Professional Documents

Culture Documents

D1 - 1 2020 - Structural Welding Code-Steel-03

D1 - 1 2020 - Structural Welding Code-Steel-03

Uploaded by

Trung Nguyen0 ratings0% found this document useful (0 votes)

10 views1 pageOriginal Title

D1_1 2020_Structural Welding Code-Steel-03

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageD1 - 1 2020 - Structural Welding Code-Steel-03

D1 - 1 2020 - Structural Welding Code-Steel-03

Uploaded by

Trung NguyenCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

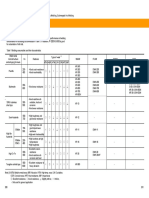

AWS D1 .1 /D1 .1 M:2020 CLAUSE 5.

PREQUALIFICATION OF WPSs

See Notes on Page 81

Single-bevel-groove weld (4) Tolerances

T-joint (T) As Detailed As Fit-Up

Corner joint (C) (see 5.4.1 .1 ) (see 5.4.1 .8)

R = +1 /1 6, –0 +1 /4, –1 /1 6

α = +1 0° –0° +1 0°, –5°

Base Metal Thickness Allowed Gas

Welding Joint (U – unlimited) Groove Preparation Welding Shielding

Process Designation T1 T2 Root Opening Groove Angle Positions for FCAW Notes

R = 1 /4 α = 45° All — e, g, k, o

SMAW TC-U4a U U

R = 3/8 α = 30° F, V, OH — e, g, k, o

R = 3/1 6 α = 30° All Required a, g, k, o

GMAW TC-U4a-GF U U R = 3/8 α = 30° F Not req. a, g, k, o

FCAW

R = 1 /4 α = 45° All Not req. a, g, k, o

R = 3/8 α = 30°

SAW TC-U4a-S U U F — g, k, o

R = 1 /4 α = 45°

Single-bevel-groove weld (4)

Butt joint (B)

Base Metal Thickness

(U = unlimited) Groove Preparation

Root Opening Tolerances Allowed Gas

Welding Joint Root Face As Detailed As Fit-Up Welding Shielding

Process Designation T1 T2 Groove Angle (see 5.4.1 .1 ) (see 5.4.1 .8) Positions for FCAW Notes

SMAW B-U4b U — R = 0 to 1 /8 +1 /1 6, –0 +1 /1 6, –1 /8 All — c, d, e, j

GMAW f = 0 to 1 /8 +1 /1 6, –0 Not limited Not

FCAW B-U4b-GF U — α = 45° +1 0°, –0° 1 0°, –5° All required a, c, d, j

R=0 ±0 +1 /4, –0

SAW B-U4b-S U — f = 1 /4 max. +0, –1 /8 ±1 /1 6 F — c, d, j

α = 60° +1 0°, –0° 1 0°, –5°

Figure 5.1 (Continued)—Prequalified CJP Groove Welded Joint Details (See 5.4.1)

(Dimensions in Inches)

87

Provided by IHS Markit under license with AWS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- D1 - 1 2020 - Structural Welding Code-Steel-02Document1 pageD1 - 1 2020 - Structural Welding Code-Steel-02Trung NguyenNo ratings yet

- D1 - 1 2020 - Structural Welding Code-Steel - 01Document1 pageD1 - 1 2020 - Structural Welding Code-Steel - 01Trung NguyenNo ratings yet

- Assembly Procedure For The 785B and 785C Dual Slope Truck Body (7258, 7960)Document69 pagesAssembly Procedure For The 785B and 785C Dual Slope Truck Body (7258, 7960)Carlos Lobo100% (1)

- Api 570 Chapter 7-Nde-Rev-005Document49 pagesApi 570 Chapter 7-Nde-Rev-005Trung NguyenNo ratings yet

- Curriculum Vitae: Name: Hà Lê DuyDocument7 pagesCurriculum Vitae: Name: Hà Lê DuyTrung NguyenNo ratings yet

- Swivel Ring - LargeDocument2 pagesSwivel Ring - LargeTrung NguyenNo ratings yet

- Nguyen Bao Trung EngDocument5 pagesNguyen Bao Trung EngTrung NguyenNo ratings yet

- Rajeev Internship ReportDocument46 pagesRajeev Internship ReportrajivNo ratings yet

- Hard FacingDocument2 pagesHard FacingArdhi WibowoNo ratings yet

- ShipProduction PDFDocument124 pagesShipProduction PDFYl WongNo ratings yet

- Manual Na3s & Na4Document164 pagesManual Na3s & Na4jhonNo ratings yet

- School Form 1 School Register For Senior High School (SF1-SHS)Document4 pagesSchool Form 1 School Register For Senior High School (SF1-SHS)dominic dalton calingNo ratings yet

- 9 Codes and Standards Relevant To The Quality Assurance of Welded ConstructionsDocument14 pages9 Codes and Standards Relevant To The Quality Assurance of Welded ConstructionstranngNo ratings yet

- Mig & MagDocument7 pagesMig & Magprap_1982No ratings yet

- Welding IntroDocument183 pagesWelding IntroDeepak KumarNo ratings yet

- Report of Underwater WeldingDocument7 pagesReport of Underwater WeldingMunirAzeemNo ratings yet

- Study of Tig WeldingDocument11 pagesStudy of Tig WeldingChandan Srivastava100% (1)

- Welding ClassificationDocument30 pagesWelding ClassificationSamNo ratings yet

- Hot Work ProcedureDocument16 pagesHot Work ProcedureAkmal YassinNo ratings yet

- Collie Welding Heat Input CalculatorDocument6 pagesCollie Welding Heat Input CalculatorManohar SeetharamNo ratings yet

- CPDACA 200 ManualDocument48 pagesCPDACA 200 ManualsunhuynhNo ratings yet

- Met Rode HandbookDocument416 pagesMet Rode Handbookral75100% (2)

- LB AW SiX SPT - ENDocument58 pagesLB AW SiX SPT - ENalireza ghaderiNo ratings yet

- AWS B2 1 1 004 2013 SWPS GMAW ShortDocument22 pagesAWS B2 1 1 004 2013 SWPS GMAW Shortreza acbariNo ratings yet

- 12.6 Welding Procedures List (Li-002)Document31 pages12.6 Welding Procedures List (Li-002)Ana GameroNo ratings yet

- BS 5950 Part 2 2001 - Specification For Materials, Fabrication and Erection - Rolled and Welded SectionsDocument41 pagesBS 5950 Part 2 2001 - Specification For Materials, Fabrication and Erection - Rolled and Welded Sections111111100% (5)

- HandoutsDocument5 pagesHandoutsJomar MontallanaNo ratings yet

- Weld CalculationDocument34 pagesWeld CalculationAshwani DograNo ratings yet

- Welding of Ferritic or Austenitic Stainless SteelDocument22 pagesWelding of Ferritic or Austenitic Stainless SteelBehnam RabieeNo ratings yet

- Weldskill 200 ACDC Product ManualDocument70 pagesWeldskill 200 ACDC Product Manualkazambo780% (1)

- SMAW Welding Skill (W-01) 1Document57 pagesSMAW Welding Skill (W-01) 1hardish_trivedi7005100% (7)

- GMAW by LincolnDocument96 pagesGMAW by LincolnManuel Dario Rubiano MartinezNo ratings yet

- Company Profil CV - Citra Harapan Jaya All CustomerDocument6 pagesCompany Profil CV - Citra Harapan Jaya All Customersutrisno00No ratings yet

- Arc WLDG Basic Workshop Practice 04092018Document2 pagesArc WLDG Basic Workshop Practice 04092018Abraiz NajamNo ratings yet

- Uniones Soldadas PDFDocument129 pagesUniones Soldadas PDFTaylor Andres AmayaNo ratings yet

- Hmine115 Workshop Practice Welding ProcessDocument72 pagesHmine115 Workshop Practice Welding ProcessGareth MashingaidzeNo ratings yet