Professional Documents

Culture Documents

Hensoldt - A Breakthrough in Rapid Prototyping For Electronics

Uploaded by

papa abdoul sow0 ratings0% found this document useful (0 votes)

15 views2 pagesOriginal Title

Hensoldt-Case_2020

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views2 pagesHensoldt - A Breakthrough in Rapid Prototyping For Electronics

Uploaded by

papa abdoul sowCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Electrifying Additive Manufacturing®

CASE STUDY: DEFENSE

HENSOLDT — A BREAKTHROUGH IN RAPID

PROTOTYPING FOR ELECTRONICS

Significant time reduction by use of AME-Electronics prototyping

CLIENT PROFILE CHALLENGE

HENSOLDT is a pioneer of technology and innovation Over the years, HENSOLDT had developed a robust in-

in the field of defense and security electronics. Based house capability to produce complex PCBs. Their main

in Taufkirchen near Munich, the company is a German challenge was, that the realization of a first prototype

Champion with strategic leadership positions in the field took several months until a proof of concept with a ful-

of sensor solutions for defense and non-defense appli- ly functional PCB could be tested. Working with clients

cations. HENSOLDT develops new products to combat in the defense arena, HENSOLDT often faced urgent

a range of threats based on innovative approaches to demands to provide quick turnaround, so they need-

data management, robotics and cyber security. With ed a way to reduce prototyping time. However, while

approximately 5,500 employees, HENSOLDT generated a two-sided population of components would enable

revenues of 1.14 billion euros in 2019. such a reduction, no one had yet been able to offer a

3D printed board that could bear the soldering process

www.hensoldt.net necessary for two sides.

In 2019, HENSOLDT approached Nano Dimension to

BACKGROUND explore solutions to expedite the prototyping process.

HENSOLDT – a true pioneer and early adopter of dis-

ruptive technologies – has always immensely believed

in the potential of additive manufacturing of electronics

(AME). This made them a natural fit with Nano Dimen-

sion, becoming one of the first customers to purchase

the DragonFly system in 2016.

2020 © Nano Dimension. All rights reserved.

www.nano-di.com | contact@nano-di.com | Nano Dimension | @3Dpcb

Electrifying Additive Manufacturing®

SOLUTION

Nano Dimension provided HENSOLDT with their n ewly

developed combination of dielectric polymer ink and

conductive ink. This combination enables the creation

of complex structures containing both blind and bur-

ied vias. It also enables the creation of a higher density

board in a smaller space and lays the groundwork for

digital inventory and on-demand production of individual

parts.

Using this unique groundbreaking process, HENSOLDT

was able to assemble the world-wide-first 10-layer

printed circuit board (PCB) to carry high-performance

electronic structures soldered to both outer sides. More-

over, the board was robust enough to withstand the as- “Military sensor solutions require per-

sembly process and to pass every electrical test with formance and reliability levels far above

flying colors. those of commercial components. To have

high-density components quickly avail-

The result of using this highly agile and individualized able with reduced effort by means of 3D

engineering methodology was that HENSOLDT was printing gives us a competitive edge in the

able to reduce the prototyping time of its new electronic development process of such high-end

circuitry from months to several days; an extraordinary electronic systems.”

achievement and truly a game-changer for the compa-

ny, as it reduced not only the time but also the cost of Thomas Müller,

the development process. Furthermore, by giving HEN- CEO of HENSOLDT

SOLDT a verified and approved design before they be-

gan production, ultimately led to a higher quality final

Rapid Prototyping of complex PCB and HiPEDs

product.

WEEKS

Conventional Sourcing

DESIGN ECAD PROTOTYPING TESTING TOOLING PRODUCTION

Accelerate Product Developement

and reduce Time-To-Market (TTM)

In-House Rapid Prototyping with

Nano Dimension AME Systems

DESIGN ECAD PROTOTYPING TESTING TOOLING PRODUCTION

Nano Dimension AME System

DAYS

Rapid Prototyping

2020 © Nano Dimension. All rights reserved.

www.nano-di.com | contact@nano-di.com | Nano Dimension | @3Dpcb

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Agency DraftDocument3 pagesAgency DraftMuskan TandonNo ratings yet

- Construction Equipment SelectionDocument38 pagesConstruction Equipment SelectionPrasannaVenkatesan100% (1)

- Pearly Beach Trust V Registrar of Deeds 1990 (4) Sa 614 (C)Document3 pagesPearly Beach Trust V Registrar of Deeds 1990 (4) Sa 614 (C)Banele BaneNo ratings yet

- Capacity Markets PresentationDocument34 pagesCapacity Markets PresentationEsinam AdukpoNo ratings yet

- Activity Sheet In: Business FinanceDocument8 pagesActivity Sheet In: Business FinanceCatherine Larce100% (1)

- Fibo Warisan 2nd Candle New v6.0Document75 pagesFibo Warisan 2nd Candle New v6.0Muhammad ZeeharzNo ratings yet

- BG, SBLC, Rwa LeaseDocument23 pagesBG, SBLC, Rwa LeaseJosephNo ratings yet

- SSRN Id2938546Document16 pagesSSRN Id2938546Hesti PermatasariNo ratings yet

- Urban Transportation Planning: Issues & ProcessDocument18 pagesUrban Transportation Planning: Issues & ProcessJigarKotadiyaNo ratings yet

- PriyaDocument24 pagesPriyaAnil RajputNo ratings yet

- Geo ToursDocument22 pagesGeo ToursOtlaadisa TauNo ratings yet

- Final QuestionnaireDocument5 pagesFinal QuestionnaireSharlee DekateNo ratings yet

- RAP Demofest 2022 Letter of InvitationDocument2 pagesRAP Demofest 2022 Letter of InvitationRomss SyNo ratings yet

- MATH40082 (Computational Finance) Assignment No. 2: Advanced MethodsDocument6 pagesMATH40082 (Computational Finance) Assignment No. 2: Advanced Methodscracking khalifNo ratings yet

- Ebix Singapore Private Limited and Ors Vs CommitteSC20211309211802221COM438457Document103 pagesEbix Singapore Private Limited and Ors Vs CommitteSC20211309211802221COM438457AYUSHI GOYAL 1750443No ratings yet

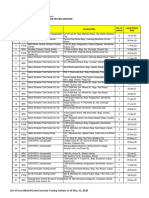

- List of Accredited PETCs As of May 31, 2020Document5 pagesList of Accredited PETCs As of May 31, 2020Butch EnalpeNo ratings yet

- Mis Essentials 4th Edition Kroenke Test BankDocument26 pagesMis Essentials 4th Edition Kroenke Test BankRebeccaPottsyxdj100% (50)

- Accounting Principles - AllDocument104 pagesAccounting Principles - AllAHMED100% (1)

- Application Form Account Opening 24011715551501951901Document5 pagesApplication Form Account Opening 24011715551501951901sri.rajaboina1983No ratings yet

- Analisa Rasio Keuangan Terhadap Kinerja Bank Umum Di IndonesiaDocument9 pagesAnalisa Rasio Keuangan Terhadap Kinerja Bank Umum Di IndonesiaAni SafiraNo ratings yet

- Apostila UK: Personal InformationDocument1 pageApostila UK: Personal InformationElena GrigoritaNo ratings yet

- Bureau of Internal Revenue (Bir) BIR Is Under The Executive Supervision and Control of The Department of FinanceDocument1 pageBureau of Internal Revenue (Bir) BIR Is Under The Executive Supervision and Control of The Department of FinanceAlexandria DiegoNo ratings yet

- May 2020 Financial Accounting Paper 1.1Document18 pagesMay 2020 Financial Accounting Paper 1.1MahediNo ratings yet

- Nomor 3 Dan 4 EquityDocument1 pageNomor 3 Dan 4 EquityYusuf RaharjaNo ratings yet

- Degree Program: BSAF (6) Course: Financial Statements Analysis Total Marks: 30 Midterm Examination Time: 30m Instructions For The ExamDocument2 pagesDegree Program: BSAF (6) Course: Financial Statements Analysis Total Marks: 30 Midterm Examination Time: 30m Instructions For The ExamUsman BalochNo ratings yet

- Company Law - MDocument16 pagesCompany Law - MMayank SharmaNo ratings yet

- Oracle Product Lifecycle Management ENGDocument60 pagesOracle Product Lifecycle Management ENGRidwansyah HaryoNo ratings yet

- Working Capital Management Test 2014Document1 pageWorking Capital Management Test 2014daveferalNo ratings yet

- Sample Exercise - First Steps To Freedom WebDocument12 pagesSample Exercise - First Steps To Freedom WebPatrick PilapilNo ratings yet

- 91 Fla BJ19Document5 pages91 Fla BJ19Juanito de MontalbanNo ratings yet