Professional Documents

Culture Documents

Engine Scania Dc16: Short Block & Ass'y Sheet

Uploaded by

Jaya PranataOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Scania Dc16: Short Block & Ass'y Sheet

Uploaded by

Jaya PranataCopyright:

Available Formats

JOB NO.

BRANCH

UNIT MODEL R580 PUB. NO

ENG MODEL DC1603 PUB. DATE

Short Block & Ass'y Sheet

QA 4 ENG S/N

MACH S/N

REVISION NO

PAGE

Engine

SECTION Assembly

SCANIA DC16

CUST NAME

.

CHECK

NO PARTS NAME CONDITION TO BE CHECKED PICTURE, NOTES, DIAGRAM

(v)

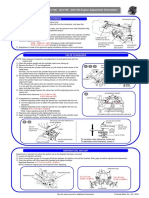

~ Fit a new cylinder head gasket

~ Lubricate the threads and underneath the heads of the cylinder

head bolts

~ Tighten them in the following four stages in the order given in

the figure

Standard Actual

60 Nm

1 CYLINDER HEAD

150 Nm

250 Nm

+ 90°

~ Make a mark with a centre punch on the head of the bolt

~ Fit gasket

Fit the lower part of the rocker cover

ROCKER ARM HOUSING ~ Torque bolt :

2

(Lower Rocker Cover) Standard Actual

26 Nm

~ Fit valve bridges

~ Fit push rod

~ Fit bearing bracket & torque

Standard Actual

40 Nm + 60°

~ Fit the rocker arm

3 VALVE MECHANISM

!!! Screw in the bolts alternately so that they are tightened

in parallel or one of the bolts may bend

~ Torque bolt :

Standard Actual

105 Nm

!!! Make sure there is not an old sealing washer at the bottom

of the injector seat.

~ Clean the sealing surfaces in the injector aperture

~ Lubricate the unit injector O-rings with engine oil

~ Fit a new sealing washer on the unit injector. A rubber insert

will keep the sealing washer in place on the unit injector

~ Place the fork clamp with bolt in position on the unit injector

and insert it into the cylinder head.

4 INJECTOR

~ Press down the unit injector by hand as far as possible

~ Torque bolt :

Standard Actual

20 Nm

+ 75 º

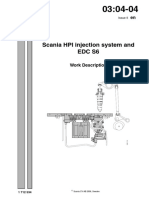

~ Adjusting the unit injector with tool 99 414

~ Fit adjusting tool 99 414 with the metal plate around the unit

injector.

~ When adjusting, loosen the lock nut and adjust the unit

injector with adjusting screw .

~ The unit injector is correctly set when the small piston is level

with the flat upper surface of the tool.

Use a finger to check.

~ Refer to tables in Order of adjustment for unit injectors

Mark On Fly Wheel Valve Overlap Adjust Intake

(degrees) On Cyl Valve on Cyl

5 ADJUSTMENT INJECTOR

TDC Down (0º) 6 4 and 5

TDC Up (180º) 7 2 and 6

TDC Down (360º) 1 3 and 7

TDC Up (540º) 4 1 and 8

~ Torque tighten the lock nut to 39 Nm after adjusting

Cyl 1 Cyl 2 Cyl 3 Cyl 4 Cyl 5 Cyl 6 Cyl 7

~ Reconnect the cables on the unit injectors.

~ Their relative position is not important.

~ Use torque screwdriver 588 179 to tighten the screws to 2 Nm.

QA4 DC 16 Assembly (Finish) 1

CHECK

NO PARTS NAME CONDITION TO BE CHECKED PICTURE, NOTES, DIAGRAM

(v)

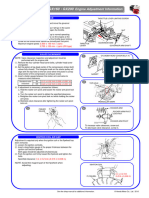

~ Adjust the valve clearance with the engine cold

~ Rotate the flywheel using tool 99 309 so that the mark on

the flywheel is visible in the bottom window according to

the table below.

Mark On Fly Wheel Valve Overlap Adjust Intake Adjust Exhaust

(degrees) On Cyl Valve on Cyl Valve on Cyl

TDC Down (0º) 6 7 and 8 4 and 5

TDC Up (180º) 7 1 and 5 2 and 6

TDC Down (360º) 1 2 and 4 3 and 7

ADJUSTMENT VALVE TDC Up (540º) 4 3 and 6 1 and 8

6

CLEARANCE

~ The intake valve clearance should be 0.45 mm and

exhaust valve clearance 0.70 mm.

~ Torque lock nut 40 Nm

Cyl 1 Cyl 2 Cyl 3 Cyl 4 Cyl 5 Cyl 6 Cyl 7 Cyl 8 Pos

Int

Exh

~ Fit the upper part of the rocker cover and torque tighten

the bolts.

Standard Actual

7 ROCKER ARM COVER

15 Nm

~ Fit the fuel manifold with overflow line.

~ Torque tighten the screws

Standard Actual

26 Nm

8 FUEL MANIFOLD

Torque tighten banjo screws on the overflow line

Standard Actual

11 Nm

~ Fit gasket and intake manifold

~ Torque bolt

Standard Actual

9 INTAKE MANIFOLD

26 Nm

~ Lubricate the joints with heat-resistant grease and fit new

gaskets

~ Fit turbo manifold & torque bolt

Standard Actual

92 Nm

TURBO MANIFOLD

10

EXHAUST MANIFOLD ~ Fit the rear exhaust manifold and junction pipe.

~ Fit the front exhaust manifold.

~ Torque bolt

Standard Actual

63 Nm

~ Fit gasket

~ Fit turbocharger & torque bolt

Standard Actual

63 Nm

~ Fit gasket & return tube

~ Torque bolt

Standard Actual

11 TURBOCHARGER

63 Nm

~ Apply oil to the inlet tube

~ Fit inlet lubricating tube

QA4 DC 16 Assembly (Finish) 2

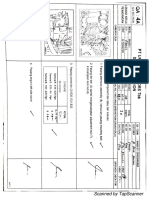

CHECK

NO PARTS NAME CONDITION TO BE CHECKED PICTURE, NOTES, DIAGRAM

(v)

~ Fit gasket then fit oil cooler

~ Torque bolt

Standard Actual

26 Nm

~ Assembling oil cooler as follow

OIL COOLER AND OIL i. Position the O-ring in the lid

12

CLEANER ii. Assemble the parts and tighten the rotor nut by hand

iii. Secure rotor shaft with locking compound

iv. Refit the rotor and spin it by hand to make sure it rotates

easily then tighten the lock nut

Standard Actual

15 Nm

~ Fit oil filter assembly

!!! Always used the new element

Standard Actual

13 OIL FILTER 25 Nm

~ Instal tube and connection line

~ Fit EDC Group

Torque bolt EDC CCV

Standard Actual

25 Nm

~ Fit CCV group (if any)

14 EDC & CCV GROUP

Torque bolt

Standard Actual

25 Nm

~ Instal tube and connection line

~ Fit gasket then fit coolant pump assy

Torque bolt

Standard Actual

15 COOLANT PUMP

25 Nm

~ Fit tentioner and torque bolt

Standard Actual Komponen

TENTIONER AND IDLER

16

ROLLER

50 Nm Tentioner

50 Nm Idler roller

~ Fit the fan bearing with bracket.

Standard Actual

50 Nm

17 FAN PULLEY

~ Install poly V-Belt

~ Install fuel filter and line

Torque bolt

Standard Actual

18 FUEL FILTER

25 Nm

~ Fit o-ring

~ Fit air compressor assy

~ Torque bolt

Standard Actual

50 Nm

19 AIR COMPRESSOR

~ Install lubricating & cooling line air compressor

QA4 DC 16 Assembly (Finish) 3

CHECK

NO PARTS NAME CONDITION TO BE CHECKED PICTURE, NOTES, DIAGRAM

(v)

~ Fit priming pump

~ Torque bolt

Standard Actual

20 PRIMING PUMP 26 Nm

~ Install all sensor

~ Fit wiring harness and install clamp

WIRING HARNESS AND

21

SENSOR

REMARKS:

EXECUTED BY MECHANIC APPROVED BY SUPERVISOR VALIDATION BY QUALITY OFFICER

Name : Name : Name :

Start : Finish : Insp. Date : Insp. Date :

Signature Signature Signature

QA4 DC 16 Assembly (Finish) 4

You might also like

- 2010_11_08 US GCV135 160 Engine Adjustment Information.xls - 2010_11_08 General GCV135_160_190 GSV190 Engine Adjustment IDocument1 page2010_11_08 US GCV135 160 Engine Adjustment Information.xls - 2010_11_08 General GCV135_160_190 GSV190 Engine Adjustment Ipeter smithNo ratings yet

- Cummins Jake BrakeDocument7 pagesCummins Jake BrakerowanNo ratings yet

- Honda HRA214 Quick AdjustDocument1 pageHonda HRA214 Quick AdjusthicksdpNo ratings yet

- Service Bulletin: Teledyne Continental Aircraft EngineDocument6 pagesService Bulletin: Teledyne Continental Aircraft EnginedavidNo ratings yet

- Scania Dc16: Disassembling Check SheetDocument3 pagesScania Dc16: Disassembling Check SheetJaya PranataNo ratings yet

- Ford Engine Service Manual Fo S Eng 240 PDFDocument6 pagesFord Engine Service Manual Fo S Eng 240 PDFDhanraj SinghNo ratings yet

- DC16 Cylinder SequenceDocument1 pageDC16 Cylinder Sequencejengandxb100% (1)

- Adjust Engine Valve Clearance (If NeededDocument1 pageAdjust Engine Valve Clearance (If NeededНиколай БелыйNo ratings yet

- Optimize alternator/starter clutch system componentsDocument7 pagesOptimize alternator/starter clutch system componentslau cv 97No ratings yet

- FrenosDocument22 pagesFrenosKevin figueroaNo ratings yet

- Timing Manual Galant ST v6!24!1998 2005 PDFDocument8 pagesTiming Manual Galant ST v6!24!1998 2005 PDFArya RamadhanNo ratings yet

- A WS PDSK 900Document69 pagesA WS PDSK 900Victor ChavesNo ratings yet

- Gx340 Gx390 Assembly GuideDocument1 pageGx340 Gx390 Assembly GuideSarmad Shah100% (1)

- GX100 Ajuste de MotorDocument1 pageGX100 Ajuste de MotorThu Naing TunNo ratings yet

- MANUAL DOOSAN V158TI DOOSAN EspañolDocument92 pagesMANUAL DOOSAN V158TI DOOSAN EspañolErick ovalleNo ratings yet

- Oversized Pressure Regulator Valve Kit: Renault/Peugot AL-4, DPODocument2 pagesOversized Pressure Regulator Valve Kit: Renault/Peugot AL-4, DPOEko hari PrasetyoNo ratings yet

- Sonnax1 PDFDocument2 pagesSonnax1 PDFEko hari PrasetyoNo ratings yet

- SKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Document12 pagesSKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Erne Lange OlsenNo ratings yet

- Align AL CE500P ManualDocument15 pagesAlign AL CE500P Manualreginaldo020471No ratings yet

- Specifi: CationsDocument3 pagesSpecifi: CationsRadek BabuszkiewiczNo ratings yet

- Mud Motor Hand BookDocument80 pagesMud Motor Hand BookHanaNo ratings yet

- BandasDocument116 pagesBandasJhon GuerraNo ratings yet

- CONE VALVE Service ManualDocument30 pagesCONE VALVE Service ManualMathieu DouNo ratings yet

- 27 GBDocument35 pages27 GBjahzooneNo ratings yet

- A86&A88-chapter 22 (REAR CONSTANT VELOCITY JOINTS AND FINAL DRIVE GEAR)Document19 pagesA86&A88-chapter 22 (REAR CONSTANT VELOCITY JOINTS AND FINAL DRIVE GEAR)Stojanov MarjanNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- DENSO Rastavljanje DizneDocument22 pagesDENSO Rastavljanje Diznegalaxy63No ratings yet

- Cylinder HeadDocument21 pagesCylinder HeadcristianNo ratings yet

- Cadenas DodgeDocument37 pagesCadenas DodgeAlfredo SalasNo ratings yet

- Av NG R 2 4L Cal Ber 1.8L Caliber 2 0L Caliber 2 4L ED3 2008 2007-08 2007-08 2007 08Document37 pagesAv NG R 2 4L Cal Ber 1.8L Caliber 2 0L Caliber 2 4L ED3 2008 2007-08 2007-08 2007 08miguel cruzNo ratings yet

- kx80 Página 171Document1 pagekx80 Página 171PabloNo ratings yet

- SONNAX 45rfeDocument2 pagesSONNAX 45rfefulltransmissionNo ratings yet

- Nissan Re4Fo4A, Ford 4F20E: Accumulator Valve KitDocument2 pagesNissan Re4Fo4A, Ford 4F20E: Accumulator Valve Kitflash_24014910No ratings yet

- Operation and maintenance of DV11 engine valvesDocument10 pagesOperation and maintenance of DV11 engine valvesООО "СК "СМП-708"No ratings yet

- VOLVO 240 SECT. 2 - ENGINE d20 d24 - Repairs Part 2Document96 pagesVOLVO 240 SECT. 2 - ENGINE d20 d24 - Repairs Part 2Myselvf100% (1)

- 2.2 L Dicor Engine: Disassembly and Assembly of Cylinder Head Sub AssembliesDocument50 pages2.2 L Dicor Engine: Disassembly and Assembly of Cylinder Head Sub AssembliesPhillip van DalenNo ratings yet

- GX240-270-340-390 Ajuste de MotorDocument1 pageGX240-270-340-390 Ajuste de Motormelgar segundoNo ratings yet

- Manual de Calibracion de Valvulas Del Daihatsu Toyota TeriosDocument10 pagesManual de Calibracion de Valvulas Del Daihatsu Toyota Teriosahmed zhranNo ratings yet

- Manual de Calibracion de Valvulas Del Daihatsu Toyota TeriosDocument10 pagesManual de Calibracion de Valvulas Del Daihatsu Toyota Teriosahmed zhranNo ratings yet

- Pneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionDocument4 pagesPneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionreliableplacementNo ratings yet

- Valves and Unit Injectors, Adjustment - Fuel Injection - Nut (Hardware)Document2 pagesValves and Unit Injectors, Adjustment - Fuel Injection - Nut (Hardware)SCANIANo ratings yet

- SEA 2019 Jet Pump SPARK Shop Supp. 219100959-021Document16 pagesSEA 2019 Jet Pump SPARK Shop Supp. 219100959-021Coke Ker JetspeedNo ratings yet

- Operating Instructions and Parts List for Drill Press Model 103.23620Document6 pagesOperating Instructions and Parts List for Drill Press Model 103.23620Argens ValenteNo ratings yet

- Reed Prentice Lathe BrochureDocument7 pagesReed Prentice Lathe BrochureErich KeaneNo ratings yet

- Maintenance Manual Front AxleDocument65 pagesMaintenance Manual Front Axlehebert perezNo ratings yet

- Service Manual Automatic Slack AdjusterDocument15 pagesService Manual Automatic Slack AdjusterEdho RidhoNo ratings yet

- Cadenas CadillacDocument27 pagesCadenas CadillacAlfredo SalasNo ratings yet

- Hpi Work DescriptionDocument32 pagesHpi Work DescriptionHari100% (8)

- CL608e/612e Mechanical AdjustmentsDocument15 pagesCL608e/612e Mechanical AdjustmentsLukáš KadeřábekNo ratings yet

- DistribucionDocument3 pagesDistribucionJeremyArgelNo ratings yet

- QuickServe Online - (4021499) K19 Service ManualDocument10 pagesQuickServe Online - (4021499) K19 Service Manualengmohsen.ramadanhotmail.com100% (1)

- Buku Manual TeriosDocument43 pagesBuku Manual TeriosFaozan BayuNo ratings yet

- 2010 - 11 - 08 General GX120 - 160 - 200 Engine Adjustment InformatDocument1 page2010 - 11 - 08 General GX120 - 160 - 200 Engine Adjustment InformatstacybriandNo ratings yet

- Procedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFDocument12 pagesProcedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFirvan hardiansyahNo ratings yet

- ANEROID OPERATION AND SERVICEDocument9 pagesANEROID OPERATION AND SERVICEUriel MFNo ratings yet

- Engine Adjustment Information: Valve ClearanceDocument1 pageEngine Adjustment Information: Valve ClearanceCareergamingNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Two Cycle Carburetor and the Back Alley MechanicFrom EverandTwo Cycle Carburetor and the Back Alley MechanicRating: 4.5 out of 5 stars4.5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- R and I Starting MotorDocument2 pagesR and I Starting MotorJaya PranataNo ratings yet

- DT4459Document2 pagesDT4459Jaya PranataNo ratings yet

- PDF Pumps HyvaDocument10 pagesPDF Pumps Hyvaandie.notoNo ratings yet

- R and I AlternatorDocument2 pagesR and I AlternatorJaya PranataNo ratings yet

- Volvo MID 128 Fault Codes PDFDocument172 pagesVolvo MID 128 Fault Codes PDFModestas100% (11)

- Scania Diagnos & Programmer 3 2.48.1Document7 pagesScania Diagnos & Programmer 3 2.48.1Jaya Pranata50% (2)

- Scania Diagnos & Programmer 3 Compression Test ToolDocument1 pageScania Diagnos & Programmer 3 Compression Test ToolJaya PranataNo ratings yet

- QA5 DC16 (Finish)Document6 pagesQA5 DC16 (Finish)Jaya PranataNo ratings yet

- Proposal Kegiatan Hut Ri-68 2013Document6 pagesProposal Kegiatan Hut Ri-68 2013Jaya PranataNo ratings yet

- Presentation 1Document1 pagePresentation 1Jaya PranataNo ratings yet

- CT 194202Document8 pagesCT 194202Mohsen PeykaranNo ratings yet

- Catalogo de Peças MANDocument250 pagesCatalogo de Peças MANpikinhosNo ratings yet

- Normal MACHINE VEBM946101 WA470 480-6 CSS-Net 2007-04-17Document1,554 pagesNormal MACHINE VEBM946101 WA470 480-6 CSS-Net 2007-04-17Michał Bujara100% (2)

- Safety Valves and Double Stop ValvesDocument24 pagesSafety Valves and Double Stop ValvesRahul PatilNo ratings yet

- Oilwell Hydraulics, IncDocument33 pagesOilwell Hydraulics, IncMayur PatelNo ratings yet

- Expansion ValveDocument23 pagesExpansion Valvemahmoud EissaNo ratings yet

- Serie 171 RTC CouplingsDocument6 pagesSerie 171 RTC CouplingsHIDRAFLUIDNo ratings yet

- Ingersoll Rand EPE, XFE, HPE, HXPE Series Parts List - Recommended Spares (March 2000)Document98 pagesIngersoll Rand EPE, XFE, HPE, HXPE Series Parts List - Recommended Spares (March 2000)J50% (4)

- Penlon SP Service ManualDocument164 pagesPenlon SP Service ManualRAUL LANDIMNo ratings yet

- Oct & Nov Oral QuestionDocument60 pagesOct & Nov Oral Questionrsinha06089411No ratings yet

- Ram Pump Users ManualDocument8 pagesRam Pump Users Manualdewa brahmantyoNo ratings yet

- Kidde Natura™ Inert Gas System IG-55 Nitrogen Agent Cylinder AssemblyDocument4 pagesKidde Natura™ Inert Gas System IG-55 Nitrogen Agent Cylinder AssemblyJoseph HoNo ratings yet

- API 574 Piping Inspection Guide for Visual Checks, Thickness Tests & Pressure ExamsDocument8 pagesAPI 574 Piping Inspection Guide for Visual Checks, Thickness Tests & Pressure ExamsEason NgNo ratings yet

- Maximizing Pressure PerformanceDocument2 pagesMaximizing Pressure PerformancePRAMOD KUMARNo ratings yet

- Pilot Relief Sarasin PDFDocument44 pagesPilot Relief Sarasin PDFLEOG85No ratings yet

- Service Manual FLE120 - FLE220Document91 pagesService Manual FLE120 - FLE220berek96No ratings yet

- 50cc (LT50 2003) Suzuki ATV Parts ListDocument27 pages50cc (LT50 2003) Suzuki ATV Parts ListMark100% (1)

- ZF As Tronic Trucks 2003 Repair ManualDocument9 pagesZF As Tronic Trucks 2003 Repair Manualkaren100% (49)

- Technical Offer Rev 0 - OptDocument47 pagesTechnical Offer Rev 0 - OptRafeek AliNo ratings yet

- Fire Fighting System Walk Down Punch ListDocument18 pagesFire Fighting System Walk Down Punch ListGomathyselvi100% (1)

- Segmented Ball Valves s19 Om en UsDocument19 pagesSegmented Ball Valves s19 Om en UsGuillermo GutierrezNo ratings yet

- I&C Construction Scope (2019)Document5 pagesI&C Construction Scope (2019)Yang Gul LeeNo ratings yet

- Recommended Actions: Transmission or Engine Accessories (If Applicable)Document3 pagesRecommended Actions: Transmission or Engine Accessories (If Applicable)sjsshipNo ratings yet

- mm09144 Trailer Air Suspension System Meritor Euroflex 9e Suspension RangeDocument50 pagesmm09144 Trailer Air Suspension System Meritor Euroflex 9e Suspension RangeLUKASNo ratings yet

- Pool Heater Owners ManualDocument170 pagesPool Heater Owners ManualTrent FontenotNo ratings yet

- Manitex 1770C Operator ManualDocument125 pagesManitex 1770C Operator ManualWilliam Roark100% (7)

- Gas Lift Mandril PDFDocument83 pagesGas Lift Mandril PDFAle Jan DraNo ratings yet

- 308 09Document4 pages308 09Cuong DinhNo ratings yet

- Vlatb 027Document12 pagesVlatb 027dharmendra tiwariNo ratings yet