Professional Documents

Culture Documents

Amercoat 56E Polyamide Epoxy High Solids Tank Lining

Uploaded by

Muhammad MustahsinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amercoat 56E Polyamide Epoxy High Solids Tank Lining

Uploaded by

Muhammad MustahsinCopyright:

Available Formats

Amercoat 56E

Polyamide Epoxy

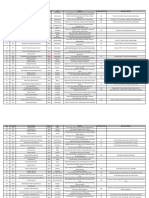

Product Data/ Physical Data

Application Instructions Finish ..................................... flat

st

Colour .................................... 1 coat ivory

nd

2 coat white

• High solids tanklining Components .......................... 2

• Qualifies to Mil-C-4556 E for fuel storage Mixing ratio (by volume)

• Excellent resistance to refined petroleum resin .................................... 4 parts

products and fuels cure ..................................... 1 part

• Suitable for water immersion service Curing mechanism ................ solvent release and chemical

reaction between components

Typical Uses Volume solids ........................ 71% (ISO 3233)*

Amercoat 56E polyamide epoxy is used in marine and

VOC ....................................... 20% by weight/290 g/l

industry as a protective lining for fuel and water tanks

in ships, for ballast water tanks and for storage tanks Dry film thickness .................. 75-150 µm per coat

of fuel oils and petroleum products, etc. Amercoat

Number of coats .................... 2 coats of 100 µm for fuel storage

56E polyamide epoxy coating system consists of two 2 coats at 150 µm as water

coats; the first coat ivory, the second coat white. tanklining

Calculated coverage .............. 8.8 m²/l at 75 µm

Approval and Certificates

4.4 m²/l at 150 µm

Complies with MIL-C-4556E specification from the US

Allow for application losses, surface irregularities, etc.

Navy for the storage of jet fuels.

Complies with the Shell test requirements for linings Flash points

for aviation fuels (tested by TNO, the Netherlands). (Closed Cup)........................ ºC ºF

resin .................................... 25 77

cure ..................................... 24 75

Amercoat 9HF...................... 26 79

Repair Amercoat 65 ........................ 24 75

Spot blast areas to Sa 2½, feathering edges of intact Amercoat 12 ........................ 24 75

coating. Thoroughly remove dust or abrasive residue

before touch up. * volume solids is measured in accordance with ISO 3233. Slight

variations ±3% may occur due to colour and testing variances.

Page 1 of 4 Revision date: 24-03-2006

Amercoat 56E

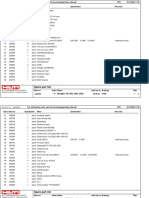

Surface Preparation Application Data

STEEL - Immersion service: Blast steel to Sa 3 in Substrate ............................... steel

accordance with Swedish Standard SIS 05 5900 -

1967, ISO 8501-1 or SSPC SP-5. Application methods ............... airless or conventional spray

NOTE: Blast to achieve a surface profile not to Potlife at ºC/ºF 30/86 20/68 10/50

exceed

75 µm as determined with Testex Tape or similar (in hours) 1½ 4 6

instrument. Remove abrasive residues and dust from Potlife is dependent on temperature and quantities mixed.

surface.

IMPORTANT - Apply Amercoat 56E as soon as Environmental Conditions

(during application)

possible after surface preparation to prevent any Air temperature .................... 5 to 50°C 41 to 122°F

contamination. Do not leave blasted steel uncoated Surface temperature ............ 5 to 60°C 41 to 140ºF

overnight. In case of contamination, remove

To prevent moisture condensation during application, surface

contaminants. Spot blast steel if needed. temperature must be at least 3°C/5ºF above dew point.

Drying Times (ASTM D1640) at 100µm dft

Application Equipment (in hours) ºC/ºF 30/86 20/68 10/50

The following equipment is listed as a guide and dry to touch .......................... 1 2 3

suitable equipment from other manufacturers may be dry through........................... 8 12 18

dry to recoat

used. Adjustments of pressure and change of tip size or topcoat (minimum)........... 8 12 18

may be needed to obtain the proper spray

characteristics. Maximum Topcoat or Self-recoat Times

(in months) ºC/ºF 30/86 20/68 10/50

AIRLESS SPRAY - Standard airless spray immersion ............................ 6 6 6

equipment, such as Graco, DeVilbiss, Nordson-Bede,

Spee-Flo or others having a 0.015 to 0.021 inch (0.38 Time before service at 150 µm

to 0.53 mm) fluid tip. (in days) ºC/ºF 30/86 20/68 10/50

immersion ............................ 3 6 10

CONVENTIONAL SPRAY - Industrial equipment such

as DeVilbiss MBC or JGA gun with 78 or 765 air cap NOTE: drying and curing times are dependent on air and steel

and "E" fluid tip and heavy mastic spring or Binks No. temperature, applied film thickness, ventilation and other

18 or 62 with a 66 x 63 PB nozzle setup. Separate air environmental conditions. Times are proportionally shorter at higher

temperature and longer at lower temperatures.

and fluid pressure regulators, mechanical pot agitator

and a moisture and oil trap in the main air supply line Thinner .................................. Amercoat 65/

are recommended. Amercoat 9HF

MIXER - Use power mixer powered by an air motor or Cleaner .................................. Amercoat 12

an explosion proof electric motor.

Application Data Summary

Like all high performance coatings, Amercoat 56E

must be applied as recommended to obtain the

maximum protection for which this coating is

formulated. To obtain the maximum performance for

which Amercoat 56E is formulated, strict adherence

to all application instructions, precautions, conditions

and limitations is necessary. If conditions exist that

are not within the requirements or limitations

described, consult your Ameron representative.

Page 2 of 4 Revision date: 24-03-2006

Amercoat 56E

Application Procedure

Amercoat 56E is packaged in the proper mixing Shipping Data

proportions of resin and cure. Packaging

resin: 16 l in 20 l can resin .................................... 16 l in 20 l can

cure: 4 l in 5 l can cure ..................................... 4 l in 5 l can

1. Flush equipment with Amercoat 12 before use. Shipping weight

2. Stir resin (in the larger container) to an even resin .................................... approx. 25 kg

consistency with a power mixer. cure .................................... approx. 7 kg

3. Add cure to resin solution, and continue stirring for Shelf life ................................. 1 year from shipment date when

5 minutes. NOTE: Since the potlife is limited and stored indoors in unopened,

shortened by high temperatures, do not mix more original containers at 5 to 40°C (41

material than will be used in 4 hours at 20°C/68ºF. to 104ºF).

4. Thin only if necessary for workability, add up to 10

vol. % of thinner.

5. Apply a wet coat even, parallel passes. Overlap

each pass 50% to avoid bare areas, pinholes or

holidays. When applying directly over inorganic

zincs at full thickness, bubbling may occur. A test

patch is recommended and if bubbling occurs,

apply a "mist coat". Consult your Ameron

representative for further information.

6. Double coat all welds, rough spots, sharp edges

and corners, rivets, bolts, etc.

7. Application at 217 µm wet film thickness will

normally provide 150 µm dry film.

8. Check thickness of dry coating with a non-

destructive dry film thickness gauge, such as

Mikrotest or Elcometer. If less than specified

thickness, apply additional material as needed.

9. Small damaged or bare areas and random

pinholes or holidays can be touched up by brush.

Repair larger areas by spray.

10.In confined areas ventilate with clean air during

application and drying until all solvents are

removed. Temperature and humidity of ventilating

air must be such that moisture condensation will

not form on surface.

# For conventional spray, use adequate air pressure

and volume to ensure proper atomization.

# Normal recommended dry film thickness is 75 to

150 µm. However, if greater thickness is applied in

local areas because of overlapping, no runs or

sags will normally occur at a dry film thickness up

to 200 µm. Total dry film thickness must not

exceed 400 µm.

11.Clean all equipment with Amercoat 12 immediately

after use or at least after each working day or shift.

When left in spray equipment, Amercoat 56E will

cure and cause clogging.

Page 3 of 4 Revision date: 24-03-2006

Amercoat 56E

Caution Any recommendations or suggestion relating to the use of

This product is flammable. Keep away from heat and open the products made by Ameron, whether in its technical

flame. Keep container closed. Use with adequate literature, or response to specific enquiry, or otherwise, is

ventilation. Avoid prolonged and repeated contact with skin. based on data believed to be reliable; however, the

If used in confined areas, observe the following precautions products and information are intended for use by Buyer’s

to prevent hazards of fire or explosion or damage to health: having requisite skill and know-how in the industry, and

1. circulate adequate fresh air continuously during therefore it is Buyer to satisfy itself of the suitability of the

application and drying; products for its own particular use and it shall be deemed

2. use fresh air masks and explosion proof equipment; that Buyer has done so, as its sole discretion and risk.

3. prohibit all flames, sparks, welding and smoking. Variation in environment, changes in procedures of use, or

Do not empty into drains. Take precautionary measures extrapolation of data may cause unsatisfactory results.

against static discharges. For specific information on

hazardous ingredients, required ventilation, possible

consequences of contact and safety measures see Safety Limitation of Liability

Data Sheet. Ameron’s liability on any claim of any kind, including claims

based upon Ameron’s negligence or strict liability, for any

loss or damage arising out of, connected with, or resulting

Safety from the use of the products, shall in no case exceed the

Since improper use and handling can be hazardous to purchase price allocable to the products or part thereof

health and cause of fire or explosion, safety precautions which give rise to the claim.

included with Product Data/Application Instruction and In no event shall Ameron be liable for consequential or

Material Safety Data Sheet must be observed during all incidental damages.

storage, handling, use and drying periods.

Due to Ameron’s policy of continuous product improvement,

the information contained in this Product Data/Application

Warranty Instructions sheet is subject to change without notice. It is

Ameron warrants its products to be free from defects in the Buyer’s responsibility to check that this issue is current

material and workmanship. Ameron’s sole obligations and prior to using the product. For the most up-to-date Product

Buyer’s exclusive remedy in connection with the products Data/Application Instructions always refer to the Ameron

shall be limited, at Ameron’s option, to either replacement of Performance Coatings & Finishes website at

products not conforming this warranty or credit to Buyer’s www.ameroncoatings.com

account in the invoiced amount of the non-conforming

products. Any claim under this warranty must be made by To avoid any confusion that may arise through translation

Buyer to Ameron in writing within five (5) days of Buyer’s into other languages, the English version of the Product

discovery of the claimed defect, but in no event later than Data/Application Instructions will be the governing literature

the expiration of the applicable shelf life, or one year from and must be referred to in case of deviations with product

the delivery date, whichever is earlier. Buyer’s failure to literature in other languages.

notify Ameron of such non-conformance as required herein

shall bar Buyer from recovery under this warranty.

Condition of Sale

All our transactions are subject to our Terms and Conditions

Ameron makes no other warranties concerning the of Sale.

product. No other warranties, whether express,

implied or statutory, such as warranties of

merchantability or fitness particular purpose, shall

apply. In no event shall Ameron be liable for

consequential or incidental damages.

Performance Coatings & Finishes

Ameron B.V. Ameron International Corporation Ameron (Australia) Pty Ltd. Ameron (New Zealand) Ltd.

Tel +(31) 345 587 587 Tel +(1) 678 393 0653 Tel +(61) 2 9421 8000 Tel +(64) 9 573 1620

www.ameron-bv.com www.ameroncoatings.com www.ameron.com.au www.ameron.co.nz

Page 4 of 4 Revision date: 24-03-2006

You might also like

- Amercoat 68 BSDocument4 pagesAmercoat 68 BSStephen Francis BothelloNo ratings yet

- Dimecote 9 Inorganic Zinc Silicate CoatingDocument4 pagesDimecote 9 Inorganic Zinc Silicate Coatingabdulgafoor54No ratings yet

- Amercoat 4801 Glass Flake Vinyl EsterDocument4 pagesAmercoat 4801 Glass Flake Vinyl Esterilyasmd7No ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- PN450X PDSDocument4 pagesPN450X PDSPeshteenNo ratings yet

- Amercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsDocument4 pagesAmercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsAchraf BoudayaNo ratings yet

- PN78HBCDocument4 pagesPN78HBCLassadNo ratings yet

- Amercoat 253Document4 pagesAmercoat 253Sherif AbdelhameedNo ratings yet

- Amercoat 450E: Product Data/ Application InstructionsDocument4 pagesAmercoat 450E: Product Data/ Application Instructions전상문No ratings yet

- Amercoat 878: Physical DataDocument2 pagesAmercoat 878: Physical Dataabdulgafoor54No ratings yet

- Nu-Klad 114A: Epoxy Filler Compound Product Data/ Application InstructionsDocument4 pagesNu-Klad 114A: Epoxy Filler Compound Product Data/ Application InstructionsCad AutocadNo ratings yet

- 0400GF Amerlock 400 GF PDS PDFDocument4 pages0400GF Amerlock 400 GF PDS PDFRenny DevassyNo ratings yet

- 0400GF Amerlock 400 GF PDSDocument4 pages0400GF Amerlock 400 GF PDSRenny DevassyNo ratings yet

- High-performance epoxy coating for steel, concrete & moreDocument4 pagesHigh-performance epoxy coating for steel, concrete & moreSherif AbdelhameedNo ratings yet

- D 977 - 98 Rdk3ny1sruqDocument4 pagesD 977 - 98 Rdk3ny1sruqRufo CascoNo ratings yet

- Amercoat 450S: Physical DataDocument2 pagesAmercoat 450S: Physical DataKhaled bouhlelNo ratings yet

- DS385Document4 pagesDS385gabriel habibNo ratings yet

- Amerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsDocument4 pagesAmerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsTony KhouryNo ratings yet

- MMC Manual MMC Flexi-Dip D-2401Document53 pagesMMC Manual MMC Flexi-Dip D-2401BigBaby Julian100% (1)

- SP 8888 PDFDocument6 pagesSP 8888 PDFMohammad ShamimNo ratings yet

- Fuel Cell BrochureDocument8 pagesFuel Cell BrochureImam SaputraNo ratings yet

- 3M Scotchkote - Custom Coating GuideDocument16 pages3M Scotchkote - Custom Coating GuideUgoRibeiroNo ratings yet

- Amercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsDocument4 pagesAmercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsTony KhouryNo ratings yet

- Amerlock 400CDocument4 pagesAmerlock 400CLalit Bom MallaNo ratings yet

- Amercoat: Amerlock 400AL/AL WNDocument4 pagesAmercoat: Amerlock 400AL/AL WNCad AutocadNo ratings yet

- SIROCCO™ Synthetic Compressor Oil Available atDocument2 pagesSIROCCO™ Synthetic Compressor Oil Available atBruce WappmanNo ratings yet

- Amercoat 56E: Polyamide Epoxy Product Data/ Application InstructionsDocument4 pagesAmercoat 56E: Polyamide Epoxy Product Data/ Application InstructionsTony KhouryNo ratings yet

- Poxeecote-D: High - Build Epoxy CoatingDocument2 pagesPoxeecote-D: High - Build Epoxy CoatingSibgathullahNo ratings yet

- Hy GardDocument2 pagesHy GardGustavo GonzalezNo ratings yet

- Ge Desalination PlantDocument2 pagesGe Desalination PlantMugesh100% (1)

- Marine PDFDocument578 pagesMarine PDFNizar BouchaalaNo ratings yet

- Amercoat 450SDocument4 pagesAmercoat 450SCad AutocadNo ratings yet

- Tib A004Document32 pagesTib A004Pranab BhattacharyaNo ratings yet

- Amercoat 878 HSDocument4 pagesAmercoat 878 HSMario KoričanNo ratings yet

- Amerlock 400gfaDocument4 pagesAmerlock 400gfaKhaled bouhlelNo ratings yet

- LUBRICACIONDocument6 pagesLUBRICACIONOrlando LaraNo ratings yet

- Surface Treatment ProcedureDocument5 pagesSurface Treatment Proceduredeepan85No ratings yet

- Engineering CatalogDocument70 pagesEngineering CatalogFihawangoNo ratings yet

- Ai1-1e 004Document20 pagesAi1-1e 004VikramNo ratings yet

- Stonclad GR Product DataDocument2 pagesStonclad GR Product DataAnonymous aii1ilNo ratings yet

- PN450XDocument4 pagesPN450XOmer ChaudhryNo ratings yet

- Astm D 3276 PDFDocument62 pagesAstm D 3276 PDFJose Luis CT100% (3)

- Product Data Sheet SP-8888Document7 pagesProduct Data Sheet SP-8888pablo gonzalezNo ratings yet

- Sterilmatic: Digital Electric Sterilizer Installation - Operation - MaintenanceDocument21 pagesSterilmatic: Digital Electric Sterilizer Installation - Operation - MaintenanceNoel GarciaNo ratings yet

- Catalog 2014Document92 pagesCatalog 2014nicolaeiliescuNo ratings yet

- Ameron PN220GDocument4 pagesAmeron PN220GLalit Bom MallaNo ratings yet

- 112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFDocument2 pages112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFFernando VittoNo ratings yet

- High Solids Glassflake Epoxy Coating Application GuideDocument4 pagesHigh Solids Glassflake Epoxy Coating Application GuideSherif AbdelhameedNo ratings yet

- 80L CylinderDocument2 pages80L CylinderHaty ATie67% (3)

- Amercoat 400AL PDFDocument4 pagesAmercoat 400AL PDFLalit Bom MallaNo ratings yet

- Amercoat 400C High Solids Epoxy CoatingDocument4 pagesAmercoat 400C High Solids Epoxy CoatingCad AutocadNo ratings yet

- ASTM D1856 092015 Aug 2019Document4 pagesASTM D1856 092015 Aug 2019karenmerino94No ratings yet

- AMSOIL OE 15W-40 Synthetic Diesel OilDocument2 pagesAMSOIL OE 15W-40 Synthetic Diesel OilamsoildealerNo ratings yet

- Flexible Adhesive For Performance Assembly: 1.1. ProcessingDocument4 pagesFlexible Adhesive For Performance Assembly: 1.1. ProcessingjpolancosNo ratings yet

- Hy Gard DKE7358 Sep02Document2 pagesHy Gard DKE7358 Sep02Jocelyn Milla MoralesNo ratings yet

- Aeration Diffusers JaegerDocument12 pagesAeration Diffusers JaegermariuspiNo ratings yet

- P8 WildenDocument32 pagesP8 WildenWalter LrNo ratings yet

- Ultem BrochureDocument41 pagesUltem BrochureinfodrumandbassmentNo ratings yet

- GE 2020 EDR Systems: Electrodialysis Reversal TechnologyDocument3 pagesGE 2020 EDR Systems: Electrodialysis Reversal TechnologyEzequiel García PalomoNo ratings yet

- Complete Branch List 16 6 2020Document22 pagesComplete Branch List 16 6 2020Muhammad MustahsinNo ratings yet

- Integrated Computer Vision and Soft Computing System For Classifying The Pilling Resistance of Knitted FabricsDocument7 pagesIntegrated Computer Vision and Soft Computing System For Classifying The Pilling Resistance of Knitted FabricsMuhammad MustahsinNo ratings yet

- Comparison of Batch To Batch Shade Variation Considering Parameters in Knit DyeingDocument19 pagesComparison of Batch To Batch Shade Variation Considering Parameters in Knit DyeingMuhammad MustahsinNo ratings yet

- 21a Pallet Load Testing To en ISO 8611 PDFDocument1 page21a Pallet Load Testing To en ISO 8611 PDFMansdrainNo ratings yet

- Controls Catalogo General 2015Document639 pagesControls Catalogo General 2015JohnnyMiranda100% (2)

- How to ensure social distancing during COVID-19Document1 pageHow to ensure social distancing during COVID-19Muhammad MustahsinNo ratings yet

- Processing of Man-Made Fibres and Blended Textiles: BlendingDocument23 pagesProcessing of Man-Made Fibres and Blended Textiles: BlendinghawNo ratings yet

- (23000929 - Autex Research Journal) Liquid Moisture Transportation Properties of Functional Underwears - Part 1Document7 pages(23000929 - Autex Research Journal) Liquid Moisture Transportation Properties of Functional Underwears - Part 1Muhammad MustahsinNo ratings yet

- (TGX) Downloaded From Torrentgalaxy - ToDocument1 page(TGX) Downloaded From Torrentgalaxy - Topavan kurapatiNo ratings yet

- Dye ClassificationDocument5 pagesDye ClassificationdivyakaushalNo ratings yet

- Avoid Fake LOKiHD Torrents - Check Site for Real TorrentsDocument1 pageAvoid Fake LOKiHD Torrents - Check Site for Real TorrentsMuhammad MustahsinNo ratings yet

- Keyword Planner: Selling and Marketing Products On AmazonDocument2 pagesKeyword Planner: Selling and Marketing Products On AmazonMuhammad Mustahsin100% (1)

- Analysis The Influenced of Plain and Twill StructuDocument7 pagesAnalysis The Influenced of Plain and Twill StructuMuhammad MustahsinNo ratings yet

- Eco-Friendly Dyeing of Cotton Fabric With Vat Dyes: Journal of Advancement in Engineering and TechnologyDocument4 pagesEco-Friendly Dyeing of Cotton Fabric With Vat Dyes: Journal of Advancement in Engineering and TechnologyMuhammad MustahsinNo ratings yet

- 104413fire Extinguisher CabinetsDFMmetricizedversionDocument9 pages104413fire Extinguisher CabinetsDFMmetricizedversionReza KhajeNo ratings yet

- Peoples, Nature and Environments - Learning To Live TogetherDocument325 pagesPeoples, Nature and Environments - Learning To Live TogetherMuhammad MustahsinNo ratings yet

- Inspecting Fire ExtinguishersDocument3 pagesInspecting Fire ExtinguisherssyooloveNo ratings yet

- Release Crash Info PrevDocument1 pageRelease Crash Info PrevMuhammad MustahsinNo ratings yet

- Indian Timber ManualDocument84 pagesIndian Timber Manualtoyota952No ratings yet

- Energies: Properties of Gasoline Stored in Various ContainersDocument9 pagesEnergies: Properties of Gasoline Stored in Various ContainersLegendary SouvikNo ratings yet

- Release Crash InfoDocument1 pageRelease Crash InfoMuhammad MustahsinNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationMuhammad MustahsinNo ratings yet

- Integrated Computer Vision and Soft Computing System For Classifying The Pilling Resistance of Knitted FabricsDocument7 pagesIntegrated Computer Vision and Soft Computing System For Classifying The Pilling Resistance of Knitted FabricsMuhammad MustahsinNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationMuhammad MustahsinNo ratings yet

- Technical Information - KeruingDocument3 pagesTechnical Information - KeruingMuhammad MustahsinNo ratings yet

- Integrated Computer Vision and Soft Computing System For Classifying The Pilling Resistance of Knitted FabricsDocument7 pagesIntegrated Computer Vision and Soft Computing System For Classifying The Pilling Resistance of Knitted FabricsMuhammad MustahsinNo ratings yet

- Technical Information - KeruingDocument3 pagesTechnical Information - KeruingMuhammad MustahsinNo ratings yet

- Evaluating The Bacterial Filtration Efficiency (BFE) of Medical Face Mask Materials, Using A Biological Aerosol ofDocument5 pagesEvaluating The Bacterial Filtration Efficiency (BFE) of Medical Face Mask Materials, Using A Biological Aerosol ofSuryateja Mergu100% (1)

- Resistance of Medical Face Masks To Penetration by Synthetic Blood (Horizontal Projection of Fixed Volume at A Known Velocity)Document21 pagesResistance of Medical Face Masks To Penetration by Synthetic Blood (Horizontal Projection of Fixed Volume at A Known Velocity)Suryateja MerguNo ratings yet

- PDIC Law Additional NotesDocument6 pagesPDIC Law Additional NotesBay Ariel Sto TomasNo ratings yet

- Marques v. Far East BankDocument3 pagesMarques v. Far East Bankmiles1280100% (1)

- Charecter JournalDocument3 pagesCharecter Journalapi-282188060No ratings yet

- Pronunciation Extra: Pre-Intermediate Unit 10Document1 pagePronunciation Extra: Pre-Intermediate Unit 10olhaNo ratings yet

- Civil Service Commission denies benefits under RA 6683Document5 pagesCivil Service Commission denies benefits under RA 6683Ariza ValenciaNo ratings yet

- Pro-choice or pro-life? The case for women's rights and rape victimsDocument2 pagesPro-choice or pro-life? The case for women's rights and rape victimsTreseaNo ratings yet

- 8 Financial Literacy Lesson1Document6 pages8 Financial Literacy Lesson1hlmd.blogNo ratings yet

- The CSS Syllabus: A Blueprint For Change (By: Abrahim Shah - 3rd in CSS 2018)Document3 pagesThe CSS Syllabus: A Blueprint For Change (By: Abrahim Shah - 3rd in CSS 2018)Taimoor AhmadNo ratings yet

- Accounting For Construction ContractsDocument8 pagesAccounting For Construction ContractsSantu DuttaNo ratings yet

- SHS LESSON 6 Ownership and OrganizationDocument9 pagesSHS LESSON 6 Ownership and OrganizationPaul AnteNo ratings yet

- T B L J: HE Anking AW OurnalDocument9 pagesT B L J: HE Anking AW OurnalsamrajcseNo ratings yet

- Spare Part List: Breaker TE 705 120V USADocument7 pagesSpare Part List: Breaker TE 705 120V USAJoseLuisCarrilloMenaNo ratings yet

- Appeal Against Conviction for MurderDocument24 pagesAppeal Against Conviction for MurderMir Ishrat NabiNo ratings yet

- Conduct, Efficiency, Discipline Rules for Civil ServantsDocument259 pagesConduct, Efficiency, Discipline Rules for Civil ServantsMansoor Ul HassanNo ratings yet

- Philips HeartStart MRXDocument1 pagePhilips HeartStart MRXPaulinaNo ratings yet

- Industrial Worker - Issue #1760, November 2013Document16 pagesIndustrial Worker - Issue #1760, November 2013Industrial WorkerNo ratings yet

- PDFDocument9 pagesPDFRajendra Patil26% (31)

- The Union Legislature Q-AnsDocument2 pagesThe Union Legislature Q-Ansconnect.amairaNo ratings yet

- What Is FCCB?: Foreign Currency Convertible Bond Is A Type of ConvertibleDocument8 pagesWhat Is FCCB?: Foreign Currency Convertible Bond Is A Type of ConvertiblesbghargeNo ratings yet

- Term Loan ProcedureDocument5 pagesTerm Loan ProcedureHardik Sharma100% (1)

- Theory of Law and Economics Law and EconomicsDocument5 pagesTheory of Law and Economics Law and EconomicsMuhammad ZikriaNo ratings yet

- 2ndlastmeritlist PDFDocument8 pages2ndlastmeritlist PDFMahnoor AsimNo ratings yet

- MRRJ Izns"K LJDKJ Esjb: Øe La ( K% Izi LaDocument1 pageMRRJ Izns"K LJDKJ Esjb: Øe La ( K% Izi LaBharat SolutionsNo ratings yet

- Subsea Connectivity Leaders GatherDocument7 pagesSubsea Connectivity Leaders GatherAnonymous TVdKmkNo ratings yet

- Vanguard 18hp - Engine # 3564470373F1Document61 pagesVanguard 18hp - Engine # 3564470373F1Matias Alfredo Contreras KöbrichNo ratings yet

- Paul Gilbert Sixes Inspired Shred GuitarDocument2 pagesPaul Gilbert Sixes Inspired Shred GuitarbinbinNo ratings yet

- De Lima vs. Guerrero (843 SCRA 1, 20 Oct. 2017)Document101 pagesDe Lima vs. Guerrero (843 SCRA 1, 20 Oct. 2017)Eugene DayanNo ratings yet

- Shell Price Change and Comparision q1 2017Document3 pagesShell Price Change and Comparision q1 2017rishiNo ratings yet

- Elastic Deformation PresentationDocument13 pagesElastic Deformation PresentationHiba AbeerNo ratings yet

- Latin Words N MaximsDocument38 pagesLatin Words N MaximsJoly_M_Hubilla_2759No ratings yet