isolator, or sim-

used for sample and standard preparations or capsule filling. ilar containment device. Air flow within the hood potentially

For such weighing the analyst places the volumetric flask, vi- can cause balance instability, so after a balance has been in-

al, or capsule shell on the balance; tares the balance after stalled under a hood, analysts should perform a rigorous

the balance display stabilizes; adds the solid or liquid com- qualification study with suitable weight artifacts (see á41ñ) in

ponents into the receiver by means of dosing units; and re- order to determine the acceptability of the balance perform-

cords the respective weights. ance in this environment.

Weighing corrosive materials: Many chemicals, such

General Chapters

Problem Samples as salts, are corrosive, and materials of this nature should

not be spilled on the balance pan or inside the balance

Electrically charged samples and receivers: Dry, finely housing. Extra care is essential when materials of this nature

divided powders may be charged with static electricity that are weighed. Analysts should consider the use of sealed con-

can make the powder either attracted to or repelled by the tainers such as weighing bottles or syringes. In the event of

receiver or the balance, causing inaccurate weight measure- a spill, requalification of balance may be necessary, depend-

ments and specimen loss during transfer. A drift in the bal- ing on the nature of the spill.

ance readings should alert the operator to the possibility

that the material has a static charge. Commercially available Safety Considerations When Weighing

balances with a built-in antistatic device can be used to rem-

edy the problem. Such devices may use piezoelectric com- During a weighing, the analyst may be exposed to high

ponents or a very small amount of a radioactive element concentrations of a pure substance. The analyst must care-

(typically polonium) to generate a stream of ions that dissi- fully consider this possibility at all times and should be famil-

pate the static charge when passed over the powder being iar with the precautions described in the substance¢s Materi-

weighed. Antistatic weigh boats, antistatic guns, and anti- al Safety Data Sheet before weighing it. Hazardous materials

static screens also are commercially available. The static should be handled in an enclosure that has appropriate air

charge depends also on the relative humidity of the labora- filtration. Many toxic—and possibly allergenic—substances

tory, which in turn depends on atmospheric conditions. Un- present as liquids or finely divided particles. When weighing

der certain conditions, static charge is caused by the type of these substances, analysts should use a mask that covers the

clothing worn by the operator and this charge can cause nose and mouth to prevent any inhalation of the substance,

large errors in the weighing. Borosilicate glassware and plas- and they should use gloves to prevent any contact with the

tic receivers have a well-known propensity for picking up skin. [NOTE—The use of gloves is good practice for handling

static charge, especially at low relative humidity. The gloves any chemical. If it is necessary to handle the container being

used to protect the operator also may increase the potential weighed, the analyst should wear gloves not only for self-

for a static charge problem. Placing the container in a metal protection but also to prevent moisture and oils from being

holder may help to shield the static charge, and antistatic deposited on the weighed container.]

gloves also can help to alleviate the problem.

Volatile samples: When weighing a liquid that has a

low boiling point, analysts must receive the specimen in a

vessel with a gas-tight enclosure of small diameter. The ana- á1265ñ WRITTEN PRESCRIPTION

lyst then tares the vessel and enclosure, adds the desired

amount of sample, and replaces the enclosure. After the bal- DRUG INFORMATION—

ance display stabilizes, the analyst records the specimen

weight.

GUIDELINES

Warm or cool samples: Samples that are warm or cool

should be equilibrated in the laboratory, or the weight read-

ings may be erroneous. With regard to warm samples, the The purpose of these guidelines—comprising format, con-

apparent weight is smaller than the true weight because of tent, and accessibility of prescription drug leaflets—is to

heat convection. For example, a flask that is warmer than help ensure that leaflets are useful. In this context, “useful”

ambient air warms up this air, which then flows upward means that recipients receive, understand, and are motiva-

ted to apply written information about their medicines to

Official from December 1, 2014

Copyright (c) 2015 The United States Pharmacopeial Convention. All rights reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chemical Resistance and Physical Properties of Carbon Brick: Standard Test Methods ForDocument5 pagesChemical Resistance and Physical Properties of Carbon Brick: Standard Test Methods ForHerald GuerreroNo ratings yet

- Intenship Report Sumit Nagar PDFDocument14 pagesIntenship Report Sumit Nagar PDFSumit NagarNo ratings yet

- Globalipl Development Limited Proforma Invoice for Diode Laser Hair Removal MachineDocument1 pageGlobalipl Development Limited Proforma Invoice for Diode Laser Hair Removal MachineSaif KareemNo ratings yet

- Business CalculusDocument272 pagesBusiness CalculusMaye Zuñiga Garcia100% (1)

- The Basic Theory of Crowning Industrial RollersDocument8 pagesThe Basic Theory of Crowning Industrial RollersJuan Carlos CárdenasNo ratings yet

- Chapter-4 Quantity SurveyingDocument40 pagesChapter-4 Quantity SurveyingAbdanur JihadNo ratings yet

- Resistivity While Drilling - Images From The StringDocument49 pagesResistivity While Drilling - Images From The StringGheorghe AndreiNo ratings yet

- MEASUREMENT TERMS AND UNITSDocument2 pagesMEASUREMENT TERMS AND UNITSJusteen BalcortaNo ratings yet

- Flexural Behavior of Reinforced Concrete (RC) Beams Retrofitted With Hybrid Fiber Reinforced Polymers (FRPS) Under Sustaining LoadsDocument10 pagesFlexural Behavior of Reinforced Concrete (RC) Beams Retrofitted With Hybrid Fiber Reinforced Polymers (FRPS) Under Sustaining LoadsFurkan IŞIKNo ratings yet

- CE 309 06 Relative Equilibrium of LiquidsDocument14 pagesCE 309 06 Relative Equilibrium of LiquidsKarl TristanNo ratings yet

- IIT-JEE Advanced Revision Package: Physical ChemistryDocument172 pagesIIT-JEE Advanced Revision Package: Physical ChemistryprathamNo ratings yet

- CE 337/CE 568: Prestressed Concrete Design: Prof. Sasankasekhar MandalDocument30 pagesCE 337/CE 568: Prestressed Concrete Design: Prof. Sasankasekhar MandalAkshay VaghasiyaNo ratings yet

- DatasheetDocument35 pagesDatasheetHeru susantoNo ratings yet

- Rosemount 8800 Series Vortex Flow Meters: CloseDocument5 pagesRosemount 8800 Series Vortex Flow Meters: ClosekEWQ 865kNo ratings yet

- Immortality Mortality Divine ParadoxDocument33 pagesImmortality Mortality Divine ParadoxNivek Johnson100% (1)

- Geotechnics & Concrete Engineering (Hong Kong) LTD.: Contact Details Registration No. HOKLAS 024 Page 1 of 1Document97 pagesGeotechnics & Concrete Engineering (Hong Kong) LTD.: Contact Details Registration No. HOKLAS 024 Page 1 of 1Tony ChungNo ratings yet

- James Clerk Maxwell Presentation For DistributionDocument36 pagesJames Clerk Maxwell Presentation For DistributionDestiny canacanNo ratings yet

- BASIC 2 EF QR NuevoDocument60 pagesBASIC 2 EF QR NuevoKarolina Uc santanaNo ratings yet

- MFDSML 2024 - Iiit NRDocument2 pagesMFDSML 2024 - Iiit NRVijay GopiKrishnanNo ratings yet

- GR 7 ASSET WORKSHEET HWDocument6 pagesGR 7 ASSET WORKSHEET HWSharon BijuNo ratings yet

- ASDO Marine Structures Tie Bar DesignCapDocument2 pagesASDO Marine Structures Tie Bar DesignCapFelipe Strafite CusterNo ratings yet

- Design of Cities: (Edmund N. Bacon) By-Abhiti Rawat and Harsh JaiswalDocument12 pagesDesign of Cities: (Edmund N. Bacon) By-Abhiti Rawat and Harsh JaiswalHarsh JaiswalNo ratings yet

- 19 SolutionsDocument8 pages19 SolutionsRainierGo0% (1)

- Visual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)Document29 pagesVisual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)MAXX ENGINEERS100% (1)

- Bphysics General Instructions: Show Your Solutions Clearly and Box Your Final Answer. Use One Side of Your Paper OnlyDocument2 pagesBphysics General Instructions: Show Your Solutions Clearly and Box Your Final Answer. Use One Side of Your Paper OnlyELLA JOY YEENo ratings yet

- BASIC CAL WEEK 7 9 ReviewerDocument9 pagesBASIC CAL WEEK 7 9 ReviewerJuan Miguel Rolyn HinguilloNo ratings yet

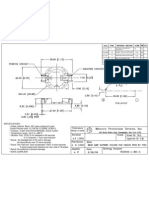

- 10/22/05 B T.B. B.S. 8/11/07 C T.B. B.S. 11/21/07 Dim. 5.30 Was 5.00 T.B. B.S. DDocument1 page10/22/05 B T.B. B.S. 8/11/07 C T.B. B.S. 11/21/07 Dim. 5.30 Was 5.00 T.B. B.S. DyogpanditNo ratings yet

- Silvaco TCAD Tutorial MOSDocument286 pagesSilvaco TCAD Tutorial MOSThomas Ho100% (4)

- Surcharging of Soft Ground To Reduce Secondary Settlement: January 2001Document12 pagesSurcharging of Soft Ground To Reduce Secondary Settlement: January 2001mcmNo ratings yet

- Python GUI For Impedance Spectroscopy Analysis: Scientia Cum Industria August 2018Document6 pagesPython GUI For Impedance Spectroscopy Analysis: Scientia Cum Industria August 2018Tomás de AlmeidaNo ratings yet