Professional Documents

Culture Documents

New Product Development

Uploaded by

Nary GurbanovaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Product Development

Uploaded by

Nary GurbanovaCopyright:

Available Formats

New Product Development

1) Exercise. In order to implement a plan a workshop has to manufacture preliminary models

for the test objectives. To make a particular component requires an overhead (fixed) cost of

USD5000 and a variable unit cost of USD6.50 per unit. What is the total cost and the

average cost of producing a lot of 3000? If the selling price is USD15 per unit, what is the

break-even point? (5 grades)

Unit (average) cost= total cost/ number of units

Total cost = fixed cost + (variable cost per unit) * (number of units)

Total cost = fixed cost/number of units + variable cost per unit

Total cost = USD 5000 + (USD 6.50 * USD 3000)

Total cost = USD 24,500

Average cost = USD 24,500/3000 = USD 8.17 per unit

Break-even point: Let X = number of units sold

USD15*X=USD5000+USD6.5*X

USD8.50*X=USD5000 X=588.2 units.

Break-even occurs when 588.2 units are made and sold.

2) Exercise. A new innovative product component made on a particular work center has a

setup time of 100 minutes and a run time of 3 minutes per piece. An order for 1500 is to be

processed on 2 machines simultaneously. The machines can be set up at the same time.

Calculate the elapsed operation time. (5 grades)

Elapsed operation time=100+3*(1500/2)=2350 min=39h and 10min.

3) Exercise. Production of the construction bricks, thousand cubic meters, is indicated in the

table below mentioned. What control measures can be implemented in Risks Assessment

techniques to recover brickworks in case of the economic recession in Azerbaijan in the

years 2021-2022? Apply the Risks Assessment using the MS Excel template. (5 grades)

2012 2013 2014 2015 2016 2017 2018 2019

213. 388.

2 450 426.1 280.6 234.1 303.1 7 462.8

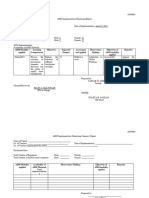

4) Exercise. A manufacturing enterprise is planning to introduce an Emission Monitoring and

Reporting equipment which is connected via the internet on an offshore oil platform in

Azerbaijan in the year 2021. Apply the Reporting technique form using MS Excel. What are

the probable prevention measures and risk assessment in case of the low sales and

unexpected failure of this equipment? (5 grades)

See MS Excel Table.

5) Essay. Analysis of new product development concepts in the manufacturing industry. (5

grades)

MBA_PRT 1203_New Product Development_ Midterm _____ _____________, 2021 Page 1

The PCP is a comprehensive product development management process. It characterizes all areas of

product creation while maintaining the focus of customer requirements. The aim of the process is to

ensure that all information necessary for an efficient and effective short-term and long-term plan is

collected at the right time. The process is performed on a product category basis and project-oriented,

which means each category is handled individually and a new project is created each time the process

is initiated. In a given product category, all projects are managed by a company manager who is

responsible for the project progress.

The PCP consists of four phases, including steps, activities and control points to be addressed during

product development. The aim of the first phase (strategic market planning) is to make sure

opportunities are clearly identified and prioritized by creating a strategic market plan for the category

of products. In addition to industry analyzes, the plan is based on corporate pre-requisites (for

example, strategy for product innovation, brand and design, and global needs).

Phase two involves parallel steps: business and primary development. During the business

opportunity step, customer insight gained an understanding of customer needs in the specific product

category. The case company uses a range of techniques such as observations, surveys and assessments

to gather client insights. Observations are preferable, as the behavior observed is richer than the

behaviour. Such research, however, is difficult to employ, because local product production processes

develop global products and demands can vary significantly from region to region. The case company

then seeks to identify the means by which products that meet the identified needs are developed. It

then describes the requirements and proposes a solution in a project proposal (PP). There is a product

council in each product category to decide whether or not proposed project for product development is

accepted. Technical solutions are developed in the primary development category to create verified

ideas or hardware solutions for the relevant product development projects.

The third phase (development of products) is aimed at developing products based on an accepted

project proposal. The phase consists of three phases, each with several phases. Each phase comprises

several activities that need to be addressed and a check point must be passed before the project is

approved in the next phase.

The aim of the first step (project specification) is to develop a requirement specification based on the

project proposal and to later carry out several theoretical examinations of how the specification can be

carried out. In this step the most information is gathered to ensure an efficient process forward

loading. This strategy is defensible, as the projects at this stage are still quite cheap. The product

specifications for the information collected and theoretical studies are then verified. This means that

more than one product development project can result from a project proposal. Prototyping refers to

the production of a prototype of the verified product specification as a last stage in the draft

specification step. The prototypes are highly accurate and several tests are performed. Cross-

functional teams from several departments, including acquisition, manufacturing, service, laboratory,

research and development are involved in these tests. The next step is project industrialization if the

prototype is accepted. This step is different in length between categories of products. The case

company must invest in real machinery and tools during the industrialisation step. These investments

can be quite extensive, and it is thus important to make the industrialization step in both cost and time

as efficient as possible so as to provide income as quickly as possible.

The project is approved for the final stage of manufacturing after the case company has secured the

processes. So the company is now beginning to produce and market the product. The case company

continually assesses the results at the beginning of this stage to determine whether any changes or

improvements are necessary. The company also assesses whether or not the project has been

successful during this assessment period. The project is finally closed and production goes on. The

aim of the final phase is to ensure that the product range is updated to life cycles and obsolete

products are properly updated. The final phase (phase-out) These two goals depend on a consistent

follow-up.

MBA_PRT 1203_New Product Development_ Midterm _____ _____________, 2021 Page 2

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Art of The Elevator Pitch: Business Marketing TipsDocument3 pagesThe Art of The Elevator Pitch: Business Marketing TipsAkanksha JainNo ratings yet

- Mod 2Document23 pagesMod 2Lem RadaNo ratings yet

- Modular Kaizen - Grace DuffyDocument36 pagesModular Kaizen - Grace DuffysamebcNo ratings yet

- Product ManagementDocument17 pagesProduct ManagementAshish BilolikarNo ratings yet

- Strategic Management Report For Nestle Malaysia BerhadDocument29 pagesStrategic Management Report For Nestle Malaysia BerhadCarrey Oliver100% (6)

- Case Study:: Strategic Brand Management Midterm Questions 1Document3 pagesCase Study:: Strategic Brand Management Midterm Questions 1Nary Gurbanova100% (1)

- E-Marketing - Final ExamDocument4 pagesE-Marketing - Final ExamNary Gurbanova0% (1)

- Subject - New Product Development Essay Companies MergeDocument2 pagesSubject - New Product Development Essay Companies MergeNary GurbanovaNo ratings yet

- Research Methods For MarketingDocument3 pagesResearch Methods For MarketingNary GurbanovaNo ratings yet

- Risk Assessment and PlanningDocument1 pageRisk Assessment and PlanningNary GurbanovaNo ratings yet

- The Articles A / AnDocument10 pagesThe Articles A / AnNary GurbanovaNo ratings yet

- Variant A: Choose The Correct Variant.Document3 pagesVariant A: Choose The Correct Variant.Nary GurbanovaNo ratings yet

- Good Luck: A) Is, Is, Am B) Is, Am, WasDocument1 pageGood Luck: A) Is, Is, Am B) Is, Am, WasNary GurbanovaNo ratings yet

- At The Playground Games - 78401Document26 pagesAt The Playground Games - 78401Nary GurbanovaNo ratings yet

- Uts Finance IvanDocument28 pagesUts Finance IvanIvan ZackyNo ratings yet

- Functions of MGTDocument2 pagesFunctions of MGTKommineni Ravie KumarNo ratings yet

- Yustika Adiningsih-f0319141-Spm A-Mindmap CH 4 Dan 5Document2 pagesYustika Adiningsih-f0319141-Spm A-Mindmap CH 4 Dan 5yes iNo ratings yet

- OM-1 Question PaperDocument10 pagesOM-1 Question PaperNohan JoemonNo ratings yet

- Upgrade: Negative Angle Indication For Luffi NG Jibs: Liebherr Customer ServiceDocument4 pagesUpgrade: Negative Angle Indication For Luffi NG Jibs: Liebherr Customer Serviceesteban0barahonaNo ratings yet

- 2013 CH 7 The Sources and Dimensions of Competitive AdvantageDocument18 pages2013 CH 7 The Sources and Dimensions of Competitive AdvantageHelen MoyoNo ratings yet

- Slides - Session 6,7Document16 pagesSlides - Session 6,7atharvaNo ratings yet

- Project Management: Leading, Creating, Implementing and ImprovingDocument4 pagesProject Management: Leading, Creating, Implementing and ImprovingTim MolefiNo ratings yet

- General Procurement Notice (GPN) For The Financial Year 2018/2019Document11 pagesGeneral Procurement Notice (GPN) For The Financial Year 2018/2019OMARY MWAKAJENo ratings yet

- What Are The Roles and Responsibilities of A Project ManagerDocument10 pagesWhat Are The Roles and Responsibilities of A Project ManagerTanjung AmandaNo ratings yet

- Value Cocreationn Vega-Vazquez2013Document13 pagesValue Cocreationn Vega-Vazquez2013Sonila ShakyaNo ratings yet

- Accounting For Materials: Problem 2.4Document11 pagesAccounting For Materials: Problem 2.4Liana Monica LopezNo ratings yet

- 334 625 1 SMDocument12 pages334 625 1 SMKhusus DewasaNo ratings yet

- 8.dedicated Freight Corridor Has Been Designed For HalfDocument7 pages8.dedicated Freight Corridor Has Been Designed For HalfEr Suraj HulkeNo ratings yet

- PSG Supplier Capability Assessment ServicesDocument2 pagesPSG Supplier Capability Assessment ServicesMohan SharmaNo ratings yet

- Main Cirque Du Soleil FinalDocument4 pagesMain Cirque Du Soleil FinalFarhan HossainNo ratings yet

- Reduce Defect Material Handling - ID02 Rev.2Document17 pagesReduce Defect Material Handling - ID02 Rev.2Fery SaputraNo ratings yet

- Industrial Visit Report On Russel GarmentDocument23 pagesIndustrial Visit Report On Russel GarmentullasNo ratings yet

- Consumer Awareness: Social Science Project Class 10thDocument22 pagesConsumer Awareness: Social Science Project Class 10thJigna Patel100% (1)

- Financing Agreement: Credit Number 7150-Zr Grant Number E071D-ZrDocument23 pagesFinancing Agreement: Credit Number 7150-Zr Grant Number E071D-Zrpaul henriNo ratings yet

- TMW6104 Project Management: Booking SystemDocument10 pagesTMW6104 Project Management: Booking SystemfatihahNo ratings yet

- Click To Edit Master Title Style: 7 InventoriesDocument103 pagesClick To Edit Master Title Style: 7 InventoriesAlvin Rindra FazrieNo ratings yet

- Karen Esther Sarmiento Rodriguez: Manager SalesDocument3 pagesKaren Esther Sarmiento Rodriguez: Manager SalesanuarNo ratings yet

- ADM-Implementation-Monitoring-Tool-as-discussed-withthe-CID-group PMDocument3 pagesADM-Implementation-Monitoring-Tool-as-discussed-withthe-CID-group PMcaesar.amigoNo ratings yet

- New Checklist For TradingDocument8 pagesNew Checklist For TradingADC VentureNo ratings yet