Professional Documents

Culture Documents

Anti-Fluttering Device

Uploaded by

Bilel MahjoubOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anti-Fluttering Device

Uploaded by

Bilel MahjoubCopyright:

Available Formats

KSB-Amri ANTI-FLUTTERING device

Pump discharge valve and valve installation.

Discharge pump, mitered elbow generates a perturbed fluid flow with large-scale fluid eddies

which could induce an uncontrolled valve trim movement.

The length of full re-establishment of a regular flow is roughly 8 times the diameter of the pipe

(AS per given by ASME Fluid journal and engineering good practice).

Reducing of this length conducts to accept a disorganized flow upstream the valve.

Greater the reducing of the length is, more the disturbance level of flow will be.

Due to economic consideration, the distance of 8 DN between hydraulic components is often

unavailable and more particularly in pumping station.

More and more, distance between pump discharge flange and butterfly valve is decreasing.

More and more quality of flow at discharge side of helico-centrifugal pump is decreasing pump

discharge bend is sharper, stabilizers of flow in discharge bend are suppressed.

In order to take into account these two opposite technical points, KSB-AMRI advises a

minimum distance between discharge pump and a butterfly valve to 3 DN because

Average level of fluctuation of flow has been half reduced,

This length is generally acceptable and available on main industrial site.

But, engineering practice recognizes that flow perturbation intensity at pump discharge can not

be predictable (calculated) at design stage.

KSB has experienced situations in which :

Valves located to 3 DN equivalent length of straight pipe from pump discharge were not

subject to valve trim movement called disc fluttering for butterfly valve,

On other seldom cases, valves installed in the same configurations (working conditions

and pipe installation) were subject to disc fluttering.

If such unpredictable phenomena occur at site, KSB-AMRI has developed an anti-fluttering

device.

Anti-fluttering device Page 1 of 3

amri

ANTIFLUTTERING SERIE 280

amri

ANTIFLUTTERING SERIE 280

You might also like

- FRP Catalogue 04.2021Document84 pagesFRP Catalogue 04.2021Bilel MahjoubNo ratings yet

- Piping System RevDocument32 pagesPiping System Revapi-25999517100% (9)

- Process Design Manual LurgiDocument25 pagesProcess Design Manual LurgiMarcelo Peretti91% (11)

- D&L Equipment PO 200619 GMAX20 Cyclone IOM Manual - KrebsDocument30 pagesD&L Equipment PO 200619 GMAX20 Cyclone IOM Manual - KrebsPitt Pacheco F100% (3)

- Dupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsDocument12 pagesDupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsFernando Tapia GibsonNo ratings yet

- Submersible Pumps GuidelinesDocument5 pagesSubmersible Pumps GuidelinesJanneth Herrera FloresNo ratings yet

- New Developments in Hydraulic Ram PumpingDocument6 pagesNew Developments in Hydraulic Ram PumpingAirPop24No ratings yet

- Pump FAQ's by Hydraulic Institute (UK)Document61 pagesPump FAQ's by Hydraulic Institute (UK)Sajjad Ahmed100% (2)

- Hydraulic Data For Pump ApplicationDocument28 pagesHydraulic Data For Pump ApplicationedwinramonNo ratings yet

- Calculation of Trunnions Rev3Document3 pagesCalculation of Trunnions Rev3Bilel MahjoubNo ratings yet

- Understanding Pump Curves #5 - Minimum Flow - Part One - Pump Industry MagazineDocument6 pagesUnderstanding Pump Curves #5 - Minimum Flow - Part One - Pump Industry MagazineAntonio SanchezNo ratings yet

- Flygt Design Recommendations For Centrifugal PumpsDocument10 pagesFlygt Design Recommendations For Centrifugal PumpsOzren DjuricNo ratings yet

- Vacuum Condenser Drainage - Proper Design & Installation GuideDocument3 pagesVacuum Condenser Drainage - Proper Design & Installation Guidenirmal_subudhiNo ratings yet

- Practical Fabrication Tips For Steam PipingDocument7 pagesPractical Fabrication Tips For Steam Pipingmahendra493100% (1)

- Tips For Layout1Document3 pagesTips For Layout1amitrai86No ratings yet

- Rectangular Tank DesignDocument35 pagesRectangular Tank Designfaizal91% (11)

- Saeid Three Phase Separator and API 521 Flare KOD DesignDocument16 pagesSaeid Three Phase Separator and API 521 Flare KOD DesignNila Gama100% (1)

- Pump Clinic 43Document3 pagesPump Clinic 43fnahas_bhNo ratings yet

- Steel-Tables 2 PDFDocument110 pagesSteel-Tables 2 PDFMahmoud AllamNo ratings yet

- Evaluation For VesselDocument10 pagesEvaluation For VesselEngineering ESIINo ratings yet

- Technical Specification For GRP Pipes and Piping ComponentDocument43 pagesTechnical Specification For GRP Pipes and Piping ComponentngoctuanNo ratings yet

- NSS & NPSHRDocument3 pagesNSS & NPSHRmariasofiarossiNo ratings yet

- Open Drain Separator SizingDocument23 pagesOpen Drain Separator SizingSuchart TarasapNo ratings yet

- d4 Intake DesignDocument5 pagesd4 Intake DesignchoibeNo ratings yet

- Slug Catcher SizingDocument11 pagesSlug Catcher Sizingsohail06100% (2)

- Sump DesignDocument12 pagesSump DesignMrigendra Nath RayNo ratings yet

- Pump Clinic 33Document8 pagesPump Clinic 33fnahas_bhNo ratings yet

- Control Valve Technical Specification For Severe Service - CCIDocument5 pagesControl Valve Technical Specification For Severe Service - CCIVikas SinghNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Self Priming Pumps IssuesDocument5 pagesSelf Priming Pumps IssuesratheeshNo ratings yet

- Design Recom. Large (891219) 04-2003 PDFDocument10 pagesDesign Recom. Large (891219) 04-2003 PDFedubarbierNo ratings yet

- Check Valve Required Straight LengthsDocument7 pagesCheck Valve Required Straight LengthsDemir Alp IlıkobaNo ratings yet

- CBV BrochureDocument8 pagesCBV BrochureHenry SuarezNo ratings yet

- Pump Minimum Flow Protection Using Automatic Recirculation ValvesDocument6 pagesPump Minimum Flow Protection Using Automatic Recirculation ValvesJose Rodrigo Salguero DuranNo ratings yet

- Offshore Orifice-Plate Impulse Line ArrangementDocument5 pagesOffshore Orifice-Plate Impulse Line ArrangementTimothy LeonardNo ratings yet

- Pump Basic RulesDocument4 pagesPump Basic RulesVictor NairNo ratings yet

- Design Recommendations: For Pump Stations With Large Centrifugal Wastewater PumpsDocument12 pagesDesign Recommendations: For Pump Stations With Large Centrifugal Wastewater PumpsTuấn Anh NguyễnNo ratings yet

- Axial Flow PumpsDocument3 pagesAxial Flow PumpsahadNo ratings yet

- Pitfalls of Pump Piping DesignDocument5 pagesPitfalls of Pump Piping DesignViệt Đặng XuânNo ratings yet

- Air Transfer TechnologyDocument14 pagesAir Transfer TechnologyRui ApolinárioNo ratings yet

- Chapter 3 - PlumbingDocument8 pagesChapter 3 - PlumbingPrabhakaran DakshinNo ratings yet

- Equipment Piping ArrangementDocument7 pagesEquipment Piping ArrangementrahulNo ratings yet

- Importance of Low Point DrainDocument10 pagesImportance of Low Point Drainpesuk100% (1)

- Failure of Circulating Water Pumps Discharge Header Cross Connect Valve - Optimum SolutionsDocument3 pagesFailure of Circulating Water Pumps Discharge Header Cross Connect Valve - Optimum SolutionsFernando100% (1)

- Selection GuideDocument12 pagesSelection GuideMiguel Angel VasquezNo ratings yet

- Effects of CavitationDocument5 pagesEffects of Cavitationamna farooqNo ratings yet

- Considerations For Designing Piping Adjacent To A Centrifugal PumpDocument3 pagesConsiderations For Designing Piping Adjacent To A Centrifugal PumpbeqsNo ratings yet

- CRV ApplicationsDocument13 pagesCRV ApplicationsMuhammad AdnanNo ratings yet

- Pitfalls of Pump Piping Design - AMARINEDocument6 pagesPitfalls of Pump Piping Design - AMARINEamadan64No ratings yet

- Mep Exam ReviewDocument16 pagesMep Exam ReviewArturo Del-RioNo ratings yet

- SO-2010-43 CVFSS Nozzle Testing & ConversionDocument2 pagesSO-2010-43 CVFSS Nozzle Testing & ConversionmjsebasNo ratings yet

- Steam Mains and DrainageDocument12 pagesSteam Mains and DrainageGeovannyNo ratings yet

- ASME Code CalculationDocument12 pagesASME Code Calculationmasoud_968370957No ratings yet

- BFW PumpsDocument3 pagesBFW PumpsMohammad Ali ZamanNo ratings yet

- Chapter Three Liquid Piping SystemDocument51 pagesChapter Three Liquid Piping SystemMelaku TamiratNo ratings yet

- Air Distribution Systems GuideDocument3 pagesAir Distribution Systems GuidejchuatsonNo ratings yet

- Delayed Float ValvesDocument6 pagesDelayed Float ValvesferasbushnaqNo ratings yet

- Wedge Gate Valves Resilient Vs Metal SeatedDocument9 pagesWedge Gate Valves Resilient Vs Metal Seatedamsyong loeNo ratings yet

- Documents Tibs TIB 7 How To Use Head CurvesDocument4 pagesDocuments Tibs TIB 7 How To Use Head CurvesNitin DhakateNo ratings yet

- ICH3800 Class 7: 1st Semester 2022Document92 pagesICH3800 Class 7: 1st Semester 2022catalinaNo ratings yet

- Pages - Steam Mains and DrainageDocument10 pagesPages - Steam Mains and DrainageSPK 27No ratings yet

- Steam Mains and DrainageDocument11 pagesSteam Mains and DrainageHoàng LÊNo ratings yet

- Review: Turbine and Related Flowmeters: !. Industrial PracticeDocument15 pagesReview: Turbine and Related Flowmeters: !. Industrial PracticemohmehrNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Process Equipment Catalog: Pumping Solutions For Process IndustriesDocument76 pagesProcess Equipment Catalog: Pumping Solutions For Process IndustriesBilel MahjoubNo ratings yet

- Conair Equipment CatalogDocument516 pagesConair Equipment CatalogBilel MahjoubNo ratings yet

- Note de Calcul Ancrage Rev3Document3 pagesNote de Calcul Ancrage Rev3Bilel MahjoubNo ratings yet

- Alpha Technology Brochure 2020 1Document51 pagesAlpha Technology Brochure 2020 1Bilel MahjoubNo ratings yet

- 3D Installation 3D Quench Plan Guide: Sens InverseDocument1 page3D Installation 3D Quench Plan Guide: Sens InverseBilel MahjoubNo ratings yet

- Sections 150x50x3 MM SL2Document2 pagesSections 150x50x3 MM SL2Bilel MahjoubNo ratings yet

- Appendix: Agitator Nozzle Analysis Wrc107 MethodDocument12 pagesAppendix: Agitator Nozzle Analysis Wrc107 MethodBilel MahjoubNo ratings yet

- Test ReportDocument18 pagesTest ReportBilel MahjoubNo ratings yet

- Ticket LabDocument8 pagesTicket LabBilel MahjoubNo ratings yet

- Tank Handling and Installation Instructions: Equipment InspectionDocument7 pagesTank Handling and Installation Instructions: Equipment InspectionBilel Mahjoub100% (1)

- Project: OT 3121-21 HOLDS Register: Hold Document Number Hold Description LAB ResponseDocument1 pageProject: OT 3121-21 HOLDS Register: Hold Document Number Hold Description LAB ResponseBilel MahjoubNo ratings yet

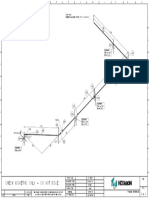

- LIGNEAIR3BBB2HDocument1 pageLIGNEAIR3BBB2HBilel MahjoubNo ratings yet

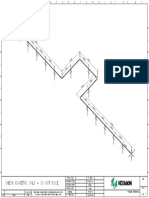

- LIGNEAIR3BBB2KDocument1 pageLIGNEAIR3BBB2KBilel MahjoubNo ratings yet

- Amercoat 450 S Tehnički List Proizvoda PDFDocument4 pagesAmercoat 450 S Tehnički List Proizvoda PDFBilel MahjoubNo ratings yet

- Batiment-De-Rejet Pompe1bDocument1 pageBatiment-De-Rejet Pompe1bBilel MahjoubNo ratings yet

- Pipes LoopsDocument1 pagePipes LoopsTsouki TsoukiNo ratings yet

- Fiberstrong Piping System Above Ground Installation Manual 1Document36 pagesFiberstrong Piping System Above Ground Installation Manual 1m 418No ratings yet

- AR15-17 Liste Des Isométrique Lot PRVDocument12 pagesAR15-17 Liste Des Isométrique Lot PRVBilel MahjoubNo ratings yet

- Qdoc - Tips Stress Analysis of GRP GRE FRP Piping System UsingDocument5 pagesQdoc - Tips Stress Analysis of GRP GRE FRP Piping System UsingBilel MahjoubNo ratings yet

- Catalog Profile PDFDocument57 pagesCatalog Profile PDFTănase FlorianNo ratings yet

- Engineering & Piping DesignDocument36 pagesEngineering & Piping DesignkumarkumaeNo ratings yet

- Technical Data Sheet Simona PP-H AlphaplusDocument1 pageTechnical Data Sheet Simona PP-H AlphaplusBilel MahjoubNo ratings yet

- 4729sbm01do05326b - Afg - Hot Water SystemDocument7 pages4729sbm01do05326b - Afg - Hot Water SystemBilel MahjoubNo ratings yet

- Attachment-3 - Subor Introduction PresentationDocument39 pagesAttachment-3 - Subor Introduction PresentationBilel MahjoubNo ratings yet