Professional Documents

Culture Documents

Pressure Reducing Valve, Direct Operated, Type ZDR 6 D

Pressure Reducing Valve, Direct Operated, Type ZDR 6 D

Uploaded by

Michail ArmitageOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Reducing Valve, Direct Operated, Type ZDR 6 D

Pressure Reducing Valve, Direct Operated, Type ZDR 6 D

Uploaded by

Michail ArmitageCopyright:

Available Formats

RE 26 570/02.

03

Replaces: 11.02

Pressure reducing valve, direct operated,

Type ZDR 6 D

Nominal size 6

Series 4X

Maximum operating pressure 210 bar

K 4279/1

Maximum flow 50 L/min

Type ZDR 6 DP2–4X/…YM…

Overview of contents Features

Contents Page – Sandwich plate design

Features 1 – Porting pattern to DIN 24 340 Form A, without locating pin

Ordering details 2 hole (standard)

Preferred types 2 – Porting pattern to ISO 4401 and CETOP–RP 121 H, with

locating pin hole, (ordering code .../60 at the end of the valve

Symbols 2 type code)

Function, section 3 – 4 pressure stages

Characteristic curves 4 – 4 adjustment elements:

Technical data 5 • Rotary knob

Unit dimensions 6 • Sleeve with hexagon and protective cap

• Lockable rotary knob with scale

• Rotary knob with scale

– Pressure reduction in ports A, B or P

– Check valve, optional (only ZDR 6 DA...)

© 2003

by Bosch Rexroth AG, Industrial Hydraulics, D-97813 Lohr am Main

All rights reserved. No part of this document may be reproduced or stored, processed, duplicated or circulated using

electronic systems, in any form or by any means, without the prior written authorisation of Bosch Rexroth AG.

In the event of contravention of the above provisions, the contravening party is obliged to pay compensation.

ZDR 6 D 1/6 RE 26 570/02.03

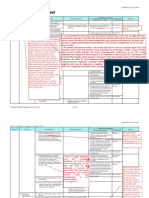

Ordering details

Z DR 6 D –4X Y *

Sandwich plate = Z Further details in clear text

Pressure reducing valve = DR No code = Without locating pin hole

/60 2) = With locating pin hole

Nominal size 6 =6

No code = NBR seals

Direct operated =D V= FKM seals

(other seals on request)

Pressure reduction in port A2 = A Attention!

Pressure reduction in port B2 = B The compatibility of the seals and pressure

Pressure reduction in port P1 = P fluid has to be taken into account!

Adjustment elements No code = With check valve

Rotary knob =1 (only possible for pressure reduction in port A2)

Sleeve with hexagon and protective cap =2 M= Without check valve

Lockable rotary knob with scale = 3 1)

Rotary knob with scale =7 Y= Internal pilot oil supply, external leakage oil drain

Series 40 to 49 = 4X 25 = Max. secondary pressure 25 bar

(40 to 49: unchanged installation and connection dimensions) 75 = Max. secondary pressure 75 bar

150 = Max. secondary pressure 150 bar

210 = Max. secondary pressure 210 bar

1) H-key with Material No. R900008158 is included within the scope of supply.

2) Locating pin 3 x 8 DIN EN ISO 8752, Material No. R900005694 (separate order)

Preferred types (readily available)

Type Material number Type Material number

ZDR 6 DA2-4X/25Y R900410808 ZDR 6 DP2-4X/25YM R900483785

ZDR 6 DA2-4X/75Y R900410813 ZDR 6 DP2-4X/75YM R900483786

ZDR 6 DA2-4X/150Y R900410849 ZDR 6 DP2-4X/150YM R900483787

ZDR 6 DA2-4X/210Y R900410855 ZDR 6 DP2-4X/210YM R900483788

ZDR 6 DB2-4X/25YM R900449839

ZDR 6 DB2-4X/75YM R900431771

ZDR 6 DB2-4X/150YM R900431172 Further preferred types and standard units can

ZDR 6 DB2-4X/210YM R900463269 be found in the EPS (Standard Price List).

Symbols ( 1 = component side, 2 = subplate side)

Type ZDR 6 DP..–4X/…YM… Type ZDR 6 DA..–4X/…YM…

1 1

M

M

P A 2 B T P A 2 B T

Type ZDR 6 DB..–4X/…YM… Type ZDR 6 DA..–4X/…Y…

1 1

M

M

P A 2 B T P A 2 B T

RE 26 570/02.03 2/6 ZDR 6 D

Function, section

Pressure reducing valves type ZDR 6 D.. are 3-way direct operated This causes a flow path to be opened at port A2 over the control

pressure reducing valves of sandwich plate design with a pressure land (9) on the control spool (2) to tank. Sufficient fluid then flows

relief function on the secondary side. It is used to reduce a system to tank to prevent any further rise in pressure. The spring chamber

pressure. The pressure reducing valve basically consists of the (7) is always drained to tank externally via drilling (6) to port T (Y).

housing (1), the control spool (2), a compression spring (3) and the A pressure gauge port (8) permits the secondary pressure at the

adjustment element (4) as well as with an optional check valve. valve to be monitored.

The secondary pressure is set by the pressure adjustment element It is only possible to fit a check valve for free-flow in ports A2 to

(4). A1 in version "DA".

Version "DA" Versions "DP" and "DB"

At rest, the valve is normally open and fluid can flow unhindered In version DP, the pressure is reduced in port P1. The control

from port A1 to port A2. The pressure in port A2 is at the same pressure and the pilot oil is taken internally from port P1.

time via the control line (5) present at the spool area opposite to In version DB, the pressure in port P1 is reduced and the pilot oil is

the compression spring (3). When the pressure in port A2 exceeds taken from port B.

the pressure level set at the compression spring (3), the control Attention!

spool (2) moves into the control position then holds the set In version DB, it must be ensured that the pressure in port B is not

pressure in port A2 constant. The control pressure and pilot oil are higher than the set pressure when the directional valve is in

taken from port A2 via control line (5). position P to A, otherwise pressure in port A will be reduced.

If the pressure in port A2 rises still further due to external forces,

the control spool (2) moves still further towards the compression

spring (3).

4 3 7 6 9 2 8

T1

P1 A1 (Y) B1

P2 A2 T2 B2

(Y) 5 1

Type ZDR 6 DA1–4X/…YM…

ZDR 6 D 3/6 RE 26 570/02.03

Characteristic curves (measured with HLP46, ϑoil = 40 °C ± 5 °C)

Type ZDR 6 DA Typ ZDR 6 DP und ZDR 6 DB

pA–qV characteristic curves pA–qV characteristic curves

250 250

210

Secondary pressure in bar →

210

Secondary pressure in bar →

200 200

Pressure stage in bar

Pressure stage in bar

150 150

150 150

100 75 100 75

50 50

25 25

0 0

50 30 10 0 10 30 50 50 30 10 0 10 30 50

Flow in L/min → Flow in L/min →

A2 to T (Y) A1 to A2 P1 to T (Y) P2 to P1

Note: The curve characteristics remain with, low set pressures, the same in relation to the pressure rating

∆pmin–qV characteristic curves ∆pmin–qV characteristic curves

Min. pressure differential

Min. pressure differential

30 30

in bar →

2 6

in bar →

20 20

1 5

10 10

0 0

0 10 20 30 40 50 0 10 20 30 40 50

Flow in L/min → Flow in L/min →

1 A1 to A2 5 P2 to P1

2 A2 to T (Y) (3. way) 6 P1 to T (Y) (3. way)

∆p–qV characteristic curves

30 3 A2 to A1 flow via

Pressure differential

3 check valve only

in bar →

20 4 A2 to A1 flow via

4 check valve and fully open control

10 cross-section

0 The characteristic curves for the pressure relief function

0 10 20 30 40 50

are valid for the outlet pressure = zero over the entire

Flow in L/min → flow range!

RE 26 570/02.03 4/6 ZDR 6 D

Technical data (for applications outside these parameters, please consult us!)

General

Installation Optional

Ambient temperature range °C – 30 to + 80 (NBR seals)

– 20 to + 80 (FKM seals)

Weight kg Approx. 1.2

Hydraulic

Pressure fluid Mineral oil (HL, HLP) to DIN 51 524 1);

Fast bio-degradable pressure fluids to

VDMA 24 568 (also see RE 90 221); HETG (rape seed oil) 1);

HEPG (polyglycols) 2); HEES (synthetic ester) 2);

Other pressure fluids on request

Pressure fluid temperature range °C – 30 … + 80 (NBR seals)

– 20 … + 80 (FKM seals)

Viscosity range mm2/s 10 … 800

Cleanliness class to ISO code Maximum permissible degree of contamination of the pressure

fluid is to ISO 4406 (C) class 20/18/15 3)

Maximum operating pressure (inlet) bar 315

Secondary pressure (output) bar 25; 75; 150; 210

Back pressure port T(Y) bar 160

Maximum flow L/min 50

1) Suitable for NBR and FKM seals

2) Only suitable for FKM seals

3) The cleanliness class stated for the components must be

adhered too in hydraulic systems. Effective filtration prevents

faults from occurring and at the same time increase the

component service life.

For the selection of filters see catalogue sheets RE 50 070,

RE 50 076 and RE 50 081.

ZDR 6 D 5/6 RE 26 570/02.03

Unit dimensions (dimensions in mm)

Types ZDR 6 DP and ZDR 6 DB 4

5 13

233

6

18 24 209 12,5

5 4

3 2 1

Ø 40

Ø 19

40

3

20

2 1

189

9

2; 3 12 10 7 1 11

Ø 35

8

84,5

3 T(Y)

Ø 39

32,5

31

45

A B

35

P

4 x Ø 5,4

23,5 40,5 8

4 x Ø 12,2; 1,4

2 84,5 11

Type ZDR 6 DA

T(Y)

Ø 39

32,5

31

45

A B

P

0,01/100mm 4 x Ø 12,2; 1,4 4 x Ø 5,4

40,5 12,5

R max 4

Valve fixing screws

Required surface finish of the M5 DIN 912-10.9,

1 Name plate mating piece Tightening torque MA= 8.9 Nm,

2 Adjustment element "1" must be ordered separately

3 Adjustment element "2"

11 Pressure gauge port G 1/4; 12 deep, internal

4 Adjustment element "3"

hexagon 6A/F

5 Adjustment element "7"

6 Space required to remove the key 12 Porting pattern to ISO 4401 and CETOP–RP 121 H,

7 Valve fixing holes with locating pin hole, Ø3 x 5 mm deep for

8 Lock nut 24A/F locating pin Ø3 x 8 mm DIN EN ISO 8752,

9 Hexagon 10A/F Material No. R900005694 (separate order)

10 Identical seal rings for 13 Porting pattern to ISO 4401 and CETOP–RP 121 H,

ports A2, B2, P2, T2 (Y) with locating pin hole, Ø4 x 4 mm deep

Bosch Rexroth AG Bosch Rexroth Limited The data specified above only serves to describe

Industrial Hydraulics the product. No statements concerning a certain

D-97813 Lohr am Main Cromwell Road, St Neots, condition or suitability for a certain application

Zum Eisengießer 1 • D-97816 Lohr am Main Cambs, PE19 2ES can be derived from our information.

Telefon 0 93 52 / 18-0 Tel: 0 14 80/22 32 56 The details stated do not release you from the

Telefax 0 93 52 / 18-23 58 • Telex 6 89 418-0 Fax: 0 14 80/21 90 52 responsibility for carrying out your own

eMail documentation@boschrexroth.de E-mail: info@boschrexroth.co.uk assessment and verification. It must be

Internet www.boschrexroth.de remembered that our products are subject to a

natural process of wear and ageing.

RE 26 570/02.03 6/8 ZDR 6 D

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aerodynamic Drag of Engine-Cooling Airflow With External InterferenceDocument17 pagesAerodynamic Drag of Engine-Cooling Airflow With External InterferenceVyssion100% (2)

- Hydraulics and Pneumatics SystemsDocument4 pagesHydraulics and Pneumatics SystemsKrista JacksonNo ratings yet

- LubricantsDocument44 pagesLubricantsHari Kumar .DNo ratings yet

- Heat Transfer in Olga 2000Document11 pagesHeat Transfer in Olga 2000Akin MuhammadNo ratings yet

- Experiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Document11 pagesExperiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Safi Ullah WarraichNo ratings yet

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document19 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- HAZOP Study Worksheet 19 Dec 2019 - Remarks1223Document52 pagesHAZOP Study Worksheet 19 Dec 2019 - Remarks1223Mizanul HoqueNo ratings yet

- Water Quality Analysis of Nairobi DamDocument43 pagesWater Quality Analysis of Nairobi DamOrwe Elly100% (1)

- IQCM Final For Industry-12!06!2015Document142 pagesIQCM Final For Industry-12!06!2015raj dasNo ratings yet

- Reservoir SimulationDocument108 pagesReservoir Simulationdaonguyencm10100% (8)

- Consistency SolutionsDocument3 pagesConsistency SolutionsRam KumarNo ratings yet

- Insulated Air Heaters HRP (Protected) : HRP 13 L HRP 13 M HRP 13 SDocument2 pagesInsulated Air Heaters HRP (Protected) : HRP 13 L HRP 13 M HRP 13 SRam KumarNo ratings yet

- Insulated Air Heaters HRP (Protected) With Housing: HRP 13 L HRP 13 M HRP 13 SDocument2 pagesInsulated Air Heaters HRP (Protected) With Housing: HRP 13 L HRP 13 M HRP 13 SRam KumarNo ratings yet

- Power and Energy Meters: Model No. Remarks Sl. WH WH W Va Var 1. ET3021 ET4021Document1 pagePower and Energy Meters: Model No. Remarks Sl. WH WH W Va Var 1. ET3021 ET4021Ram KumarNo ratings yet

- SS Pressure Gauge (Compact Case) Bourdon Type: Special FeaturesDocument4 pagesSS Pressure Gauge (Compact Case) Bourdon Type: Special FeaturesRam KumarNo ratings yet

- CPM1300Document44 pagesCPM1300Ram KumarNo ratings yet

- Ut-1201 Flow MeterDocument12 pagesUt-1201 Flow MeterRam KumarNo ratings yet

- Igyx 18 Inductive Proximity SwitchDocument2 pagesIgyx 18 Inductive Proximity SwitchRam KumarNo ratings yet

- BTG Product DigestDocument26 pagesBTG Product DigestRam KumarNo ratings yet

- Session 1.2C - National Sewerage and Septage Management Program PDFDocument19 pagesSession 1.2C - National Sewerage and Septage Management Program PDFWilbur SuandingNo ratings yet

- Eurol Vacuumolie ISO-VG 100: Mineral Vacuum Pump OilDocument1 pageEurol Vacuumolie ISO-VG 100: Mineral Vacuum Pump Oilاحمد سعيدNo ratings yet

- BGRDocument44 pagesBGRkapilNo ratings yet

- Grundfosliterature 5501Document68 pagesGrundfosliterature 5501Mykola Titov100% (1)

- GranulationDocument16 pagesGranulationalishba aliNo ratings yet

- Turbulent-Flow Hydro Static Bearings Analysis and Experimental ResultsDocument15 pagesTurbulent-Flow Hydro Static Bearings Analysis and Experimental Resultsallwl2006100% (1)

- Chap. 4.2 Desigh and Rating of Tube Bundle Heat ExchangersDocument22 pagesChap. 4.2 Desigh and Rating of Tube Bundle Heat ExchangersMeshal Al-mutairiNo ratings yet

- 81460229single Accumulator Charging ValveDocument8 pages81460229single Accumulator Charging ValveCésar Cusi LazoNo ratings yet

- Subsonic Compress Ible Flow Over Air FoilsDocument3 pagesSubsonic Compress Ible Flow Over Air FoilsRidwan FadlikaNo ratings yet

- Actuators: Version 2 EE IIT, Kharagpur 1Document30 pagesActuators: Version 2 EE IIT, Kharagpur 1Khaled MahranNo ratings yet

- RotameterDocument2 pagesRotameterJove MultisystemsNo ratings yet

- Water Requirements For Crops: Chapter No 02 by Santosh Kumar GargDocument55 pagesWater Requirements For Crops: Chapter No 02 by Santosh Kumar Gargyasir_mushtaq786No ratings yet

- Lecture - 8: Fluid Motion: Streamlines EtcDocument13 pagesLecture - 8: Fluid Motion: Streamlines Etcrohit singhNo ratings yet

- Oil SeparatorDocument2 pagesOil SeparatorOnofreNo ratings yet

- 20 - Design of Hydraulic Fracturing TreatmentDocument14 pages20 - Design of Hydraulic Fracturing Treatmentمرتضى عبد الباري خنوبةNo ratings yet

- Valvula de Alivio WatsonDocument2 pagesValvula de Alivio WatsonLuis Panti EkNo ratings yet

- Hydraulics - PDF - Pressure - Fluid DynamicsDocument8 pagesHydraulics - PDF - Pressure - Fluid DynamicsJghhhsh JsjsjjsNo ratings yet

- Water Supply Peak Flow CalculationDocument60 pagesWater Supply Peak Flow CalculationPradeep SukumaranNo ratings yet

- CHE435 Fall22 Week 5 ClassDocument29 pagesCHE435 Fall22 Week 5 ClassStolen RememberNo ratings yet

- Valvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FDocument2 pagesValvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FGrecia Paola Garza RodriguezNo ratings yet