Professional Documents

Culture Documents

8in Ultra XL - DuraMax

Uploaded by

Nuring Tyas WicaksonoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8in Ultra XL - DuraMax

Uploaded by

Nuring Tyas WicaksonoCopyright:

Available Formats

Technical Data S ummary

8" Ultra XL and Ultra XL-HP Motors

Equipped with DuraMax™ High Performance Elastomer

The Baker Hughes Ultra™ Series line of Additionally, the torque production of the Ultra

drilling motors is designed for drilling XL-HP motor is further enhanced with the

applications demanding high performance with introduction of Baker Hughes’ newly

unsurpassed reliability. The Navi-Drill™ Ultra developed DuraMax high performance

motor design delivers longer drilling runs, elastomer. The DuraMax high performance

greater horsepower and torque, improved elastomer delivers 50% more torque and

penetration rates, increased temperature power downhole for today's demanding, high

capabilities, and increased reliability. endurance Hughes Christensen PDC bits,

together with the durability and reliability you

The proven Navi-Drill Ultra series drive train is have come to expect from the leader in

built for long, hard service under the most downhole motors. With the DuraMax high

demanding conditions. The drive train has performance elastomer, standard Ultra motors

been proven through millions of hours of are transformed into premium high power

drilling. Ultra motors represent the 'Gold drilling tools.

Standard' in today's demanding drilling

environments. The combination of increased power together

with industry recognized reliability and

The Ultra XL power section utilizes this motor performance make the Ultra XL-HP motor the

technology in extended lengths to provide perfect tool for your next demanding drilling

unparalleled power for all drilling applications project.

requiring low bit speeds

Features Benefits

Premium high performance elastomer delivers

Internally developed power section 50% more torque and power downhole for

technology: today’s demanding, high endurance PDC bits.

8" Ultra XL and XL-HP Motor

DuraMax elastomer and Ultra-HP motors Provides the durability and reliability above the

level of the standard elastomer offering

Extended Length of the power section Higher torque output leads to greater ROP

Adjustable deflection angle on the motor for

AKO (Adjustable Kick-Off Sub)

achieving required DLS as per directional plan

Medium Bit Speed Optimized PDC bit performance and life

The new high temperature elastomer allows

High Temperature Elastomer

for up to 160C temperature rating

Improved Reliability compared to the universal

Titanium flex shaft

joint

High make-up torque reduces the possibility of

downhole back-off during tough and dynamic

Optimized Connections

drilling applications for increased motor

reliability and drilling performance

©2012-2012 Baker Hughes Incorporated. All rights reserved.

UTR-70-01-010 Rev. C

Technical Data S ummary

8" Ultra XL and Ultra XL-HP Motors

Equipped with DuraMax™ High Performance Elastomer

General Tool Specifications US Units SI Units Performance Charts

Length 34.8 ft 10,65 m 250 15000

Weight Range 4,080 – 4,480 lbs 1850 – 2030 kg 900 GPM

Bit Size Range 9-7/8" – 17-1/2" 251 – 445 mm

200 12000

6-5/8" API Reg. Box

Top Connection (Optional) 730 GPM

(6-5/8" H90 Box)

Bit Connection (Optional) 6-5/8" API Reg. Box

Torque [ft-lbs]

150 560 GPM 9000

Max. slick OD at Wear Pad 8.5 inch 216,50 mm

Speed [rpm]

Max. slick OD at Wear Ring 8.7 inch 220,50 mm

395 GPM

Deflection Angle of AKO 0º – 2.5º 100 6000

BUR and surface RPM limits Refer to BUR Chart Books

50 3000

Power Section US Units SI Units Standard DuraMax

Torque Operational Limit Operational Limit

Lobe Configuration 5/6 0 0

Flow Rate 395 – 900 gpm 1500 – 3400 lpm 0 200 400 600 800 1000 1200 1400 1600

Differential Pressure [psi]

Speed 85 – 195 RPM

250 20000

Speed to Flow Ratio 0.22 rev/gal 0,06 rev/l

Rotor Nozzle Yes 3400 LPM

Maximum Flow w/ Nozzle 990 gpm 3750 lpm 200 16000

No Load Pressure Drop 305 psi 21 bar 2770 LPM

Temperature

w/Standard or DuraMax elastomer 265°F 130°C

Speed [1/Min]

Torque [Nm]

150 2140 LPM 12000

w/High Temperature elastomer 320°F 160°C

1500 LPM

100 8000

Performance US Units SI Units

Standard or High Temperature elastomer 50 4000

Operational Limits Standard DuraMax

Differential Pressure 870 psi 60 bar Torque Operational Limit Operational Limit

Torque 7,700 ft-lbs 10 500 Nm 0 0

0 10 20 30 40 50 60 70 80 90 100 110

Power Output 285 hp 215 kW Differential Pressure [bar]

Maximum Operational * Motor Performance specifications and related charts are derived from dynamometer

Differential Pressure 1,400 psi 96 bar testing performed with water at 68°F (20°C) as the working fluid. Motor power sections

Torque 12,500 ft-lbs 16 500 Nm were assembled for maximum performance and longevity in the testing environment on

DuraMax elastomer surface and are presented for comparative analysis and operational calculations. Motor

Operational Limits performance specifications subject to change without notice. Actual downhole

Differential Pressure 1,300 psi 90 bar operational performance may vary due to temperature, fluid type and rotor/stator fit

Torque 11,500 ft-lbs 15 500 Nm adjustments. If the motors, that have been assembled to compensate for downhole

Power Output 430 hp 320 kW temperature effects, are surface tested, they may show reduced performance on

Maximum Operational surface and at low temperatures.

Differential Pressure 1,750 psi 120 bar

Torque 15,500 ft-lbs 21 000 Nm

Bearing Section US Units SI Units

Bearing Type Mud Lubricated

Operational Limits

WOB (Standard Bearings) 45,000 lbs 200 kN

Maximum Operational

WOB (Standard Bearings) 67,400 lbs 300 kN

Backreaming Weight 41,000 lbs 180 kN

Drilling & Evaluation Although the information contained herein is believed to be accurate, no other representations are made concerning the information. Under no circumstances shall Baker Hughes be liable for any incorrect or incomplete

2001 Rankin Road information. All technical specifications and commercial information concerning the product and/or services described herein may be changed at any time without further notice. Refer to Supplemental Technical Specifications

Houston, Texas 77073 (TDS-20-60-0000-00) for further environmental specific specifications and information on the application, operation, and handling of Baker Hughes tools. Technical Data Summaries are controlled documents and can only be

Phone: +1 713-625-4200 released through the Documentation & Records Management System(s) Group.

www.bakerhughes.com UTR-70-01-010

You might also like

- LS Gen IV Engines 2005 - Present: How to Build Max PerformanceFrom EverandLS Gen IV Engines 2005 - Present: How to Build Max PerformanceRating: 5 out of 5 stars5/5 (2)

- 6.75in Ultra XL - DuraMaxDocument2 pages6.75in Ultra XL - DuraMaxNuring Tyas Wicaksono0% (1)

- Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-1000001784-015 PDFDocument3 pagesPage: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-1000001784-015 PDFeaglego00No ratings yet

- 9 5in Modular Motor - MMTR 70 01 003Document2 pages9 5in Modular Motor - MMTR 70 01 003Qiang ZhangNo ratings yet

- Motores Abiertos Cerrados 1Document2 pagesMotores Abiertos Cerrados 1Kevin ChoqueNo ratings yet

- C4.4 IOPU Spec SheetDocument3 pagesC4.4 IOPU Spec SheetFire Suppression SystemNo ratings yet

- Specifications: SS-7148210-18279848-000 SS Page 1 of 7Document7 pagesSpecifications: SS-7148210-18279848-000 SS Page 1 of 7Razi A. RahimNo ratings yet

- Hydraulic Drive Head Motor: The Sensible ChoiceDocument2 pagesHydraulic Drive Head Motor: The Sensible Choicechaky212No ratings yet

- Page: M-1 of M-4 © 2018 Caterpillar All Rights Reserved MSS-IND-18377729-018 PDFDocument4 pagesPage: M-1 of M-4 © 2018 Caterpillar All Rights Reserved MSS-IND-18377729-018 PDFeaglego00No ratings yet

- Specifications: SS-9054182-18396700-000 SS Page 1 of 6Document6 pagesSpecifications: SS-9054182-18396700-000 SS Page 1 of 6المهندسوليدالطويلNo ratings yet

- 980L Block HandlerDocument2 pages980L Block Handlercorsini999No ratings yet

- Specifications:: 1. Traveling Block (YG-150)Document6 pagesSpecifications:: 1. Traveling Block (YG-150)Dewantoro HarisNo ratings yet

- Cat C 4.4-Ind-18377729-011Document4 pagesCat C 4.4-Ind-18377729-011Ramadan SiagianNo ratings yet

- Bou CatddDocument2 pagesBou CatddDJNo ratings yet

- MSS Ind 18375269 009Document3 pagesMSS Ind 18375269 009Abaidi RabieNo ratings yet

- SS-7097286-18396700-035 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18396700-022 PDFDocument5 pagesSS-7097286-18396700-035 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18396700-022 PDFابرار عمرNo ratings yet

- SS-11279002-18375269-002 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18375269-014 PDFDocument5 pagesSS-11279002-18375269-002 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18375269-014 PDFANDRES CASASNo ratings yet

- SS-9408177-18375269-020 SS Page 1 of 5: Page: M-1 of M-3 © 2016 Caterpillar All Rights Reserved MSS-IND-18375269-007 PDFDocument5 pagesSS-9408177-18375269-020 SS Page 1 of 5: Page: M-1 of M-3 © 2016 Caterpillar All Rights Reserved MSS-IND-18375269-007 PDFAlfredoNo ratings yet

- 404D 22TA Industrial PN1821Document2 pages404D 22TA Industrial PN1821Sea Man MktNo ratings yet

- 500 650 HCI 1205 Top Drive PDFDocument2 pages500 650 HCI 1205 Top Drive PDFLuisAngelPerezNo ratings yet

- 500 650 HCI 1205 Top Drive PDFDocument2 pages500 650 HCI 1205 Top Drive PDFSebastian LegardaNo ratings yet

- SCHOTTEL TugsDocument16 pagesSCHOTTEL TugsBalaji GaneshNo ratings yet

- PC800-8/LC-8: Hydraulic ExcavatorDocument24 pagesPC800-8/LC-8: Hydraulic ExcavatorAnwar ShafaruddienNo ratings yet

- Electric Mining Shovel Product OverviewDocument5 pagesElectric Mining Shovel Product OverviewCasa ChvzNo ratings yet

- Schottel TugsDocument14 pagesSchottel TugsSea Man MktNo ratings yet

- 403D-11 Engine (PN1814 75th)Document2 pages403D-11 Engine (PN1814 75th)luis navarreteNo ratings yet

- 6991 1820 01 - Diamec Smart 8 Technical Specification - EnglishDocument8 pages6991 1820 01 - Diamec Smart 8 Technical Specification - EnglishPABLONo ratings yet

- Baker Hughes Drilling ServicesDocument176 pagesBaker Hughes Drilling Servicestxcrude100% (1)

- SM 14Document8 pagesSM 14fjhernandez_76No ratings yet

- SMH14 03 2000008Document8 pagesSMH14 03 2000008Bullet DassNo ratings yet

- Workshop Rebuild John DeereDocument2 pagesWorkshop Rebuild John DeereKevin TtitoNo ratings yet

- R30CDocument4 pagesR30CEnrique MurgiaNo ratings yet

- YASA P400 Product Sheet PDFDocument2 pagesYASA P400 Product Sheet PDFFaris Fauzi FarisNo ratings yet

- Caterpillar 299CDocument12 pagesCaterpillar 299CForomaquinas100% (2)

- Link Belt RTC 8060Document2 pagesLink Belt RTC 8060Ivan Aaron Martinez BeiFongNo ratings yet

- PTD 500Document2 pagesPTD 500Samuel HernándezNo ratings yet

- Sauer Danfoss Orbital Motors PDFDocument5 pagesSauer Danfoss Orbital Motors PDFSoledad Navarro LazoNo ratings yet

- Drs PM MotorsDocument33 pagesDrs PM MotorsIsraelHernandezNo ratings yet

- Limitadores de TorqueDocument10 pagesLimitadores de TorqueMARCONo ratings yet

- Timberjack SkidderDocument22 pagesTimberjack SkidderOliver Queen100% (2)

- BRANDT HMA RG Series Agitators Spec Sheet EnglishDocument1 pageBRANDT HMA RG Series Agitators Spec Sheet EnglishChristopher MeyersNo ratings yet

- Powertech 4045T Diesel Engine: Generator Drive Engine SpecificationsDocument2 pagesPowertech 4045T Diesel Engine: Generator Drive Engine SpecificationsClaudia M. Cárdenas Pineda100% (1)

- Lehh0599 00Document6 pagesLehh0599 00Alfonso RivasNo ratings yet

- Inpak-Catalogue-the GGHFFDocument12 pagesInpak-Catalogue-the GGHFFALAZAR MICHAELNo ratings yet

- Top Drive22157614Document11 pagesTop Drive22157614consultor rbpssNo ratings yet

- Motor 6068HF475 250 HP 2200 RPMDocument2 pagesMotor 6068HF475 250 HP 2200 RPMKaguayo CraftsNo ratings yet

- @perkins: 400 Series 403C-11Document2 pages@perkins: 400 Series 403C-11OGNo ratings yet

- DD-140 Spec Sheet PDFDocument2 pagesDD-140 Spec Sheet PDFislanmateusfrNo ratings yet

- Brochure Industria MaderapapeleraDocument20 pagesBrochure Industria Maderapapeleragersan21No ratings yet

- Benefits and Advantages:: X870D/Lx870D Series Feller BunchersDocument4 pagesBenefits and Advantages:: X870D/Lx870D Series Feller Buncherstystar_21No ratings yet

- MSS Epg 1000028912 085Document10 pagesMSS Epg 1000028912 085Manuel HernandezNo ratings yet

- 6135HFM85 C AuxDocument2 pages6135HFM85 C AuxAdrian NazareNo ratings yet

- 82 - 352 - 6068TF275 - 170 Spec PDFDocument2 pages82 - 352 - 6068TF275 - 170 Spec PDFnay hlaing SoeNo ratings yet

- Electro-Mechanical Actuators: Made inDocument6 pagesElectro-Mechanical Actuators: Made inSandro BeckerNo ratings yet

- Funk TransmissionsDocument4 pagesFunk TransmissionsNoe Melgarejo PonceNo ratings yet

- Funk 28000 Triple Pump DriveDocument1 pageFunk 28000 Triple Pump Driverakhikishore143No ratings yet

- Cat 980M 982M Wheel Loader BrochureDocument36 pagesCat 980M 982M Wheel Loader BrochureAMNo ratings yet

- Especificaciones TecnicasDocument2 pagesEspecificaciones TecnicasLuis Alirio Casas OsorioNo ratings yet

- SS-8416177-18396700-002 SS Page 1 of 5: Page: M-1 of M-3 © 2017 Caterpillar All Rights Reserved MSS-IND-18396700-009 PDFDocument5 pagesSS-8416177-18396700-002 SS Page 1 of 5: Page: M-1 of M-3 © 2017 Caterpillar All Rights Reserved MSS-IND-18396700-009 PDFMuhammad Ary safartaNo ratings yet

- 6.75in SAGR 1000 MD LogDocument5 pages6.75in SAGR 1000 MD LogNuring Tyas WicaksonoNo ratings yet

- The Best of Both Worlds-A Hybrid Rotary Steerable System: Oklahoma City, Oklahoma, USADocument9 pagesThe Best of Both Worlds-A Hybrid Rotary Steerable System: Oklahoma City, Oklahoma, USAStefany Jimenez MendozaNo ratings yet

- 9.5in Ultra XL - DuraMaxDocument2 pages9.5in Ultra XL - DuraMaxNuring Tyas WicaksonoNo ratings yet

- Bit CalculationsDocument1 pageBit CalculationsleopumpkingNo ratings yet

- BAP LogDocument4 pagesBAP LogNuring Tyas WicaksonoNo ratings yet

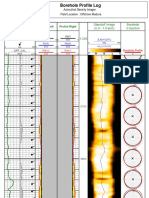

- Borehole Profile LogDocument6 pagesBorehole Profile LogNuring Tyas WicaksonoNo ratings yet

- 6.75in Triple Combo-SAGR LogDocument5 pages6.75in Triple Combo-SAGR LogNuring Tyas WicaksonoNo ratings yet

- 8 1/4" Copilot: Technical Data SheetDocument2 pages8 1/4" Copilot: Technical Data SheetNuring Tyas WicaksonoNo ratings yet

- Logs PresentationDocument25 pagesLogs PresentationJohann Mateo Farrachol Lanza100% (1)

- The Best of Both Worlds-A Hybrid Rotary Steerable System: Oklahoma City, Oklahoma, USADocument9 pagesThe Best of Both Worlds-A Hybrid Rotary Steerable System: Oklahoma City, Oklahoma, USAStefany Jimenez MendozaNo ratings yet

- Fmev Chap12 SoniclogDocument21 pagesFmev Chap12 SoniclognaeemdehrajNo ratings yet

- US Emulsification 2002Document19 pagesUS Emulsification 2002Nuring Tyas WicaksonoNo ratings yet

- Aade 11 Ntce 64Document6 pagesAade 11 Ntce 64AndresoPaezNo ratings yet

- Aade 11 Ntce 64Document6 pagesAade 11 Ntce 64AndresoPaezNo ratings yet

- E Totco US PDFDocument2 pagesE Totco US PDFNuring Tyas WicaksonoNo ratings yet

- Anti CollisionDocument9 pagesAnti CollisionNuring Tyas WicaksonoNo ratings yet

- PVD Training Course Portfolio 2014Document16 pagesPVD Training Course Portfolio 2014Nuring Tyas Wicaksono0% (1)

- Basic Well Log Analysis - Introduction - Oct2013Document35 pagesBasic Well Log Analysis - Introduction - Oct2013Jorge PirelaNo ratings yet

- SperryDrill Specification SheetDocument49 pagesSperryDrill Specification SheetNuring Tyas WicaksonoNo ratings yet

- Stick and SlipDocument12 pagesStick and SlipNuring Tyas WicaksonoNo ratings yet

- Definde CemenvtDocument2 pagesDefinde Cemenvtvindictive666No ratings yet

- Coursedetalies - PHP Sid 3024Document3 pagesCoursedetalies - PHP Sid 3024Nuring Tyas WicaksonoNo ratings yet

- J EOR PPTDocument40 pagesJ EOR PPTabkinz0% (1)

- Fully IntegratedDocument10 pagesFully IntegratedNuring Tyas WicaksonoNo ratings yet

- Planning PDFDocument12 pagesPlanning PDFSalvador LimachiNo ratings yet

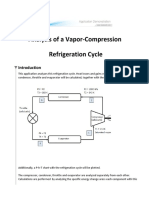

- Analysis of A Refrigeration Cycle With Coolprop PDFDocument6 pagesAnalysis of A Refrigeration Cycle With Coolprop PDFDario MendezNo ratings yet

- The Techno City Project Trivandrum, Kerala, India Latest Technologies Report For MEP ServicesDocument28 pagesThe Techno City Project Trivandrum, Kerala, India Latest Technologies Report For MEP ServicesSyraj HamzaNo ratings yet

- Donaldon General Brochure WideDocument20 pagesDonaldon General Brochure WidecivodulNo ratings yet

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Nguyễn Thành Trung100% (1)

- BE State of The Transition 2023Document131 pagesBE State of The Transition 2023Chetan GaonkarNo ratings yet

- Master List of Investigatory ProjectsDocument23 pagesMaster List of Investigatory ProjectsNiel Christian Chu61% (18)

- LADWP Power Rate Proposal Cost Reduction ReportDocument143 pagesLADWP Power Rate Proposal Cost Reduction ReportBill RosendahlNo ratings yet

- Unico LRPDocument71 pagesUnico LRPSha'ban Hussaini100% (1)

- Technical: Iso/Tr 17766Document11 pagesTechnical: Iso/Tr 17766pandunugraha04100% (1)

- E by M of ElectronDocument7 pagesE by M of ElectronMAsimNo ratings yet

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDocument2 pagesAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaNo ratings yet

- Viadrus U22 Upute Za Ugradnju I KorištenjeDocument28 pagesViadrus U22 Upute Za Ugradnju I KorištenjevladoNo ratings yet

- Final LiteratureDocument17 pagesFinal Literatureak9922No ratings yet

- 2019 Book AchievingTheParisClimateAgreem PDFDocument535 pages2019 Book AchievingTheParisClimateAgreem PDFDennys VirhuezNo ratings yet

- Chapter 15 - HydrocarbonsDocument16 pagesChapter 15 - HydrocarbonsNabindra RuwaliNo ratings yet

- De-Soldering Gun: Instruction ManualDocument6 pagesDe-Soldering Gun: Instruction ManualLjubisa DjordjevicNo ratings yet

- Brochure - Thermalia (R) Dual (55-140) Dual H (35-90) - ExA - 111016Document28 pagesBrochure - Thermalia (R) Dual (55-140) Dual H (35-90) - ExA - 111016Nur Rachman HardiantoNo ratings yet

- 2019 - Roadmap OverviewDocument5 pages2019 - Roadmap OverviewClean Air BDNo ratings yet

- Ventilation System On Board ShipDocument21 pagesVentilation System On Board Shipanis sayadNo ratings yet

- Dynamics of Structure - Lectures PDFDocument25 pagesDynamics of Structure - Lectures PDFAnonymous lrwiLCOUfNo ratings yet

- Atlite Exit - Emergency CatalogDocument65 pagesAtlite Exit - Emergency CatalogGarima GuptaNo ratings yet

- Chapter 18 Class 10th PDFDocument9 pagesChapter 18 Class 10th PDFMuneer KaleriNo ratings yet

- Isitia 2018Document10 pagesIsitia 2018Marson Ady PutraNo ratings yet

- Part 9 - Fire FightingDocument10 pagesPart 9 - Fire FightingJohnSmithNo ratings yet

- SHPP GL CHextras - FullDocument708 pagesSHPP GL CHextras - FullLuis Faustino Rodriguez LopezNo ratings yet

- Qatar Engineering & Construction Company WLL (Qcon)Document12 pagesQatar Engineering & Construction Company WLL (Qcon)Dan DumbravescuNo ratings yet

- Wind Turbines - Protective Measures - Requirements For Design, Operation and MaintenanceDocument28 pagesWind Turbines - Protective Measures - Requirements For Design, Operation and Maintenancexcv100% (4)

- 4th Periodic Test Grade 9 ScienceDocument4 pages4th Periodic Test Grade 9 ScienceMark Ryan J Bacus75% (4)

- Contract0r AgreementDocument13 pagesContract0r AgreementramadhanNo ratings yet