Professional Documents

Culture Documents

Component List For SKF Lubrication Systems Products

Uploaded by

Jorge Enrique Pulido AyalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Component List For SKF Lubrication Systems Products

Uploaded by

Jorge Enrique Pulido AyalaCopyright:

Available Formats

Component List for SKF Lubrication Systems Products

Original date: 01-October-2010

Revised date: 12-December-2013

Version No.: 1.8

Scope of the Document

This document contains product information to be used for the selection of components for FGA E&T-CPT

programs. This document provides a basic guide to selecting the correct type of lubrication system for the correct

application. It also provides the necessary contact information to assist in application engineering, program

management review, and stocking locations for ease of purchasing.

All information contained in this document is superseded by the requirements of the FGA E&T-CPT

Global Specification.

A current, and accurate, copy of the specification can be obtained from the following web addresses:

http://supplierinfo.fiatpowertrain.com

https://gsp.extra.chrysler.com/mfg/amedd/powertrain.htm

Document Management Information

http://www.skf.com/portal/skf_lub/home/skflibrary?contentId=876429&lang=en. Any printed copy is an

uncontrolled copy. The user shall verify with the project engineer that he/she is using the appropriate version of

the specification for the specific project he/she is working on.

Any questions or comments with respect to this specification should be directed to the project engineer for the

specific project in question.

Revision

Version

Date Paragraph Affected Revised By

No.

DD-Month-YYYY

01-October-2010 1 Original release R. Gomez

Eva-M Tausend

02-February-2011 1.1 Minor formatting changes. D. Schultz

2.2.5, 3.10 - added KFB1-M-W-XXX

2.5.4, 3.7 - added ETP unit

2.11, 3.29 (inserted section) - added check valves for

progressive feeders

2.12.4, 2.12.5, 3.21.1 - connectors for cycle switches

3.5.1 - minor drawing revision

03-February-2012 1.2 Correction made to Section 2.17.2 R. Reynolds

3/4" Female Quick Coupling read 995-001-521, which

is 3/4" Male; changed to 995-001-519

27-June-2012 1.3 Replaced all FPT logo with new FP logo, as requested R. Reynolds

by John H. Janssen Jr., Chrysler LLC

3.0 - revised voltage code +564 to +1FV; and added

note "...FP projects in China use voltage code +1FW"

01-October-2012 1.4 Added note "...FP projects in Brazil use voltage code R. Reynolds

+MDG", as requested by Mr. Giuliano of Fiat.

19-December-2012 1.5 Added missing technical drawings for all. R. Reynolds

1.1 Revised contact to Mr. Angelo Giuliano

26-March-2013 1.6 Added order form as requested by Dario Canevari of R. Reynolds

Fiat; and other general updates

19-June-2013 1.7 Fiat Powertrain is now Fiat Group Automobiles S.p.A. R. Reynolds

Engine and Transmission; replaced old logo &

company name with new on all pages

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 2 of 82

Revision

Date Version Paragraph Affected Revised By

DD-Month-YYYY No.

12-December-2013 1.8 2.4 Removed MFE1-BW* Pumps S.Moninger

2.5.3 Added 3D Model

2.17.1 Update filter part numbers

2.24 Added Orsco information

3.1.7 Modified drawing for legibility

3.3 Updated quick disconnect part numbers

3.6 Removed MFE1-BW* Pumps

3.7 Added link to technical data brochure

3.8 Changed drawing

3.10 Added quick disconnect note

3.12.1 – 3.22 Added link to technical data brochure

3.26, 3.27 Added link to technical data brochure

3.30 - 3.34 Added link to technical data brochure

3.37 Updated filter part numbers

3.41-3.42 Added link to technical data brochure

3.44-3.46 Added Orsco Drawings

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 3 of 82

Index

Document Management Information…………………………………………………………………………………..…2

1.0 SKF Lubrication Systems Persons to Contact…………………………………………………………...…...7

1.1 CPT and FGA E&T Contact……………………………………………………………..……………………..7

2.0 List of Components…………………………………………………………………….…………………………..8

2.1 Pumps for single line parallel piston distibutors for oil………………….…..……………..…………….8

2.2 Pumps for single line parallel piston distributors for fluid grease…………………………….………..9

2.3 Pumps for high speed spindle lubrication Oil+Air……………………………………...………………10

2.4 Pumps for Progressive systems for oil………………………………………...………………………..11

2.5 Piston pumps for Progressive systems for grease ……………………………………………………12

2.6 Single line parallel piston distributor for oil…………………………….……………………………….13

2.7 Single line parallel piston distributor for fluid grease………………………………………………….14

2.8 Manifolds for single point distributors……………...………………..………………………………….15

2.9 Oil+Air metering units……………………………………………………….…………………………….16

2.10 Progressive feeder….......…………………………………………………………………………….….17

2.11 Check Valves for Progressive feeder.….…………………………..………………………………….18

2.12 Cycle switches and connectors for Progressive feeder……………….……………………………19

2.13 Over pressure indicators for Progressive feeder……………………………………………………19

2.14 Electronic pressure switches………………………………………………………………………….20

2.15 Flow monitors for piston distributor systems…………………………..…………………………….20

2.16 Oil+Air streak sensor……………………………………..…………………………………………….21

2.17 Filter…………………………………………………………………………………..………………….21

2.18 Quick disconnect couplings-CPT Only! ………….………………………………………………….22

2.19 Glycerine filled pressure gauges…………………………….……………………………………….23

2.20 Solenoid valves……………………………………………………………………………………..….23

2.21 Vario Units for MQL systems…………………………………………….……………..…………….25

2.22 DigitalSuper units for MQL systems………………………………………………………………….26

2.23 Aerosol Monitor for MQL systems………………………………………………………...………….26

2.24 Oil/Air for Part Lubrication………………………………………………………………......…………27

3.0 Technical Information and Drawings………………………………………………………………………….28

3.1 MFE pumps for piston distributor systems for oil………………………………………………………28

3.1.1 Standard dimensions of reservoirs: 3,6 and 15 liter (all dimensions in mm)………………29

3.1.2 Standard dimensions of reservoirs: 30 and 50 liter (all dimensions in mm)………….……30

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 4 of 82

3.1.3 MFE5-KW*-C100+1FV………………………………………………………………………….31

3.1.4 MFE5-BW*-C100+1FV………………………………………………………………………….32

3.1.5 MFE5-KW*-F100+140…………………………………………….…………………………….33

3.1.6 MFE5-BW*-F100+140………………………………….……………………………………….34

3.1.7 P-886-BWW*-C100……………………………………………………..……………………….35

3.2 Angle brackets for filter assembly…………………………………………………………………….36

3.3 Quick disconnect coupling…………………………………………………………………………….37

3.4 Glycerine filled pressure gauges…………………………………………………………..………….38

3.5 MFE pumps for piston distributors for fluid grease……………………………………….…………39

3.5.1 Standard dimensions of reservoirs: 3 and 6 liter (plastic)………………………………….40

3.5.2 MFE2-KW*F-C100+1FV……………………………………………………………………….41

3.5.3 MFE2-KW*F-F100+140……………………………………………………………….……….42

3.6 MF pumps for Progressive systems for oil…………………………………………………….…….43

3.6.1 Standard dimensions of reservoirs: 6 liter (all dimensions in mm)………………………..44

3.6.2 MF1-BW*C100+1FV………………………………………………………..………………….45

3.6.3 MF1-BW*F100+140………………………………………………………………………...….46

3.7 ETP-X-WZ-XXXXX-X+924……………………………………………………………...……….…….47

3.8 KFG1-5W2x-V71+924 piston pump for Progressive systems for fluid grease………...……..….48

3.9 KFG1-5W2x-V71+924 piston pump for Progressive systems for fluid grease……....…………..49

3.10 KFB1-M-W-XXX………………………………………………………………………….……………..50

3.11 KFA1-M-WA-V71+924 pumps for Progressive systems for grease……….………….………….51

3.12 Piston distributor 341 and Manifolds…………………………………………….……….……….….52

3.13 Piston distributor 342 ,343 and 345 Series………………………………………………………….52

3.14 Piston distributor 351 and Manifolds……………………………………………….………..……….52

3.15 Piston distributor 352,353 and 355 Series…………………………………………….…………….52

3.16 Piston distributor 391 and Manifolds……………………………………………………….…..…….52

3.17 Piston distributor 392 and 393 Series…………………………………...………………………..….52

3.18 Oil+Air mixing valves…………………………………………….…………….……………………….53

3.19 Progressive Feeder VPG…………………………………………………………………………..….53

3.20 Progressive Feeder VPKG…………………………………………………………………………….53

3.21 Progressive Feeder VPBG…………………………………………………………………………….53

3.22 Progressive Feeder PSG2……………………………………………...………………………….….53

3.23 177-300-094 cycle switch for VP and PSG Progressive Feeders………..……………………….54

3.24 177-300-095 cycle switch for VPK Progressive Feeders…………………………………...…….55

3.25 177-300-097 cycle switch for VPB Progressive Feeders……………………………………...….56

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 5 of 82

3.26 Cycle Switch Connectors for Progressive Feeders…………………………..…………………….57

3.27 Over pressure Indicators for Progressive Feeders………………………………...……………….57

3.28 Pressure Switch 176-190-001……………………………………………………………….………..58

3.29 Pressure Switch DS-EP-40-D-4..................................................................................................59

3.30 Flow Monitor GS300……………………………………………………………………………………60

3.31 Oil+Air Streak Sensor………………………………………………………………………….………60

3.32 Solenoid Valve 161-110-031………………………………………………………………………….61

3.33 Solenoid Valve 161-120-064………………………………………………………………...………..61

3.34 Solenoid Valve 161-140-050………………………………………………………………….………61

3.35 Solenoid Valve VPG-VEN-V71A……………………………………………………………………...62

3.36 Solenoid Valve VPG-VEN-V71……………………………………………………………….……….63

3.37 Pressure Filter NC63 acc. to DIN 24550…………………………………………………………….64

3.38 Check valves for Progressive Feeders………………………………………………………………65

3.39 Lubrilean Vario UFV10-014-2……………………………………………………………………...….66

3.40 Lubrilean VarioPlus UFV10-019-2……..………………………………………………………...…..67

3.41 Lubrilean VarioSuper……………………………………………………………………………….….68

3.42 Lubrilean DigitalSuper…………………………………………………………………………….……68

3.43 Lubrilean Aerosol Monitor………………………………………………………………………….….69

3.44 VSR System for part lubrication with external controls………………………………………….....70

3.45 LGPTN spray nozzle assemblies for oil/air……………………………………………………….…71

4.0 Order form……………………………………………………………………………………………………….....72

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 6 of 82

1. SKF Lubrication Systems Persons to Contact

USA

Frank Casinelli

Lubrication Specialist

SKF Lubrication Systems USA

15918 Patriot

Macomb, MI 48044

Tel: 248 982 7411

Frank.P.Casinelli@skf.com

Italy

Antonio Polito

Sales Coordinator

SKF Industrie S.p.A - Lubrication Business Unit

Via Gramsci, 55

20032 Cormano (MI) / Italy

Phone: +39-02-663089

Fax: +39-02-66308937

Mobile: +39-335-7631749

Antonio.Polito@skf.com

1.1 CPT and FGA E&T contact

FP & CPT Europe (Italy) North America

Address Corso Settembrini, https://gsp.extra.chrysler.com/mfg/amedd/control/index.

167-10135 Torino (TO) htm

Website

Project Contact Mr. Angelo Giuliano

Company Fiat Group Automobiles S.p.A.

Office +39-011.0035734

Mobile

Fax +39-011.0038075

E-Mail angelo.giuliano@fptpowertrain.com

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 7 of 82

2.0 List of components

2.1 Pumps for single line parallel piston distributors for oil

Photo SYMBOL ORDER CODE DESCRIPTION RESERVOIR Notes

CPT only CPT Only! Quick fill to be

Gear pump for oil ordered separately. See

Flow rate: 0,5 ltr/min section 3.3.

MFE5-KW3-C100+1FV Pressure: 27 bar

Electrical: 220-240 / 3l-plastic reservoir

2.1.1 MFE5-KW6-C100+1FV Standard components:

380-420V @ 50 Hz; 6l-plastic reservoir

Filter w/ dirt indicator

254-280/440-460V @ Pressure gauge

60Hz; both +/- 5%, Low level float switch

UL/SCA Breather

CPT only CPT Only! Quick fill to be

Gear pump for oil ordered separately. See

MFE5-BW3-C100+1FV Flow rate: 0,5 ltr/min 3l metal reservoir section 3.3.

MFE5-BW7-C100+1FV Pressure: 27 bar 6l metal reservoir

2.1.2 MFE5-BW16-C100+1FV Electrical: 220-240 / 15l metal reservoir Standard components:

MFE5-BW30-C100+1FV 380-420V @ 50 Hz; 30l metal reservoir Filter w/ dirt indicator

MFE5-BW50-C100+1FV 254-280/440-460V @ 50l metal reservoir Pressure gauge

60Hz; both +/- 5%, Low level float switch

UL/SCA Breather

FP only

Gear pump for oil FP Only!

Flow rate: 0,5 ltr/min

MFE5-KW3-F100+140 Pressure: 27 bar Standard components:

Electrical: 400V, 3PH, 3l-plastic reservoir

2.1.3 MFE5-KW6-F100+140 Filter w/ dirt indicator

50Hz 6l-plastic reservoir

Pressure gauge

Low level float switch

Breather

FP only

Gear pump for oil FP Only!

MFE5-BW3-F100+140 Flow rate: 0,5 ltr/min 3l metal reservoir

MFE5-BW7-F100+140 Pressure: 27 bar 6l metal reservoir Standard components:

2.1.4 MFE5-BW16-F100+140 Electrical: 400V, 3PH, 15l metal reservoir Filter w/ dirt indicator

MFE5-BW30-F100+140 50Hz 30l metal reservoir Pressure gauge

MFE5-BW50-F100+140 50l metal reservoir Low level float switch

Breather

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 8 of 82

CPT Only! Quick fill to be

ordered separately. See

CPT Only

section 3.3.

Piston pumps for oil

P-886-BWW7-C100 7L metal reservoir Standard components:

2.1.5 Volume/stroke: 30cc

P-886-BWW16-C100 16L metal reservoir Filter w/ dirt indicator

Oil Pres max: 25bar

Pressure gauge

Air Pres max: 10bar

Low level float switch

Breather

2.2 Pumps for single line parallel piston distributors for fluid grease

Photo SYMBOL ORDER CODE DESCRIPTION RESERVOIR Notes

CPT only

Gear pump for fluid

grease CPT Only! Quick fill to be

Flow rate: 0,2 ltr/min ordered separately. See

MFE2-KW3F-C100+1FV Pressure: 38 bar 3l plastic tank section 3.3.

2.2.1

MFE2-KW6F-C100+1FV Electrical: 220-240 / 6l plastic tank

380-420V @ 50 Hz; Use with 213-900 grease

254-280/440-460V @ filter in section 2.17

60Hz; both +/- 5%,

UL/SCA

FP only

Gear pump for fluid

FP Only!

grease

MFE2-KW3F-F100+140 3l plastic tank

2.2.2 Flow rate: 0,2 ltr/min

MFE2-KW6F-F100+140 6l plastic tank Use with 213-900 grease

Pressure: 38 bar

filter in section 2.17

Electrical: 400V, 3PH,

50Hz

Gear pump for Fluid

grease unit for 5-15

points

1.4l plastic

2.2.3 KFB1-M-W+924 Max Flow rate: 50 CPT Only!

reservoir

cm³/min

Pressure: 38 bar

Electrical: 24VDC

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 9 of 82

2.3 Pumps for high speed spindle lubrication Oil+Air

Photo SYMBOL ORDER CODE DESCRIPTION RESERVOIR Notes

CPT only! Quick fill to

CPT only be ordered separately.

Gear pump for oil See section 3.3.

Flow rate: 0,5 ltr/min

MFE5-KW3-C100+1FV 3l-plastic

Pressure: 27 bar Standard

2.3.1 3 phase motor reservoir

Electrical: 220-240 / 380- components:

420V @ 50 Hz; 254-280/440- Filter w/ dirt indicator

460V @ 60Hz; both +/- 5%, Pressure gauge

UL/SCA Low level float switch

Breather

FP only FP Only!

MFE5-KW3-F100+140 Gear pump for oil 3l-plastic

2.3.2 3 phase motor Flow rate: 0,5 ltr/min reservoir Use with 213-900

Pressure: 27 bar grease filter in section

Electrical: 400V, 3PH, 50Hz 2.17

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 10 of 82

2.4 Pumps for Progressive systems for oil

Photo SYMBOL ORDER CODE DESCRIPTION RESERVOIR Notes

CPT only

For circulating

systems

Flow rate: 0,1

ltr/min

CPT Only!

Pressure: 60 bar 6l metal reservoir

2.4.1 MF1-BW7-C100+1FV Quick fill to be ordered

Electrical: 220-240 /

separately. See section 3.3.

380-420V @ 50 Hz;

254-280/440-460V

@ 60Hz; both +/-

5%, UL/SCA

FP only

For circulating

systems

Flow rate: 0,1

ltr/min 6l metal reservoir

2.4.2 MF1-BW7-F100+140 FTP only!

Pressure: 60 bar

Electrical: 400V,

3PH, 50Hz

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 11 of 82

2.5 Piston pumps for Progressive systems for grease

Photo SYMBOL ORDER CODE DESCRIPTION Notes

Q= 2,5cm³/min Quick fill to be ordered

KFG1-5W1GA-V71+924 Q= 1,8cm³/min separately. See section

2.5.1 L P KFG1-5W1GB-V71+924 Q= 1,3cm³/min 3.3.

KFG1-5W1GC-V71+924 Q= 0,8cm³/min

KFG1-5W1GD-V71+924 Electric piston pump for

grease, 24VDC

Q= 2,5cm³/min Quick fill to be ordered

KFG1-5W2A-V71+924 Q= 1,8cm³/min separately. See section

KFG1-5W2B-V71+924 Q= 1,3cm³/min 3.3.

2.5.2

L P

KFG1-5W2C-V71+924 Q= 0,8cm³/min

KFG1-5W2D-V71+924 Electric piston pump for

fluid grease, 24VDC

Q= 2,0cm³/min Quick fill to be ordered

Q= 1,5cm³/min separately. See section

KFA1-M-WA-V71+924 Q= 1,0cm³/min 3.3.

2.5.3

L P

KFA1-M-WB-V71+924 Electric piston pump for

KFA1-M-WC-V71+924 grease, 24VDC CPT Only!

Grease unit for 5 points or

less.

2.5.4 ETP-X-WZ-XXXXX+924

Metering: 10 mm3/stroke, 15 CPT Only!

mm3/stroke, 20 mm3/stroke

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 12 of 82

2.6 Single line parallel piston distributors for oil

Photo SYMBOL ORDER CODE DESCRIPTION Notes

0.01 to 0.16 cm3

341-1XX-X0000-00 Single piston distributor for oil

0.05 to 0.60 cm3

2.6.1 351-0XX-X0000-00 Single piston distributor for oil

0.20 to 1.50 cm3

391-000-X0000-00 Single piston distributor for oil

342-4XX-XX000-XX

2.6.2 343-4XX-XXX00-XX Standard piston distributor for oil

345-4XX-XXXXX-XX

352-0XX-XX000-XX

353-0XX-XXX00-XX

2.6.3 Standard piston distributor for oil

355-0XX-XXXXX-XX

392-000-XX000-XX

2.6.4 393-000-XXX00-XX Standard piston distributor for oil

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 13 of 82

2.7 Single line parallel piston distributors for fluid grease

Photo SYMBOL ORDER CODE DESCRIPTION Notes

341-7XX-X0000-00 Standard piston distributor for fluid grease 0.01 to 0.16 cm3

351-1XX-X0000-00 Standard piston distributor for fluid grease 0.05 to 0.60 cm3

2.7.1

391-100-X0000-00 Standard piston distributor for fluid grease 0.10 to 0.30 cm3

342-5XX-XX000-XX

2.7.2 343-5XX-XXX00-XX

Standard piston distributor for fluid grease

345-5XX-XXXXX-XX

352-1XX-XX000-XX

353-1XX-XXX00-XX

2.7.3 Standard piston distributor for fluid grease

355-1XX-XXXXX-XX

392-100-XX000-XX

2.7.4 393-100-XXX00-XX Standard piston distributor for fluid grease

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 14 of 82

2.8 Manifolds for single point piston distributors

Photo SYMBOL ORDER CODE DESCRIPTION Notes

G 1/8

VL-0xAAG1 G 1/4

2.8.1 VL-0xAAG2 M10x1 To be used with 341 single

VL-0xAAM1 M14x15 piston distributors

VL-0xAAM2

Manifolds for 341 series

G 1/8

VL-0xBAG1 G 1/4

VL-0xBAG2 M10x1 To be used with 351 single

2.8.2 M14x15

VL-0xBAM1 piston distributors

VL-0xBAM2

Manifolds for 351 series

G 1/8

VL-0xCAG1 G 1/4

VL-0xCAG2 M10x1 To be used with 391 single

2.8.3

VL-0xCAM1 M14x15 piston distributors

VL-0xCAM2

Manifolds for 391 series

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 15 of 82

2.9 Oil+Air metering units

Photo SYMBOL ORDER CODE DESCRIPTION Notes

For use in Oil+Air Systems

using the MFE5-KW3-

2.9.1 MV20x-100-xxxxxxxx Oil+Air metering unit

C100+1FV

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 16 of 82

2.10 Progressive feeders

Photo SYMBOL ORDER CODE DESCRIPTION Notes

Progressive sectional feeder

Metered quantity of lubricant:0,1-1,2

cm³/stroke

2.10.1 VPG Threaded inlet port: G1/4

Threaded outlet port: G1/8

Progressive sectional feeder

Metered quantity of lubricant:0,05÷0,6

cm³/stroke

2.10.2 VPKG Threaded inlet port: G1/8

Threaded outlet port: G1/8

Progressive block feeder

Metered quantity of lubricant:0,2

cm³/stroke

2.10.3 VPBG Threaded inlet port: G1/8

Threaded outlet port: G1/8

Progressive sectional feeder

Metered quanitity of lubricant: 0,06 -

0,84 cm³/stroke

2.10.4 PSG2 Threaded inlet port: G1/4

Threaded outlet port: G1/4

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 17 of 82

2.11 Check Valves for progressive feeders

Photo SYMBOL ORDER CODE DESCRIPTION Notes

VPG-RV G1/8, ø 4mm, 10 bar

2.11.1 VPG-RV6 G1/8, ø 6mm, 10 bar

VPG-RV8 G1/8, ø 8mm, 10 bar

With sleeve fitting

G1/8, ø 6mm, 3 bar and compression nut

2.11.2 VPKG-RV

G1/8, ø 6mm, 3 bar Quick connection

2.11.3 VPKG-RV-VS

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 18 of 82

2.12 Cycle switches and connectors for Progressive feeder

Photo SYMBOL ORDER CODE DESCRIPTION Notes

3 wires cycle switch for NC contact, connection:

2.12.1 177-300-094

VP/PSG M12x1

G

NC contact, connection:

2.12.2 177-300-095 3 wires cycle switch for VPK

M12x1

NC contact, connection:

2.12.3 177-300-097 3 wires cycle switch for VPB

M12x1

Straight Socket w/ 5 m cable

for 4 pole; UL-CSA

179-990-600

177-300-094, 177-300-095, approved

and 177-990-097

cycle switches

2.12.4

Elbow Socket w/ 5 m cable

for

4 pole; UL-CSA

179-660-601 177-300-094, 177-300-095,

approved

and 177-990-097

cycle switches

2.13 Over pressure indicators for Progressive feeder

Photo SYMBOL ORDER CODE DESCRIPTION Notes

VPG-UE16-2 16 bar - 232 PSI - 1.6 MPa

VPG-UE32-2 32 bar - 464 PSI - 3.2 MPa

VPG-UE63-2 63 bar - 915 PSI - 6.3 MPa

VPG-UE80-2 80 bar - 1160 PSI - 8 MPa

2.13.1 VPG-UE100-2 100 bar - 1450 PSI - 10 MPa

VPG-UE50-3 50 bar - 725 PSI - 5 MPa

VPG-UE100-3 100 bar - 1450 PSI - 10 MPa

VPG-UE150-3 150 bar - 2175 PSI - 15 MPa

VPG-UE200-3 200 bar - 2900 PSI - 20 MPA

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 19 of 82

2.14 Electronic pressure switches

Photo SYMBOL ORDER CODE DESCRIPTION Notes

electronic pressure switch,

Rated Pressure: Max 100

P bars.

Permissible overpressure: M12x1, 4-pins

2.14.1 DS-EP-40-D-4

200 bars

Ambient and Fluid 1-1701-EN Brochure

temperature range: -25 to +

800 C

IP 67 rating

P

2.14.2 176-190-001 electronic pressure switch,

2.15 Flow monitors for piston distributor systems

Photo SYMBOL ORDER CODE DESCRIPTION Notes

24VDC

2.15.1 GS300 Flow range:

0,01-0,6cc/cycle

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 20 of 82

2.16 Oil+Air streak sensor

Photo SYMBOL ORDER CODE DESCRIPTION Notes

2.16.1 GS4011-S20 Oil+air streak sensor, 120 - 600 mm³/hr

GS4011-S50 Oil+air streak sensor, 60 - 120 mm³/hr

2.17 Filter

Photo SYMBOL ORDER CODE DESCRIPTION Notes

169-460-099-V57 3 µm - Oil

169-460-087-V70 10µm - Oil

2.17.1 169-460-185 25µm - Oil

Oil pressure line with electrical

contamination indicator, electrical

connection: 24VDC,4pin connector, M12x1

25 µm - Grease

Screen filter for grease.

2.17.2 213-900 Flow rate - 2 l/min.

Max operating pressure - 45 bar

Connection - M14x1.5

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 21 of 82

2.18 Quick disconnect couplings - CPT ONLY!

Photo SYMBOL ORDER CODE DESCRIPTION Notes

995-003-534 3/8” (Couplers only) CPT Only!

995-003-527 5/8” All quick disconnections must be

995-003-528 3/4” approved by AME control’s

2.18.1 engineering and chemical

management.

See section 3.3

995-003-529 1/8” (Couplers only) CPT Only!

995-002-096 1/4” All quick disconnections must be

995-003-530 3/8” approved by AME control’s

995-003-531 1/2” engineering and chemical

995-003-532 3/4” management.

2.18.2 995-005-088 1/8” (Complete quick disconnect with See section 3.3

995-005-096 1/4” coupler, strainer and housing)

995-005-097 3/8”

995-003-533 1/2”

995-005-521 3/4”

995-001-228 3/8” (Couplers only) CPT Only!

995-003-517 1/2” All quick disconnections must be

approved by AME control’s

engineering and chemical

management.

995-001-227 3/8” (Complete quick disconnect with See section 3.3

2.18.3

995-003-518 1/2” coupler, strainer and housing)

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 22 of 82

2.19 Glycerine filled pressure gauges

Photo SYMBOL ORDER CODE DESCRIPTION Notes

169-104-015 0-40 bar / 0-580 PSI / 0-4 MPa

169-110-015 0-100 bar / 0-1450 PSI / 0 - 10 MPa

2.19.1 169-125-015 0-250 bar / 0-3625 / 0-25 MPa

Glycerine pressure gauge, G1/4

face in MPA, PSI, bar

2.20 Solenoid valves

Photo SYMBOL ORDER CODE DESCRIPTION Notes

2.20.1 1-1703-EN Brochure

161-110-031+924 2/2 way valve

For OIL and GREASE

2/2 way Zero Leakage Valve

2.20.2 VPG-VEN-V71A+924

For OIL

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 23 of 82

2/2 way Zero Leakage Valve

with Union Block for remote

2.20.3 VPG-VEN-V71+924 mounting

FOR OIL

3/2 way valve

161-120-064+924

2.20.4 For OIL and GREASE See brochure 1-1703-EN

4/2 way valve

2.20.5 161-140-050+924 See brochure 1-1703-EN

FOR OIL

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 24 of 82

2.21 VARIO Units for MQL systems

Photo ORDER CODE DESCRIPTION Notes

Lubrilean VARIO

1.8 liter capacity

Internal or external lubrication Can be used with SKF

Compressed air port: LubriOil or SKF LubriFluid.

2.21.1 UFV10-014-2

Min: 6 bars See page 15 of brochure

Optional: 8 bars 1-5102-EN

Max: 10 bars

Manual slide valve actuation

Lubrilean VARIOPLUS

1.8 liter capacity

Internal or external lubrication

Compressed air port: Can be used with SKF

Min: 6 bars LubriOil or SKF LubriFluid.

2.21.2 UFV10-019-2

Optional: 8 bars See page 15 of brochure

Max: 10 bars 1-5102-EN

24 VDC actuation

Level monitoring for 4 points

Lubrilean VARIOSUPER-

1.8 liter capacity

Internal or external lubrication Basic Information

Compressed air port:

Min: 6 bars Can be used with SKF

2.21.3 UFV30-003

Optional: 8 bars LubriOil or SKF LubriFluid.

Max: 10 bars See page 15 of brochure

24 VDC actuation 1-5102-EN

Level monitoring for 2 points

Pressure monitoring

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 25 of 82

2.22 DigitalSuper Units for MQL systems

Photo ORDER CODE DESCRIPTION Notes

LUBRILEAN DIGITALSUPER 1 See brochure 1-5109-EN

1.8 liter capacity

Internal or external lubrication Requires FP-CPT Controls

Compressed air port: engineering prior approval.

2.22.1 UFD10-020 Min: 6 bars, Optional: 8 bars, Max: 10 bars

24 VDC actuation Can be used with SKF

Level monitoring for 4 points LubriOil or SKF LubriFluid.

Flow sensor See page 15 of brochure

Pressure monitoring 1-5102-EN

LUBRILEAN DIGITALSUPER 2

For machining centers with double spindles See brochure 1-5109-EN

or turning machines with two turrets

1.8 liter capacity Requires FP-CPT Controls

Internal or external lubrication engineering prior approval

2.22.2 UFD20-020 Compressed air port:

Min: 6 bars, Optional: 8 bars, Max: 10 bars Can be used with SKF

24 VDC actuation LubriOil or SKF LubriFluid.

Level monitoring for 4 points See page 15 of brochure

Flow sensor 1-5102-EN

Pressure monitoring

2.23 Aerosol Monitor for MQL systems

Photo ORDER CODE DESCRIPTION Notes

See brochure 1-5109-EN

2.23.1 AM1000 Aerosol monitor

ACCESSORIES

Spray blocks, nozzles and coaxial tubes see brochure 1-5102-EN

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 26 of 82

2.24 Oil/Air for Part Lubrication

Photo ORDER CODE DESCRIPTION NOTES

VSR System for part lubrication with external

2.24.2 VSR-GD-XY CPT Only!

controls

LGTPN-X-NY-XX-XXX

2.24.3 LGTCN-X-NY-XX-XXX LGTPN spray nozzle assemblies for oil/air CPT Only!

LGTFN-X-NY-XX-XXX

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 27 of 82

3.0 Technical Information and Drawings

Voltage key for electric motors:

For CPT plants - 480 Volts, 3PH, 60 Hz: SKF voltage key: +1FV

For FP plants - 400 Volts, 3PH, 50 Hz. SKF voltage key: +140

For direct current pumps (KFG & KFA) the operating voltage is 24 VDC. SKF voltage key: +924

For FP Projects in China 220/380V, 50Hz +/- 10% "CCC" motor; SKF voltage key: +1FW

For FP Projects in Brazil 460V, 60Hz +/- 10% "CCC" motor; SKF voltage key: +MDG

Quick disconnects

FP units include a manual fill with strainer only. CPT units include a blank plate where a quick disconnect must be

installed. A list of quick disconnect couplings can be found in section 3.3. Any drawing, graphic or photo showing

a quick disconnect is for representative purposes only. Quick disconnects must be ordered separately

3.1 MFE-pumps for piston distributor system for oil

MFE Brochure and Technical Information, Publication 1-1202-EN

Technical data gear pump units:

Output: 0,5 l/min

Max. back pressure: 27 bar

Operating viscosity: 20 to 1500 mm²/s

Medium: Mineral- or synthetic oil compliant with:

plastics, NBR- elastomers, copper and copper alloys

Operating temperatur: +10 to +40 °C

All gear pump units for piston distributor parallel system are without filter and quick disconnects.

Depending on applications and plants filter and/or quick disconnects can be assembled.

Quick disconnects must be ordered separately! See section 3.3.

Summary of MFE-pumps for piston distributor system for CPT

MFE5-KW3-C100+xxx MFE5-BW3-C100+xxx MFE5-BW30-C100+xxx

MFE5-KW6-C100+xxx MFE5-BW7-C100+xxx MFE5-BW50-C100+xxx

MFE5-BW16-C100+xxx

Summary of MFE-pumps for piston distributor system for FP

MFE5-KW3-F100+xxx MFE5-BW3-F100+xxx MFE5-BW30-F100+xxx

MFE5-KW6-F100+xxx MFE5-BW7-F100+xxx MFE5-BW50-F100+xxx

MFE5-BW16-F100+xxx

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 28 of 82

3.1.1 Standard dimensions of reservoirs: 3, 6 and 15 liter (all dimensions are in mm)

Reservoir Height Width Depth Center Whole

capacity [mm] [mm] [mm] distance Ø[mm]

[liter] [mm]

H H1 H2 * B B1 B2 T T1 * T2 * D1 D2 D

3 plastic --- 154 350 245 320 320 135 --- --- 220 17,5 7

6 plastic --- 183 380 290 390 390 178 --- --- 220 20 8,5

3 metal 152 170 365 238 315 315 134 220 220 220 110 7

6 metal 216 236 430 320 360 380 142 210 250 300 140 9

15 metal 250 304 500 436 475 490 180 260 285 400 124 9

Units for FP Units for CPT

Representative

only!!

See note below

Please notice: FP units include manual fill with strainer only. CPT units include a blank

plate where a quick disconnect must be installed. Quick fill disconnect MUST BE

ORDERED SEPARATELY. Please see section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 29 of 82

3.1.2 Standard dimensions of reservoirs: 30 and 50 liter (all dimensions are in mm)

Reservoir Reservoir Width Tank Height - Depth

capacity Center- Center Height overall

[liters] footprint

B C D G H

A E F

30 metal 430 x 240 500 ~514 510 ~381 ~523 320 ~394

50 metal 490 x 270 570 586 580 475 ~617 374 ~448

Representative only!!

See note below

Please notice: FP units include manual fill with strainer only. CPT units include a blank

plate where a quick disconnect must be installed. Quick fill disconnect MUST BE

ORDERED SEPARATELY. Please see section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 30 of 82

3.1.3 MFE5-KW3-C100

Please notice: FP units include manual fill with strainer only. CPT units include a blank

plate where a quick disconnect must be installed. Quick fill disconnect MUST BE

ORDERED SEPARATELY. Please see section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 31 of 82

3.1.4 MFE5-BW3-C100

Please notice: FP units include manual fill with strainer only. CPT units include a blank

plate where a quick disconnect must be installed. Quick fill disconnect MUST BE

ORDERED SEPARATELY. Please see section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 32 of 82

3.1.5 MFE5-KW3-F100

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 33 of 82

3.1.6 MFE5-BW3-F100

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 34 of 82

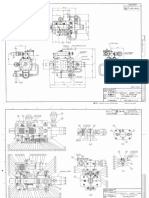

3.1.7 P-886-BWW*-C100

Please notice: FP units include manual fill with strainer only. CPT units include a blank

plate where a quick disconnect must be installed. Quick fill disconnect MUST BE

ORDERED SEPARATELY. Please see section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 35 of 82

3.2 Angle bracket for filter assembling

881-280-086 881-260-041

Reservoir capacity Angle bracket

(liters) Order No.

3 plastic ---

6 plastic ---

3 metal 881-260-041

6 metal 881-280-086

15 metal 881-280-086

30 metal 881-280-086

50 metal 881-280-086

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 36 of 82

3.3 Quick disconnect coupling

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 37 of 82

3.4 Glycerine filled pressure gauges

Technical data

Ranges: 0-40 bar, 0-100 bar, 0-250 bar

Measurements: bar, psi and MPa

Damping: Glycerine

Casing: Stainless steel

Thread: G 1/4

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 38 of 82

3.5 MFE-pumps for piston distributors for fluid grease

Technical data

Output: 0.2 l/min

Max. back pressure: 38 bar

Fluid grease NLGI-class: 00,000

Operating temperature: +10 +40 °C

Degree of protection acc. to DIN EN 60529: IP54

Summary of MFE-pumps for piston distributors for fluid grease for CPT

MFE2-KW6F-C100+xxx MFE2-KW3F-C100+xxx

Summary of MFE-pumps for piston distributors for fluid grease for FP

MFE2-KW3F-F100+xxx MFE2-KW6F-F100+xxx

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 39 of 82

3.5.1 Standard dimensions of reservoirs: 3 and 6 liter (plastic)

Reservoir Height Width Depth Center Hole

capacity [mm] [mm] [mm] distance Ø[mm]

[liter] [mm]

H H1 H2 * B B1* T T1 * D1 D2 D

3 plastic --- 154 350 245 330 130 --- 220 --- 7

6 plastic --- 183 380 285 390 178 --- 110 110 8,5

For CPT units, see note below

regarding quick disconnect.

Please notice: FP units include manual fill with strainer only. CPT units include a blank

plate where a quick disconnect must be installed. Quick fill disconnect MUST BE

ORDERED SEPARATELY. Please see section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 40 of 82

3.5.2 MFE2-KW*F-C100

Please notice: FP units include manual fill with strainer only. CPT units include a blank

plate where a quick disconnect must be installed. Quick fill disconnect MUST BE

ORDERED SEPARATELY. Please see section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 41 of 82

3.5.3 MFE2-KW*F-F100

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 42 of 82

3.6 MF pumps for Progressive systems for oil

Technical data:

Technical data units MF1-BW7-V100+XXX

Output: 0.1 l/min

Max. back pressure: 60 bar

Operating viscosity: 20… 1500 mm²/s

Mineral- or synthetic oil compliant with: plastics, NBR- elastomers, copper and copper alloys

Operating temperature: +10 +40 °C

Degree of protection acc. to DIN EN 60529: IP54

Summary of MFE-pumps for progressive systems for oil for CPT

MF1-BW7-C100+xxx

Summary of MFE-pumps for progressive systems for oil for FP

MF1-BW7-F100+xxx

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 43 of 82

3.6.1 Standard dimensions of reservoirs: 6 liter (all dimensions are in mm)

Reservoir Height Width Depth Center Hole

capacity [mm] [mm] [mm] distance Ø[mm]

[liter] [mm]

H H1 H2 * B B1 B2 T T1 * T2 * D1 D2 D

6 metal 216 236 430 320 360 380 142 210 250 300 140 9

Units for FP Units for CPT

Representative

only!!

See note below

Please notice: FP units include manual fill with strainer only. CPT units include a blank

plate where a quick disconnect must be installed. Quick fill disconnect MUST BE

ORDERED SEPARATELY. Please see section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 44 of 82

3.6.2 MF1-BW*-C100

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 45 of 82

3.6.3 MF1-BW*-F100

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 46 of 82

3.7 Compact Greaser ETPxWZ-xxxxx-x+924

See brochure 1-0988-EN

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 47 of 82

3.8 KFG1-5W2x-V71+924 piston pump for Progressive systems for fluid grease

Quick

fill/disconnect

is shown for

representative

purposes

only. Quick

disconnect

couplings

must be

ordered

separately.

Please see

section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 48 of 82

3.9 KFG1-5W1x-V71+924 piston pump for Progressive systems for grease

Quick

fill/disconnect

is shown for

representative

purposes

only. Quick

disconnect

couplings

must be

ordered

separately.

Please see

section 3.3.

P

L

Use hard grease NLGI-2 only !

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 49 of 82

3.10 KFB1-M-W+924

Quick

fill/disconnect

is shown for

representative

purposes

only. Quick

disconnect

couplings

must be

ordered

separately.

Please see

section 3.3.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 50 of 82

3.11 KFA1-M-WA-V71+924 pumps for Progressive systems for grease

Quick

fill/disconnect

is shown for

representative

purposes

only. Quick

disconnect

couplings

must be

ordered

separately.

Please see

section 3.3.

P

L

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 51 of 82

3.12 Piston Distributor 341 and Manifolds

Single Piston Distributor 341; Metering up to 0.16 ccm See brochure 1-5001-EN

Manifolds for Single Piston Distributor 341 See brochure 1-5001-EN

3.13 Piston Distributor 342,343,345 Series; Metering up to 0.16 ccm See brochure 1-5001-EN

3.14 Piston Distributor 351 and Manifolds

Single Piston Distributor 351; Metering up to 0.60 ccm See brochure 1-5001-EN

Manifolds for Single Piston Distributor 351 See brochure 1-5001-EN

3.15 Piston Distributor 352,353,355 Series; Metering up to 0.60 ccm See brochure 1-5001-EN

3.16 Piston Distributor 391 and Manifolds

Single Piston Distributor 391; Metering up to 1.5 ccm See brochure 1-5001-EN

Manifolds for Single Piston Distributor 391 See brochure 1-5001-EN

3.17 Piston Distributor 392, 393 Series; Metering up to 1.5 ccm See brochure 1-5001-EN

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 52 of 82

3.18 Oil + Air Mixing Valves, MV20x-100-xxxxxxxx

See brochure 1-5012-EN

3.19 Progressive Feeder VPG

See brochure 1-3016-EN

3.20 Progressive Feeder VPKG

See brochure 1-3015-EN

3.21 Progressive Feeder VPBG Sizes

See brochure 1-3017-EN

3.22 Modular Feeder PSG2

See brochure 1-3013-EN

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 53 of 82

3.23 Cycle Switch 177-300-094 for VP and PSG progressive feeders

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 54 of 82

3.24 Cycle Switch 177-300-095 for VPK progressive feeders

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 55 of 82

3.25 Cycle Switch 177-300-097 for VPB progressive feeders

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 56 of 82

3.26 Cycle Switch Connectors for Progressive Feeders

See brochure 1-0107-6-EN

3.27 Overpressure Indicators for Progressive Feeders

See brochure 1-0107-6-EN

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 57 of 82

3.28 Pressure Switches - 176-190-001

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 58 of 82

3.29 Pressure Switches - DS-EP-40-D-4

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 59 of 82

3.30 Flow Monitor GS300

See brochure 1-1704-EN

3.31 Oil + Air Streak Sensor GS4011-S…

See brochure 1-1704-EN

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 60 of 82

3.32 2/2 Way Directional Valve for Oil and Grease - 161-110-031+924

See brochure 1-1703-EN

3.33 3/2 Way Directional Valve for Oil and Grease - 161-120-064+924

See brochure 1-1703-EN

3.34 4/2 Way Directional Valve for Oil - 161-140-050+924

See brochure 1-1703-EN

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 61 of 82

3.35 Zero Leakage 2/2 Way Valve for Oil - VPG-VEN-V71A+924

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 62 of 82

3.36 Zero Leakage 2/2 Way Valve with Union Block - VPG-VEN-V71+924

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 63 of 82

3.37 Pressure filter NG63 acc. to DIN24550

Technical data

Pressure stage up to: 100 bar

Operating temperature: -10 - +100 °C

Flows: up to 63 l/min

Differential pressure switch

Switching pressure: 5bar -10%

Perm. operating pressure: 420 bar

Type of contact: 1 NO-contact (75%) / 1 NC-contact (100%)

Max. switching voltage: 24 V

Electrical connector: 4pin connector; M12x1 ICE 60947-5-2

Max. switching output at resistive load: max. 15 VA/W AC/DC

Type of enclosure: (DIN40050: IP 65

Type of indication: 1 electrical switching contact at 75% and

at 100% of the cracking pressure.

Description Order-No Filter rating:

Pressure filter 169-460-099-V57 3 µm

Pressure filter 169-460-087-V70 10 µm

Pressure filter 169-460-185 25 µm

Spare parts

Filter element 169-400-257 3 µm

Filter element 169-400-250 10 µm

Filter element 169-400-185-V57 25 µm

Repair set seals 995-901-056

Pressure switch 176-200-012

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 64 of 82

3.38 Check valves for progressive feeders

Part Number Thread d1 Tubing Opening Notes Image

size Pressure

(bar)

VPG-RV G1/8 tapered ø4 10 bar

VPG-RV6 G1/8 tapered ø6 10 bar

VPG-RV8 G1/8 tapered ø8 10 bar

VPKG-RV G1/8 tapered ø6 3 bar With sleeve fitting +

compression nut

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 65 of 82

3.39 Lubrilean Vario UFV10-014-2

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 66 of 82

3.40 Lubrilean VarioPlus UFV10-019-2

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 67 of 82

3.41 Lubrilean VarioSuper

See brochure 1-5102-EN

3.42 Lubrilean DigitalSuper

See brochure 1-5102-EN

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 68 of 82

3.43 Lubrilean Aerosol Monitor AM1000

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 69 of 82

3.44 VSR System for part lubrication with external controls

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 70 of 82

3.45 LGPTN spray nozzle assemblies for oir/air

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 71 of 82

ORDER FORM

PAGE 1 of 11

CPT ONLY COMPONENTS

Section Order Code Description Notes Order Code Qty. Delivery Plant

MFE5-KW3-C100+1FV Gear pump for oil, 3L plastic reservoir

2.1.1

MFE5-KW6-C100+1FV Gear pump for oil, 6L plastic reservoir

MFE5-BW3-C100+1FV Gear pump for oil, 3L metal reservoir

MFE5-BW7-C100+1FV Gear pump for oil, 6L metal reservoir

2.1.2 MFE5-BW16-C100+1FV Gear pump for oil, 15L metal reservoir

MFE5-BW30-C100+1FV Gear pump for oil, 30L metal reservoir Quick fill sold

separately.

MFE5-BW50-C100+1FV Gear pump for oil, 50L metal reservoir

See section

Pneumatic piston pump for oil, 7L 3.3.

P-886-BWW7-C100

metal reservoir

2.1.5

Pneumatic piston pump for oil, 16L

P-886-BWW16-C100

metal reservoir

Gear pump for fluid grease, 3L

MFE2-KW3F-C100+1FV

plastic reservoir

2.2.1

Gear pump for fluid grease, 6L plastic

MFE2-KW6F-C100+1FV

reservoir

Gear pump for fluid grease, 1.4L

2.2.3 KFB1-M-W+924

plastic reservoir

2.3.1 MFE5-KW3-C100+1FV Gear pump for oil, 3L plastic reservoir

For circulating oil systems, 6L metal

2.4.1 MF1-BW7-C100+1FV

reservoir Quick fill sold

Compact unit for grease, separately.

KFA1-M-WA-V71+924

Q= 2,0cm³/min See section

Compact unit for grease, 3.3.

2.5.3 KFA1-M-WB-V71+924

Q= 1,5cm³/min

Compact unit for grease,

KFA1-M-WC-V71+924

Q= 1,0cm³/min

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 72 of 82

ORDER FORM

PAGE 2 of 11

CPT ONLY COMPONENTS

Section Order Code Description Notes Order Code Qty. Delivery Plant

ETPxWZ-xxxxx-x+924 Compact greaser, 24VDC See page 46 for

2.5.4

FK008-x Grease cartridge for ETP order code key.

995-003-534 Quick disconnect 3/8” Couplers only

2.18.1 995-003-527 Quick disconnect 5/8”

995-003-528 Quick disconnect 3/4” See section 3.3

995-003-529 Quick disconnect 1/8”

995-002-096 Quick disconnect 1/4” Couplers only

995-003-530 Quick disconnect 3/8”

995-003-531 Quick disconnect 1/2” See section 3.3

995-003-532 Quick disconnect 3/4”

2.18.2

995-005-088 Complete quick disconnect 1/8” Complete quick

995-005-096 Complete quick disconnect 1/4” disconnect with

coupler strainer

995-005-097 Complete quick disconnect 3/8”

and housing.

995-003-533 Complete quick disconnect 1/2”

995-005-521 Complete quick disconnect 3/4” See section 3.3

995-001-228 Quick disconnect 3/8” Couplers only

995-003-517 Quick disconnect 1/2” See section 3.3

995-001-227 Complete quick disconnect 3/8” Complete quick

2.18.3 disconnect with

coupler strainer

and housing.

995-003-518 Complete quick disconnect 1/2” See section 3.3

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 73 of 82

ORDER FORM

PAGE 3 of 11

CPT ONLY COMPONENTS

Section Order Code Description Notes Order Code Qty. Delivery Plant

2.24.1 VSR-GD-XY VSR system for part lubrication

LGTPN-X-NY-XX-XXX

Spray nozzle assemblies for

2.24.2 LGTCN-X-NY-XX-XXX

Oil+Air

LGTFN-X-NY-XX-XXX

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 74 of 82

ORDER FORM

PAGE 4 of 11

FPT ONLY COMPONENTS

Section Material Code Description Notes Order Code Qty. Delivery Plant

Gear pump for oil, 3L plastic

MFE5-KW3-F100+140

reservoir

2.1.3

Gear pump for oil, 6L plastic

MFE5-KW6-F100+140

reservoir

Gear pump for oil, 3L metal

MFE5-BW3-F100+140

reservoir

Gear pump for oil, 6L metal

MFE5-BW7-F100+140

reservoir

Gear pump for oil, 15L metal

2.1.4 MFE5-BW16-F100+140

reservoir

Gear pump for oil, 30L metal

MFE5-BW30-F100+140

reservoir

Gear pump for oil, 50L metal

MFE5-BW50-F100+140

reservoir

Gear pump for fluid grease, 3L

MFE2-KW3F-F100+140

plastic reservoir

2.2.2

Gear pump for fluid grease, 6L

MFE2-KW6F-F100+140

plastic reservoir

Gear pump for oil, 3L plastic

2.3.2 MFE5-KW3-F100+140

reservoir

For circulating oil systems, 6L

2.4.2 MF1-BW7-F100+140

metal reservoir

CPT - FPT COMMON COMPONENTS

Section Material Code Description Notes Order Code Qty. Delivery plant

KFG1-5W1GA-V71+924 Pump for grease, Q= 2,5cm³/min

KFG1-5W1GB-V71+924 Pump for grease, Q= 1,8cm³/min Quick fill sold

2.5.1 separately. See

KFG1-5W1GC-V71+924 Pump for grease, Q= 1,3cm³/min section 3.3.

KFG1-5W1GD-V71+924 Pump for grease, Q= 0,8cm³/min

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 75 of 82

ORDER FORM

PAGE 5 of 11

CPT - FPT COMMON COMPONENTS

Section Material Code Description Notes Order Code Qty. Delivery plant

KFG1-5W2A-V71+924 Pump for fluid grease, Q= 2,5cm³/min

KFG1-5W2B-V71+924 Pump for fluid grease, Q= 1,8cm³/min Quick fill sold

2.5.2 separately. See

KFG1-5W2C-V71+924 Pump for fluid grease, Q= 1,3cm³/min section 3.3.

KFG1-5W2D-V71+924 Pump for fluid grease, Q= 0,8cm³/min

341-1xx-10000-00 Single piston distributor for oil, 0.01cm³

341-100-60000-00 Single piston distributor for oil, 0.02cm³

341-1xx-20000-00 Single piston distributor for oil, 0.03cm³ See page 52 for

2.6.1

341-1xx-30000-00 Single piston distributor for oil, 0.06cm³ order code key.

341-1xx-40000-00 Single piston distributor for oil, 0.10cm³

341-1xx-50000-00 Single piston distributor for oil, 0.16cm³

351-0xx-30000-00 Single piston distributor for oil, 0.05cm³

351-0xx-40000-00 Single piston distributor for oil, 0.10cm³

See page 52 for

2.6.1 351-0xx-50000-00 Single piston distributor for oil, 0.20cm³

order code key.

351-0xx-60000-00 Single piston distributor for oil, 0.40cm³

351-0xx-70000-00 Single piston distributor for oil, 0.60cm³

391-000-40000-00 Single piston distributor for oil, 0.10cm³

391-000-50000-00 Single piston distributor for oil, 0.20cm³ See page 52 for

2.6.1

order code key.

391-100-60000-00 Single piston distributor for oil, 0.30cm³

342-4xx-xx000-xx Standard piston distributor for oil, 2 port

See page 52 for

2.6.2 343-4xx-xxx00-xx Standard piston distributor for oil, 3 port

order code key.

345-4xx-xxxxx-xx Standard piston distributor for oil, 5 port

352-0xx-xx000-xx Standard piston distributor for oil, 2 port

See page 52 for

2.6.3 353-0xx-xxx00-xx Standard piston distributor for oil, 3 port

order code key.

355-0xx-xxxxx-xx Standard piston distributor for oil, 5 port

392-000-xx000-xx Standard piston distributor for oil, 2 port See page 52 for

2.6.4

393-000-xxx00-xx Standard piston distributor for oil, 3 ports order code key.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 76 of 82

ORDER FORM

PAGE 6 of 11

CPT - FPT COMMON COMPONENTS

Section Material Code Description Notes Order Code Qty. Delivery plant

See page 52 for

341-7xx-x0000-00 Single piston distributor fluid grease

order code key.

See page 52 for

2.7.1 351-1xx-x0000-00 Single piston distributor fluid grease

order code key.

See page 52 for

391-100-x0000-00 Single piston distributor fluid grease

order code key.

342-5xx-xx000-xx Standard piston distributor for fluid grease, 2 port

See page 52 for

2.7.2 343-5xx-xxx00-xx Standard piston distributor for fluid grease, 3 port

order code key.

345-5xx-xxxxx-xx Standard piston distributor for fluid grease, 5 port

352-1xx-xx000-xx Standard piston distributor for fluid grease, 2 port

See page 52 for

2.7.3 353-1xx-xxx00-xx Standard piston distributor for fluid grease, 3 port order code key.

355-1xx-xxxxx-xx Standard piston distributor for fluid grease, 5 port

392-100-xx000-xx Standard piston distributor for fluid grease, 2 port See page 52 for

2.7.4

393-100-xxx00-xx Standard piston distributor for fluid grease, 3 port order code key.

VL-02AAG1 Manifold for single pist.dist. 341; 2-port, G1/8

Manifolds for 341

VL-03AAG1 Manifold for single pist.dist. 341; 3-port, G1/8 series

VL-05AAG1 Manifold for single pist.dist. 341; 5-port, G1/8

VL-02AAG2 Manifold for single pist.dist. 341; 2-port, G1/4

VL-03AAG2 Manifold for single pist.dist. 341; 3-port, G1/4

VL-05AAG2 Manifold for single pist.dist. 341; 5-port, G1/4

2.8.1

VL-02-AAM1 Manifold for single pist.dist. 341; 2-port, M10x1

Manifolds for 341

VL-03-AAM1 Manifold for single pist.dist. 341; 3-port, M10x1 series

VL-05-AAM1 Manifold for single pist.dist. 341; 5-port, M10x1

VL-02-AAM2 Manifold for single pist.dist. 341; 2-port, M14x1.5

VL-03-AAM2 Manifold for single pist.dist. 341; 3-port, M14x1.5

VL-05-AAM2 Manifold for single pist.dist. 341; 5-port, M14x1.5

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 77 of 82

ORDER FORM

PAGE 7 of 11

CPT - FPT COMMON COMPONENTS

Material

Section Description Notes Order Code Qty. Delivery plant

Code

VL-02BAG1 Manifold for single pist.dist. 351; 2-port, G1/8

VL-03BAG1 Manifold for single pist.dist. 351; 3-port, G1/8

VL-05BAG1 Manifold for single pist.dist. 351; 5-port, G1/8

VL-02BAG2 Manifold for single pist.dist. 351; 2-port, G1/4

VL-03BAG2 Manifold for single pist.dist. 351; 3-port, G1/4

VL-05BAG2 Manifold for single pist.dist. 351; 5-port, G1/4 Manifolds

2.8.2 for 351

VL-02-BAM1 Manifold for single pist.dist. 351; 2-port, M10x1 series

VL-03-BAM1 Manifold for single pist.dist. 351; 3-port, M10x1

VL-05-BAM1 Manifold for single pist.dist. 351; 5-port, M10x1

VL-02-BAM2 Manifold for single pist.dist. 351; 2-port, M14x1.5

VL-03-BAM2 Manifold for single pist.dist. 351; 3-port, M14x1.5

VL-05-BAM2 Manifold for single pist.dist. 351; 5-port, M14x1.5

VL-02CAG1 Manifold for single pist.dist. 391; 2-port, G1/8

VL-03CAG1 Manifold for single pist.dist. 391; 3-port, G1/8

VL-05CAG1 Manifold for single pist.dist. 391; 5-port, G1/8

VL-02CAG2 Manifold for single pist.dist. 391; 2-port, G1/4

VL-03CAG2 Manifold for single pist.dist. 391; 3-port, G1/4

VL-05CAG2 Manifold for single pist.dist. 391; 5-port, G1/4 Manifolds

2.8.3 for 391

VL-02-CAM1 Manifold for single pist.dist. 391; 2-port, M10x1 series

VL-03-CAM1 Manifold for single pist.dist. 391; 3-port, M10x1

VL-05-CAM1 Manifold for single pist.dist. 391; 5-port, M10x1

VL-02-CAM2 Manifold for single pist.dist. 391; 2-port, M14x1.5

VL-03-CAM2 Manifold for single pist.dist. 391; 3-port, M14x1.5

VL-05-CAM2 Manifold for single pist.dist. 391; 5-port, M14x1.5

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 78 of 82

ORDER FORM

PAGE 8 of 11

CPT - FPT COMMON COMPONENTS

Section Material Code Description Notes Order Code Qty. Delivery plant

MV201-100-x0000000 Oil+Air mixing valve, 1 port

MV202-100-xx000000 Oil+Air mixing valve, 2 port

MV203-100-xx000000 Oil+Air mixing valve, 3 port

MV204-100-xx000000 Oil+Air mixing valve, 4 port See page 53

2.9.1 for order

MV205-100-xx000000 Oil+Air mixing valve, 5 port code key.

MV206-100-xx000000 Oil+Air mixing valve, 6 port

MV207-100-xx000000 Oil+Air mixing valve, 7 port

MV208-100-xx000000 Oil+Air mixing valve, 8 port

VPG/03xx/00A1-xxx Feeder, 3 sections (max. 6 outlets)

VPG/04xx/00A1-xxxx Feeder, 4 sections (max. 8 outlets)

VPG/05xx/00A1-xxxxx Feeder, 5 sections (max.10 outlets)

VPG/06xx/00A1-xxxxxx Feeder, 6 sections (max. 12 outlets) See page 53

2.10.1 for order

VPG/07xx/00A1-xxxxxxx Feeder, 7 sections (max. 14 outlets) code key.

VPG/08xx/00A1-xxxxxxxx Feeder, 8 sections (max. 16 outlets)

VPG/09xx/00A1-xxxxxxxxx Feeder, 9 sections (max. 18 outlets)

VPG/10xx/00A1-xxxxxxxxxx Feeder, 10 sections (max. 20 outlets)

VPKG/03xx/00A1-xxx Feeder, 3 sections (max. 6 outlets)

VPKG/04xx/00A1-xxxx Feeder, 4 sections (max. 8 outlets)

VPKG/05xx/00A1-xxxxx Feeder, 5 sections (max. 10 outlets)

VPKG/06xx/00A1-xxxxxx Feeder, 6 sections (max. 12 outlets) See page 53

2.10.2 for order

VPKG/07xx/00A1-xxxxxxx Feeder, 7 sections (max. 14 outlets) code key.

VPKG/08xx/00A1-xxxxxxxx Feeder, 8 sections (max. 16 outlets)

VPKG/09xx/00A1-xxxxxxxxx Feeder, 9 sections (max. 18 outlets)

VPKG/10xx/00A1-xxxxxxxxxx Feeder, 10 sections (max. 20 outlets)

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 79 of 82

ORDER FORM

PAGE 9 of 11

CPT - FPT COMMON COMPONENTS

Section Material Code Description Notes Order Code Qty. Delivery plant

VPBG/03xx/00A1-xxx Feeder, 3 sections (max. 6 outlets)

VPBG/04xx/00A1-xxxx Feeder, 4 sections (max. 8 outlets)

VPBG/05xx/00A1-xxxxx Feeder, 5 sections (max. 10 outlets)

See page 53

VPBG/06xx/00A1-xxxxxx Feeder, 6 sections (max. 12 outlets)

2.10.3 order code

VPBG/07xx/00A1-xxxxxxx Feeder, 7 sections (max. 14 outlets) key.

VPBG/08xx/00A1-xxxxxxxx Feeder, 8 sections (max. 16 outlets)

VPBG/09xx/00A1-xxxxxxxxx Feeder, 9 sections (max. 18 outlets)

VPBG/10xx/00A1-xxxxxxxxxx Feeder, 10 sections (max.20 outlets)

PSG2/03xx/00A1-xxx Feeder, 3 sections (max. 6 outlets)

PSG2/04xx/00A1-xxxx Feeder, 4 sections (max. 8 outlets)

PSG2/05xx/00A1-xxxxx Feeder, 5 sections (max. 10 outlets)

See page 53

PSG2/06xx/00A1-xxxxxx Feeder, 6 sections (max. 12 outlets)

2.10.4 for order

PSG2/07xx/00A1-xxxxxxx Feeder, 7 sections (max. 14 outlets) code key.

PSG2/08xx/00A1-xxxxxxxx Feeder, 8 sections (max. 16 outlets)

PSG2/09xx/00A1-xxxxxxxxx Feeder, 9 sections (max. 18 outlets)

PSG2/10xx/00A1-xxxxxxxxxx Feeder, 10 sections (max.20 outlets)

NOTE: VPG

Check valve for VPKG, VPBG; sectional

VPG-RV

10 bar, ø 4mm feeders

already have

internal

Check valve for VPKG, VPBG; check valves

2.11.1 VPG-RV6

10 bar, ø 6mm at every

outlet.

However,

Check valve for VPKG, VPBG; VPKG and

VPG-RV8

10 bar, ø 10mm VPBG do

not.

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 80 of 82

ORDER FORM

PAGE 10 of 11

CPT - FPT COMMON COMPONENTS

Section Material Code Description Notes Order Code Qty. Delivery plant

With sleeve fitting

2.11.2 VPKG-RV Check valve for VPKG, VPGB; 3 bar, ø 6mm

and compression nut

2.11.3 VPKG-RV-VS Check valve for VPKG, VPGB; 3 bar, ø 6mm Quick connection

2.12.1 177-300-094 Cycle switch for VPG / PSG2

2.12.2 177-300-095 Cycle switch for VPKG

2.12.3 177-300-097 Cycle switch for VPBG

179-990-600 Straight socket connector w/ 5 meters cable

2.12.4

179-660-601 Elbow socket connector w/ 5 meters cable

VPG-UE16-2 Over pressure indicator, 16 bar

VPG-UE32-2 Over pressure indicator, 32 bar

VPG-UE63-2 Over pressure indicator, 63 bar

VPG-UE80-2 Over pressure indicator, 80 bar

2.13.1 VPG-UE100-2 Over pressure indicator, 100 bar

VPG-UE50-3 Over pressure indicator, 50 bar

VPG-UE100-3 Over pressure indicator, 100 bar

VPG-UE150-3 Over pressure indicator, 150 bar

VPG-UE200-3 Over pressure indicator, 200 bar

2.14.1 DS-EP-40-D-4 electronic pressure switch, M12x1, 4-pins

2.14.2 176-190-001 electronic pressure switch,

2.15.1 GS300 Flow monitor for piston distr. system

GS4011-S20 Oil+air streak sensor, 120 - 600 mm³/hr

2.16.1

GS4011-S50 Oil+air streak sensor, 60 - 120 mm³/hr

169-460-099-V57 Pressure filter w/ dirt indicator, 3 µm - Oil

2.17.1 169-460-087-V70 Pressure filter w/ dirt indicator, 10 µm - Oil

169-460-185 Pressure filter w/ dirt indicator, 25 µm - Oil

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 81 of 82

ORDER FORM

PAGE 11 of 11

CPT - FPT COMMON COMPONENTS

Section Material Code Description Notes Order Code Qty. Delivery plant

2.17.2 213-900 Screen filter for grease, 25 µm

Pressure gauge, 0-40 bar /

169-104-015

0-580 PSI/ 0-4 MPa

Pressure gauge, 0-100 bar/

2.19.1 169-110-015

0-1450 PSI/ 0-10 MPa

Pressure gauge, 0-250 bar/

169-125-015

0-3625 PSI/ 0-25 MPa

2.20.1 161-110-031+924 2/2 way valve, oil and grease

2.20.2 VPG-VEN-V71-A+924 2/2 way Zero Leakage Valve, oil

With union

block for

2.20.3 VPG-VEN-V71+924 2/2 way Zero Leakage Valve, oil

remote

mounting

3/2 way valve, oil, oil and

2.20.4 161-120-064+924

grease

2.20.5 161-140-050+924 4/2 way valve, oil

2.21.1 UFV10-014-2 Lubrilean Vario

2.21.2 UFV10-019-2 Lubrilean VarioPlus

2.21.3 UFV30-003 Lubrilean VarioSuper

2.22.1 UFD10-020 Lubrilean DigitalSuper 1

2.22.2 UFD20-020 Lubrilean DigitalSuper 2

2.23.1 AM1000 Aerosolmonitor

File name: FPT_CPT_SKF_Project_Book_version_1.8.doc

Original date: 01-October-2010

Revised Date: 12-December-2013 Page No.: 82 of 82

You might also like

- Embedded DSP Processor Design: Application Specific Instruction Set ProcessorsFrom EverandEmbedded DSP Processor Design: Application Specific Instruction Set ProcessorsNo ratings yet

- PileDriverIIIPump Modesl2331etc A50 92Document8 pagesPileDriverIIIPump Modesl2331etc A50 92Juan Santiago RojasNo ratings yet

- 07 Circulating Systems-1Document19 pages07 Circulating Systems-1ScarduelliNo ratings yet

- Auto Grease Lubrication Systems ExplainedDocument21 pagesAuto Grease Lubrication Systems ExplainedFrezgi BirhanuNo ratings yet

- 951 130 407 enDocument26 pages951 130 407 enli geneNo ratings yet

- Vs VSR Inj Manual 3 2004Document17 pagesVs VSR Inj Manual 3 2004Mark DiNo ratings yet

- Lubrificação Martelo Indeco HP3000Document24 pagesLubrificação Martelo Indeco HP3000Tiago PachecoNo ratings yet

- Single Line Progressive SystemsDocument70 pagesSingle Line Progressive SystemsOverhaul QANo ratings yet

- Original Operating and Assembly Manual: PFP - UDocument16 pagesOriginal Operating and Assembly Manual: PFP - USugiharto RichardNo ratings yet

- 09 Pressure SwitchDocument6 pages09 Pressure SwitchSugiharto Richard100% (1)

- SKF P-289Document3 pagesSKF P-289seansotoNo ratings yet

- SKF Group: Tom Johnstone, President and CEODocument30 pagesSKF Group: Tom Johnstone, President and CEOJuan Diego JulyNo ratings yet

- Install Troubshoot ManDocument19 pagesInstall Troubshoot ManMohamed MabroukNo ratings yet

- Group 12 Lubrication System GuideDocument29 pagesGroup 12 Lubrication System GuideMarco CalderonNo ratings yet

- 09 EP-tronic ControllingDocument8 pages09 EP-tronic ControllingSugiharto RichardNo ratings yet

- 09 GIGA-multitronic ControllingDocument30 pages09 GIGA-multitronic ControllingSugiharto RichardNo ratings yet

- 3 LSA Lube Product Range 0614 RevisedDocument126 pages3 LSA Lube Product Range 0614 RevisedFathi Ben YahmedNo ratings yet

- 09 ISU3 ControllingDocument2 pages09 ISU3 ControllingSugiharto RichardNo ratings yet

- 1 LSA Our Company 0614 V1 RevisedDocument42 pages1 LSA Our Company 0614 V1 RevisedFathi Ben YahmedNo ratings yet

- Kiln Gear Ring Oil Automatic SprayDocument78 pagesKiln Gear Ring Oil Automatic SprayAdi IrpaiNo ratings yet

- Ecco Finishing-Airless Oprema Za Farbanje VP Bez Vazduha-EDocument18 pagesEcco Finishing-Airless Oprema Za Farbanje VP Bez Vazduha-EPithakaras CasparNo ratings yet

- Pump 609-28839-1 - Doc 41A68607C03 PDFDocument13 pagesPump 609-28839-1 - Doc 41A68607C03 PDFwhmidi7331No ratings yet

- Price Als & Afs Jomon UpdateDocument4 pagesPrice Als & Afs Jomon UpdateSugiharto RichardNo ratings yet

- DROPSADocument27 pagesDROPSAcguillermosmNo ratings yet

- High Chiept PCR & Maint - BWPDocument27 pagesHigh Chiept PCR & Maint - BWPMuhammadSyarifudinNo ratings yet

- Automatic and Manual GreasingDocument10 pagesAutomatic and Manual GreasingAhmed SalahNo ratings yet

- Spray Nozzle PlanoDocument10 pagesSpray Nozzle Planor7510mNo ratings yet

- Grease Pump LAGG 18AE SKFDocument3 pagesGrease Pump LAGG 18AE SKFLC ChongNo ratings yet

- Kohler Lincoln VentmeterDocument14 pagesKohler Lincoln VentmeterGilmer CaceresNo ratings yet

- LSA - Our Brands: Presented By: ToDocument42 pagesLSA - Our Brands: Presented By: ToFathi Ben YahmedNo ratings yet

- B - Equipment and Maintenance Manual: 8576.4001 - Lubrication Central Unit - Roughing Mill AreaDocument11 pagesB - Equipment and Maintenance Manual: 8576.4001 - Lubrication Central Unit - Roughing Mill AreasundyaNo ratings yet

- Safe Grease 2Document22 pagesSafe Grease 2ivancho310No ratings yet

- Plan and record for hydraulic circuit designDocument5 pagesPlan and record for hydraulic circuit designCarri Tezaa100% (2)

- 32600EFSI 10-3 Lubrication PumpsDocument18 pages32600EFSI 10-3 Lubrication PumpsEnrique CastilloNo ratings yet

- Centralised Lubrication System For A Manitou MT 732 CompleteDocument35 pagesCentralised Lubrication System For A Manitou MT 732 CompleteChester Dalitso MwanzaNo ratings yet

- Beka EP1 Manual BooksDocument46 pagesBeka EP1 Manual BooksSyahrulNo ratings yet

- SKF Pinion SolutionsDocument31 pagesSKF Pinion SolutionsLLNo ratings yet

- Groeneveld General Manual Twin-3Document64 pagesGroeneveld General Manual Twin-3JasonNo ratings yet

- Pump 84962 B Section c8 Page 240b HydrauDocument8 pagesPump 84962 B Section c8 Page 240b Hydrauleaw81No ratings yet

- 08 Spray Nozzles Chain Lubrication PDFDocument2 pages08 Spray Nozzles Chain Lubrication PDFSugiharto RichardNo ratings yet

- Alemite Oil Mist ManualDocument34 pagesAlemite Oil Mist ManualWong DaNo ratings yet

- 951-130-184 - US - KFGS Manaul - New SKF PDFDocument48 pages951-130-184 - US - KFGS Manaul - New SKF PDFZT350No ratings yet

- 08 PU-lubrication Pinion For Gearings PDFDocument4 pages08 PU-lubrication Pinion For Gearings PDFSugiharto RichardNo ratings yet

- Brochure Valvula Alivio 83948Document4 pagesBrochure Valvula Alivio 83948Robert Karlo RodriguezNo ratings yet

- DIN-51502-Designation of LubricantsDocument7 pagesDIN-51502-Designation of LubricantsOscar Marino Campo BonellNo ratings yet

- 11 Lubrication SystemDocument19 pages11 Lubrication SystemMohammad Jahangir AlamNo ratings yet

- Precision Ball Bearings GuideDocument24 pagesPrecision Ball Bearings GuideConrad Hendrik De KockNo ratings yet

- O&m RnaaDocument20 pagesO&m RnaaГеннадий ПарфентьевNo ratings yet

- Jt60at60 Enh Hydraulic (Id0598687 - 01 - SVC)Document67 pagesJt60at60 Enh Hydraulic (Id0598687 - 01 - SVC)Sebastián Fernando Canul MendezNo ratings yet

- Flender Gear Units: Double-Screw-Extruder Gear UnitDocument110 pagesFlender Gear Units: Double-Screw-Extruder Gear UnitAmirmasoudNo ratings yet

- Hose Reel Pump Assembly: Assembly, Disassembly and Repair GuideDocument18 pagesHose Reel Pump Assembly: Assembly, Disassembly and Repair GuideВиталий КозловскийNo ratings yet

- O&M Shuaibah Final Rev02 PDFDocument810 pagesO&M Shuaibah Final Rev02 PDFgustavo aguilarNo ratings yet

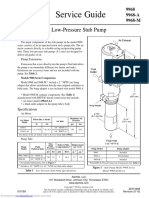

- Service Guide: Low-Pressure Stub PumpDocument10 pagesService Guide: Low-Pressure Stub PumpGer DclNo ratings yet

- LSG007 - Automated System DesignDocument6 pagesLSG007 - Automated System DesignwilmerNo ratings yet

- SKF Crusher SolutionsDocument32 pagesSKF Crusher SolutionsLLNo ratings yet

- Spec-Sheet TranServe2+MachineDocument2 pagesSpec-Sheet TranServe2+MachineEduardo Yagüe GomezNo ratings yet

- Visco SinDocument2 pagesVisco SinSyeda Fatima ali100% (1)

- Construction Lube Apps 18 Jan 16Document46 pagesConstruction Lube Apps 18 Jan 16José Cesário NetoNo ratings yet

- 96494-00-TO Theory RevU PDFDocument111 pages96494-00-TO Theory RevU PDFPrasad NagavaraNo ratings yet

- MIM WinGD X52 20200728Document187 pagesMIM WinGD X52 20200728oboy emmaNo ratings yet

- Caterpillar Product Speci CationsDocument4 pagesCaterpillar Product Speci CationsJorge Enrique Pulido AyalaNo ratings yet

- Service Champ Sales DeckDocument15 pagesService Champ Sales DeckJorge Enrique Pulido AyalaNo ratings yet

- New Account Set Up ProcessDocument9 pagesNew Account Set Up ProcessJorge Enrique Pulido AyalaNo ratings yet

- HXL Startup FlyerDocument2 pagesHXL Startup FlyerJorge Enrique Pulido AyalaNo ratings yet

- Deposit Shield DefinitionDocument3 pagesDeposit Shield DefinitionJorge Enrique Pulido AyalaNo ratings yet