Professional Documents

Culture Documents

Analysis of A Combined Braytonrankine Cycle With T

Uploaded by

Arturo MarcanoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of A Combined Braytonrankine Cycle With T

Uploaded by

Arturo MarcanoCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/328944558

ANALYSIS OF A COMBINED BRAYTON/RANKINE CYCLE WITH TWO

REGENERATORS IN PARALLEL

Article · October 2018

DOI: 10.5380/reterm.v16i2.62205

CITATIONS READS

0 375

5 authors, including:

Tadeu M. Fagundes Elizaldo dos Santos

Florida State University Universidade Federal do Rio Grande (FURG)

9 PUBLICATIONS 49 CITATIONS 300 PUBLICATIONS 1,389 CITATIONS

SEE PROFILE SEE PROFILE

Liercio Isoldi Luiz A. O. Rocha

Universidade Federal do Rio Grande (FURG) Universidade do Vale do Rio dos Sinos

284 PUBLICATIONS 1,208 CITATIONS 360 PUBLICATIONS 3,036 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Earth-Air Heat Exchangers (EAHE) View project

Modelagem Computacional e Otimização Geométrica de dispositivos conversores de energia das ondas do mar em energia elétrica View project

All content following this page was uploaded by Tadeu M. Fagundes on 15 January 2019.

The user has requested enhancement of the downloaded file.

Tecnologia/Technology

ANALYSIS OF A COMBINED BRAYTON/RANKINE CYCLE

WITH TWO REGENERATORS IN PARALLEL

J. T. dos Santosa, ABSTRACT

T. M. Fagundesa, This work presents a configuration of two regenerators in parallel for a

E. D. dos Santosb, power generation Brayton/Rankine cycle where the output power is 10

MW. The working fluids considered for the Brayton and Rankine cycles are

L. A. Isoldib, air and water, respectively. The addition of a regenerator with the previous

existing cycle of this kind resulted in the addition of a second-stage turbine

and L. A. O. Rochac in the Rankine cycle of reheat. The objective of this modification is to

increase the thermal efficiency of the combined cycle. In order to examine

a

Universidade Federal do Rio Grande do Sul, the efficiency of the new configuration, it is performed a thermodynamic

modelling and numerical simulations for both cases: a regular

Escola de Engenharia

Brayton/Rankine cycle and the one with the proposed changes. At the end

Porto Alegre, RS, Brasil of the simulations, the two cycles are compared, and it is seen that the new

b

Universidade Federal de Rio Grande, configuration reaches a 0.9% higher efficiency. In addition, the vapor

quality at the exit of the higher turbine is higher, reducing the required mass

Escola de Engenharia

flow rate in 14%.

Rio Grande, RS, Brasil

c

Universidade do Vale do Rio dos Sinos,

Programa de Pós-Graduação em Engenharia

Mecânica, São Leopoldo, RS, Brasil

luizor@unisinos.br

Received: May 25, 2017

Revised: June 19, 2017 Keywords: Brayton/Rankine cycle, thermal efficiency, parallel

Accepted: July 20, 2017 configuration, regenerators

NOMENCLATURE In the current Brazilian energetic matrix,

power-generating cycles, which transform the heat

ṁ mass flow rate, kg/s resultant of fossil fuels into electric energy, play a

T temperature, K relevant part, because, even though the society

p pressure, kPa claims for cleaner energy production methods, these

x vapor quality cycles present a strategic alternative supply for the

k polytrophic coefficient drought season. In addition, this method provides a

W work, kJ low initial cost and relatively low implementation

Q heat, kJ costs.

h specific enthalpy, kJ/kg Within this context, seeking for alternative to

improve the efficiency of these cycles is extremely

Greek symbols important, not only in an economic point of view,

reducing the fuel consumption, but also in an

Η efficiency ambient-friendly part, reducing the emission of

pollutants to the atmosphere.

Subscripts Considering this necessity of a more efficient

use of the energetic resources available, this study

c cycle aims to model and numerically simulate a combined

t thermal Brayton/Rankine power generation cycle with an

s ideal alternative configuration of the heat regenerators,

w water adding a regenerator in parallel and a second-stage

a air turbine in the combine cycle.

b pump The study of combined Brayton/Rankine cycle

n-m process n-m with the use of regenerators has been a point of focus

X state X for some researchers. Bejan et al. (2012) showed that

the path to improve the efficiency of regenerator,

INTRODUCTION aiming the maximum heat transfer and minimum

head loss, was to turn the current parallel channel

10 Engenharia Térmica (Thermal Engineering), Vol. 16 • No. 2 • December 2017 • p. 10-17

Tecnologia/Technology Santos, et al. Analysis of a Combined Brayton/Rankine…

structure into more complex structures in the form of Brayton combined with two reverse Brayton cycles

dendritic channels, with the tree shaped configuration in parallel, with the regeneration occurring before the

being a tendency of evolution for those systems. reverse cycles. Through the analysis of the First Law

Can Gülen e Raub W. Smith (2009) described a of Thermodynamics, it was found that the cycle

simple, but very precise method, to estimate how could reach a higher thermal efficiency when

much power can be extracted from a lower Rankine compared to that of a common cycle, but with a

cycle given an exergy output by a gas turbine (higher lower specific work. The optimal efficiency found

Brayton cycle). The method is based in the Second for this system was of 51.2%.

Law of Thermodynamics and, according to the Gomez et al. (2014) presented a power

authors, considering the technical and economic generation plant in which a closed Brayton cycled

restrictions, the model can deliver the maximum was combined in parallel with a vapor Rankine cycle,

power that can be extracted by the lower cycle to any exploiting the cold exergy available due to the

gas turbine by just considering the output exergy. regasification process of liquid natural gas. The cold

Habib and Zubair (1992) examined the exergy was used to bring the helium used in the

performance of regenerative/reheat Rankine power Brayton cycle to cryogenic temperatures in the

generating plants through an exergetic analysis. His compressor entrance and to generate electrical power

results indicate that most losses occurred in the boiler through direct expansion. Energetic and exergetic

and that these losses could be minimized by heating analysis showed that it is possible to obtain high

the feeding water, reducing the irreversibility of the power efficiency in the power plant, given the right

cycle in 18%. conditions.

Akiba et al. (1993) created three types of Considering this necessity of a more efficient

computer software to calculate the thermodynamic usage of the available energetic resources, this study

properties of working fluids and evaluate the proposed an alternative configuration of heat

performance of the combined Brayton/Rankine cycle. regenerators in a combined Brayton/Rankine cycle,

Several parameters were varied in order to analyze where a regenerator in parallel is added to the system

their effects over the performance of the combine along with a second stage turbine.

cycle in power plants. According to the authors, the In order to analyze the performance of this new

numerical results were very compatible to the data of configuration, a thermodynamic modelling and

active power plants. numerical simulations were performed for two cases:

Khaliq and Kaushik (2004) applied the Second a regular Brayton/Rankine cycle and another one

Law of Thermodynamics in a combined with the proposed modifications. At the end of the

Brayton/Rankine cycle with reheat of the gas turbine. simulations, the results obtained for both cycles are

It was investigated the effects of pressure, compared.

temperature, number of reheats and pressure loss. It

was noticed that the combustion chamber accounted COMBINED BRAYTON/RANKINE CYCLE

for more than 50% of the total exergy loss. In WITH REGENERATORS IN PARALLEL

addition, the efficiency of the cycle and the

maximum output power were found in a medium In this work, a new configuration for the

pressure and were improved significantly when two Brayton/Rankine cycle was proposed. The objective

reheat stages were present. However, for more than was to increase the efficiency by inserting an extra

two reheat stages, the efficiency and output power regenerator and a second stage turbine, using the

did not raise significantly. concept of reheat for the Rankine cycle.

Franco and Casarosa (2004) evaluated the It was proposed that this extra regenerator

feasibility of high efficiency combined cycles. The would be in parallel with the previous existing, as

results showed that it is possible to obtain power illustrated in Fig. 1. In this case, the hot air output

plants with efficiency higher than 62%. In order to do from the gas turbine (in red in Fig. 1) would be

that, it would be necessary to make appropriate use divided in two streams at the same temperature: the

of the existing technologies, without the need of first passing through regenerator 1 and being used to

waiting for new technological development of heat the vapor input for the first stage turbine. This

turbines. flow was called ṁ4a. The second flow was used to

Alabdoadaim et al. (2004) investigated the reheat the vapor output from the first stage turbine

performance of a big cycle composed of a Brayton, through regenerator 2. This flow was called ṁ4b.

two reverse parallel Brayton and a Rankine cycle. In order to equate the cycle mathematically, the

The expansion pressure relation between the two following hypothesis were considered: Steady-state

reverse Brayton cycles was varied, considering system; Air modelled as an ideal gas with polytrophic

values above the atmospheric pressure. Results coefficient k = 1.4; no head and heat losses; no

showed that the best thermal efficiencies occurred for changes in kinetic and potential energies; Pumps,

higher expansion pressures, reaching values of compressors, turbines and regenerators are adiabatic.

approximately 54%. In the formulation of the mathematical model of

Zhang et al. (2012) proposed a regenerative the different components of the cycle, it was used the

Engenharia Térmica (Thermal Engineering), Vol. 16 • No. 2 • December 2017 • p. 10-17 11

Tecnologia/Technology Santos, et al. Analysis of a Combined Brayton/Rankine…

approach similar to Moran and Shapiro (2002). In addition, ηc is the isentropic efficiency of the process.

this approach, the volumes of control are defined as It is important to mention at this time that specific

well as the energy and mass balance for each process power, enthalpy and heat per unit mass are given in

of the cycle, which are: kJ/kg, for all the times these properties are

Process 1-2: Isentropic compression through the mentioned.

compressor. For process 2-3, the heat per unit mass

Process 2-3: Heat input by the delivered to the air

heating/combustor heat transfer.

Process 3-4: Isentropic expansion through the Q 2 3

turbine. h3 h2 (3)

Process 4-5: Heat rejection through the cooling m a

heat exchanger.

Process 6-7: Heat input through regenerator 1. where h3 is the specific enthalpy of the standard air

Process 7-10: Isentropic expansion through the leaving the combustor.

first stage turbine. For the gas turbine, process 3-4, the power per

Process 10-11: Heat input through regenerator unit mass generated in the turbine, given, h4s and h4

2. the enthalpies of air in the exit of the turbine, for

Process 11-8: Isentropic expansion through the ideal and real cases, respectively, given in and ηta the

second stage turbine. isentropic efficiency of the turbine.

Process 8-9: Heat rejection through the

condenser. W ta

Process 9-6: Isentropic compression through the h3 h4 (4)

pump. m a

h3 h4

a (5)

h3 h4 s

In the cooling heat exchanger, represented by

the process 4-5, the heat per unit mass that is

removed from the fluid, in kJ/kg, is given by

Q sai

h4 h5 (6)

m a

where h5 is the specific enthalpy that leaves the

combustor, in kJ/kg.

The volumes of control of the regenerators of

Figure 1. Illustration of the proposed the combined cycle were established, with process 4-

Brayton/Rankine cycle with regenerators in 5 in the air part and processes 6-7 and 10-11 for the

parallel. water part. By applying mass and energy balances,

the air mass flow rates that pass through regenerators

The work generated in the compressor in the 1 and 2, respectively, are obtained as

process 1-2 is presented as

m w h h5

Wc 4 (7)

h2 h1 (1) m 4 a h7 h6

ma

m w h h5

and a correction to a real case, where irreversibility is 4 (8)

m 4b h11 h10

considered, can be obtained as

h2 s h1 a m

m 4a m

4b (9)

c (2)

h2 h1 where ṁw is the mass flow rate of water, h5 is the

specific enthalpy that leaves the combustor, h7 and

where Ẇc/ṁa the power per unit mass consumed by h11 are the specific enthalpies of saturated vapor that

the compressor h1 and h2 the enthalpies of air at the leave each of the regenerators.

inlet and outlet of the compressor and h2s the specific For the process 6-9, Eq. (7) the power per unit

enthalpy at the compressor outlet to the ideal case. In mass consumed by the pump, in kJ/kg for an ideal

12 Engenharia Térmica (Thermal Engineering), Vol. 16 • No. 2 • December 2017 • p. 10-17

Tecnologia/Technology Santos, et al. Analysis of a Combined Brayton/Rankine…

case is given as For the condenser (process 8-9), the heat per

unit mass absorbed by the condenser can be derived

W b as

h6 h9 (10)

m w

Q 8 9

h8 h9 (18)

and the correction to a real case is m w

h6 s h9 where h9 is the specific enthalpy of the vapor at the

b (11)

h6 h9 exit of the condenser.

Through the power balance in the three cycles,

Here, h9 is the specific enthalpy of the saturated Brayton, Rankine and Combined cycle, the work

liquid in the inlet of the pump and h6s and h6 are the from the Brayton cycle (Wa), the Rankine cycle (Ww)

specific enthalpies of the compressed liquid that and the total work (Wt) can be obtained, respectively,

leaves the pump, in kJ/kg, for the ideal and real by

cases, respectively.

For the regenerators, processes 6-7 and 10-11, W a W ta W c (19)

the heat per unit mass delivered to the fluid is,

respectively, as W w W wa W wb W b (20)

Q 6 7

h7 h6 (12) W t W w W a (21)

m w

The ideal thermal efficiency, tcc , is defined as

Q 10 11

h11 h10 (13) the total liquid work produced by a determined

m w power cycle divided by the external heat that is

delivered to it. Applying this definition to the

where h7 and h11 are the specific enthalpies of combined cycle, the objective function, is obtained:

saturated vapor that leaves each of the regenerators.

For equating purposes, it is considered that the vapor W t

generator is inside the control volume of the tcc (22)

regenerator. Q23

In the first stage vapor turbine, disregarding the

losses, it is possible to obtain the power per unit mass METHODOLOGY

generated by the turbine as

The methodology used in this work was a

W wa thermodynamic modelling coupled with numerical

h7 h10 (14) simulation and comparing the results obtained for

m w two systems: a benchmark case, where a regular

combined Brayton/Rankine cycle and a second case

The real enthalpy of the outlet flow can be obtained based in the cycle illustrated in Figure 1.

if the isentropic efficiency of the turbine is known, The equations for both cases are practically the

through same, apart from the benchmark case only having

one regenerator and turbine. Thus, Eqs. (10), (13),

h7 h10 (14), (16), (17) and (18) are suppressed.

twa (15)

h7 h10s In order to have a strict comparison between

both cases, the input data for both have to be the

Here, Ẇ h10 and h10s are the specific enthalpies of the same, given that a change in the thermodynamic

vapor at the outlet of the turbine, for real and ideal properties or the efficiencies of the cycles would lead

cases, respectively. The same can be considered for to disparities in the comparison, thus nullifying the

the second stage turbine, results.

The algebraic system of non-linear equations

W wb were solved using the software Interactive

h8 h11 (16) Thermodynamics (IT) and the thermodynamic

m w properties of the fluids involved in the process,

standard air and water, were obtained with the

h8 h11 software’s database.

twb (17) In the present work, all equations were solved

h8 h11 with residual error below 10-13, thus it is possible to

Engenharia Térmica (Thermal Engineering), Vol. 16 • No. 2 • December 2017 • p. 10-17 13

Tecnologia/Technology Santos, et al. Analysis of a Combined Brayton/Rankine…

affirm that the numerical error did not influence the vapor) were also analyzed. However, since the

results obtained. efficiency of the system did not increase considerably

Opposite to the numerical results, the and the vapor quality of the fluid at the exit of the

hypothesis used in the modelling for this work might second stage decrease abruptly, with values below

have more influence over eventual deviation of the 90%, these results were suppressed from this text.

results obtained here. However, this is not going to

be analyzed in this work. ANALYSIS AND RESULTS

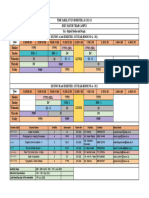

The thermodynamic properties, as well as the

efficiency of the cycle components are shown in Using the previously described methodology

Table 1. As previously mentioned, the same values and model, all interest parameters were obtained for

were considered for both systems in such a way that the studied cycles. These parameters are: efficiency,

the only points with a degree of freedom in the cycle mass flow rates, turbines powers, outlet vapor turbine

with two regenerators were in points 10 and 11, the vapor qualities and external heat delivered to the

exact points where the cycles are different. system.

The results obtained for the relevant parameters

Table 1. Thermodynamic properties, efficiencies and to the benchmark case are shown in Tab. 2.

total power for the benchmark case (regular cycle).

Parameter Value Table 2. Relevant parameters obtained for the

T1 300 benchmark case.

p1 100 Parameter Value

T3 1,400 ṁa 239.8

p3 1,200 ṁw 30.44

p4 100 ηtcc 0.4939

T5 480 Q23 202,500

p5 100

T7 673 Ẇa 6.89E+04

p7 8,000 Ẇw 3.11E+04

p8 8 x8 0.8034

p9 8

Ẇt 100,000 The results obtained for the cycle with

ɳc 0.84 regenerators in parallel can be seen through the

ɳta 0.88 graphs of Figs. 2-6.

ɳtw 0.9

ɳb 0.8

However, the post-reheat temperature, T11, was

considered to be the same 673 K, the same

temperature as T7 (the temperature of the fluid

leaving the regenerator for the benchmark case). This

was necessary in order to consider that the tcc

regenerator from both cases would have the same

capacity.

After these considerations, the only

thermodynamic property from the system that

remained free to analyze its influence in the proposed

system was the pressure from point 10, the

intermediate pressure between the two stages of the

turbine. It is important to reiterate that the pressure

from points 10 and 11 are considered the same. Figure 2. Effect of the pressure of point 10 over the

By modeling the cycle with regenerators in ideal thermal efficiency of the cycle with two

parallel, the pressure in point 10 was changed from regenerators in parallel.

400 to 1500 kPa, with intervals of 100 kPa. With this,

the responses of the cycle for this range of pressure Looking at Fig. 2, it is seen that as the pressure

were obtained. These values were compared to the of point 10 increases, there is an increase of thermal

one obtained in the benchmark case. In addition, it is efficiency in the combined cycle, starting with

important to restate that this pressure range was 49.46% for a 400 kPa pressure and reaching 49.84%

chosen because the vapor quality of the fluid at the for 1500 kPa. In addition, by comparing the results

first stage turbine of the low cycle always remained from Fig. 2 to the benchmark case, it is seen that the

in the saturation region. proposed cycle reaches higher efficiencies, with a

Pressure values above 1500 kPa (superheated thermal efficiency increasing up to 0.45%. Looking

14 Engenharia Térmica (Thermal Engineering), Vol. 16 • No. 2 • December 2017 • p. 10-17

Tecnologia/Technology Santos, et al. Analysis of a Combined Brayton/Rankine…

in other perspective, this means that if the benchmark Furthermore, for a power plant active for more than

case is turned into a cycle with regenerators in 20 years, a great amount of fuel could be saved, thus

parallel, its efficiency would increase by roughly 1%. the importance of this result has a big impact

The results shown in Figure 3 reveals that, for economically.

the proposed cycle, a lower mass flow rate of air was

obtained, especially for pressure values around 1500

kPa for point 10.

Figure 4. Change in the external heat given to the

cycle in function of the pressure on point 10 for the

Figure 3. Variation of the mass flow rates of the studied cycle.

working fluids regarding the pressure of point 10, for

the proposed cycle. By looking at Figure 5, it is seen that the

resulting vapor qualities for the proposed cycle were

By looking at Figure 3, it is possible to notice more adequate than the benchmark case. This

that, as pressure p10 increases, the mass flow rate of improvement was expected, since it was added an

air that goes through regenerator 1 also increased, extra regenerator, and consequently a new reheat

while reducing the mass flow rate that goes through process to the system.

regenerator 2. This result is comprehensible, since as

the intermediate pressure between the two stages

turbine (p10) increases, less energy is needed in the

second regenerator in order to change the working

fluid up to the properties considered in point 11.

It is possible to notice that the exceeding energy

that did not pass through the second regenerator is

utilized mainly in the first regenerator, where a mass

flow rate of compressed liquid (increasing with the X

increase of p10) has to be transformed into

superheated vapor.

Still regarding the results in Figure 3, it is seen

that the mass flow rate of vapor increases steadily

with the increase of p10. However, when compared to

the benchmark case, even for the highest value of p10

studied, this mass flow rate was reduced significantly

for the new cycle, being, at the worst case, 14.3%

lower than the mass flow rate for the benchmark Figure 5. Results for the vapor quality at the exit of

case. This reduction brings a benefit of having more the turbines for different values of pressure on

compact installations. point 10.

By analyzing the results Figure 3, combined

with Fig 4, it is seen that the reduction of the total There is an increase in the vapor quality, going

mass flow rate was consequence of the reduction of from 80.34% of the benchmark case, for a minimum

the external heat given to the cycle, as expected. This of 91.51% for the proposed cycle. This would mean a

result is shown in Figure 4. lower wear of the vapor turbines, since they are

If it is considered that the rate of mixture for projected to work mainly with vapor, being damaged

combustion (ar and fuel) are the same for both cases, by liquid fluids.

this decrease of 0.9% found for the total air flow and Finally, the net amount of work produced for

for the heat delivered to the cycle would account for the turbines of the system were analyzed. Results are

an equal reduction for the fuel consumption. shown in Figure 6.

Engenharia Térmica (Thermal Engineering), Vol. 16 • No. 2 • December 2017 • p. 10-17 15

Tecnologia/Technology Santos, et al. Analysis of a Combined Brayton/Rankine…

By analyzing Figure 6, it was noticed that the reducing the wear of the vapor turbines, because the

power generated by the gas turbine was reduced. But, vapor quality at the exit of the turbines was higher. In

since the system efficiency increased, these results this case, the turbines could work in a system with

was already expected, because all the heat coming less liquid.

into the system from external sources do so through As the main disadvantages of applying the

the higher cycle. In addition, since the cycle proposed in this work in a power generation

thermodynamic properties of the air were fixed, a plant are: the introduction of a second stage turbine,

smaller amount of air and, thus, a lower power is coupled with automation systems that would control

generated by it. the air flows and a possible increase in the air and

vapor piping.

It is also shown in this work that the usage of

regenerators in parallel is a good alternative to

increase the thermal efficiency of power plants.

However, an exergetic and economic analysis would

be required to analyze, in a wider form, if the

application of the proposed system is advantageous.

These analyses are going to be addressed in future

works.

ACKNOWLEDGEMENTS

The authors thank the Conselho Nacional de

Desenvolvimento Científico e Tecnológico (CNPq)

and the Comissão de Aperfeiçoamento de Pessoal de

Nível Superior (CAPES) for the financial support, as

Figure 6. Influence of pressure p10 over the liquid well as the universities UFRGS and FURG that

power of the turbines for the proposed cycle. helped in the making of this work.

It is also noticed that the turbines of the REFERENCES

Rankine cycle made up for the power reduction in

the gas turbine. This is mainly due to the second Alabdoadaim M. A., Agnew B., and Alaktiwi

stage turbine, where the power produced increased as A, 2004, Examination of the Performance Envelope

the pressure level increased. This result was also of Combined Rankine, Brayton and Two Parallel

expected, since by increasing p10 it is also reduced Inverse Brayton Cycles, Journal of Power and

the energy removed from the working fluid in the Energy, Vol. 218, pp. 377-385.

first stage turbine and, consequently, increased the Bejan, A., Lorente, S., and Kang, D., 2012,

amount of energy available to be extracted by the Constructal Design of Regenerators, International

second stage turbine. Journal of Energy Research, Vol. 37, pp 1509-1518.

Can Gülen S., and Smith, R. W., 2009, Second

CONCLUSIONS Law Efficiency of the Rankine Bottoming Cycle of a

Combined Cycle Power Plant, Journal of

Through the present study, it is concluded that Engineering for Gas Turbines and Power, Vol. 132,

the application of regenerators in parallel in pp. 1017-1-27.

combined Brayton/Rankine cycles can account for Franco, A., and Casarosa, C., 2004,

several benefits. The main advantage is the Thermoeconomic Evaluation of the Feasibility of

improvement of the cycle efficiency, which would Highly Efficient Combined Cycle Power Plants,

reduce significantly the energy consumption, Energy, Vol. 29, pp. 1963-1982.

resulting in less fuel consumption while also Gómez, M. R., Garcia, R. F., Gómez, R. R., and

reducing the pollution that comes from the Carila, J. C., 2014, Thermodynamic Analysis of a

combustion of fossil fuels. Brayton Cycle and Rankine Cycle Arranged in Series

In addition, the vapor mass flow rate is reduced Exploiting the Cold Exergy of LNG (Liquefied

in 14.3%. This opens the possibility of having more Natural Gas), Energy, Vol. 66, pp. 927-937.

compact and cheaper systems, since every Habib M. A., and Zubair S. M., 1992, Second-

component in the cycle could be reduced, for a given Law-Based Thermodynamic Analysis of

power demand. On the other hand, for the same Regenerative-Reheat Rankine-Cycle Power Plants,

installation, more power could be extracted from the Energy, Vol. 17, pp. 295-301.

cycle. Khaliq A., and Kaushik S. C., 2004, Second-

The utilization of an extra regenerator benefited Law Based Thermodynamis Analysis of

the reheating process of the Rankine cycle. This Brayton/Rankine Combined Power Cycle with

proposition showed to be interesting in the aspect of Reheat, Applied Energy, Vol. 78, pp. 179-197.

16 Engenharia Térmica (Thermal Engineering), Vol. 16 • No. 2 • December 2017 • p. 10-17

Tecnologia/Technology Santos, et al. Analysis of a Combined Brayton/Rankine…

Masashi, A., Emad A., and Masao, T., 1993, A

Study of High-Accuracy Calculations of Combined

Brayton/Rankine Cycles for Power Generation,

JSME International Journal, Serie B, Vol. 36, No. 1,

pp. 178-183.

Moran, M. J., and Shapiro, H., 2002,

Fundamentals of Engineering Thermodynamics, 4th

ed., John Wiley & Sons.

Zhang Z., Chen L., and Sun F., 2012, Energy

Performance Optimization of Combined Brayton and

Two Parallel Inverse Brayton Cycles with

Regeneration before the Inverse Cycles, Scientia

Iranica, Transactions B: Mechanical Engineering 19,

pp. 1279-1287.

Engenharia Térmica (Thermal Engineering), Vol. 16 • No. 2 • December 2017 • p. 10-17 17

View publication stats

You might also like

- Thermodynamic Optimization of Bottoming CycleDocument15 pagesThermodynamic Optimization of Bottoming CycleStjepkoKatulićNo ratings yet

- Venture Building, A New Model For Entrepreneurship and Innovation - LinkedInDocument16 pagesVenture Building, A New Model For Entrepreneurship and Innovation - LinkedInkhaledhassangamal9516No ratings yet

- Thermodynamic Analysis of Brayton Cycle PDFDocument9 pagesThermodynamic Analysis of Brayton Cycle PDFAltimate SonaNo ratings yet

- A Novel Design Approach For Small Scale Low Enthalpy Binary GeothermalDocument10 pagesA Novel Design Approach For Small Scale Low Enthalpy Binary GeothermalDidit Setyo PamujiNo ratings yet

- Thermoeconomic Analysis of Organic RankineDocument14 pagesThermoeconomic Analysis of Organic RankinePower Power100% (1)

- Thermo-Economic Performance Comparison of Two Configurations ofDocument17 pagesThermo-Economic Performance Comparison of Two Configurations ofSallyNo ratings yet

- Toy Car Lab - 2Document3 pagesToy Car Lab - 2api-260771184No ratings yet

- Mohagheghi - Thermodynamic Optimization of Recuperated S-Co2 Brayton Cycles For Waste Heat Recovery ApplicationsDocument13 pagesMohagheghi - Thermodynamic Optimization of Recuperated S-Co2 Brayton Cycles For Waste Heat Recovery ApplicationsJahangir MalikNo ratings yet

- Energy Conversion and Management: Hang Li, Wei Su, Liyan Cao, Feng Chang, Wenkai Xia, Yiping DaiDocument10 pagesEnergy Conversion and Management: Hang Li, Wei Su, Liyan Cao, Feng Chang, Wenkai Xia, Yiping DaiANTHONY PAUL ALCARRAZ HUARANGANo ratings yet

- A Critical Overview of Working Fluids in Organic Rankine, Supercritical Rankine, and Supercritical Brayton Cycles Under Various Heat Grade SourcesDocument28 pagesA Critical Overview of Working Fluids in Organic Rankine, Supercritical Rankine, and Supercritical Brayton Cycles Under Various Heat Grade SourcesamirNo ratings yet

- Energy: 2 Zilong Zhu, Yaping Chen, Jiafeng Wu, Shaobo Zhang, Shuxing ZhengDocument10 pagesEnergy: 2 Zilong Zhu, Yaping Chen, Jiafeng Wu, Shaobo Zhang, Shuxing ZhengSadbin MiaNo ratings yet

- Modelado IntercambiadorDocument16 pagesModelado Intercambiadorpaula vergaraNo ratings yet

- 1 s2.0 S1359431118348919 MainDocument8 pages1 s2.0 S1359431118348919 MainLilou MGKNo ratings yet

- Energy Conversion and ManagementDocument9 pagesEnergy Conversion and ManagementAbeer El ShahawyNo ratings yet

- Energy Exergy and Exergoeconomic Analysis of Two Supercr 2021 Applied ThermDocument16 pagesEnergy Exergy and Exergoeconomic Analysis of Two Supercr 2021 Applied ThermApiwit Jumnonjit100% (1)

- Energy Conversion and Management: Huy Quoc Nguyen, Bahman ShabaniDocument29 pagesEnergy Conversion and Management: Huy Quoc Nguyen, Bahman ShabaniCarlos JavierNo ratings yet

- Optimum Superheat Utilization of Extraction Steam in Double ReheatDocument10 pagesOptimum Superheat Utilization of Extraction Steam in Double ReheatAhmed AsaadNo ratings yet

- Sdarticle 1Document8 pagesSdarticle 1Ravikiran TatavarthyNo ratings yet

- Energy Conversion and Management: SciencedirectDocument12 pagesEnergy Conversion and Management: SciencedirectVina Itoe AlvinaNo ratings yet

- J Enconman 2016 09 080Document11 pagesJ Enconman 2016 09 080RAHMAN MARUF MORSHED, 180011237No ratings yet

- Energy Conversion and Management: 2 Mingzhang Pan, Xingyan Bian, Yan Zhu, Youcai Liang, Fulu Lu, Gang XiaoDocument15 pagesEnergy Conversion and Management: 2 Mingzhang Pan, Xingyan Bian, Yan Zhu, Youcai Liang, Fulu Lu, Gang XiaoSebastian LopezNo ratings yet

- 1 s2.0 S1110016820303409 MainDocument11 pages1 s2.0 S1110016820303409 MainQuen CuestaNo ratings yet

- Análisis de Rendimiento Termodinámico de Diferentes Ciclos Orgánicos de Rankine para Generar Energía A Partir de Recursos de Energía Renovable.Document9 pagesAnálisis de Rendimiento Termodinámico de Diferentes Ciclos Orgánicos de Rankine para Generar Energía A Partir de Recursos de Energía Renovable.ManuNo ratings yet

- J Rser 2011 05 019Document6 pagesJ Rser 2011 05 019ediah004No ratings yet

- Sustainable Energy Technologies and AssessmentsDocument13 pagesSustainable Energy Technologies and AssessmentsMuhammadAsimNo ratings yet

- Technological Improvements in Energetic Efficiency - 2018Document22 pagesTechnological Improvements in Energetic Efficiency - 2018marzinusNo ratings yet

- 10.1016 - J.RENENE.2013.05.039 Simulation Study of The Combination of Absorption Refrigeration and Ejector Expansion SystemsDocument12 pages10.1016 - J.RENENE.2013.05.039 Simulation Study of The Combination of Absorption Refrigeration and Ejector Expansion SystemsrezarossNo ratings yet

- ATR - Modelling and SimulationDocument7 pagesATR - Modelling and SimulationQian Jun AngNo ratings yet

- 1-s2.0-S0149197016300816-Mingjun Wang Ammonia-Water Mixture 2016Document23 pages1-s2.0-S0149197016300816-Mingjun Wang Ammonia-Water Mixture 2016rezarossNo ratings yet

- Energy: Carlo Carcasci, Riccardo Ferraro, Edoardo MiliottiDocument10 pagesEnergy: Carlo Carcasci, Riccardo Ferraro, Edoardo MiliottipuNo ratings yet

- A Novel Hybrid Solid Sorption Compression Refrigerati - 2020 - International JouDocument29 pagesA Novel Hybrid Solid Sorption Compression Refrigerati - 2020 - International JouJake OkuyeNo ratings yet

- Yongqiang Feng - Thermoeconomic Comparison Between Pure and Mixture Working FluidsDocument14 pagesYongqiang Feng - Thermoeconomic Comparison Between Pure and Mixture Working FluidsSyaiful NasutionNo ratings yet

- Conceptual Design and Analysis of A Novel Process For Hydrogen Liquefaction PDFDocument24 pagesConceptual Design and Analysis of A Novel Process For Hydrogen Liquefaction PDFDilla WahabNo ratings yet

- Investigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusDocument14 pagesInvestigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusEmre EmlekNo ratings yet

- 2018 Kong Thermodynamics Solar PanelsDocument8 pages2018 Kong Thermodynamics Solar PanelsRahmanNo ratings yet

- Applied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaDocument10 pagesApplied Thermal Engineering: Pardeep Garg, Pramod Kumar, Kandadai Srinivasan, Pradip DuttaKumbamNo ratings yet

- Energy Conversion and Management: Mehdi Mehrpooya, Roozbeh Lazemzade, Mirhadi S. Sadaghiani, Hossein ParishaniDocument12 pagesEnergy Conversion and Management: Mehdi Mehrpooya, Roozbeh Lazemzade, Mirhadi S. Sadaghiani, Hossein ParishaniFranco Camacho CanchariNo ratings yet

- Thermodynamic Performance Analysis of Different Organic Rankine Cycles To Generate Power From Renewable Energy ResourcesDocument8 pagesThermodynamic Performance Analysis of Different Organic Rankine Cycles To Generate Power From Renewable Energy ResourcesAndhdNo ratings yet

- 10 1016@j Enconman 2018 08 042 PDFDocument15 pages10 1016@j Enconman 2018 08 042 PDFteorikdeliNo ratings yet

- J Egyr 2020 08 013Document15 pagesJ Egyr 2020 08 013Adarsh Kp OrkkatryNo ratings yet

- Niu 2012Document11 pagesNiu 2012MichelNo ratings yet

- Budisulistyo 2015Document11 pagesBudisulistyo 2015Rizky Putra GustamanNo ratings yet

- 1 s2.0 S0306261917304543 MainDocument19 pages1 s2.0 S0306261917304543 MainHebaNo ratings yet

- Thermochemical Properties Estimation For Biodiesel Related MixturesDocument11 pagesThermochemical Properties Estimation For Biodiesel Related Mixturesalberth_carantónNo ratings yet

- 1 s2.0 S2451904922002414 Main - ContohDocument21 pages1 s2.0 S2451904922002414 Main - ContohLIA PUTRIYANANo ratings yet

- Case Studies in Thermal Engineering: T. Srinivas, B.V. ReddyDocument7 pagesCase Studies in Thermal Engineering: T. Srinivas, B.V. Reddyayupermata2106No ratings yet

- Yuan 2021Document13 pagesYuan 2021Sirine SaidiNo ratings yet

- 10 1016@j Enconman 2020 112523Document20 pages10 1016@j Enconman 2020 112523Usama ArifNo ratings yet

- Desalination andDocument6 pagesDesalination andrabeea ahmedNo ratings yet

- Analysis and Optimization of Cascade Rankine Cycle For Liquefied N - 2013 - EnerDocument17 pagesAnalysis and Optimization of Cascade Rankine Cycle For Liquefied N - 2013 - EnerSyed Jiaul HoqueNo ratings yet

- Exergy Analysis of A Pilot Scale Reactor Using - 2021 - Journal of Cleaner ProdDocument11 pagesExergy Analysis of A Pilot Scale Reactor Using - 2021 - Journal of Cleaner ProdMariateresa DelgadocaballeroNo ratings yet

- A Novel Study of Using Oil Refinery Plants Waste Gases For Thermal PDFDocument25 pagesA Novel Study of Using Oil Refinery Plants Waste Gases For Thermal PDFNyaz AzeezNo ratings yet

- Applied Thermal Engineering: Research PaperDocument8 pagesApplied Thermal Engineering: Research Paperbrayan asprillaNo ratings yet

- Progress and Prospects For Research and Technology Development of Supercritical CO2 Thermal Conversion Systems For Power Energy Storage and Waste HeDocument19 pagesProgress and Prospects For Research and Technology Development of Supercritical CO2 Thermal Conversion Systems For Power Energy Storage and Waste Hegetahun esubalewNo ratings yet

- Merch N 2017Document13 pagesMerch N 2017pbNo ratings yet

- Campo2015 PDFDocument12 pagesCampo2015 PDFarkarnis enginnerNo ratings yet

- Double-Effect Distillation and Thermal Integration Applied To The Ethanol Production ProcessDocument13 pagesDouble-Effect Distillation and Thermal Integration Applied To The Ethanol Production ProcessAhmad AsyraafNo ratings yet

- Performance Comparison and Parametric Op PDFDocument15 pagesPerformance Comparison and Parametric Op PDFAdda Dà DY RerriballahNo ratings yet

- Energy Conversion and Management: Javier Peña-Lamas, Juan Martinez-Gomez, Mariano Martín, José María Ponce-OrtegaDocument11 pagesEnergy Conversion and Management: Javier Peña-Lamas, Juan Martinez-Gomez, Mariano Martín, José María Ponce-OrtegaJuan MartinezNo ratings yet

- Energy Conversion and ManagementDocument12 pagesEnergy Conversion and Managementjhugo_mirandaNo ratings yet

- Implementation of The Characteristic Equation Method in Quasi-DynamicDocument16 pagesImplementation of The Characteristic Equation Method in Quasi-DynamicAlvaro Antonio Ochoa VillaNo ratings yet

- IDS StreamDP Brochure WEBDocument4 pagesIDS StreamDP Brochure WEBgeosains enjiniringNo ratings yet

- Lado SaraiDocument4 pagesLado SaraiJagat PapaNo ratings yet

- Effect of Microcrystalline Cellulose From Banana Stem Fiber On Mechanical Properties and Cystallinity of PLA Composite FilmsDocument5 pagesEffect of Microcrystalline Cellulose From Banana Stem Fiber On Mechanical Properties and Cystallinity of PLA Composite FilmsHubby Mukaffa Al-JauzyNo ratings yet

- Combinepdf 2Document19 pagesCombinepdf 2Nehal IsmailNo ratings yet

- PSY563Document1 pagePSY563Za-c Pelangi Senja100% (1)

- Graphic Design Thesis TopicsDocument8 pagesGraphic Design Thesis Topicsafkololop100% (1)

- The Resources, You Can Also Search and Watch Video Presentations Regarding The TopicDocument2 pagesThe Resources, You Can Also Search and Watch Video Presentations Regarding The TopicStefie Grail Coilan EganNo ratings yet

- CPM Global 0181 PDFDocument20 pagesCPM Global 0181 PDFSMM ENTREPRISENo ratings yet

- My KFUEIT - DashboardDocument3 pagesMy KFUEIT - DashboardMuhammad Saad AbdullahNo ratings yet

- Ngan Hang Cau Hoi Trac NghiemDocument50 pagesNgan Hang Cau Hoi Trac NghiemTÂM NGÔ NHƯNo ratings yet

- 1568 - File - CEC 411 Highway Route LocationDocument6 pages1568 - File - CEC 411 Highway Route Locationpraisejah moyoNo ratings yet

- Conflict: Communication, Coaching, andDocument16 pagesConflict: Communication, Coaching, andNemam ImeNo ratings yet

- Statistical Soup - ANOVA, ANCOVA, MANOVA, & MANCOVADocument1 pageStatistical Soup - ANOVA, ANCOVA, MANOVA, & MANCOVAsapaNo ratings yet

- EthicsDocument4 pagesEthicsIra DionisioNo ratings yet

- Markham College School Profile 2022 2023Document2 pagesMarkham College School Profile 2022 2023lskdfjNo ratings yet

- Greatest InventionsDocument1 pageGreatest InventionsTeresa MainNo ratings yet

- The Identification of Unknown Compound Lab ReportDocument5 pagesThe Identification of Unknown Compound Lab Reportwgoodin0% (1)

- Ambetronics Engineers PVT LTD: Questionnaire FormDocument2 pagesAmbetronics Engineers PVT LTD: Questionnaire FormGovind RaoNo ratings yet

- Patterns and Correlates of New Psychoactive Substance Use in A Sample of Australian High School StudentsDocument7 pagesPatterns and Correlates of New Psychoactive Substance Use in A Sample of Australian High School StudentsFirli FarhatunnisaNo ratings yet

- Action Pack 6 TB PDFDocument82 pagesAction Pack 6 TB PDFAmneh YasserNo ratings yet

- iFIX Automation Reference Section2Document587 pagesiFIX Automation Reference Section2megamoto02 motosNo ratings yet

- MODULE 4-Modern PhysicsDocument21 pagesMODULE 4-Modern PhysicsANGELO NINO ALVARADONo ratings yet

- FBXCVSDZX H AIATS For Olympiads 2024 - Class IXDocument22 pagesFBXCVSDZX H AIATS For Olympiads 2024 - Class IXAtul KunduNo ratings yet

- Operating Manual: MAN DieselDocument232 pagesOperating Manual: MAN DieselYamaç YenerNo ratings yet

- Le Chatelier's PrincipleDocument15 pagesLe Chatelier's PrincipleAldrick VeranoNo ratings yet

- ERDAS Field Guide 2013Document792 pagesERDAS Field Guide 2013ElhadjRomanNo ratings yet

- Midterm Leadership GGDocument5 pagesMidterm Leadership GGGiang GiangNo ratings yet

- Ba-Dmd Sem 2 (S)Document1 pageBa-Dmd Sem 2 (S)dadagiri222002No ratings yet