Professional Documents

Culture Documents

Bro - GS MAG-M EN - Indd - L

Bro - GS MAG-M EN - Indd - L

Uploaded by

Giang NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bro - GS MAG-M EN - Indd - L

Bro - GS MAG-M EN - Indd - L

Uploaded by

Giang NguyenCopyright:

Available Formats

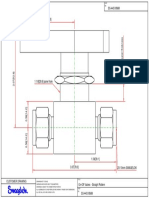

Pump construction, operating limits and performances

Close-coupled drivers are conventional drivers mounted directly to pumps frame. No base, coupling or guards

SEALLESS MAG DRIVE CHEMICAL

GEAR PUMPS, NO MECHANICAL SEAL

are required for this mounting style.

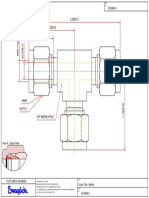

• Connections: Threaded NPT and BSP

• Max viscosity: 25000 cSt

• Max system pressure: 50bar standard, 150 bar HP Version.

GS MAG-M

Higher pressure version available on request.

• Flow up: to 80 mc/h

• Head up: to 30 bar

• Temperature range: from -147 °F (-100 °C) to +392 °F (+200 °C)

• Electric motors: from 0,25 kW up to 75 kW

• NEMA and IEC standard available

Pumping Applications

• Aggressive, explosive and toxic liquids • Refineries

• Acids & lyes • Chemical and petrochemical industries

• Hydrocarbons • Refrigeration and heat engineering

• Heat transfer liquids • Liquid gas plants

• Liquid gases • Galvanic engineering

• Liquids Difficult-to-seal • Power stations

• Ultrapure liquids • Tank installations

• Pharmaceutical industries

• Fibers industries

Manufactured by: For more information please contact:

A unit of

M PUMPS s.r.l. - Via dell’Artigianato, 120 GS MAG-M Series

45015 Corbola (Ro) - Italy - www.mpumps.it The separation of liquid chamber/atmosphere by means of an isolation shell is the

Tel. +39 0426 346304 - Fax +39 0426 349126 best solution to pump aggressive, explosive and toxic liquids, hydrocarbons, heat

transfer liquids and liquids difficult to seal.

The hermetic sealless is the best solution for the chemical, pharmaceutical and

petrochemical industry.

A wide range of pumps covers the different performances.

The best solution for Sampling applications.

Printed on 06-05-2012

PUMP DETAILS

Epoxy primer and polyacrylic enamel water-based painting for the

best quality resistance linked to the environmental respect.

Housing & Cover are machined from rolled bar forging that is cut

turned, machined and ground into its final shape, thus ensuring

maximum hardness as apposed to using cast parts.

Materials:

- AISI 316L (standard)

- Cast Iron G25 (standard) The rear shell is made of one single piece, no welding, ellipsoidal

- Hastelloy® C276, profile that has been studied to withstand higher pressures than

- Incoloy® 825, the traditional one.

- Duplex,

- Other on request. Available two versions, AISI 316 the standard construction, and

Hastelloy® C276 for high pressure version - providing a safe and

efficient solution – system pressure max 150bar.

Titanium Alloy is an upgrade when higher pressure ratings and

increased efficiency are required.

The bearings are aided by a metal backing to increase resistance

especially for corrosive environments.

A PTFE lining is coated into the ID of the bearings forming a solid

lubricant film.

PTFE plates are installed to reduce wear.

QUICK REPLACE KIT to guarantee an easy and fast High power synchronous magnetic coupling designed by

maintenance. our Technical Office and with rare earth magnetic elements

mechanically locked.

The high performance magnets can operate at liquid temperature

of up to 200 °C (392 °F).

Rotors are achieved from rolled bar forging that is cut, turned and

ground into its final shape as opposed to using cast parts, thus

ensuring maximum hardness.

The material adopted in standard executions are S31803

Duplex for AISI 316L construction and 39 NiCrMo3 for cast iron

construction. The pump can be supply with alluminium bracket with IEC B3-B5

Other materials on request. motor or with a robust WCB foot mounted bracket that allows IEC

B5 standard motor.

The sealing system with O-Rings prevents from leaking in the

atmosphere different materials available:

- Viton® (standard) Connections available:

- EPDM Threaded BSP(GAS) or NPT.

- FEP Flanged according to ANSI 150#, 300#, DIN PN16.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cameron Manual Type F FCDocument7 pagesCameron Manual Type F FCEnrique HortaNo ratings yet

- Manual de Partes Hp675wcu-Ex t2 (c07), Xp750wcu-Ex t2 (c08), Hp750wcu-Ex t2 (c09), Xp825wcu - Ex t2 (c10)Document134 pagesManual de Partes Hp675wcu-Ex t2 (c07), Xp750wcu-Ex t2 (c08), Hp750wcu-Ex t2 (c09), Xp825wcu - Ex t2 (c10)Carlos Alberto Rosado VillanuevaNo ratings yet

- Track Structure On BridgesDocument85 pagesTrack Structure On BridgesSudipto PaulNo ratings yet

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- Buoyancy Calculation Report For 10INCH PipelineDocument7 pagesBuoyancy Calculation Report For 10INCH PipelineEmmanuel LawrenceNo ratings yet

- Lifting Belt Inspection ChecklistDocument2 pagesLifting Belt Inspection Checklistamit choudharyNo ratings yet

- Hyundai Dash 9 Posi Nega Sytem PDFDocument70 pagesHyundai Dash 9 Posi Nega Sytem PDFthailan100% (2)

- Manual de Manutenção de SopradorDocument10 pagesManual de Manutenção de SopradorEleno Ribeiro100% (1)

- SS 4 RS 2V SwagelokCompany 2DSalesDrawing 05 21 2023Document1 pageSS 4 RS 2V SwagelokCompany 2DSalesDrawing 05 21 2023Giang NguyenNo ratings yet

- RoboVac G40 - Manual - ENDocument12 pagesRoboVac G40 - Manual - ENGiang NguyenNo ratings yet

- Aerospace 08 00128 v2Document18 pagesAerospace 08 00128 v2Giang NguyenNo ratings yet

- SS 8M0 1 4RP MaleConnector (ISOParallelThreadRP) MetricDocument1 pageSS 8M0 1 4RP MaleConnector (ISOParallelThreadRP) MetricGiang NguyenNo ratings yet

- NTU Intnlpros HiRes Jul2011Document28 pagesNTU Intnlpros HiRes Jul2011Giang NguyenNo ratings yet

- The Mixture of The Phase Stabilized Ammonium Nitrate Containing Potassium Nitrate and 1HT As The New Gas Generant CompositionDocument7 pagesThe Mixture of The Phase Stabilized Ammonium Nitrate Containing Potassium Nitrate and 1HT As The New Gas Generant CompositionGiang NguyenNo ratings yet

- High Pressure OxygenDocument2 pagesHigh Pressure OxygenGiang NguyenNo ratings yet

- SS 8M0 3 SwagelokCompany 2DSalesDrawing 01 06 2023Document1 pageSS 8M0 3 SwagelokCompany 2DSalesDrawing 01 06 2023Giang NguyenNo ratings yet

- SS 44S10MM SwagelokCompany SalesDrawing 12 28 2022Document1 pageSS 44S10MM SwagelokCompany SalesDrawing 12 28 2022Giang NguyenNo ratings yet

- TranscriptDocument2 pagesTranscriptGiang NguyenNo ratings yet

- Inspection of Curvic Couplings Using A CMMDocument10 pagesInspection of Curvic Couplings Using A CMMGiang NguyenNo ratings yet

- Education:: "The Noise Generation in Mechanical Systems"Document3 pagesEducation:: "The Noise Generation in Mechanical Systems"Giang NguyenNo ratings yet

- Roland Bouanais: Research InterestsDocument10 pagesRoland Bouanais: Research InterestsGiang NguyenNo ratings yet

- C11000 (Electrolytic Tough Pitch)Document2 pagesC11000 (Electrolytic Tough Pitch)Giang NguyenNo ratings yet

- Dynamics of Contained Liquids: A Personal Odyssey: H Norman AbramsonDocument7 pagesDynamics of Contained Liquids: A Personal Odyssey: H Norman AbramsonGiang NguyenNo ratings yet

- Sakman2000 Parametric Study of Simplex Fuel Nozzle Internal Flow and PerformanceDocument5 pagesSakman2000 Parametric Study of Simplex Fuel Nozzle Internal Flow and PerformanceGiang NguyenNo ratings yet

- 0674 - Spray Dynamics of Aeroengine Fuel InjectorsDocument3 pages0674 - Spray Dynamics of Aeroengine Fuel InjectorsGiang NguyenNo ratings yet

- Influence of Geometry On The Performance of Simplex Nozzles Under Constant Pressure DropDocument5 pagesInfluence of Geometry On The Performance of Simplex Nozzles Under Constant Pressure DropGiang NguyenNo ratings yet

- Preliminary Gas Turbine Combustor Design Using A Network ApproachDocument8 pagesPreliminary Gas Turbine Combustor Design Using A Network ApproachGiang NguyenNo ratings yet

- 3oz Lip: Trijong Pham NAM PhricDocument3 pages3oz Lip: Trijong Pham NAM PhricGiang NguyenNo ratings yet

- Average Viscosities LiquidsDocument1 pageAverage Viscosities LiquidsGiang NguyenNo ratings yet

- FANUC ROBOT - ARC Mate 0ibDocument2 pagesFANUC ROBOT - ARC Mate 0ibR Dinansyah PrawirasapoetraNo ratings yet

- Technical Specification Carbon Steel Heat Exchangers: Project No: 338033Document14 pagesTechnical Specification Carbon Steel Heat Exchangers: Project No: 338033jdgh1986No ratings yet

- 54th ESS Schedule FinalDocument8 pages54th ESS Schedule FinalAchmad Arifudin HidayatullohNo ratings yet

- Fire Pumps: Horizontal Split-Case, Vertical Turbine, In-Line and End Suction PumpsDocument4 pagesFire Pumps: Horizontal Split-Case, Vertical Turbine, In-Line and End Suction PumpsAndri AjaNo ratings yet

- Barton CatDocument24 pagesBarton CatCharleda911100% (1)

- Opho2023 Open SolsDocument43 pagesOpho2023 Open SolsNguyễn DũngNo ratings yet

- Lecture 8 Bond Stress, Development Length and AnchorageDocument14 pagesLecture 8 Bond Stress, Development Length and AnchorageManoj SharmaNo ratings yet

- What Is The Viscosity Grade of An Engine Oil?Document3 pagesWhat Is The Viscosity Grade of An Engine Oil?BEN EMEKANo ratings yet

- Vacuum Cushion-Klarity PDFDocument2 pagesVacuum Cushion-Klarity PDFkolgepengNo ratings yet

- (TM F QQT) : Indian StandardDocument14 pages(TM F QQT) : Indian StandardSubodh SontakkeNo ratings yet

- Lesson 09 - Calculations of ScrewDocument5 pagesLesson 09 - Calculations of Screw4gen_5No ratings yet

- Unit 3 PhysicsDocument5 pagesUnit 3 PhysicsChristine MoniqueNo ratings yet

- SMPNGC Booklet Nov 2017Document17 pagesSMPNGC Booklet Nov 2017Jayjay TabuzoNo ratings yet

- CIV5304: Design of Structural Elements III: Engr DR Nuruddeen Muhammad MusaDocument30 pagesCIV5304: Design of Structural Elements III: Engr DR Nuruddeen Muhammad MusaNuruddeen MuhammadNo ratings yet

- Temerature تقريرDocument12 pagesTemerature تقريرAbdullah IyadNo ratings yet

- 27 - Iwcf Ss Sample Questions - AnswersDocument8 pages27 - Iwcf Ss Sample Questions - Answersbaskaran v0% (1)

- Rotomolded Tanks - Importance of Rotomolded TanksDocument3 pagesRotomolded Tanks - Importance of Rotomolded Tanksrotomould03No ratings yet

- Exhausto - Solutii VentilatiiDocument12 pagesExhausto - Solutii VentilatiialanatoraNo ratings yet

- Stress DistributionDocument17 pagesStress Distributionsugunay123No ratings yet

- Oscillations A2Document2 pagesOscillations A2Md Irtiza HafizNo ratings yet

- Sequentronic Automated Manual Transmission Driver InformationDocument2 pagesSequentronic Automated Manual Transmission Driver InformationMed Chahine KohiNo ratings yet