Professional Documents

Culture Documents

DataSheet - 0782 Load Cell - en - 130801

Uploaded by

Minh HiếuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DataSheet - 0782 Load Cell - en - 130801

Uploaded by

Minh HiếuCopyright:

Available Formats

Globally Approved

0782 Load Cell

for Accuracy and Safety

Vehicle Weighing

Use the 0782 load cell in new truck,

railroad track and other heavy capacity

weighbridge applications or as a

replacement for cells in an old weigh-

bridge to enhance its performance. The

0782 is ideally suited to this application.

Tank Weighing

The capacity range from 20t to 300t

allows the weighing of big tanks

and silos with ease. The stainless

steel design (20t–200t), hermetic

sealing and IP68 protection provides

the best reliability in tank weighing

applications.

GAGEMOUNT Module

The optional METTLER TOLEDO

GAGEMOUNT (20t–100t) weigh

module adds suspension, check-

ing and anti-tiping to your 0782

load cell and includes top and

bottom mounting plates to sim-

plify installation. Available in

nickel plated mild steel or stain-

less steel. 0782 High Capacity Load Cell

Every 0782 high capacity load cell features:

• OIML C3 and NTEP IIILM 10.000d approvals

(20t–100t)

• ATEX Zone1/2 and 21/22 approvals

• FM Class I,II,III Div 1 approvals

• Stainless steel (20t–200t)

• Hermetically sealed design

• IP68 protection class

The 0782 is approved for use in various applications

in Europe, Asia, America and almost everywhere else

in the world. If an approval is required, the 0782

probably already complies.

The 0782 load cell is even approved for hazardous

areas.

0782 Load Cell Specifications

Parameter unit of measure Specification

Model No. 0782

Rated Capacity (R.C.) t (klb, nominal) 20 (44) 30 (66) 50 (110) 100 (220) 200 (441) 300 (661)

Rated Output mV/V @R.C. 2 ± 0.1%

Zero load Output %R.C. ≤1

Combined Error 1) 2) %R.C. ≤ 0.018 ≤ 0.05 ≤ 0.06

Repeatability Error %A.L. 3) ≤ 0.01 ≤ 0.02

Creep, 30 minute %A.L. ≤ 0.0167 ≤ 0.03 ≤ 0.04

Min. Dead Load Output Return (DR), 30 min %A.L. ≤ 0.0167 ≤ 0.03 ≤ 0.04

Min. Dead load Output %R.C./°C (../°F) ≤ 0.002 (0.001)

Temperature Effect on

Sensitivity 2) %A.L./°C (../°F) ≤ 0.0009 (0.0005) ≤ 0.002 (0.001)

Compensated -10 ~ +40 (+14 ~ +104)

Temperature Range Operating °C (°F) -40 ~ +65 (-40 ~ +150)

Safe Storage -40 ~ +80 (-40 ~ +176)

OIML Cert. No. R60/2000-NL-01.04

European Cert. No. NMi TC5844

Class C3

nmax 3000

OIML / European

Y 6666 –

Approval 4)

PLC 0.7

Humidity Symbol none

Min. dead load kg (lb) 0 (0)

Z 3000

Number 01-004

Class III L M

NTEP Approval 4) nmax 10000 –

Vmin kg (lb) 1.4 (3.0) 2.1 (4.5) 3.5 (7.5) 7.0 (15.0)

Min. dead load kg (lb) 50 (100)

Number, cat. 2 KEMA 02ATEX1249 X

II 2 G Ex ib IIC T4 … T6

Rating

II 2 D Ex ibD 21 IP68 T60°C

Entity Parameters Ui=25V, Ii=600mA, Pi=0.57 - 1.25W, Ci=2.6 - 6nF, Li=10.25 - 30µH

ATEX Approval 4) Number, cat. 3 KEMA 06ATEX0122

II 3 G Ex nL IIC T6

Rating II 3 G Ex nA II T6

II 3 D Ex tD A22 IP 68 T60°C

Entity Parameters Ui = 25V, Ci 2.6 - 6nF, Li 10.25 - 30 µH

Number, USA 3013511

IS/I,II,III/1/ABCDEFG/T4

Rating

Factory Mutual NI/I,II,III/2/ABCDFG/T4

Approval 4) Vmax=20V, Imax=600mA, Pi=1.25W

Entity Parameters

Ci=4nF, Li=17.7µH Ci=6nF, Li=26.5µH

System Drawing No, USA 142730

Recommended 5 ~ 15

Excitation Voltage V AC/DC

Max. 20

Excitation 1160 ± 10 1160 ± 15

Terminal Resistance Ω

Output 1000 ± 3

Insulation Resistance @50VDC MΩ > 5000

Breakdown Voltage V AC >500

Spring Element stainless steel 4340

Enclosure stainless steel

Material

Cable entry fitting stainless steel

Cable PVC

Type welded

Protection IP Rating IP 68

NEMA Rating NEMA 6/6P

Safe 125

Load Limit %R.C.

Ultimate 300

Safe Dynamic Load %R.C. 70

Fatigue Life cycles @R.C. >1,000,000

Direction of Loading compression

Restoring Force 5) %A.L./mm (../in) 3) 0.8 (19) 2 (52) 1.6 (40) 2.5 (63)

Max Horizontal Travel 6) ± mm (in) 4 (0.16) 5 (0.20) 6 (0.24)

Deflection @ R.C., nominal mm (in) 0.25 (0.010) 0.32 (0.013) 0.42 (0.017)

Weight, nominal kg (lb) 2.8 (6.2) 3 (6.6) 3.3 (7.3) 4.5 (9.9) 12.5 (27.6) 21.7 (48)

Length m (ft) 13 (42.5) 20 (66) 30 (98)

Cable

Diameter mm (in) 5.8 (0.23)

Barometric Pressure Effect on Zero Load Output kg/kPa (lb/in.Hg) 3 (6.6) 4.5 (9.9) 7.5 (16.5) 15 (33) 30 (66) 45 (99)

1)

Error due to the combined effect of non-linearity and hysteresis

2)

Typical values only. The sum of errors due to Combined Error and Temperature Effect on Sensitivity comply with the requirements of OIML R60 and NIST HB44.

3)

A.L. = Applied Load

4)

See certificate for complete information.

5)

% of Applied Load (A.L.) per mm (in) displacement of the top button relative to the bottom button.

6)

Maximum horizontal displacement of the top button relative to the bottom button.

7)

In process, consult factory.

2 METTLER TOLEDO Data Sheet 0782 Load Cells

©08/2013

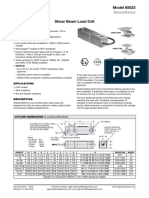

0782 Load Cell Dimensional Drawings mm [inch]

L

302 [11.90]

R (2x) 251 [9.88]

ØD1

H1

[1.58)

H

Ø40

H1

149 [5.87]

Ø26 [1.02]

H3

H2

H2

CL

CL CL

ØD1 ØD1

W ØD

ØD

300t only

Capacity Dimensions and Locations

D D1 H H1 H2 H3 L L1 R W

20–30t 76 37.8 150 112 19 75 33.5 50 160 96

[33–66 kIb] [2.99] [1.49] [5.91] [4.41] [0.75] [2.95] [1.40] [1.97] [6.30] [3.78]

50t 76 37.8 150 112 19 75 35.5 50 305 96

[110 kIb] [2.99] [1.49] [[5.91] [4.41] [0.75] [2.95] [1.40] [1.97] [12.0] [3.78]

100t 102 53.8 150 112 19 75 50.6 64 305 123

[220 kIb] [4.02] [2.12] [5.91] [4.41] [0.75] [2.95] [1.99] [2.52] [12.0] [4.84]

200t 158 80 195 145 25 93 75.25 93 400 180

[440 kIb] [6.22] [3.15] [7.68] [5.71] [0.98] [3.66] [2.96] [3.66] [5.75] [7.09]

300t 192 106 250 192 29 128 99.20 110 900 213

[660 kIb] [7.56] [4.17] [9.84] [7.56] [1.14] [5.04] [3.91] [4.33] [35.4] [8.39]

0782 Load Cell Receivers mm [inch] 20t–50t 0782 Load Cell Receivers mm [inch] 100t

See detail A See detail A 90.0 [3.54]

ø79.5 [ø3.13]

0-ring 0-ring

[1.38]

[1.57]

35.0

40.0

3]

3

4.

[ø

.0

10

51.0 [2.01]

ø1

150.2 157.3 150.2 157.3

[5.91] [6.19] [5.91] [6.19]

209.0 [8.23]

12.0

[0.47]

A A A

View from the assembly bottom

See detail A See detail A

[1.38]

35.0

Ø 76.2 Ø 76.2

[3.00] [3.00] ø80.0 [ø3.15] Assembly with receiver CP

Ø 69.85 Ø 69.85

Ø 3.2 [2.75]Ø 3.2 [2.75]

46.3 [0.12]

46.3 [0.12]

[1.82] [1.82]

25.4 min 25.4 min

Retain lower [1.00] [1.00]

receiver to

lower mounting

A Section A–Awith .500 DIA

plate Section A–A Detail A Detail A

ent roll pin

only item 2 or equivalent only item 2 Receiver mounting plate top &Receiver

bottom mounting plate top & bottom

METTLER TOLEDO Data Sheet 0782 Load Cells 3

©08/2013

0782 Load Cell Order Information

Description Item No.

Load Cell 0782 – 20t 71201708

Load Cell 0782 – 30t 71201709

Load Cell 0782 – 50t 71201710

Load Cell 0782 – 100t 71201711

Load Cell 0782 – 200t 71210093

Load Cell 0782 – 300t 71210169

Upper Receiver – up to 50t 61039191

Lower Receiver – up to 50t 61039190

0782 Bottom Gasket 68000443

Receiver Kit SS 0782 – 100t 72209873

Bolded entries are stocked

0782 Load Cell Cable Colours

Colour Function

Green + Excitation

Black – Excitation

White + Signal

Red – Signal

Yellow + Sense

Blue – Sense

Yellow (long) Shield

Full Connectivity

Our sensors and instruments are professional

communicators. METTLER TOLEDO supplies

you with various data communication inter-

faces that allow you to communicate with

your PLCs, MES or ERP systems.

Global Approvals

The 0782 is provided with all listed

approvals. No need to think about options

and additional charges. Simplifies the con-

duct of global business, order processing

and service-part stocking.

Weighing Electronics

METTLER TOLEDO offers a complete family of electronics from simple

Our extensive service network is among the best in the world and weighing to application solutions for filling, stock control, batching,

ensures maximum availability and service life of your product. formulation, counting, checkweighing.

Quality certificate ISO 9001

Environment certificate ISO14001

Subject to technical changes.

www.mt.com

Visit for more information

©08/2013 Mettler-Toledo AG

Printed in Switzerland MTSI 44099801

MarCom Industrial

You might also like

- For Accuracy and Safety: Globally ApprovedDocument4 pagesFor Accuracy and Safety: Globally Approvedjhudgson144No ratings yet

- For Accuracy and Safety: Globally ApprovedDocument4 pagesFor Accuracy and Safety: Globally ApprovedQuốc NguyễnNo ratings yet

- Model 355: Tedea-HuntleighDocument2 pagesModel 355: Tedea-HuntleighJuan Carlos BallinariNo ratings yet

- Liquid - Datasheet MTB en 0707Document4 pagesLiquid - Datasheet MTB en 0707Surya TanjayaNo ratings yet

- Model 355: Tedea-HuntleighDocument3 pagesModel 355: Tedea-HuntleighHonorio RiveraNo ratings yet

- sb8 Datasheet enDocument3 pagessb8 Datasheet ensrinivas raghavanNo ratings yet

- Datasheet Celda de Carga 0745ADocument6 pagesDatasheet Celda de Carga 0745ALuis IglesiasNo ratings yet

- Flintec SB8Document2 pagesFlintec SB8josueNo ratings yet

- ThamesSideIndia T34Document4 pagesThamesSideIndia T34Bulk WeighingNo ratings yet

- Product Information 1110g Load Cells CPR-MDocument2 pagesProduct Information 1110g Load Cells CPR-MmoftahNo ratings yet

- Type B8D Load Cell: Short DescriptionDocument4 pagesType B8D Load Cell: Short DescriptionLe TruongNo ratings yet

- SB8 Beam Load Cell: Product Description ApprovalsDocument3 pagesSB8 Beam Load Cell: Product Description ApprovalsAngga PratamaNo ratings yet

- A48-Rev7-GB RC3 Data SheetDocument2 pagesA48-Rev7-GB RC3 Data SheetFarit ArdiansyahNo ratings yet

- Flintec. SLB BrosurDocument2 pagesFlintec. SLB BrosurMuchamad Fajar NugrohoNo ratings yet

- SB8 Beam Load Cell: Product Description ApprovalsDocument3 pagesSB8 Beam Load Cell: Product Description ApprovalsPhilippe MeynardNo ratings yet

- MAR - DS - MT1241 - Load Cells - ENDocument4 pagesMAR - DS - MT1241 - Load Cells - ENRidho Prakoso Al FarisiNo ratings yet

- Platform Size 350x350 MM: Easy System IntegrationDocument4 pagesPlatform Size 350x350 MM: Easy System IntegrationHuy VũNo ratings yet

- Packaging Code: GRT31CR61H106KE01 - (1206, X5R, 10uf, DC50V) Reference SheetDocument28 pagesPackaging Code: GRT31CR61H106KE01 - (1206, X5R, 10uf, DC50V) Reference Sheetvax1No ratings yet

- Digital Load Cell  CPD - Pfister Waagen Bilanciai GMBHDocument3 pagesDigital Load Cell  CPD - Pfister Waagen Bilanciai GMBHAli FartashfarNo ratings yet

- For Accuracy and Safety: Globally ApprovedDocument6 pagesFor Accuracy and Safety: Globally ApprovedJairoHJNo ratings yet

- Type SBT Load Cell: Product Description Key FeaturesDocument2 pagesType SBT Load Cell: Product Description Key FeaturesKelly FosterNo ratings yet

- 8 - C1. Load Cell SpecificationDocument2 pages8 - C1. Load Cell SpecificationRisOne Aiiyankx AiiNo ratings yet

- ThamesSideIndia T12Document2 pagesThamesSideIndia T12Prabhavathi RamasamyNo ratings yet

- Model 65023: SensortronicsDocument3 pagesModel 65023: SensortronicsReinaldo Castillo RivasNo ratings yet

- Baykon br016 CompressionDocument2 pagesBaykon br016 CompressionGodfried SimonNo ratings yet

- Celula de CargaDocument2 pagesCelula de CargaDavid PaezNo ratings yet

- Safety Maintenance and Operating Instruction: SHOMAL Engineering & Manufacturing Co. (PIROOZ)Document9 pagesSafety Maintenance and Operating Instruction: SHOMAL Engineering & Manufacturing Co. (PIROOZ)shakouri1370_8902064No ratings yet

- Q50 Pancake Load Cell BrosurDocument2 pagesQ50 Pancake Load Cell BrosurHermantoro W. PradanaNo ratings yet

- Advance CertaDrive 38W 0.9A Panel LED Driver Datasheet CI038C090V042CNU1 (PAd-19010DS)Document8 pagesAdvance CertaDrive 38W 0.9A Panel LED Driver Datasheet CI038C090V042CNU1 (PAd-19010DS)Hugo MartinezNo ratings yet

- bk2 Datasheet enDocument3 pagesbk2 Datasheet enGustavo José BolsoniNo ratings yet

- Model 1022 Model 1022: Tedea-HuntleighDocument2 pagesModel 1022 Model 1022: Tedea-HuntleighAnggiet ZoaNo ratings yet

- SB6 Beam Load Cell: Product Description ApprovalsDocument3 pagesSB6 Beam Load Cell: Product Description ApprovalsPhilippe MeynardNo ratings yet

- C3000 SD Analog PTZ Camera StationDocument4 pagesC3000 SD Analog PTZ Camera StationArca MakmurNo ratings yet

- Datasheet BM14GDocument1 pageDatasheet BM14GShahryarNo ratings yet

- Pc12 Datasheet enDocument3 pagesPc12 Datasheet enGabriel RodríguezNo ratings yet

- H3G DatasheetDocument4 pagesH3G Datasheetfery jarimNo ratings yet

- Data Sheet SX18 @enDocument2 pagesData Sheet SX18 @enSatria GoNo ratings yet

- PTZ CameraDocument4 pagesPTZ CameraTrần MinhNo ratings yet

- Model 240 Model 240: Tedea-HuntleighDocument3 pagesModel 240 Model 240: Tedea-HuntleighJuan Carlos BallinariNo ratings yet

- Thames Side T85 Data Sheet 11.2017Document4 pagesThames Side T85 Data Sheet 11.2017Alaeldin AlhennawyNo ratings yet

- Datasheet: L6D Load Cell: SpecificationsDocument1 pageDatasheet: L6D Load Cell: SpecificationsEzequiel Victor HugoNo ratings yet

- MT1022Document2 pagesMT1022Cân điện tử Nguyễn MinhNo ratings yet

- sb14 Beam Datasheet en PDFDocument3 pagessb14 Beam Datasheet en PDFJosé TimanáNo ratings yet

- Avery Tronix Load Cell T302Document4 pagesAvery Tronix Load Cell T302Cardoso MalacaoNo ratings yet

- Tension Compression Load Cell Tension Compression Load Cell: Model 614Document3 pagesTension Compression Load Cell Tension Compression Load Cell: Model 614Juan Carlos BallinariNo ratings yet

- Load Cell, 500kg 3t, Shear Beam: SpecificationDocument2 pagesLoad Cell, 500kg 3t, Shear Beam: SpecificationPablito LPNo ratings yet

- q50 Compression Datasheet enDocument3 pagesq50 Compression Datasheet enBulk WeighingNo ratings yet

- CELDA DE CARGA Flintec SB4Document2 pagesCELDA DE CARGA Flintec SB4RodolfoNo ratings yet

- Ta2232 00 - en GBDocument3 pagesTa2232 00 - en GBعبد الله عبد الحيNo ratings yet

- Type H8C Load Cell: Short DescriptionDocument5 pagesType H8C Load Cell: Short DescriptionJunior ArroyoNo ratings yet

- SMFT2Document2 pagesSMFT2noureddineNo ratings yet

- Model 65023: SensortronicsDocument3 pagesModel 65023: SensortronicsCarlos CatañoNo ratings yet

- GOLDI - 72GN1 Monocrystalline Module (PERC) : Key FeaturesDocument1 pageGOLDI - 72GN1 Monocrystalline Module (PERC) : Key Featuresklp_kedarpNo ratings yet

- H3G DatasheetDocument4 pagesH3G DatasheetMaskur EfendiNo ratings yet

- Packaging Code: GRT32EC81C476KE13 - (1210, X6S:EIA, 47uf, DC16V) Reference SheetDocument30 pagesPackaging Code: GRT32EC81C476KE13 - (1210, X6S:EIA, 47uf, DC16V) Reference Sheetfebry alwan putraNo ratings yet

- Varistor 110vDocument3 pagesVaristor 110vWalter CalleNo ratings yet

- A91 - Rev5 - GB pc60 Data Sheet PDFDocument2 pagesA91 - Rev5 - GB pc60 Data Sheet PDFhdq64590No ratings yet

- TDC Certificate PDFDocument2 pagesTDC Certificate PDFAlaxmi NarayanNo ratings yet

- FTL enDocument2 pagesFTL enclaudiu.gheorghe5710No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Concept Note For The Conversion of 75 TPHDocument2 pagesConcept Note For The Conversion of 75 TPHMeera MishraNo ratings yet

- Stock Price Prediction Using LSTMDocument29 pagesStock Price Prediction Using LSTMKunal GargNo ratings yet

- Fixed Frequency, 99% Duty Cycle Peak Current Mode Notebook System Power ControllerDocument44 pagesFixed Frequency, 99% Duty Cycle Peak Current Mode Notebook System Power ControllerAualasNo ratings yet

- Lab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Document4 pagesLab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Penelope MeloNo ratings yet

- Topic: Partnership: Do Not Distribute - Highly Confidential 1Document7 pagesTopic: Partnership: Do Not Distribute - Highly Confidential 1Tharun NaniNo ratings yet

- Rules, Scripts and BeanshellDocument7 pagesRules, Scripts and BeanshelltgudyktzxNo ratings yet

- Reflection and ShearDocument7 pagesReflection and ShearsamNo ratings yet

- PDPP - Presentation.3.Concurrent. Engineering - January.2021Document17 pagesPDPP - Presentation.3.Concurrent. Engineering - January.2021Ashish KumarNo ratings yet

- Chapter Test 2nd Quarter.Document5 pagesChapter Test 2nd Quarter.Roziel MontalbanNo ratings yet

- Walking Bass Line Theory BasicsDocument11 pagesWalking Bass Line Theory BasicsKikemol Lv O100% (10)

- Digital Signal ProcessingDocument6 pagesDigital Signal Processing5adjcourt allagaddaNo ratings yet

- An Ecient Uniform-Cost Normalized Edit Distance AlgorithmDocument12 pagesAn Ecient Uniform-Cost Normalized Edit Distance Algorithmanon-75650No ratings yet

- Laplace TransformDocument2 pagesLaplace TransformumangNo ratings yet

- Septic Tank - Components and Design of Septic Tank Based On PopulationDocument7 pagesSeptic Tank - Components and Design of Septic Tank Based On Populationمنير أحمدNo ratings yet

- Speech Enhancement Using Minimum Mean-Square Error Short-Time Spectral Amplitude EstimatorDocument13 pagesSpeech Enhancement Using Minimum Mean-Square Error Short-Time Spectral Amplitude EstimatorwittyofficerNo ratings yet

- ABB MNS IAC Additional Test ReportDocument14 pagesABB MNS IAC Additional Test ReportSheik100% (1)

- Exercises Conditional SentencesDocument2 pagesExercises Conditional SentencesDivine GuancoNo ratings yet

- Practical 3 CGR PDFDocument4 pagesPractical 3 CGR PDFKalpesh PiloreNo ratings yet

- 201 28-NM1 1Document186 pages201 28-NM1 1rajabalihvacNo ratings yet

- Contoh Pembentangan Poster Di ConferenceDocument1 pageContoh Pembentangan Poster Di ConferenceIka 1521No ratings yet

- CFR 2011 Title49 Vol3 SubtitleBDocument626 pagesCFR 2011 Title49 Vol3 SubtitleBmgmqroNo ratings yet

- Transportation ProblemDocument3 pagesTransportation ProblemSalilNo ratings yet

- DREHMO Matic-C ENDocument36 pagesDREHMO Matic-C ENsimbamikeNo ratings yet

- Corrosion Performance of Mild Steel and GalvanizedDocument18 pagesCorrosion Performance of Mild Steel and GalvanizedNarasimha DvlNo ratings yet

- C1 Questions Part 4Document34 pagesC1 Questions Part 4Mohammad KhanNo ratings yet

- TP 3017D Taman Angkasa Nuri - V01Document25 pagesTP 3017D Taman Angkasa Nuri - V01Najwa AzmanNo ratings yet

- Alp - Sizer InfoDocument13 pagesAlp - Sizer InfoLê Quang DuyNo ratings yet

- Heat & Mass Transfer PDFDocument2 pagesHeat & Mass Transfer PDFabyabraham_nytro50% (6)

- Maquinaria Forestal..Document14 pagesMaquinaria Forestal..Juan G ContrerasNo ratings yet

- Ericsson Command LineDocument39 pagesEricsson Command LinejulescarrelNo ratings yet