Professional Documents

Culture Documents

Lab 5.1 Soldadura

Lab 5.1 Soldadura

Uploaded by

Iván D. ArdilaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab 5.1 Soldadura

Lab 5.1 Soldadura

Uploaded by

Iván D. ArdilaCopyright:

Available Formats

Simulation of Lab 5.

1

Date: martes, 25 de agosto de 2020

Designer: Solidworks

Study name: Estudio soldadura lab 5

Analysis type: Static

Table of Contents

Description...........................................1

Assumptions..........................................2

Model Information..................................2

Study Properties.....................................3

Units..................................................4

Material Properties.................................4

Loads and Fixtures..................................5

Connector Definitions..............................6

Contact Information................................6

Mesh information....................................7

Sensor Details........................................8

Resultant Forces....................................8

Beams.................................................8

Study Results........................................9

Conclusion..........................................11

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 1

Assumptions

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 2

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 3

Model Information

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 4

Model name: Lab 5.1

Current Configuration: Predeterminado

Solid Bodies

Document Name and Document Path/Date

Treated As Volumetric Properties

Reference Modified

Saliente-Extruir1

Mass:0.39 kg

C:\Users\ivan-\OneDrive\E

Volume:5e-05 m^3

scritorio\diseño 2\lab\Lab

Solid Body Density:7800 kg/m^3

5.1.SLDPRT

Weight:3.822 N

Aug 25 13:08:39 2020

Shell Bodies

Document Name and Document Path/Date

Formulation Volumetric Properties

Reference Modified

Superficie-Equidistancia2

Thickness:5 mm

C:\Users\ivan-\OneDrive\E

Weight:4.5864 N

scritorio\diseño 2\lab\Lab

Thin Volume:6e-05 m^3

5.1.SLDPRT

Mass:0.468 kg

Aug 25 13:08:39 2020

Density:7800kg/m^3

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 5

Study Properties

Study name Static 1

Analysis type Static

Mesh type Mixed Mesh

Thermal Effect: On

Thermal option Include temperature loads

Zero strain temperature 298 Kelvin

Include fluid pressure effects from SOLIDWORKS Off

Flow Simulation

Solver type FFEPlus

Inplane Effect: Off

Soft Spring: Off

Inertial Relief: Off

Incompatible bonding options Automatic

Large displacement Off

Compute free body forces On

Friction Off

Use Adaptive Method: Off

Result folder SOLIDWORKS document

(C:\Users\ivan-\OneDrive\Escritorio\diseño 2\lab)

Units

Unit system: SI (MKS)

Length/Displacement mm

Temperature Kelvin

Angular velocity Rad/sec

Pressure/Stress N/m^2

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 6

Material Properties

Model Reference Properties Components

Name: 1.0044 (S275JR) SolidBody 2(Saliente-

Model type: Linear Elastic Isotropic Extruir1)(Lab 5.1),

Default failure Unknown SurfaceBody 1(Superficie-

criterion: Equidistancia2)(Lab 5.1)

Yield strength: 2.75e+08 N/m^2

Tensile strength: 4.1e+08 N/m^2

Elastic modulus: 2.1e+11 N/m^2

Poisson's ratio: 0.28

Mass density: 7800 kg/m^3

Shear modulus: 7.9e+10 N/m^2

Thermal expansion 1.1e-05 /Kelvin

coefficient:

Curve Data:N/A

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 7

Loads and Fixtures

Fixture name Fixture Image Fixture Details

Entities: 1 face(s)

Type: Fixed Geometry

Fixed-1

Resultant Forces

Components X Y Z Resultant

Reaction force(N) 0.0272012 0.0218756 -4999.98 4999.98

Reaction Moment(N.m) 0 0 0 1e-33

Load name Load Image Load Details

Entities: 4 edge(s)

Reference: Face< 1 >

Type: Apply force

Values: ---, ---, -5000 N

Moments: ---, ---, --- N.m

Force-1

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 8

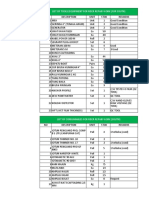

Connector Definitions

Edge Weld Connector

Model Reference Connector Details Edge-weld Size Graph

Type: Fillet, Single-

Sided

Standard: European

Standard

Partial Safety 1.25

Factor:

Correlation Factor: 0.85

Electrode: Custom

Weld Strength: 430N/m^2

Weld size: 3mm

Terminating Part: Superficie-

Equidistancia2

Edge Weld Connector-1

Mating Part: Saliente-Extruir1

Connector Forces

Type Min Max Mean

Weld throat size (mm.) 1652.1 3.483E+05 1.2221E+05

Joint normal force (N) -59254 97333 784.07

Shear-Weld axis force (N) -37546 944.61 -22459

Shear-Surface normal

0 0 0

force (N)

Bending moment (N.m) -96.459 141.92 1.1674

Contact Information

No Data

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 9

Mesh information

Mesh type Mixed Mesh

Mesher Used: Curvature-based mesh

Jacobian points 4 Points

Jacobian check for shell On

Maximum element size 2.30489 mm

Minimum element size 2.30489 mm

Mesh Quality Plot High

Mesh information - Details

Total Nodes 68068

Total Elements 40853

Time to complete mesh(hh;mm;ss): 00:00:06

Computer name:

Sensor Details

No Data

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 10

Resultant Forces

Reaction forces

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N 0.0272012 0.0218756 -4999.98 4999.98

Reaction Moments

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N.m 0 0 0 1e-33

Beams

No Data

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 11

Study Results

Name Type Min Max

Stress1 VON: von Mises Stress 1.110e+00 N/m^2 1.136e+08 N/m^2

Node: 12110 Node: 8136

Lab 5.1-Static 1-Stress-Stress1

Name Type Min Max

Displacement1 URES: Resultant Displacement 0.000e+00 mm 1.282e-02 mm

Node: 5 Node: 55534

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 12

Name Type Min Max

Lab 5.1-Static 1-Displacement-Displacement1

Name Type Min Max

Strain1 ESTRN: Equivalent Strain 4.037e-12 3.472e-04

Element: 9920 Element: 9349

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 13

Name Type Min Max

Lab 5.1-Static 1-Strain-Strain1

Conclusion

Vemos en el estudio realizado que al no poner soldadura al otro lado de la pieza esta va a fallar, se deforma

debido a la fuerza.

Se observa la importancia de la aplicación de la soldadura.

Analyzed with SOLIDWORKS Simulation Simulation of Lab 5.1 14

You might also like

- ANSYS Mechanical APDL for Finite Element AnalysisFrom EverandANSYS Mechanical APDL for Finite Element AnalysisRating: 4.5 out of 5 stars4.5/5 (8)

- Support RDM Study FinalDocument9 pagesSupport RDM Study Finalel chapoo JrNo ratings yet

- Simulation of Blind Box: No DataDocument11 pagesSimulation of Blind Box: No DataSatrio AmiruddinNo ratings yet

- Project 3-StaticDocument11 pagesProject 3-StaticMahmoud ElhossinyNo ratings yet

- BASE PARA COJINETE SD-Static 1-1Document10 pagesBASE PARA COJINETE SD-Static 1-1hecnel peñaNo ratings yet

- Fourth Project-Static 2-1Document10 pagesFourth Project-Static 2-1nabaz muhamadNo ratings yet

- Part1.SLDPRTneww Static 2 1Document11 pagesPart1.SLDPRTneww Static 2 1KABERA CYUSA MariusNo ratings yet

- Fourth Project-Static 2-1Document10 pagesFourth Project-Static 2-1Nabaz MuhamadNo ratings yet

- Ventana de Avion-Static 3-1Document11 pagesVentana de Avion-Static 3-1Alejandra PaezNo ratings yet

- Simulation of Bucket: No DataDocument10 pagesSimulation of Bucket: No Datasiaga 1No ratings yet

- Simulation of Pinion: No DataDocument13 pagesSimulation of Pinion: No DataAtul DahiyaNo ratings yet

- No Rod1 Material-3Document11 pagesNo Rod1 Material-3koraina2015No ratings yet

- Assem1-Static 1-1Document11 pagesAssem1-Static 1-1andre careraNo ratings yet

- Connecting Rod Design 1 Assembly-Static 1-1Document10 pagesConnecting Rod Design 1 Assembly-Static 1-1stuxmanwinNo ratings yet

- Simulation of Part2: No DataDocument12 pagesSimulation of Part2: No DataAlejandra PaezNo ratings yet

- Simulation of Part1: No DataDocument10 pagesSimulation of Part1: No DataprajaatosNo ratings yet

- Lifting Lug Stress AnalysisDocument10 pagesLifting Lug Stress AnalysisChaitanya Sai TNo ratings yet

- Simulation of Part1: No DataDocument10 pagesSimulation of Part1: No DataNguyễn Minh HoàngNo ratings yet

- Simulation of Spring: Date: Martes, 25 de Agosto de 2020 Designer: Solidworks Study Name: Resorte 1 Analysis TypeDocument10 pagesSimulation of Spring: Date: Martes, 25 de Agosto de 2020 Designer: Solidworks Study Name: Resorte 1 Analysis TypeIván D. ArdilaNo ratings yet

- Test-Static 1-1Document10 pagesTest-Static 1-1wahyuNo ratings yet

- Simulation of Pecsi: No DataDocument9 pagesSimulation of Pecsi: No DataDanNo ratings yet

- Connecting Rod Design 2 Assembly-Static 1-1Document10 pagesConnecting Rod Design 2 Assembly-Static 1-1stuxmanwinNo ratings yet

- Simulation of Test 1: No DataDocument10 pagesSimulation of Test 1: No Datasiaga 1No ratings yet

- 1-Static 1-1Document10 pages1-Static 1-1Minh LâmNo ratings yet

- An AliyaDocument12 pagesAn AliyaMostarchinaNo ratings yet

- Garpu Static 1 1Document10 pagesGarpu Static 1 1Agus HidayatNo ratings yet

- Simulation of Part14: No DataDocument10 pagesSimulation of Part14: No DataMuflih MuhammadNo ratings yet

- Part4-Static 1-1Document13 pagesPart4-Static 1-1Atul DahiyaNo ratings yet

- U Section-Bending Load Performance-1Document8 pagesU Section-Bending Load Performance-1mQa tech360No ratings yet

- Simulation of Hadi 1: No DataDocument11 pagesSimulation of Hadi 1: No DataHafiz ShamNo ratings yet

- 2well-Static 1-1Document10 pages2well-Static 1-1Amer AlbasserNo ratings yet

- Hook-Static 1-1Document7 pagesHook-Static 1-1Ankit TomarNo ratings yet

- 1-Static 2-1Document10 pages1-Static 2-1Minh LâmNo ratings yet

- Part3 Torsion Testing 02 2Document11 pagesPart3 Torsion Testing 02 2Aung Pyae theinNo ratings yet

- Simulation of Assem1: No DataDocument9 pagesSimulation of Assem1: No Dataahmed el sayedNo ratings yet

- Gear SimulationDocument11 pagesGear SimulationKhurram SattarNo ratings yet

- Simulation of Part1 - Copy: No DataDocument19 pagesSimulation of Part1 - Copy: No DataAbigail LimNo ratings yet

- Simulation of Part2: No DataDocument10 pagesSimulation of Part2: No DataGOUAL SaraNo ratings yet

- Simulation of Part8: No DataDocument11 pagesSimulation of Part8: No DataSaid AnejareNo ratings yet

- Beam - Diagrams-Static 2-1Document14 pagesBeam - Diagrams-Static 2-1Yeissamoruta U. TpevoitinskyNo ratings yet

- JIB-3-Static 1-1Document10 pagesJIB-3-Static 1-1AzhaghiaNo ratings yet

- Simulation End Plate Spoon Pile 8-01-2021Document9 pagesSimulation End Plate Spoon Pile 8-01-2021Rendra Maha Putra JfNo ratings yet

- Stress Analysis of Worn-Out Trunnion PinDocument10 pagesStress Analysis of Worn-Out Trunnion PinChaitanya DattaNo ratings yet

- Part2-Static 3-1Document11 pagesPart2-Static 3-1Stephanny Cedeño VázquezNo ratings yet

- Assem1 Static 5 1Document13 pagesAssem1 Static 5 1DanieCybrog Njungkel MenantangmasadepanNo ratings yet

- Scenario 1-SimulationXpress - Study-2Document11 pagesScenario 1-SimulationXpress - Study-2Samantha SeetaramNo ratings yet

- Battery Room StudyDocument9 pagesBattery Room StudyViel ManaloNo ratings yet

- Simulation of Part3: No DataDocument10 pagesSimulation of Part3: No DataGOUAL SaraNo ratings yet

- Report Simulation Static SolidworkDocument10 pagesReport Simulation Static SolidworkAndika MuhammadNo ratings yet

- Simulation of PLAT: No DataDocument11 pagesSimulation of PLAT: No Data03081111No ratings yet

- Rectangular Hollow Plate-Fine Analysis-1Document14 pagesRectangular Hollow Plate-Fine Analysis-1Francisco UribeNo ratings yet

- Mohamed Yasser Farhat Assignment2Document21 pagesMohamed Yasser Farhat Assignment2Mohamed YasserNo ratings yet

- Link1Copy-Static 1-1Document9 pagesLink1Copy-Static 1-1Saumya SuyalNo ratings yet

- Beam-Static 1-4Document16 pagesBeam-Static 1-4Khang LêNo ratings yet

- Rapport 15000Document10 pagesRapport 15000Said AnejareNo ratings yet

- Analisa Bracket Puli OPSI 1Document11 pagesAnalisa Bracket Puli OPSI 1Muhamad HafidzNo ratings yet

- Machine Design-Static 2-1Document9 pagesMachine Design-Static 2-1Muhammad Usama 796-FET/BSME/F18No ratings yet

- Tutor1-Static 1-1Document12 pagesTutor1-Static 1-1SuskeketNo ratings yet

- Static AnalysisDocument13 pagesStatic AnalysisVictoryNo ratings yet

- 4th Q. Physical Science - Aristotle and Galilean MotionDocument28 pages4th Q. Physical Science - Aristotle and Galilean MotionItsClarenceNo ratings yet

- 3 - Nouns and PronounsDocument11 pages3 - Nouns and PronounsEko Setyo PrayogiNo ratings yet

- List of Participants - 6RSTC - R-2 - RectifiedDocument23 pagesList of Participants - 6RSTC - R-2 - RectifiedMAIDUL ISLAMNo ratings yet

- Pseudo ForceDocument8 pagesPseudo Forcesudhindra975% (8)

- HDP Serie Installation Operation and Maintenance ManualDocument68 pagesHDP Serie Installation Operation and Maintenance ManualMar CrucisNo ratings yet

- EnergyConservationP SDocument2 pagesEnergyConservationP Srayraymamabolo2004No ratings yet

- DTR MPP6 1v91Document53 pagesDTR MPP6 1v91معين عزامNo ratings yet

- High Resolution Wide-Angle Compact Catadioptric Telescope Onboard MicrosatelliteDocument141 pagesHigh Resolution Wide-Angle Compact Catadioptric Telescope Onboard MicrosatelliteМРязанскийNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- The New prEN 15193-1 To Calculate The Energy RequiDocument8 pagesThe New prEN 15193-1 To Calculate The Energy RequiEsraa KhairyNo ratings yet

- Design of CorbelDocument3 pagesDesign of CorbelAkshay KumarNo ratings yet

- Insect Vision: Zales Promo Code GemstoneDocument11 pagesInsect Vision: Zales Promo Code Gemstonejohn cenaNo ratings yet

- Bifilar Oscillations Practical 2Document4 pagesBifilar Oscillations Practical 2GaganNo ratings yet

- Mathematics: (A) (B) 0 (C) Does Not Exist (D) None of These Is - (A) 0 (B) 1 (C) - 1 (D) Does Not ExistDocument17 pagesMathematics: (A) (B) 0 (C) Does Not Exist (D) None of These Is - (A) 0 (B) 1 (C) - 1 (D) Does Not ExistSubrata KarmakarNo ratings yet

- Duty Point Calculation For Pumping Line From Nuwarawewa WTP To Stage Iii TowerDocument18 pagesDuty Point Calculation For Pumping Line From Nuwarawewa WTP To Stage Iii TowerjanithNo ratings yet

- Cleanroom PresentationDocument30 pagesCleanroom Presentationjonh366No ratings yet

- Tri-Bore PVDF Hollow Fibers With A Super-Hydrophobic Coating For Membrane DistillationDocument11 pagesTri-Bore PVDF Hollow Fibers With A Super-Hydrophobic Coating For Membrane DistillationKellyNo ratings yet

- CBSE Class 11 Mathematics Worksheet PDFDocument2 pagesCBSE Class 11 Mathematics Worksheet PDFAshish GambhirNo ratings yet

- These de Maitrise en Sciences MathematiquesDocument54 pagesThese de Maitrise en Sciences MathematiquesMbulanga CrispinNo ratings yet

- Lesson 1.2 Real Number Line, Inequality, Intervals, and Absolute ValueDocument19 pagesLesson 1.2 Real Number Line, Inequality, Intervals, and Absolute ValuesdeloagNo ratings yet

- Ac One ShotDocument52 pagesAc One Shotjasonob2334No ratings yet

- ShiplinePlus TFOI 6 10 12kVDocument2 pagesShiplinePlus TFOI 6 10 12kVAbhi ETAPNo ratings yet

- Syllabus Engineering Mechanics - GE23211Document2 pagesSyllabus Engineering Mechanics - GE23211harishaerophdNo ratings yet

- Y9 Eoy V1 ('Copy') : 1/1 PointDocument6 pagesY9 Eoy V1 ('Copy') : 1/1 PointAnaiya PatelNo ratings yet

- Chris Lls Publications 42610Document11 pagesChris Lls Publications 42610cifarha venantNo ratings yet

- 17 SM II Soil DynamicsDocument43 pages17 SM II Soil DynamicsAhmer MehmoodNo ratings yet

- Pure Substance Model and Two-Phase Flow Basics: - Fall 2010 Problem Set 6Document3 pagesPure Substance Model and Two-Phase Flow Basics: - Fall 2010 Problem Set 6pstgouveiaNo ratings yet

- List of Tools/Equipment For Riser Repair Work (For South)Document4 pagesList of Tools/Equipment For Riser Repair Work (For South)Naufal IkhsanNo ratings yet

- GM Series: DMG - Innovative TechnologiesDocument20 pagesGM Series: DMG - Innovative TechnologiesSEETHARAM SVRNo ratings yet

- FCL Midterm WPS OfficeDocument7 pagesFCL Midterm WPS OfficeTk KimNo ratings yet