Professional Documents

Culture Documents

M 300 S H S, H T M (HTM) MIG W: Idalloy Eries IGH Ilicon IGH Ensile Atte Ires

Uploaded by

Bala SingamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M 300 S H S, H T M (HTM) MIG W: Idalloy Eries IGH Ilicon IGH Ensile Atte Ires

Uploaded by

Bala SingamCopyright:

Available Formats

TECHNICAL BULLETIN

MIDALLOY 300 SERIES HIGH SILICON, HIGH TENSILE MATTE (HTM) MIG WIRES

CLASSIFICATION

• AWS 5.9 Classes, ER308LSi (UNS# S30888), ER309LSi (UNS# S30988), ER316LSi (UNS# S31688)

• ASME SFA 5.9 Classes, ER308LSi, ER309LSi, ER316LSi.

• A#8 F#6

DESCRIPTION

• Midalloy 300 Series High Silicon, High Tensile Matte (HTM) MIG Wires are manufactured to our specifications to give

consistent, dependable welds with the lowest levels of carbon, sulfur, and phosphorous. The increased silicon content

assures better arc stability with excellent wash and wetting behavior resulting in a smooth bead appearance, uniform

penetration, less porosity, and less spatter. The wire has the best feeding characteristics possible. To accomplish this, we

made two basic design changes to our standard MIG wire:

1) Tensile Strength:

We increased the tensile strength of our wire substantially to improve columnar strength and lower the co-efficient of

friction within the liner.

Diameters Standard MIG Wire Midalloy HTM MIG Wire

.030” - .035” - .045” 158,000 PSI – 171,000 PSI 210,000 PSI – 239,000 PSI

2) Matte Finish:

We changed the standard, mechanically cleaned bright finish to a gas-cleaned matte finish. The matte finish has two

advantages over the bright finish. The feed roles tend to grip better, creating less birdnesting and the wire can pick up

a lubricant easier, thus giving less friction through the liner and better contact with the contact tip.

APPLICATIONS

• Midalloy HTM wires are used for a variety of applications where matching filler metals are required for various 300 series

base materials.

• These products are also used for overlay welding, as well as certain dissimilar welds of carbon steel to stainless steel.

TYPICAL CHEMISTRY

GRADE C Si MN S P Ni Cr Mo Cu Fer (Delong)

308LSi .01 .85 1.86 .010 .015 10.7 20.0 .06 .05 9.4

309LSi .01 .87 1.90 .010 .015 13.7 23.5 .06 .05 13.1

316LSi .01 .87 1.86 .010 .015 12.3 18.5 2.55 .05 8.3

Other grades available upon request

WELDING PARAMETERS

SHORT ARC – (with Tri-Mix – 90% Helium, 7½% Argon, 2 ½% CO2 Shielding gas)

Current, Amps Open Circuit Power

Diameters (D.C.R.P.) Voltage Source Type

.030” 50 – 145 17 – 22 CP

.035” 65 – 175 17 – 22 CP

.045” 100 – 225 17 – 22 CP

SPRAY ARC – (with Argon and 1% to 5% Oxygen Shielding gases)

Current, Amps Open Circuit Power

Diameters (D.C.R.P.) Voltage Source Type

.030” 160 – 210 24 - 28 CP or CC

.035” 180 – 300 24 - 28 with voltage sensing type

.045” 200 – 375 24 - 28 wire feeder

STANDARD PACKAGING

• All spools are Level Layer wound

12” 30 lb. baskets or plastic spools; 1890 lb. pallet weight

10” 10 lb. plastic spools; Individual cartons

4” 2 lb. plastic spool; 36 lbs./carton

4/5/16

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the

designs or specifications of such products at any time without notice.

Office and Corporate Warehouse

630 Axminister Drive

St. Louis, MO 63026 • 636-349-6000 • 800-776-3300

Fax 636-349-2240

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Aptest NDT EquipmentDocument40 pagesAptest NDT EquipmentSiva ShankarNo ratings yet

- Dry Sand Rubber/Wheel Abrasion Test (ASTM G 65)Document2 pagesDry Sand Rubber/Wheel Abrasion Test (ASTM G 65)NarendraNo ratings yet

- Hpx-Pro: For Non-Destructive TestingDocument8 pagesHpx-Pro: For Non-Destructive TestingJohan PintoNo ratings yet

- Hha Brochure Pmi Master SmartDocument5 pagesHha Brochure Pmi Master SmartBala SingamNo ratings yet

- This Domain Is Registered at NamecheapDocument3 pagesThis Domain Is Registered at NamecheapBala SingamNo ratings yet

- Dumond Smart Strip SdsDocument7 pagesDumond Smart Strip SdsBala SingamNo ratings yet

- Calibration PDFDocument3 pagesCalibration PDFBala SingamNo ratings yet

- AstrologyDocument464 pagesAstrologyBala SingamNo ratings yet

- Calibration Block - BIGPROBEDocument19 pagesCalibration Block - BIGPROBEBala SingamNo ratings yet

- X-MET Presentation PDFDocument39 pagesX-MET Presentation PDFTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- Find Non-Destructive Inspection Technician Jobs in Nisku, ABDocument4 pagesFind Non-Destructive Inspection Technician Jobs in Nisku, ABBala SingamNo ratings yet

- Smart Strip Peel Away - Product DatasheetDocument2 pagesSmart Strip Peel Away - Product DatasheetBala SingamNo ratings yet

- Session 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowDocument48 pagesSession 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowBala SingamNo ratings yet

- ThiruvarutpaDocument19 pagesThiruvarutpaBala SingamNo ratings yet

- Muffle FurnaceDocument2 pagesMuffle FurnaceBala SingamNo ratings yet

- Vickers 30kg ManualDocument12 pagesVickers 30kg ManualBala SingamNo ratings yet

- Calibration PDFDocument3 pagesCalibration PDFBala SingamNo ratings yet

- Industrial Building For Sale/Lease: Asking Price: $4,650,000Document3 pagesIndustrial Building For Sale/Lease: Asking Price: $4,650,000Bala SingamNo ratings yet

- 19 - K Days Parking MapDocument1 page19 - K Days Parking MapBala SingamNo ratings yet

- Qualitest Broucher FinalDocument8 pagesQualitest Broucher FinalBala SingamNo ratings yet

- Canadian DRIP List - Canadian DRIP PrimerDocument6 pagesCanadian DRIP List - Canadian DRIP PrimerBala SingamNo ratings yet

- Canon D420 - Windows 8 Notice - ENGDocument1 pageCanon D420 - Windows 8 Notice - ENGSaulNo ratings yet

- PipelineDocument77 pagesPipelineBala SingamNo ratings yet

- AI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsDocument15 pagesAI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsBala SingamNo ratings yet

- AC Coupon TM GuideDocument4 pagesAC Coupon TM GuideBala SingamNo ratings yet

- Proth Psgs Manual PDFDocument106 pagesProth Psgs Manual PDFBala SingamNo ratings yet

- Proth Psgs Manual PDFDocument106 pagesProth Psgs Manual PDFBala SingamNo ratings yet

- Multi Channel IndicatorDocument1 pageMulti Channel IndicatorBala SingamNo ratings yet

- AI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsDocument15 pagesAI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsBala SingamNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelAde Aidil SyuhadaNo ratings yet

- Welding Consumables For Steels With Yield Strength 460MPa PDFDocument75 pagesWelding Consumables For Steels With Yield Strength 460MPa PDFali509No ratings yet

- Welding TechnologyDocument390 pagesWelding Technologygueess100% (2)

- BOC185ACDC Manual v2Document32 pagesBOC185ACDC Manual v2beachboy12No ratings yet

- Weld Cost Calc XL1.3.2mmDocument3 pagesWeld Cost Calc XL1.3.2mmAdrian DavidNo ratings yet

- Parametric Optimization of Mig WeldingDocument8 pagesParametric Optimization of Mig WeldingMihaela NastaseNo ratings yet

- Unit IV Unit IV: Industrial Inert GasesDocument19 pagesUnit IV Unit IV: Industrial Inert GasesermiasNo ratings yet

- Cebora 130 886 ManualDocument7 pagesCebora 130 886 ManualvidinpetreceNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingcarlmac6183% (6)

- Welding and Joining of Magnesium Alloys: Frank CzerwinskiDocument24 pagesWelding and Joining of Magnesium Alloys: Frank Czerwinskivenkat mechNo ratings yet

- Panorama FCW en v2 PDFDocument36 pagesPanorama FCW en v2 PDFFrancisco JesusNo ratings yet

- 3 Chemical Reactions in WeldingDocument13 pages3 Chemical Reactions in WeldingPrafulla Subhash SarodeNo ratings yet

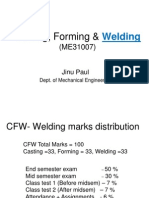

- Casting, Forming & WeldingDocument90 pagesCasting, Forming & WeldingmahdiNo ratings yet

- Arc Welding Techniques and Processes ExplainedDocument30 pagesArc Welding Techniques and Processes ExplainedDanem HalasNo ratings yet

- WPS Sa 335 P91 PipeDocument3 pagesWPS Sa 335 P91 Pipecsankarananth50% (2)

- 01112015000000B - Boehler EMK 8 - Solid WireDocument2 pages01112015000000B - Boehler EMK 8 - Solid WirePopa RobertNo ratings yet

- Welding and Joining of Shape Memory AlloysDocument22 pagesWelding and Joining of Shape Memory AlloysLetíciaNo ratings yet

- Kemppi Product Catalogue 2008-09Document96 pagesKemppi Product Catalogue 2008-09asddgarNo ratings yet

- Comparison Welding Wire A5.18-ER70S-3 - A5.18-ER70S-6Document3 pagesComparison Welding Wire A5.18-ER70S-3 - A5.18-ER70S-6QuyetNo ratings yet

- Bhel Haridwar - Training Report - 800 MW Bar CIM Block 4 (EEE)Document27 pagesBhel Haridwar - Training Report - 800 MW Bar CIM Block 4 (EEE)Amit Kumar67% (6)

- MAG-welding of Zn-Coated Steel, A Continued Process Study: Research ReportDocument42 pagesMAG-welding of Zn-Coated Steel, A Continued Process Study: Research ReportbertilssonNo ratings yet

- (RMD™) MIG Welding ProcessDocument5 pages(RMD™) MIG Welding ProcessPradip GoswamiNo ratings yet

- Fate of Manganese Associated With The Inhalation of Welding Fumes: Potential Neurological EffectsDocument7 pagesFate of Manganese Associated With The Inhalation of Welding Fumes: Potential Neurological EffectsAndrea Carolina Salas LalindeNo ratings yet

- Ice 1.1 Steam Welding PrincipleDocument82 pagesIce 1.1 Steam Welding PrincipleThilagavathy SethuramahNo ratings yet

- Notes On Wire Electrodes EN 440: Table 3Document1 pageNotes On Wire Electrodes EN 440: Table 3raduonoNo ratings yet

- QA vs QC vs INSPECTION: The Key DifferencesDocument138 pagesQA vs QC vs INSPECTION: The Key DifferencesMohd SharainiNo ratings yet

- Manual Na3s & Na4Document164 pagesManual Na3s & Na4jhonNo ratings yet

- Ch-3 - Advanced Welding ProcessesDocument17 pagesCh-3 - Advanced Welding ProcessesNishanta BasisthaNo ratings yet

- DLL Shielded Metal Arc Welding NCIDocument11 pagesDLL Shielded Metal Arc Welding NCIMaricar Carandang100% (1)

- Ewm Welding BookDocument104 pagesEwm Welding BookPrabhakar KattulaNo ratings yet