100% found this document useful (3 votes)

1K views60 pagesAgenda: - Moulding Starch

The document discusses various topics related to candy production including the components and properties of moulding starch, how moulding starch is processed, details on mogul machines used for starch moulding candy, troubleshooting issues that can occur with moguls, and guidelines for curing candy in stoving rooms. Moguls are versatile starch moulding machines that can produce various candy products through depositing onto starch in mould boards and accessories help condition the starch and improve production.

Uploaded by

ISRAEL ATONAL SALAZARCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

1K views60 pagesAgenda: - Moulding Starch

The document discusses various topics related to candy production including the components and properties of moulding starch, how moulding starch is processed, details on mogul machines used for starch moulding candy, troubleshooting issues that can occur with moguls, and guidelines for curing candy in stoving rooms. Moguls are versatile starch moulding machines that can produce various candy products through depositing onto starch in mould boards and accessories help condition the starch and improve production.

Uploaded by

ISRAEL ATONAL SALAZARCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Overview: Introduces the key topics covered such as starch molding, moguls, troubleshooting, and curing techniques.

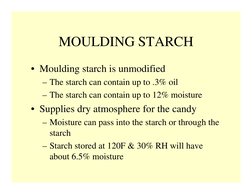

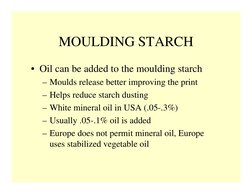

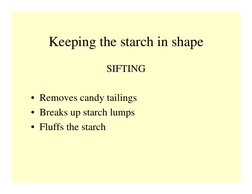

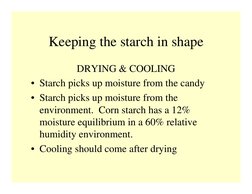

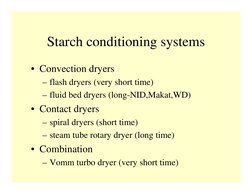

- Moulding Starch: Explains the components and processing of moulding starch, its characteristics, and industrial applications.

- Moguls: Details the functionality and applications of mogul machines in candy production.

- Accessories to the Mogul: Lists additional tools used alongside moguls to optimize performance.

- Troubleshooting at the Mogul: Covers common issues and solutions in mogul operation like starch flow and foreign candy.

- Stoving or Curing: Explains the principles and practices in curing and stoving candy to achieve desired textures.